Abstract

Tofu, a non-fermented soybean curd is a nutritious and digestible product with a high quality protein. Tofu making procedure includes soaking of beans, grinding, filtering, boiling, coagulating and moulding. The flavour, quality and the texture of tofu produced is significantly influenced by its processing parameters. Studies were carried out on the processing parameters like solid content of milk, thermal treatment of soybeans with sodium bicarbonate, stirring time after adding coagulant and moulding of tofu on the texture and quality of tofu. Our studies showed that the texture of the final product depended on the solid content of milk before coagulation. Pretreatment of soybeans with sodium bicarbonate, for 10 min and milk obtained with low solid content of 7° Brix resulted in regular, smooth textured tofu with less beany flavour. Duration of stirring during coagulation and moulding parameters had a significant effect on the yield of tofu. Stirring the milk after adding the coagulant for 5 s before settling and pressing the tofu with a load of 1,000 g initially for 15 min followed by 500 g for another 15 min, yielded (22.6 g/100 ml of milk) soft textured firm tofu.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Tofu (Soybean curd) is one of the most important food products made from soybean protein (Kohyma et al. 1995). As per the ‘American Journal of Clinical Nutrition’ the protein present in tofu is the most balanced protein for human consumption. It is an important traditional food for eastern Asians due to its good nutrition and digestibility (Tsai et al. 1981). Western countries have recently increased interest in eating tofu due to its benefits to human health and the United States has increased tofu consumption substantially after the FDA in the United States allowed soy health claim in 1999 (Fukushima 1981; Levinton 1982; Wang 1984).

Tofu is usually considered as salt- or acid-coagulated water based gel, with soy lipids and proteins trapped in its gel networks (Kohyma et al. 1995). It is an inexpensive, nutritious and versatile meat or cheese substitute with bland taste and porous texture and hence called “Tofu is meat without bone”. On the moisture free basis, tofu contains about 50% protein and 27% oil, and the remaining constituents are carbohydrates and minerals. It is cholesterol free, rich source of proteins, minerals and PUFA. Therefore tofu can form an alternative protein source, which is higher than soybean (on dbw) (Tripathi and Misra 2005).

Its preparation generally includes soaking and grinding of soybeans in water, filtering, boiling and coagulation of soymilk, molding and pressing. Several processing factors affect the quality and texture of tofu, such as cultivar of soybean (Shen et al. 1991; Sun and Breene 1991) processing methods (Beddows and Wong 1987) and type of coagulant (Lim et al. 1990; Tsai et al. 1981; deMan et al. 1986). The taste of tofu is significantly affected by its final texture (Kohyama and Nishinari 1993; Jackson et al. 2002).

The yield, moisture content, textural characteristics and colour of tofu are important to product quality and acceptability (Cai and Chang 1997). Tofu processors desire a high quality product and high tofu yield. Tofu manufacturers are concerned, firstly with the yield and secondly texture, which determines its acceptability (Abd Karim et al. 1999). Hence the purpose of this research was to assess the quality of tofu in terms of yield and texture and also to obtain optimal processing conditions for regular good quality, smooth textured tofu.

Processing factors include soymilk heating rate and time, stirring speeds, time for coagulation, temperature for coagulation, pressing time and weight (Hou et al. 1977). The amount of water needed to make soymilk is also important because it affects soymilk solid content, solid and protein recoveries and tofu texture. The textural property is governed by soymilk concentration, coagulant type and concentration, gelation pressure and temperature and gelation time (Hou et al. 1977; Cai and Chang 1998). Coagulation of soymilk is the most important step in tofu making and the most difficult to control because it depends on complex interrelationships of many variables. Increasing coagulation temperature and rate of stirring immediately after adding coagulant increases hardness (Saio 1979). Stirring method and mixing speed and time has a significant effect on tofu yield and quality (Shurtleff and Aoyagi 1990). A complex interaction of several chemical factors takes place in making soft tofu.

Our objectives were to evaluate relationships of solid content of soymilk, concentration of coagulant, temperatures for mixing and stirring times at fixed speed, pressing time and pressure on the yield and texture of soft tofu. Based on the results of the research, processors who manufacture tofu can produce consistent texture and good quality.

Materials and methods

Soybeans were procured from local market. CaSo4 and MgCl2 were obtained from Rankem fine chemicals.

Preparation of soymilk

Soybeans (200 g) were cleaned and soaked in excess of water at room temperature for 12 h. Beans were dropped directly to the boiling water to which 1% sodium bicarbonate solution was added and blanched at 85°C for 5, 10 and 15 min. Each batch was then processed by hand dehulling and the cotyledons were ground in a high speed blender adding water (1.6 L). The soybean slurry was indirectly heated in water bath for 45 min at 85°C with constant stirring. The hot slurry was filtered through double layered cheese cloth to separate soymilk from residue (okara) and the fatty layer formed was removed after cooling the soymilk. The soymilk solid content was determined using and Abbe Refractometer (American optical mode, 10450) and was adjusted to 7°, 8°and 9° Brix using water.

Preparation of tofu

Soymilk (200 ml) was heated to 95°C for 5 min. It is then cooled to 80°C with constant stirring at room temperature (Hou et al. 1977). Magnesium chloride of 0.2% and Calcium sulphate of 0.2% w/v (1:1) solution was prepared and was added to soymilk and stirred for 5, 10, 15 and 20 min at different batches. Milk was allowed to coagulate for 15 min, without disturbing. The coagulated milk was transferred into cheesecloth lined on plastic porous plastic mold. The curd was pressed with 500, 700 and 1,000 g weight and 1,000 g initially for 15 min, and then reduced to 500 g weight for the next 15 min. At the end of pressing, the cloth was removed and the tofu was stored in water under refrigerated conditions.

Yield and texture analysis

Yield of tofu was calculated as the wet weight/g of tofu per 100 ml of soymilk. Textural properties were measured by compression method using a Texture Analyzer (LLOYD texture instrument LR 5K. England) equipped with a 50 kg load cell. Tofu samples (1.5 cm cube) were cut from the central portion of tofu cake (5 cubes from one cake). Measurements were carried out using a weighing a beam of 5 kg and a 5 cm diameter cylindrical plunger at a crosshead speed of 20 mm/min. Hardness, cohesiveness, springiness and chewiness were calculated from the texture profile analysis curve as described by Bourne (1978).

Data analysis

Duncan’s multiple range test was used to determine difference in processing methods. A significant level was defined as a probability of 0.05 or less. All treatments were done in triplicates.

Results and discussion

Effect of thermal treatment with NaHCo3 on the texture of tofu

The texture of the tofu varied depending on the time of blanching (Table 1). Blanching for 5 min resulted in tofu with hard texture, while blanching for 10 min resulted in regular tofu. With increased blanching time for 15 min, tofu was not firm and was soft. Tofu prepared with the blanched soybeans had less beany flavor compared to unblanched ones. Watanabe et al. (1964) reported that boiling soybean slurry for more than 20 min not only reduces the total solids recovery and tofu yield but also affects the tofu texture. As the blanching time increases, the solid content of soymilk decreases. Nsofor et al. (1997) reported that lower starch and total solids contents was observed in the blanched samples. The solid content of milk determines the texture of tofu. Our earlier experiment report says that the increase in solid content of soymilk produces hard textured tofu. Blanching reduces the solid content and produces soft textured tofu.

Blanching also denatures soybean proteins, thereby limiting both solubility (Che Man et al. 1989) and soy solids extractability (Nsofor et al. 1997). Nelson et al. (1976) reported that presoaking and blanching whole soybeans in 0.5% NaHCo3 improved the tenderization of soybeans.

Blanching of soybeans is essential not only for protein denaturation, to obtain proper curd formation but also for improving nutritional value to destroy the antinutritional factors and reducing beany flavor (Wang and Hesseltine 1982). As boiling time increased, the digestibility of soybean milk increased and reached a maximum of 97.3% after 15 min. These results agree with the theory that proper heat treatment increased the digestibility of soybean proteins owing to the destruction of heat labile trypsin inhibitors and possibly other biologically active components.

The blanched soybeans had an increased stability due to higher pH of 6.82 when compared to unblanched having the pH of 6.35. Sodium bicarbonate was responsible for the higher pH of the unblanched samples. Lower starch and less solid contents were observed in the blanched soybeans (Nsofor and Ugwa 1999).

Effect of total solid content of soymilk on the texture of tofu

The amount of water required to prepare soymilk is important because it affects soymilk solid content, quality and texture of tofu. Texture of tofu is an important quality attribute that affects product acceptability. As tofu is bland, texture plays an important role in product acceptability. Lower soymilk solid content results in higher moisture content of tofu (Cai and Chang 1997) which in turn produces soft textured tofu. Increased solid content increases the hardnessb of tofu as water retention in the tofu gel is less. Lim et al. (1990) also reported that increased total solids of soymilk were associated with increased hardness of tofu.

Hardness of tofu ranged from 4.39, 5.89 and 6.00 N in 7°, 8°, and 9° Brix. A solid content of 7° Brix yielded regular tofu while 9° Brix yielded hard tofu. Cohesiveness ranged from 0.457, 0.482, and 0.489 in 7°, 8°, and 9° Brix respectively. Springiness ranged from 2.513, 2.807, 3.093 in 7°, 8°, 9° Brix. Chewiness of tofu varied between 5.09 and 9.0.

Textural parameters like hardness, cohesiveness, springiness and chewiness were analyzed using force time textural curve. Hardness is the force necessary to attain a given deformation of the material (Szczesniak et al. 1963). Tofu with greater hardness means harder and firmer. Cohesiveness is related to work required to overcome the internal bonding of the material (Friedman et al. 1963). Hence tofu with greater cohesiveness requires more work to break down the internal bonding. Springiness is described as the rate at which a deformed material recovers to its undeformed conditions after the deforming force is removed. Tofu with higher springiness possesses higher elasticity. Chewiness in defined as the energy required to masticate a solid food product to a state of readiness for swallowing and is instrumentally quantified as a product of hardness X cohesiveness X springiness (Szczesniak and Bourne 1995). Therefore Tofu with greater chewiness is stiffer and harder to eat (Cai and Chang 1997).

Textural parameters of tofu were influenced by the solid content of soymilk. Significant correlations were found among soymilk solid content and textural attributes. A higher soymilk solid content produced tofu with greater hardness, cohesiveness, springiness and chewiness of tofu (Table 2). Therefore tofu made from soymilk from 9° Brix was harder, firm more elastic, chewier than tofu made form lower ° Brix soymilk. Cai and Chang (1997) reported that water to bean ratio of 9:1, 10:1, 11:1 and 12:1 produced 9.2, 8.4, 7.8 and 7.1° Brix soymilk. As the solid content increased, the tofu produced was with greater fracturability, hardness, cohesiveness springiness and chewiness. Similar reports were reported by Lim et al. (1990). Soymilk ° Brix of 7 and 8 has a greater difference in hardness compared to 8 and 9° Brix. The difference in cohesiveness and springiness among 7, 8 and 9° Brix soymilk was not influenced by solid content but there was marked difference in chewiness of 2.91(Nmm) in 7 and 8° Brix. 7° Brix yielded moderate hardness, less elastic, and less chewy tofu. According to Cai and Chang (1997) lower soymilk °Brix and longer coagulation time produced tofu with a significantly higher moisture content. Shen et al. (1991) reported that there was a significant correlation between the texture and total solid content of soymilk. Higher soymilk solid content produced tofu with greater hardness, cohesiveness, springiness and chewiness of tofu.

Tofu texture is an important quality attribute that affects product acceptability. The definitions and measurements of food textural parameters have been described by Friedman et al. (1963), Szczesniak et al. (1963), Bourne (1978) and Szczesniak and Bourne (1995).

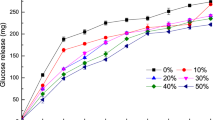

Effect of stirring time (sec) on the yield of tofu

Stirring is necessary to keep the coagulant suspended. Speed of stirring and time of stirring should be sufficient to maintain uniform distribution of coagulant in the soymilk. Stirring speed and time had a significant influence on tofu yield and quality.

Mixing soymilk with coagulant in a short period of time to homogeneity is important to produce a high yield of tofu, because prolonged stirring might break the curd (Hou et al. 1977). Longer stirring time destroys the structure of gel and results in lesser tofu yield, coarser texture and lower sensory overall score (Cai and Chang 1998). The relationship between stirring speed and volume of tofu was investigated by Watanabe et al. (1964) who found that increasing stirring speed decreases tofu volume. Stronger mixing increases the hardness and reduces the gross weight and moisture content of the curds (Wang and Hesseltine 1982).

Lower stirring time for 5 to 10 s resulted higher yield of tofu. With further increase in stirring time to 15 to 20 s the yield was lower. Yield of tofu was expressed as fresh weight of tofu obtained from 100 ml of soymilk. The yield of tofu was not significantly different at stirring time ranging from 5–10 s, but decreased after 20 s (Table 3). This is in correlation with the work of Hou et al. (1977) wherein high yield of tofu were obtained when stirring time was within 25 s for 207 rpm and within 15 s for 285 rpm. Cai and Chang (1998) reported that decrease in mixing time from 10 to 5 s resulted in softer and lower sensory overall score of tofu.

Moulding of tofu with different weights on the yield and texture of tofu

The pressure and time of pressing of bean curds affects the content and composition of tofu (Cai and Chang 1999). Pressure applied to press the tofu can also affect the curd texture (Wang and Hesseltine 1982).

The yield and texture of tofu varies with the weight applied and time used for pressing the curd (Table 4). A weight of 1,000 and 700 g for 30 min yielded 22.5 and 22.3 g of tofu (wet wt) and the texture resulted in harder and slightly harder tofu. A pressure of 500 g for 30 min and 1,000 g of load initially for 15 min, followed by reducing to 500 g yielded same amount of tofu but the texture varied. Smooth and puffy natured texture was seen in tofu pressed with 1,000 g initial weight for 15 min followed by 500 g. Variation in the yield is due to difference in applying different weights for a known period. Increase in weight applied decreases the yield, as the water is drained off from the tofu. This in turns affects the texture of tofu.

Pressing with lower pressure also increases protein content of the tofu. Cai and Chang (1999) reported that the protein content of tofu increased when pressed with lower pressure for a shorter time. This is due to the removal of some carbohydrates during pressing processes.

Conclusion

Processing method had a significant effect on the yield and texture of tofu. In general a solid content of 7° Brix yield regular, smooth textured tofu. With the increase in solid content >7° Brix yields harder tofu. Yield of tofu was high with stirring of milk with the coagulant for 5 s. Blanching of soybeans with sodium bicarbonate for 10 min reduces beany flavor and soft texture. Moulding of tofu with a load of of 500 g results in enhanced yield of tofu. Thus the optimum conditions for regular, smooth textured tofu are solid content of 7° Brix, stirring time for 5 s, blanching of soybeans with 1% sodium bicarbonate for 10 min and pressing the tofu with 1,000 g initial weight for 15 min followed by 500 g.

References

Abd Karim A, Sulebele GA, Azhar ME, Ping CY (1999) Effect of carrageenan on yield and properties of tofu. Food Chem 66(2):159–165

Beddows CG, Wong J (1987) Optimization of yield and properties of silken tofu from Soybean I. The water: bean ratio. Int J Food Sci Technol 22:15–21

Bourne MC (1978) Texture profile analysis. Food Technol 32(7):62k–66

Cai TD, Chang KC (1997) Dry tofu characteristics affected by soymilk solid content and coagulation time. J Food Qual 20:391–402

Cai TD, Chang KC (1998) Characteristics of production-scale tofu as affected by soymilk coagulation method: propeller blade size, mixing time and coagulant concentration. Food Res Int 31(4):289–295

Cai TD, Chang KC (1999) Processing effect on soybean storage proteins and their relationship with tofu quality. J Agric Food Chem 47:720–727

Che Man YB, Wei LS, Nelson AI (1989) Acid inactivation of soybean lipoxygenase with retention of protein solubility. J Food Sci 54:963–967

deMan JM, deMan L, Gupta S (1986) Texture and microstructure of soybean curd(tofu) as affected by different coagulants. Food Microstruct 5:83–89

Friedman HH, Whitney JE, Szczesniak AS (1963) The texturometer-a new instrument for objective texture measurement. J Food Sci 28:390–396

Fukushima D (1981) Soy protein for food centering around soy sauce and tofu. J Am Oil Chem Soc 58:346–354

Hou HJ, Chang KC, Shih MC (1977) Yield and textural properties of soft tofu as affected by coagulation method. J Food Sci 62(4):824–827

Jackson CJC, Dini JP, Lavandier C, Rupasinghe HPV, Faulkner H, Poysa V et al (2002) Effects of processing on the content and composition of isoflavones during the manufacturing of soy beverage and tofu. Process Biochem 37:1117–1123

Kohyama K, Nishinari K (1993) Rheological studies on the gelation process of soybean 7 S and 11 S proteins in the presence of glucono-.delta.-lactone. J Agric Food Chem 41(1):8–14

Kohyma K, Sano Y, Doi E (1995) Rheological characteristics and gelation mechanism of tofu (soybean curd). J Agric Food Chem 43:1808–1812

Levinton R (1982) US per capita Soyfoods consumption upto 9 pounds. Soyfoods 6:6

Lim BT, Deman JM, Deman L, Buzzell RI (1990) Yield and quality of tofu as affected by soybean and soymilk characteristics. Calcium sulfate coagulant. J Food Sci 55:1088–1092

Nelson AI, Steinberg MP, Wei LS (1976) Illinois process preparation of soymilk. J Food Sci 41:57–62

Nsofor LM, Ugwa IS (1999) Tofu analogue development from whole soybeans by simulated exrusion process. J Food Sci Technol 36(4):325–328

Nsofor LM, Okpara BU, Osuji CM (1997) Storage stability and chemical properties of soymilk from sprouted soybeans. J Food Sci Technol 34(6):477–482

Saio K (1979) Tofu relationship between texture and fine structure. Cereal Foods World 24:342

Shen CF, Deman L, Buzzell RI, Deman JM (1991) Yield and quality of tofu as affected by soybean soymilk characteristics. Glucon-delta-lactone coagulant. J Food Sci 56:109–112

Shurtleff W, Aoyagi A (1990) Tofu and soymilk production: The book of Tofu, vol 2. Soyfoods Center, Lafyette

Sun N, Breene WM (1991) Calcium sulfate concentration influence on yield and quality of tofu from five soybean varieties. J Food Sci 56:1604–1607

Szczesniak AS, Bourne MC (1995) Letters. J Food Sci 60(6):7

Szczesniak AS, Brandt MA, Friedman HH (1963) Development of standard rating scales for mechanical parameters of texture and correlation between the objective and the sensory methods of texture evaluation. J Food Sci 28:397–403

Tripathi AK, Misra AK (2005) Soybean—a consummate functional food: a review. J Food Sci Technol 42(2):111–119

Tsai SJ, Lan CY, Kao CS, Chen SC (1981) Studies on the yield and quality characteristics of tofu. J Food Sci 46:1734–1740

Wang HL (1984) Tofu and Tempeh as potential protein sources in the western diet. J Am Oil Chem Soc 61(3):528–535

Wang HL, Hesseltine CW (1982) Coagulation conditions in tofu processing. Process Biochem 1:1808–1812

Watanabe T, Fukamachi, E, Nakayama O, Teramachi, Y, Abe K, Seruga S, Miyanaga S (1964) Research into the standardization of the tofu making process. National Food Institute reports (Japan), parts 1–3

Acknowledgments

First author thanks University Grants Commission, New Delhi, for giving the opportunity to pursue the research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rekha, C.R., Vijayalakshmi, G. Influence of processing parameters on the quality of soycurd (tofu). J Food Sci Technol 50, 176–180 (2013). https://doi.org/10.1007/s13197-011-0245-z

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-011-0245-z