Abstract

Poly methyl methacrylate (PMMA) resin is the most widely used material for fabrication of dentures since 1937 as it exhibits adequate physical, mechanical and esthetic properties. But one of the major problems faced using this material is that, it is highly prone to plaque accumulation due to surface porosities and its food retentive properties. This in turn increases the bacterial activity causing denture stomatitis. In efforts to impart antimicrobial property to these resins, various nanoparticles (NP) have been incorporated viz. Silver, Zirconia oxide, Titanium dioxide (TiO2), Silica dioxide (SiO2) etc. However, as additives they can affect the mechanical properties of the final product. Therefore, the aim of the present study was to evaluate and compare the effect of different concentration of TiO2 NP on the flexural strength of PMMA resins. Specimens made from heat polymerizing resin (DPI) without NP were used as a control group (Group A). The two experimental groups, (Group B and Group C) had 0.5 and 1 % concentration of TiO2 NP respectively. The specimens were stored in 37 °C distilled water for 50 ± 2 h. A three-point bending test for flexural strength measurement was conducted following ADA specification no. 12. The maximum mean flexural strength (90.65 MPa) belonged to the control group; and acrylic resin with 1 % TiO2 NP demonstrated the minimum mean flexural strength (76.38 MPa). But, the values of all the three groups exceeded the ADA Specification level of 65 MPa. Conclusion may be drawn from the present study that addition of TiO2 NP into acrylic resin can adversely affect the flexural strength of the final product and is directly proportional to the concentration of NP.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Synthetic acrylic resins have a long clinically proven history of use for dentures since they exhibit adequate physical, mechanical, and esthetic properties. However, they are susceptible to microbial adhesion, leading to denture stomatitis, which is the most common infectious disease affecting the palatal mucosa, and is highly prevalent in denture wearers [1]. Generally, denture cleansing and oral hygiene care are essential for the prevention of this lesion; however, for some geriatric or hospitalized patients, denture cleansing might be compromised owing to cognitive impairment, reduced motor dexterity and memory loss [2]. Treatment of denture stomatitis should start with educating patients on meticulous daily washing of their dentures. It has been reported that mechanical cleaning methods are insufficient for a complete reduction of microorganisms on denture bases [3]. Therefore, recently there has been tendency towards incorporation of anti microbial agents into the denture resin itself and other similar intraoral drug delivery systems [1]. Various nanoparticles (NP) have been added to different dental materials viz. TiO2, SiO2, ZnO, CeO2, Ag, CuO etc. in order to induce antimicrobial property [4]. Amongst these, TiO2 has received recent attention because of its prominent catalytic effect, white color, low toxicity, high stability, efficiency, availability and low cost [5, 6]. Antimicrobial activities of TiO2 against Candida albicans, Staphylococcus aureus, Pseudomonas aeruginosa, Escherichia coli, Lactobacillus acidophilus, etc. have been proved by recent studies [7]. Of the two widely used phases viz. anatase and rutile, anatase phase TiO2 exhibits more photocatalytic activity. The reason for this could be the difference in the position of the conduction band between the two groups.

On the other hand, (NP) as an additive can alter the physical properties of the substrate. Therefore, before incorporating any additive, it is recommended to evaluate its effect on the mechanical properties of acrylic resin to avoid any deleterious effect. Hence, aim of this study was to evaluate and compare the effect of different concentration of anatase TiO2 (NP) on the flexural strength of poly methyl methacrylate (PMMA) resins.

It was hypothesized that adding TiO2 (NP) to heat cure acrylic resin with the purpose of imparting anti microbial properties, can affect the flexural strength of the final product.

Materials and Methods

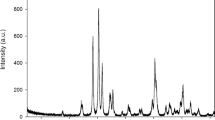

A total of 45 acrylic specimens of dimensions 65 × 10 × 3.3 mm were prepared, according to ADA specification no. 12, [8] for testing flexural strength. To prepare this, a stainless steel metal die (Fig. 1) of the same dimension was fabricated. Petrolatum jelly (Vaseline, Hindustan Lever, Mumbai, India) was applied to the die and the die was invested in a dental flask using type III dental stone (Kaldstone, Kalabhai Pvt Ltd. Mumbai, India). Grooves were made on either sides of the die for easy removal. After the stone was set, the die was retrieved and a negative mold obtained (Fig. 2). Acrylic monomer (Dental products of India, Mumbai, India) containing anatase phase TiO2 (NP) in two concentrations of 0.5 and 1 % was prepared. To achieve the above concentrations, 0.02 and 0.04 gm of TiO2 NP/ml of monomer were added. 7 nm of amorphous anatase TiO2 NP (Sisco Research laboratory, Mumbai, India) were used. The monomer containing NP was sonicated (Confident dental equipments Ltd., Bangalore) for 1 h for proper dispersion of NP. The powder and liquid were mixed in a ratio of 3:1 (by volume), and the material was packed into the prepared mold. Heat polymerization was carried out in a curing unit (Apex-India) in conventional manner. A control group consisting of acrylic resin without addition of NP was also prepared. The specimens were trimmed, finished and polished by standardized procedures. A total of 45 samples were prepared with 15 samples in each group. Group A, B and C consisted of acrylic resin with 0, 0.5 and 1 % TiO2 NP respectively (Fig. 3). The specimens were visually inspected to make sure they were free of voids. Prior to flexural strength testing, the specimens were stored in 37 °C distilled water for 50 ± 2 h to simulate oral environment. The acrylic specimens were inserted in universal testing machine (Star Testing Machine, 248, India) for three-point bending test. The distance between the support arms was kept constant at 50 mm. The initial applied force was zero followed by gradual increase with the rate of 5 mm/min until the specimen fractured (Figs. 4, 5). The flexural load was measured at the point of fracture of the specimen in newtons. The ultimate flexural strength was measured using the following formula:

F = Maximum applied force in Newton, I = distance between the support arms, b = width of the specimen prior to water storage, h = height of the specimen prior to water storage.

I, b, and h values were 50, 10 and 3.3 mm respectively.

Statistical analysis was carried out using SPSS 20 software package (IBM Company). The mean flexural strength of each group was analyzed with one way analysis of variance (ANOVA) followed by post hoc multiple comparison test (Bonferroni’s test). Statistical significance was set at p < 0.05.

Results

Flexural strength testing was done for three study groups; each contained about 15 specimens with different concentration of NP. The mean flexural strength of each group in MPa is illustrated in Table 1. The results revealed that the flexural strength values of all the three study groups exceeded the minimal value of 65 MPa (ADA Specification no. 12). As evident from the table, the maximum mean flexural strength (90.65 MPa) belonged to the control group and the minimum mean flexural strength (76.38 MPa) belonged to acrylic resin with 1 % NP. The flexural strength decreased as the concentration of TiO2 (NP) increased. One way ANOVA revealed a statistical significant difference (p < 0.05) in flexural strength among the three groups (Table 2). Post hoc test showed that, there was a significant mean difference in flexural strength values between group A and group B and between group A and group C (Table 3).

Discussion

Heat cure PMMA resin has been the material of choice for fabrication of dentures for its properties of availability, dimensional stability, handling characteristics, color, and compatibility with oral tissues [9]. But one of the major problems faced by clinician and patient in using acrylic resin is its potential for microbial adhesion. Micro-organisms show more adherence to acrylic resin than natural tooth surface. Various physical and chemical methods have been used for denture cleaning [10]. Mechanical methods have been proved to be ineffective in eradicating micro-organisms completely; also toothpastes which are most popular as mechanical denture cleanser are highly abrasive leading to formation of microporosities on the denture surface. These microporosities in turn may harbour more microorganisms [11, 12]. The commercially available peroxide solution most widely used for chemical denture cleaning is insufficient because it can only kill bacteria with a 3-log reduction [13]. Therefore recently, efforts have been made in incorporating certain antimicrobial agents into the denture resin itself [1]. Of the various antimicrobial agents added, NP have gained tremendous attention owing to their efficacy and availability.

NP are generally of a size no. <100 nm, and the exploitation of their unique attributes to combat infection has increased markedly over the past decade [4]. The structure of material that has particles of a nanometer size possesses special properties. The reason could be in their high surface area to volume ratio. This results in appearance of new mechanical, chemical, electrical, optical, magnetic, electro-optical, and magneto-optical properties of the NPs that are different from their bulk properties [14, 15]. The potential of (NP) to control the formation of biofilms within the oral cavity, as a function of their biocidal, anti-adhesive, and delivery capabilities, is now coming under close scrutiny. Possible uses as constituents of prosthetic device coatings, as topically applied agents, and within dental materials are being explored [4]. In particular, the use of nanoparticulate silver, copper, zinc, silicon, titanium and their oxides are considered in relation to their effects on bacterial populations. Amongst them, titanium dioxide has gained importance recently because of its higher photocatalytic activity, high stability, low cost and safety toward both humans and the environment.

TiO2 exists in three phases in nature: anatase, rutile and brookite [16]. Although rutile type can absorb light of a wider frequency range, the anatase type exhibits higher photocatalytic activity. The reason for this could be the difference in the energy structure between the two types. Due to the difference in the position of the conduction band, the anatase type exhibits higher overall photocatalytic activity than the rutile type [17]. Hence, in the present study anatase phase TiO2 was used. Also, anatase TiO2 photocatalyst does not require light of shorter wavelength viz. ultraviolet rays which could be hazardous to humans. It allows reaction to be accelerated with light of relatively long wavelengths contained in sunlight.

The concentration of NP added is an important factor in determining its effect on the mechanical properties of the substrate. For instance, in a study conducted by Elsaka et al. [18] on the influence on physical properties of TiO2 NP added to conventional glass ionomer cement (GIC), TiO2 were incorporated in 3, 5 and 7 % concentration [18]. GIC-containing 3 and 5 % TiO2 NP improved the mechanical properties. However, a decrease in mechanical properties was found as the concentration increased to 7 %. In another study conducted by Sodagar et al. [7] on the effect of TiO2 and SiO2 NP on cold cure resin, the strength decreased as the concentration of NP increased. Also, addition of nanosized oxides up to 2.5 % increased the tear strength of silicone elastomer, above which the strength decreased [19]. In a study conducted by Ahmad et al. [20] on the antibacterial properties of TiO2, different concentrations of NP were studied ranging from 0 to 1 %. It was concluded from the study that, as the concentration of NP increased, the antibacterial property of the NP also increased with maximum antimicrobial property at 1 % concentration. But, effect of addition of TiO2 NP on the flexural strength of heat cured PMMA resin is still a matter of concern. Therefore, in the present study, two different representative concentrations of 0.5 and 1 % TiO2 as additive in PMMA resin were used. An inverse relationship between NP size and antimicrobial activity has been demonstrated; where NP in the size range of 1–10 nm has been shown to have the greatest biocidal activity against bacteria [4]. Therefore, in the present study 7 nm diameter TiO2 was used.

The maximum mean flexural strength belonged to the control group i.e. 90.65 MPa and the minimum mean flexural strength belonged to group C (76.38 MPa). Based on our obtained results, the addition of titanium dioxide NP to heat cure acrylic resins at concentration of 0.5 and 1 % had adverse effect on the flexural strength of final product. A standard minimal limit has been established for flexural strength of acrylic resins by ADA (specification no. 12) as 65 MPa [8]. Though, the flexural strength values of all the three groups exceeded the minimum flexural strength value of 65 MPa, the values decreased with increase in concentration of TiO2. These findings are in consistent with study by Sodagar et al. [21] on the effect of silver NP on flexural strength of acrylic resins. Also in a study conducted by Shibata [3], addition of apatite-coated TiO2 to acrylic resin affected the mechanical properties of the material adversely. In another study by Sodagar et al. [7] on the effect of TiO2 and SiO2 NP on the flexural strength of cold cure acrylic resins, he found that the NP additive had a deleterious effect on the flexural strength of the final polymerized material. The decrease in flexural strength values could be attributed to the effect of nano-sized oxides on the internal structure of polymerized PMMA [7]. The NP additive can act as an impurity and interfere with the polymerization reaction. The NP additive acts as a plasticizer leading to increase in amount of residual unreacted monomer, decreasing the strength of the material [3].

This study compared the effect of TiO2 (NP) on the flexural strength of commonly used heat cured resin in the fabrication of dentures. The study was limited to just one brand of commercially available acrylic resin. Also the effect of aging on the flexural strength of acrylic resin containing TiO2 NP after some time intervals could not be tested because of time constraints.

Although the study was in vitro study, the values are helpful in comparing material under controlled situations and can be useful in predicting their clinical performance. Thus longer follow-ups and in vivo studies using different commercially available acrylic resins are suggested for further investigations on similar issues.

Conclusion

Within the limitations of this study, it may be concluded that incorporation of TiO2 NP into the heat cure acrylic resin with the purpose of imparting antimicrobial properties can adversely affect the flexural strength of the final product and this effect is directly proportional with the concentration of NP.

References

Dhir G, Berzins DW et al (2007) Physical properties of denture base resins potentially resistant to candida adhesion. J Prosthodont 16:465–472

Nam KY, Lee CH, Lee CJ (2012) Antifungal and physical characteristics of modified denture base acrylic incorporated with silver nanoparticles. Gerodontology 29:e413–e419

Shibata T, Hamada N et al (2007) Antifungal effect of acrylic resin containing Apatite-coated TiO2 photocatalyst. Dent Mater J 26:437–444

Allaker RP (2010) The use of nanoparticles to control oral biofilm formation. J Dent Res 89:1175–1186

Mu R, Xu Z, Li L, Shao Y, Wan H, Zheng S (2010) On the photocatalytic properties of elongated TiO2 nanoparticles for phenol degradation and Cr(VI) reduction. J Hazard Mater 176:495–502

Pant HR, Pandeya DR, Nam KT, Baek WI, Hong ST et al (2011) Photocatalytic and antibacterial properties of a TiO2/nylon-6 electrospun nanocomposite mat containing silver nanoparticles. J Hazard Mater 189:465–471

Sodagar A, Bahador A et al (2013) The effect of TiO2 and SiO2 nanoparticles on flexural strength of poly(methyl methacrylate) acrylic resins. J Prosthodont Res 57:15–19

Revised American Dental Association Specification No. 12 for denture base polymers

Anusavice KJ (2003) Philip’s science of dental materials, 11th edn. W.B. Saunders, St. Louis, p 721

Dills SS, Olshan AM, Goldner S, Brogdon C (1988) Comparison of the antimicrobial capability of an abrasive paste and chemical-soak denture cleaners. J Prosthet Dent 60:467–470

Kanno T, Nakamura K, Ikai H, Hayashi E, Shirato M, Mokudai T, Iwasawa A, Niwano Y, Kohno M, Sasaki K (2012) Novel denture-cleaning system based on hydroxyl radical disinfection. Int J Prosthodont 25:376–380

Pisani MX, Bruhn JP, Paranhos HF, Silva-Lovato CH, de Souza RF, Panzeri H (2010) Evaluation of the abrasiveness of dentifrices for complete dentures. J Prosthodont 19:369–373

Moore TC, Smith DE, Kenny GE (1984) Sanitization of dentures by several denture hygiene methods. J Prosthet Dent 52:158–163

Lainovic T, Blazic L, Potran M (2012) Nanotechnology in Dentistry-current state and future perspectives. Serb Dental j 59(1):44–47

Hajipour MJ, Fromm KM et al (2012) Antibacterial properties of nanoparticles. Trends Biotechnol 30(10):499–511. doi:10.1016/10j.tibtech.2012.06.004

Gupta K, Singh RP, Pandey A, Pandey A (2013) Photocatalytic antibacterial performance of TiO2 and Ag-doped TiO2 against S. aureus. P. aeruginosa and E. coli. Beilstein J. Nanotechnol. 4:345–351

www.ecoquest.cl/tio2%20photocatalysis%20technonews%20japan.pdf

Elsaka SE, Hamouda IM, Swain MV (2011) Titanium dioxide nanoparticles addition to a conventional glass-Ionomer restorative: influence on physical and antibacterial properties. J Dent 39(9):589–598

Han Y, Kiat-amnuay S, Powers JM, Zhao Y (2008) Effect of nano-oxide concentration on the mechanical properties of a maxillofacial silicone elastomer. J Prosthet Dent 100:465–473

Ahmad R, Sardar M (2013) TiO2 nanoparticles as an antibacterial agents against E. coli. Int J Innov Res Sci Eng Technol 2(8):3569–3574

Sodagar A et al (2012) Effect of silver nano particles on flexural strength of acrylic resins. J Prosthodont Res 56(2):120–124

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nazirkar, G., Bhanushali, S., Singh, S. et al. Effect of Anatase Titanium Dioxide Nanoparticles on the Flexural Strength of Heat Cured Poly Methyl Methacrylate Resins: An In-Vitro Study. J Indian Prosthodont Soc 14 (Suppl 1), 144–149 (2014). https://doi.org/10.1007/s13191-014-0385-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13191-014-0385-8