Abstract

The aim is to evaluate and compare the flexural strength of different provisional restorative materials reinforced with glass and polyethylene fibers. A total of 90 samples were prepared and divided into three groups based on the type of fiber reinforcement, unidirectional S-glass (Splint-It) and ultra-molecular weight polyethylene (Ribbond). Unreinforced samples served as control group. Again each group was subdivided into three subgroups based on type of provisional restorative resins, heats cure polymethyl methacrylate, self-cure poly methyl methacrylate and self-cure bis-acryl composite. Samples were loaded in a universal testing machine until fracture occurs. The mean flexural strengths (MPa) were subjected to the one-way ANOVA, followed by the Tukey-HSD test at a significance level of 0.001. The result shows all the fiber reinforced samples possessed greater strength than the control samples. In control samples, the heat cure poly methyl methacrylate resin (72.74 ± 2.28 MPa) had the greatest flexural strength, followed by self-cure bis-acryl composite (67.05 ± 2.35 MPa) and self-cure poly methyl methacrylate resin (52.88 ± 1.90 MPa). In both heat and self-cure poly methyl methacrylate resin, the polyethylene fiber reinforcement (96.00 ± 2.63 MPa, 86.17 ± 1.92 MPa) provides the greatest strength than glass fiber reinforcement (92.68 ± 1.58 MPa, 76.40 ± 2.11 MPa). In self-cure bis-acryl composite, the glass fiber (105.95 ± 3.07 MPa) shows better reinforcement than polyethylene fiber (99.41 ± 1.74 MPa).The fibers reinforcement increases the flexural strength of provisional restorative resins.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

It is important that the prepared tooth or teeth be protected and the patient be kept comfortable by a provisional restoration, while a definite restoration is being fabricated. The basic requirements of a provisional restoration are essentially the same as for the definitive restoration, with the exception of longevity and possibly the sophistication of color.

The commonly used provisional material resins, namely polymethyl methacrylate (PMMA), polyethyl methacrylate (PEMA), composite resin (bis-acryl composite), and poly urethane dimethacrylate are of different polymerizing nature and each material has physical properties unique to its chemistry [1–5]. PMMA is the most commonly used material for indirectly made provisional fixed partial dentures. Its strength, color stability, ease of manipulation and polishing make it a desirable material [1, 2]. PEMA is suitable for intra-oral use but it demonstrates a very large marginal gap that would be clinically unacceptable [6–8]. Bis-acryl composite resins are more expensive but show low exothermic reaction on setting, good marginal fit, and moderate color retention and strength [5].

Provisional restorations with improved physical properties are required for conditions like bruxism [9], certain TMJ disorders, full mouth rehabilitation [8], assessing tolerance to increased vertical dimension [10] and when periodontally involved teeth are retained & used as abutments during the osseointegration of implants [11, 12]. Presently there is no such material available that meets the ideal requirements for all situations [9, 13]. These materials may be reinforced by incorporating various types of materials to improve certain features such as fracture resistance. The traditional methods involved the use of a metal wire, lingual cast metal reinforcement [14, 15] and heat processed acrylic resin provisional restoration [16].

The development of fibrous composite materials in the dental industry has given a new approach to improve the performance of dental acrylic resins [17, 18]. The fibers investigated in this manner are carbon [19], aramid [20, 21], polyethylene [10, 22] and glass fibers [23–26]. Carbon and aramid fibers were useful in strengthening polymers, but were not used because of the easy lateral spreading of the fibers during processing and their poor esthetic quality [20]. The ultra-high molecular weight polyethylene fibers are more esthetic and have good mechanical properties, but adhesion to the polymer is insufficient. This problem is minimized by “plasma” treatment of the polyethylene fibers [10, 22, 27]. A Silanized glass fiber has shown a better adhesion to the polymer matrix and superior esthetics.

The flexural strength of a provisional restoration is highly important to resist fracture particularly, when the patient is subjected to use the provisional restoration for an extended period or when long-span prosthesis is planned [1, 2, 5]. The objective of this study was to determine and compare the effect of unidirectional S-glass fibers and ultra-high molecular weight polyethylene fibers reinforcement on flexural strength of heat cure PMMA, self-cure PMMA and self-cure bis-acryl composite resin.

Materials and Methodology

The provisional restorative materials selected for this study were commercially available heat cure polymerizing PMMA, self-cure PMMA and self-cure bis-acryl composite resin. The reinforcement fibers used were Splint-It, 3 mm width unidirectional dimethacrylate resin reinforced S-glass fibers and Ribbond, 3 mm width leanoweave cold plasma treated ultra-high molecular weight polyethylene fibers (Fig. 1and 2; Table 1).

For preparation and standardization of samples, a rectangular metal die made of steel was used. It consisted of two parts. The bottom die consisted of two metal projections 5 mm high, simulating the abutment teeth. The mesial projection represented a prepared premolar tooth and the distal projection represented a prepared molar tooth. The 12 mm distance between the two abutments had a 10 mm wide raised portion of height 3 mm, represented the molar sanitary pontic area. The top die consisted of a rectangular hollow space, which had 7 mm deep three compartments. Indices were made on either side for correct alignment (Fig. 3) and then both the parts were mounted and locked tight. The die was designed in such way that the samples were obtained as three units FPD representing a premolar and two molars teeth. This pattern sparked to precision from a machined steel bar using a Spark Erosion Machine. Wax samples were made with help of metal die and invested in dental flasks using Type III gypsum material and dewaxed.

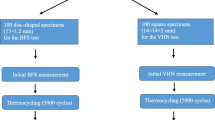

The samples prepared were divided into three groups namely: Group A, B and C based on the type of fibers used. Group A non-reinforced samples as the control group. Group B reinforced with unidirectional S-glass fibers (Splint-It) and Group C samples reinforced with ultra-molecular weight polyethylene fibers (Ribbond). Each group was further subdivided into three subgroups based on the type of provisional restorative resins as Subdivision I for heat-cure PMMA, Subdivision II for self-cure PMMA and Subdivision III for self-cure bis-acryl composite resin. A total of 90 samples were prepared, with 30 in each group. These 30 samples were further divided into three subgroups containing 10 each.

For Group A the mould space was coated with cold mould seal and the three selected provisional restorative resins were mixed individually according to the manufacture instructions and packed in three separate flasks.

For group B and group C, the unidirectional S-glass fibers and polyethylene fibers were cut to a length of 22 mm. Since the glass and polyethylene fibers were already dimethacrylate reinforced and plasma treated they did not require any pretreatment procedure. Prior to placing the fibers, they were impregnated in a mix of polymer and monomer for self-cure and heat cure PMMA resin samples while for composite resin samples they were wet with the bonding agent. After applying a layer of separating medium, the mold was packed with half the amount of resin material mixed as per the manufacturer’s instruction. Another small metal die of dimensions 22 × 3 × 1.5 mm was used to provide space for fiber incorporation within the sample while packing resins in the mold space (Fig. 4). This metal die had projections which served as stops to ensure uniformity in indentation created in resins samples thereby providing proper standardization of fiber placement. The prepared fibers were then placed into the imprint left by the small metal die (Fig. 5). The remaining half of the resin was then packed and the samples were polymerized according to manufacturer’s instructions and bench cooled. All the resins samples were retrieved from the flask were trimmed, finished and polished to the final dimensions of 25.5 mm length and height of 7 mm (±0.2 mm). The samples were stored in distilled water for 24 h before testing.

The flexural strength for all specimens was tested by loading them in the Universal Testing Machine [Shimadzu test apparatus–TM-L, Autograph AGS 2000G-Shimadzu Co., Kyoto, Japan] with a load cell of 20 kN and across head speed of 1 mm/min. The samples were placed horizontally and supported on 2 jigs with a span of 18 mm between them. The load was applied at the center in a perpendicular direction. The samples were subjected to the loading until fracture occurred and the maximum flexural load during fracture was recorded as fracture load in kg. This was converted into Newton’s using the formula 1 kg = 9.81 Newtons. The flexural strength (MPa) was calculated from the fracture load using the formula, \( FS = 3WL/\left( {2bd^{2} } \right) \) where FS is the flexural strength (MPa or MN/m2), W the maximum load before fracture (N), L the distance between the supports (mm), b the width of the samples (mm), d the thickness of the samples (mm).

In addition to this, the nature of the fracture was noted and categorized as, catastrophic or partial. In catastrophic fractures the pontic were sheared off by the load whereas in partial the prosthesis remained intact at the joints and only a portion of the pontic fractured.

Results

The mean flexural strength (MPa) values (Fig. 6) and standard deviations of the three groups have been tabulated and the data was subjected to multivariate analysis ANOVA and Post hoc test Tukey-HSD (Table 2). For finding out the significance between the glass and polyethylene fibers, the independent t-test was subjected in the groups B and C at a significance level of 0.01 (Table 3).

In control samples (Group A), the heat cure PMMA resin (72.74 ± 2.28 MPa) had greatest flexural strength, followed by self-cure composite (67.05 ± 2.35 MPa) and self-cure PMMA resin (52.88 ± 1.90 MPa) and the difference was highly statistically significant at the 0.001 level.

In Group B which was glass fiber reinforced, the highest flexural strength was seen in Subgroup III and followed in decreasing order by Subgroups I and II. The difference between the Subgroups was statistically significant at the level 0.001. In Group C which was polyethylene fiber reinforced, the highest flexural strength was seen in Subgroup III and followed in decreasing order by Subgroups I and II. The difference between the Subgroups was statistically significant at the level 0.001. In both heat and self-cure PMMA resin, the polyethylene fiber reinforcement (96.00 ± 2.63 MPa, 86.17 ± 1.92 MPa) provides the greater flexural strength than glass fiber reinforcement (92.68 ± 1.58 MPa, 76.40 ± 2.11 MPa). In self-cure bis-acryl composite, glass fiber reinforcement (105.95 ± 3.07 MPa) provides the greatest strength than polyethylene fiber reinforcement (99.41 ± 1.74 MPa).

The both glass and polyethylene fiber reinforcement shows highest flexural strength in self-cure bis-acryl composite resin and followed in decreasing order by heat-cure and self-cure PMMA resin. The overall highest flexural strength was seen in glass fiber reinforced self-cure bis-acryl composite resin (105.95 ± 3.07 MPa). Whereas highest reinforcement (63 %) was seen in polyethylene reinforced self-cure PMMA resin (Table 4). The control group shows catastrophic fracture pattern whereas all fiber reinforced samples shows “partial” fracture pattern (Fig. 7).

Discussion

This study compared the effect of fiber reinforcement on the flexural strength of commonly used resins in the fabrication of provisional restorations. Although the study was in vitro study, the values were helpful in comparing materials under controlled situations and can be a useful in predicting their clinical performance [1, 2, 5].

The findings of this study were found to be in agreement with Osman and Owen [13] study, which revealed that the heat cure PMMA had higher flexural strength followed by bis-acryl composite and self-cure PMMA resin without any fiber reinforcement.

The commonly used glass fibers in dentistry are E & S glass fibers. The tensile strength of S-glass fibers (4,750 MPa) is more comparing to E-glass fibers (2,000 MPa). The glass fibers are available in unidirectional and woven form and compared to woven glass fiber, the unidirectional glass fiber has more flexural strength [9]. Plasma treatment of polyethylene fibers increases the surface energy and thereby improves their chemical activity [27].

Kim et al. [28] compared three experimental fibers post (E-glass, polyethylene and aramid) having common customized resin matrix. In our study we used pre-impregnated glass fibers and plasma treated polyethylene fibers. The pre-impregnation makes fibers to be united and also ensured uniform impregnation without any voids in between the fibers.

This study showed that the tested fibers increased the flexural strength of provisional restoration resins. Accurately placed and orientated impregnated fibers increased flexural strength. The increase was due to transfer of stress from the weaker polymer matrix to the fibers that have a high tensile strength. The stronger the adhesion between the fiber and the matrix, the greater the strengthening effect. In the both heat cure and self-cure PMMA resins, polyethylene fibers show better reinforcement than glass fibers. The improved performance of polyethylene fibers could be due to the use of plasma treatment to increase the degree of adhesion of the polyethylene fibers to the resins [10, 22]. Whereas the glass fiber with dimethacrylate resin pre-impregnation causes less reinforcement in multiphase PMMA resins as the highly cross-linked dimethacrylate polymer matrix did not form an interpenetrating polymer network bond with multiphase acrylic resin [29].

In this study it was noticed that the percentage of reinforcement was appreciably increased in auto polymerizing PMMA than heat cure PMMA resin. This was maybe due to inadequate impregnation that occurred with the heat curing PMMA, which formed a high viscous dough stage with a poor wetting property. With auto polymerizing acrylic resins, the resin was applied to the fiber bundle still in a relatively low viscous stage, and better impregnation of the fibers can be obtained [30].

In the case of auto polymerizing bis-acryl composite resin, glass fibers showed better reinforcement than polyethylene fibers. This may be due to the fact that pre-impregnated dimethacrylate resin enhances the bonding of bis-acryl composite with glass fibers [29, 31].

In Eronat et al. [32] study, the woven E-glass fiber reinforcement in hybrid composite showed more flexural strength than in micro-filled composite material. The previous studies like Kulkarni et al. [33] and Sen et al. [34], the polyethylene fiber reinforced composite material (micro-filled and hybrid) showed more flexural strength than silanized woven E-glass fiber reinforced composite. But our result contraindicated this, where unidirectional S-glass fiber shows more reinforcement than polyethylene fiber in bis-acryl composite. The results of both studies cannot be compared, since type and form of glass fibers (woven E-glass and unidirectional S-glass), pre-impregnation materials used and also type of composite materials (direct filling composite and bis-acryl composite) were different. Factors that related to the strength of the fiber composite were “type of fiber, quantity of fibers in the polymer matrix, orientation of fibers, fiber impregnation, and adhesion of fiber to the polymer matrix” [32].

The mode of failure of fiber reinforced resins samples showed a “Partial” fracture pattern, where the joints remained intact but a small portion of the pontics were separated as a result of a cohesive failure of the resin materials. Clinically, this is perhaps the most favorable mode of fracture of the provisional prosthesis as the restoration remains intact and the treatment rendered is unlikely to be compromised [3].

Conclusion

They are different glass and polyethylene fiber system available, and the each fiber system varies in the type, form, fiber content and pre-impregnation technique employed. So the results are valid only for the products deployed in the study.

Within the limitations of this in vitro study, the following observations were made:

-

All the fiber reinforced samples possessed greater strength than the control samples.

-

Within the control samples, the heat cure PMMA resin had the highest flexural strength, followed by bis-acryl composite and self-cure PMMA resin.

-

In both heat and self-cure PMMA resin, the polyethylene fiber reinforcement (Ribbond) provides the greatest strength than glass fiber reinforcement (Splint-It).

-

In self-cure bis-acryl composite, glass fiber reinforcement (Splint-It) provides the greatest strength than polyethylene reinforcement (Ribbond).

-

Both glass (Splint-It) and polyethylene fiber (Ribbond) reinforcement showed highest flexural strengths in bis-acryl composite resin followed by heat cure and self-cure PMMA resin.

-

Both glass and polyethylene fiber reinforcement altered the mode of failure of the provisional restorative resins under compressive load from a catastrophic failure to a partial fracture pattern.

References

Aunsavice KJ (2003) Philip’s science of dental materials, 11th edn. W.B. Saunders, St. Louis, pp 73–102, 143–170

Craig RG, Powers JM (2002) Restorative dental materials, 11th edn. Mosby, St. Louis, pp 68–116, 635–680

Rosenstiel SF (2001) Contemporary fixed prosthodontics, 3rd edn. Mosby, St. Louis, pp 380–415, 697–706

Shillinburg HT (1997) Fundamentals of fixed prosthodontics, 3rd edn. Quintessence Pub. Co, Ann Arbor, pp 224–227

Debra HR, Diaz-Arnold AM, Vargas MA (2002) Flexural strength of provisional crown and fixed partial denture resins. J Prosthet Dent 87(2):225–228

Ireland MF, Dixon DL, Breeding LC, Ramp MH (1998) In vitro mechanical property comparison of four resins used for fabrication of provisional fixed restorations. J Prosthet Dent 80(3):158–162

Ehrenberg D, Weiner GI, Weiner S (2006) Long-term effects of storage and thermal cycling on the marginal adaptation of provisional resin crowns: A pilot study. J Prosthet Dent 95(2):230–236

Wasssell RW, St George G, Ingledew RP, Steele JG (2002) Crowns and other extra-coronal restorations: Provisional restorations. Br Dent J 12(11):619–630

Tamer HA, Rosenstiel SF et al (2004) The effect of fiber reinforcement on the fracture toughness and flexural strength of provisional restorative resins. J Prosthet Dent 91:258–264

Ramos V, Runyan DA, Christensen LC (1996) The effect of plasma-treated polyethylene fiber on the fracture strength of poly methyl methacrylate. J Prosthet Dent 76(1):94–96

Meiers JC, Freilich MA (1988). Use of a prefabricated fiber-reinforced composite resin framework to provide a provisional fixed partial denture over an integrating implant: A clinical report. J Prosthet Dent 60(4):517–519

Freilich MA, Duncan JP, Alarcon EK, Eckrote KA, Jon Goldberg A (2002) The design and fabrication of fiber-reinforced implant prostheses. J Prosthet Dent 88(4):449–454

Osman YI, Owen CP (1993) Flexural strength of provisional restorative materials. J Prosthet Dent 70(1):94–96

Emtiaz S, Tarnow DP (1998) Processed acrylic resin provisional restoration with lingual cast metal framework. J Prosthet Dent 79(4):484–488

Bluche LR, Bluche PF, Morgano SM (1997) Provisional fixed prosthesis reinforced with a metal casting. J Prosthet Dent 77(6):634–635

Galindo D, Soltys JL, Graser GN (1998) Long-term reinforced fixed provisional restorations. J Prosthet Dent 79(6):698–701

Goldberg AJ, Burstone CJ (1992) The use of continuous fiber reinforcement in dentistry. Dent Mater 8(3):197–202

Vallittu PK (1995) A Review of methods used to reinforce poly methyl Methacrylate resin. J Prosthodont 4(3):183–187

Segerström S, Ruyter EI (2007) Mechanical and physical properties of carbon–graphite fiber-reinforced polymers intended for implant supra structures. Dent Mater 23(9):1150–1156

Vallittu PK, Lassila VP, Lappalainen R (1994) Acrylic resin-fiber composite—part I: the effect of fiber concentration on fracture resistance. J Prosthet Dent 71(6):607–612

John J, Gangadhar SA, Shah I (2001) Flexural strength of heat-polymerized polymethyl methacrylate denture resin reinforced with glass, aramid, or nylon fibers. J Prosthet Dent 86(4):424–427

Samadzadeh A, Kugel G, Hurley E, Aboushala A (1997) Fracture strength of provisional restorations reinforced with plasma-treated woven polyethylene fiber. J Prosthet Dent 78(3):447–450

Solnit GS (1991) The effect of methyl methacrylate reinforcement with silane-treated and untreated glass fibers. J Prosthet Dent 66(3):310–314

Nohrström TJ, Vallittu PK, Yli-Urpo A (2000) The effect of placement and quantity of glass fibers on the fracture resistance of interim fixed partial dentures. Int J Prosthodont 13(1):72–78

Stipho HD (1998) Effect of glass fiber reinforcement on the some mechanical properties of auto polymerizing polymethyl methacrylate. J Prosthet Dent 79(5):580–584

Vallittu PK (1998) Some aspects of the tensile strength of unidirectional glass fiber-poly methyl methacrylate used in dentures. J Oral Rehabil 25(2):100–105

Pereira CL, Demarco FF, Cenci MS, Osinaga PWR, Piovesan EM (2003) Flexural strength of composites: influences of polyethylene fiber reinforcement and type of composite. Clin Oral Invest 7(2):116–119

Kim MJ, Jung WC, Oh S et al (2011) Flexural properties of three kinds of experimental fiber-reinforced composite posts. Dent Mater J (Japan) 30(1):38–44

Vallittu PK (1999) Flexural properties of acrylic resin polymers reinforced with unidirectional and woven glass fibers. J Prosthet Dent 81(3):318–327

Vallittu PK (1994) Acrylic resin-fiber composite—part II: the effect of polymerization shrinkage of polymethyl methacrylate applied to fiber roving on transverse strength. J Prosthet Dent 71(6):613–617

Bae J-M, Kim K-N, Hattori M, Hasegawa K, Yoshinari M, Kawada E, Oda Y (2001) The flexural properties of fiber-reinforced composite with light-polymerized polymer matrix. Int J Prosthodont 14(1):33–39

Eronat N, Candan U, Turkun M (2009) Effects of glass fiber layering on the flexural strength of microfill and hybrid composites. J Esthet Restor Dent 21(3):171–178

Kulkarni G, Lau D, Hafezi S (2009) Development and testing of fiber-reinforced composite space maintainers. J Dent Child 76(3):204–208

Sen BH, Yigit Ozer S, Kaya S et al (2011) Influence of fiber-reinforced composites on the resistance to fracture of vertically fractured and reattached fragments. J Endod 37(4):549–553

Acknowledgments

The authors offer their thanks to Dr. T. V. Padmanabhan, Professor and Head of the Department of Prosthodontics and Crown & Bridge, Faculty of Dental Sciences, Sri Ramachandra University, Chennai, Tamil Nadu.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Natarajan, P., Thulasingam, C. The Effect of Glass and Polyethylene Fiber Reinforcement on Flexural Strength of Provisional Restorative Resins: An In Vitro Study. J Indian Prosthodont Soc 13, 421–427 (2013). https://doi.org/10.1007/s13191-012-0148-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13191-012-0148-3