Abstract

A Sudanese sorghum cultivar (Fetarita) was germinated for 3 days. Stability and clarity of sorghum pastes, freeze-thaw stability, gel consistency, and swelling power were measured every 24 h. There is no substantial difference in stability and clarity between flour samples from germinated and ungerminated sorghum, but a different behavior was observed between samples stored at room temperature and at 4 °C. Cooked paste derived from germinated sorghum flour presented higher syneresis than that derived from ungerminated sorghum flour over the first three cycles but when the cycle number increased, both flours showed zero syneresis value. For the gel consistency the flours derived from germinated sorghum produced thinnest gels. The neutral and acid gel consistency increased when the germination time increased. Germination had not much effect on the swelling power of sorghum flour.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Sorghum (Sorghum bicolor L. Moench) is a major cereal crop in the semiarid tropics of Africa and Asia. Sorghum together with millet is commonly consumed by the poorer section of the population in many countries and it forms a major source of proteins and calories in the diet of large segments of the population of Africa (Belton and Taylor 2004). In many parts of Sudan, where sorghum is a major food grain, people depend on whole sorghum meals, as the main meal. It is generally consumed as fermented flat bread (Kisra), thick porridge (Aceda), thin fermented gruel (Nasha), non-alcoholic beverages (Abreh and Hulu-mur) and alcoholic beverages (Merissa and Assaliya). A protein quality problem, which is apparently unique to sorghum, was that the digestibility (nutritional value) of sorghum protein is significantly reduced when the grain is wet cooked and processed (Mertz et al. 1984; Axtell et al. 1981; Hassan and El Tinay 1995). The quality of the protein is critically important for humans in developing countries where cereals are staple diet. Due to the importance of sorghum, considerable research was undertaken with the objectives to improve the protein quality of sorghum, to indicate how traditional technologies such as malting and fermentation affect digestibility and anti-nutritional factors. Numerous studies have reported higher levels of nutrients, such as amino acids, digestive protein, available carbohydrates, and other compounds, and lower levels of non-nutritive factors in cereal sprouts as compared to non germinated seeds (Shem et al. 1990; Elkhalifa and El Tinay 1994 and Elmaki et al. 1999).

Germination is a common practice in sorghum producing areas. Grains are malted for the production of weaning foods, opaque beers and other traditional dishes. Germination triggers the enzymatic activity of sprouting seeds, leading to the breakdown of proteins, carbohydrates and lipids into simpler forms (Nout and Ngoddy 1997). This processing method activates intrinsic amylases, proteases, phytases and fiber-degrading enzymes that disrupt protein bodies, thereby increasing nutrient accessibility (Taylor et al. 1985).

Recently, there has been increased interest in sorghum as a gluten-free cereal to substitute the gluten-rich cereals in the diet of people suffering from celiac disease (Elkhalifa et al. 2005). In food preparation, ingredients are considered largely for their physical and functional properties which will provide the final products with desirable qualities and/or facilitate processing of the products. Starch and protein are among the many important ingredients used in food manufacture. Limited information is available regarding the physicochemical properties of flours milled from grains treated by the traditional processing method of germination. The aim of this study was to determine some of the physicochemical properties of flour from germinated sorghum.

Materials and methods

Materials

In Sudan, for all practical purposes, most of the sorghum malt is prepared from the Fetarita cultivar. Rural Sudanese strongly believe in the nutritional superiority of Fetarita over other sorghum cultivars (Dirar 1993). Sorghum Fetarita cultivar was grown in Gadarif, Sudan, and harvested in the year 2009. The material was carefully cleaned and stored at 4 °C.

Methods

Sorghum germination

Sorghum seeds were germinated according to the traditional Sudanese method of germination. The sorghum grains (500 g) were steeped in distilled water overnight with two changes of water during the day to remove dirt and husk. The wet grain was subsequently soaked in 1–2 volumes of 0.2% formaldehyde solution for 40 min to retard mold growth during germination. The soaked grains were then washed with distilled water several times and soaked in water for 20 min to remove residual formaldehyde. The wet sorghum was spread out thinly on a jute bag saturated with distilled water and covered with another jute bag. Grains were allowed to germinate in the dark for 3 days at room temperature (27 ± 2 °C). Samples (100 g) were taken every day. Water was sprayed on the grains when necessary. The germinated grains were dried to constant weight at 40 °C (to obtain final moisture content of about 5%). The root portions were manually removed. The grains (germinated and ungerminated) were ground in a hammer mill (Gibbons Electric, Essex, UK) to pass through a 0.4 mm (60 BSS mesh) screen and the flours were stored at 4 °C.

Stability and clarity of sorghum flour pastes

The procedure of Craig et al. (1989) was modified for determination of stability and clarity of sorghum flour pastes. Sorghum flour pastes were obtained by suspending 0.05 g samples in 5 ml water in screw-cap tubes and subsequent heating in a boiling water-bath for 30 min. The tubes were thoroughly shaken every 5 min. After cooling at room temperature (15 min), the%T (% transmittance) at 650 nm was determined against distilled water (blank) in a UV2100 Recording Spectrophotometer (Shimadzu, Kyoto, Japan). Three samples were stored at both room temperature (27 ± 2 °C) and 4 °C and the%T was determined every 24 h for 3 days.

Freeze-thaw stability

Freeze-thaw stability (syneresis) of samples was measured using 6% (w/w) sorghum flour pastes. To freeze, the gel samples were maintained at −18 °C in a freezer for 22 h. Thawing the samples was done by placing the tubes in a water bath at 30 °C for 90 min; then samples were centrifuged for 15 min at 1180 × g after which any clear supernatant liquid (syneresis) was decanted and the residue weighed. The percentage of syneresis was then calculated as the ratio of the weight of the liquid decanted and the total weight of the gel before centrifugation multiplied by 100. Four freeze-thaw cycles were performed (Zheng and Sosulski 1998).

Gel consistency

Gel consistency was performed by modifying the procedure described by Chanderashekar and Kirles (1988). The modified procedure consisted of suspending 200 mg of sorghum flour in 0.2 ml 95% ethanol and 3 ml of either 0.1 N acetic acid or distilled water in screw-cap tubes. The suspension was cooked in a vigorously boiling water bath for 8 min. After cooking, the tubes were allowed to cool in an upright position at room temperature for 30 min. After cooling, the tubes were placed horizontally over ruled paper for 1 h at room temperature and the gel front migration was read to the nearest millimetre. A high value indicated a thinner gel.

Swelling power

Swelling power was determined according to Zhang and Hamaker (1998) with some modifications. Water was added to flour slurries and incubated at 85 °C and 100 °C for 30 min. Lump formation was prevented by stirring the mixture every 5 min. After the samples were cooled at room temperature for 15 min, they were centrifuged at 4900 × g for 10 min. The supernatants were carefully removed and the swollen flour sediment was weighed. Swelling power is the ratio of weight of the wet sediment to the initial weight of the dry flour.

Statistical analysis

Three separate batches, for a particular treatment, were taken and analyzed separately and the figures were then averaged. Data were assessed by analysis of variance (ANOVA) (Snedecor and Cochran 1987) and by Duncan’s multiple range test with a probability P ≤ 0.05 (Duncan 1955) using SAS/STAT software.

Results and discussion

Stability and clarity of sorghum flour pastes

Paste clarity is a requisite parameter in food applications such as fruit pie fillings or canned specialty products, such as Chinese style foods, where clarity has paramount importance so as to maintain the attractive appearance of vegetables; on the other hand, paste used for spoonable salad dressing should be opaque. Stability and clarity of sorghum flour pastes were studied as shown in Fig. 1(a) and (b). There is no substantial difference between flour samples from germinated and ungerminated sorghum, but a different behavior was observed between samples stored at room temperature and at 4 °C. The% T were lower at 4 °C, indicating that the lower temperature favored starch retrogradation. Sorghum was reported to contain a high amount of starch, 60–80%, (Becker and Hanners 1991). Paste clarity is related to the state of dispersion and the retrogradation tendency of the starch and hence will influence other technologically important qualities of starch. A fairly transparent paste is desirable in fruit pie-fillings, whereas opacity is desirable in salad dressing and instant desserts. Paste clarity is influenced by many factors like concentration, pH, extent of modification and type of modification. Elkhalifa et al. (2004) reported similar behavior with starch derived from fermented and unfermented sorghum flour. Miles et al. (1985a and 1985b) have found evidence that retrogradation consists of two separable processes: gelation of amylose molecules exuded from the granules during gelatinization, and recrystallization of amylopectin. In this study, storage at low temperature (4 °C) might have resulted in the formation of less perfect crystallites than storage at room temperature and in a higher rate of aggregation of amylose chains, thus decreasing the%T significantly. Within the same storage temperature and after 24 h of storage time, flour from germinated sorghum showed an increased%T as compared with flour from ungerminated sorghum (Fig. 1(a) and (b)).

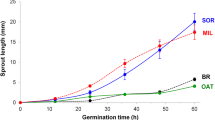

Freeze-thaw stability

Freeze-thaw stability indicates retrogradation of starch pastes and reflected by defined quality of a typical food product or a class of foods, When starch gels are subjected to freeze-thaw cycling, water used in the preparation of the gels will separate because of the tendency of starch molecules to reassociate, thus forming insoluble aggregates. The gels are characterized as weepy, grainy, or spongy. The stability of starch to freeze-thaw cycling will enhance its suitability for use in food products. Conventionally, freeze-thaw stability is evaluated by gravimetrically measuring the amount of liquid separated from starch gels after a certain number of freeze-thaw cycles, or by a modified line spread test (Dreher et al. 1983). Flour derived from germinated sorghum presented higher syneresis than that derived from ungerminated sorghum flour over the first three cycles (Fig. 2), but when the cycle number increased, both flours showed zero syneresis value. This higher syneresis of flour derived from germinated sorghum may be due to starch depolymerisation, it is well known that depolymerised starch is more prone to syneresis. Elkhalifa et al. (2004) observed similar behaviour with starch isolated from fermented and unfermented sorghum flours. These results showed that flours derived from sorghum (germinated and ungerminated) are not particularly suitable for frozen food products.

Gel consistency and swelling power

Acid gel consistency of sorghum flours was measured at pH 2.6. Values obtained ranged from 55 to 145 mm (Table 1). The germinated sorghums produced the thinnest gels (gels with the highest values). The acid gel consistency increased when the germination time increased. Chanderashekar and Kirles (1988) reported that acid gels made from hard sorghums at pH 2.4 gives gel consistency between 92 and 118 mm.

A similar trend as that found with acid gels was observed with neutral gels prepared with distilled water pH 7.5 (Table 1). The germinated sorghums give gel consistency values between 47.5 and 85 mm, whereas the value for the ungerminated sample was 35 mm. The neutral gels made with germinated grains thinnest than that made from ungerminated one. It is well known that germination of sorghum produces amylases, which breakdown starch and hence lowers the viscosity of sorghum gruel. These results indicate a correlation between the germinated sorghum flour and gel consistency (acid and neutral). This indicates the involvement of protein in limiting starch gelatinization in germinated sorghums and thereby producing thinner gels. Efficient grain modification during germination is mainly due to the combined action of cell wall degradation enzymes such as β-glucanase and proteases, which help to break down the protein matrix. These enzymes expose the starch granules to amylase attack during mashing (Palmer 1989). The involvement of protein in limiting starch gelatinization is also supported by the differences in water uptake of germinated and ungerminated sorghum flour at temperatures 85 and 100 °C (Table 1). Other evidence for the involvement of protein in limiting starch gelatinization was obtained by Chandrashekar and Desikachar (1981), who showed that the addition of papain to sorghum flour prior heating resulted in an increased water uptake. Starch gelatinization is an important determinant of cereal food quality as it influences textural properties (Hoseney 1986).

It has been reported that sorghum gelatinises at temperatures above 80 °C (Palmer 1989). Sorghum flour had lower swelling power at 85 °C than at 100 °C (Table 1). The general increase in swelling power with higher temperature is presumably due to granule water uptake, which gelatinizes the starch. As the temperature increased, the starch vibrated more vigorously, breaking intermolecular bonds and allowing hydrogen-bonding sites to engage more water molecules (Claver et al. 2010). This indicates that sorghum flour requires higher temperatures to reach full granule swelling. Germination had not much effect on sorghum flour swelling power at 85 °C as the maximum reduction in the swelling power was by 23% after 3 days of germination but at 100 °C the swelling power of sorghum flour decreased as the germination time increased to reach its minimum value after 72 h (Table 1). This indicates that the starch granules have been substantially degraded after undergoing maximum swelling around their respective gelatinization temperature.

Conclusion

From the above data it can be concluded that the process of germination had certain technological effects on the physicochemical properties of sorghum flour, as it increases the syneresis value during the freezing and thawing cycles, decreases the swelling power and increases the gel consistency. Clarity of sorghum flour paste was not so much affected by germination, but storage of the pastes at low temperature (4 °C) decreases the clarity of both pastes. As previous studies have shown that germination improved the nutritive value of sorghum flour; it seems to be possible to design some new foods based on germinated sorghum. Sorghum is used in weaning foods in countries such as Sudan, Ethiopia and India. As germinated sorghum flour reduces the viscosity of the food product. It is thus possible to use double the quantity of flour to make a product of similar consistency, so the energy density of weaning foods can be increased.

References

Axtell JD, Kirleis AW, Hassan MM, Mason ND, Mertz ET, Munck L (1981) Digestibility of sorghum proteins (rat assay/pepsin assay/temperature effects/fermentation). Proc Natl Acad Sci 78:1333–1335

Becker R, Hanners GC (1991) Carbohydrate composition of cereal grains. In: Lorenz KJ, Kulp K (eds) Handbook of cereal science and technology. Marcel Dekker, New York, pp 482–483

Belton PS, Taylor JRN (2004) Sorghum and millets: protein sources for Africa. Trends Food Sci Technol 15:94–98

Chandrashekar A, Desikachar HSR (1981) Studies on the hydration of starches, flour and semolina from different cereal grains. J Food Sci Technol 18:12–17

Chanderashekar A, Kirles AW (1988) Influence of protein on starch gelatinization in sorghum. Cereal Chem 65:457–462

Claver IP, Zhang H, Li Q, Zhu K, Zhou H (2010) Impact of the soak and the malt on the physicochemical properties of the sorghum starches. Int J Mol Sci 11:3002–3015

Craig SA, Maningat CC, Seib PA, Hoseney RC (1989) Starch paste clarity. Cereal Chem 66:173–182

Dirar HA (1993) Indigenous fermented foods of the Sudan. CAB International, Wallingford

Dreher ML, Tinsley AM, Scheerens JC, Berry JW (1983) Buffalo gourd root starch. Part II. Rheologic behavior, freeze-thaw stability and suitability for use in food products. Starch/Starke 35:157–162

Duncan BD (1955) Multiple range and multiple F tests. Biometrics 11:1–42

Elkhalifa AO, El Tinay AH (1994) Effect of fermentation on protein fractions and tannin content of low- and high-tannin cultivars of sorghum. Food Chem 49:265–269

Elkhalifa AO, Schiffler B, Bernhardt R (2004) Effect of fermentation on the starch digestibility, resistant starch and some physicochemical properties of sorghum flour. Nahrung/Food 48:91–94

Elkhalifa AO, Schiffler B, Bernhardt R (2005) Effect of fermentation on the functional properties of sorghum flour. Food Chem 92:1–5

Elmaki HB, Babiker EE, El Tinay AH (1999) Changes in chemical composition grain malting starch and tannin contents and protein digestibility during germination of sorghum cultivars. Food Chem 64:331–336

Hassan IAG, El Tinay AH (1995) Effect of fermentation on tannin content and in vitro protein and starch digestibilities of two sorghum cultivars. Food Chem 53:149–151

Hoseney RC (1986) Princioles of cereal science and technology. Am Asso of Cereal Chem, St Paul, MN

Mertz ET, Hassen MM, Cairns-Wittern C, Kirleis AW, Tu L, Axtell JD (1984) Pepsin digestibility of sorghum and other major cereals. Proc Natl Acad Sci 81:1–2

Miles MJ, Morris VJ, Orford PD, Ring SD (1985a) The roles of amylose and amylopectin in the gelation and retrogradation of starch. Carbohydr Res 135:271–281

Miles MJ, Morris VJ, Orford PD, Ring SD (1985b) Gelation of amylose. Carbohydr Res 135:257–269

Nout MJR, Ngoddy PO (1997) Technological aspects of preparing affordable fermented complementary foods. Food Control 8:279–287

Palmer GH (1989) Cereals in malting and brewing. In: Palmer GH (ed) Cereal science and technology. Aberdeen University Press, Aberdeen, pp 61–462

Shem MN, Lekule FP, Zakayo GZ, Eggum BO (1990) Nutritive value of germinated and ungerminated high tannin sorghum for growing pigs. Acta Agric Scand 40:253–258

Snedecor GW, Cochran WG (1987) Statistical methods, 7th edn. The Iowa State University Press, Ames

Taylor JRN, Noveille L, Liebenberg NW (1985) Protein body degradation in the starchy endosperm of germinating sorghum. J Exp Biol 36:1287–1295

Zhang G, Hamaker BR (1998) Low a-amylase starch digestibility of cooked sorghum flours and the effect of protein. Cereal Chem 75:710–713

Zheng GH, Sosulski FW (1998) Determination of water separation from cooked starch and flour pastes after refrigeration and freeze-thaw. J Food Sci 63:134–139

Acknowledgements

This work was supported by the Alexander von Humboldt Foundation (AvH) through a Fellowship to Abd Elmoneim O. Elkhalifa.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Elkhalifa, A.E.O., Bernhardt, R. Some physicochemical properties of flour from germinated sorghum grain. J Food Sci Technol 50, 186–190 (2013). https://doi.org/10.1007/s13197-011-0315-2

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-011-0315-2