Abstract

Generation of value-added materials from waste product is in high demand for sustainable chemistry. In order to reduce the use of toxic chemicals in the synthesis of metal nanoparticles, alternative green methods are in demand. Herein, we report the synthesis of copper oxide nanoparticles from plant extract of Colocasia esculenta leaves which is thrown as waste after cultivation. The synthesized nanoparticle was characterized using UV, FT-IR, EDX, TEM, AAS, DLS, and XPS. The synthesized nanoparticles were used as heterogenous catalyst for carrying out the click reaction of azide and alkyne. The catalyst showed good catalytic activity for the synthesis of various 1,2,3-triazoles with very low catalyst loading (0.535 mol% of copper) giving excellent yield of various triazoles. The catalyst could be easily separated from the reaction medium and recycled several times without losing much catalytic activity. The catalyst showed good TON (177.6) and TOF (29.6 h−1) for the optimized reaction. Thus, the method has several advantages such as synthesis of the nanoparticle from cheap sources (plant extract of waste Colocasia esculenta leaves), use of the water as environmentally benign solvent for carrying out the click reaction, one-pot reaction, low catalyst loading, recyclability of catalyst, and high yield of 1,2,3-triazole products.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

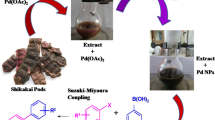

Nanotechnology has seen great advancement in modern science due to its multi-faceted applications in material science, catalysis, medicine, drug delivery, as sensors, etc. Over the years, numerous nanoparticles of metals and its derivates in the form of oxides, hydroxides, sulfides, phosphates, fluorides, and chlorides are synthesized and found application in many fields [1,2,3,4,5,6,7,8,9,10,11,12,13,14]. The nonomaterials can be synthesized using various chemical, physical, and biological methods. In order to reduce the use of toxic chemicals in the synthesis of metal nanoparticles, alternative green methods are explored and getting attention. Over the last few years, different types of microorganisms including fungi, yeast, bacteria, actinomycetes, and viruses and various biomolecules such as amino acids, and polysaccharides have been explored for synthesis of metal nanoparticles [15,16,17,18,19,20,21,22,23,24]. However, developing green synthesis of the nanoparticles using plant extract is necessary as such methods are simple, non-hazardous, environmentally friendly, cost-effective, and sustainable [25,26,27,28,29,30,31]. In literature, various plants are used to synthesize different nanoparticles which are used in different fields [32,33,34,35,36,37,38,39]. The copper nanoparticles (CuNPs) are significantly gaining the interest of researchers and have been explored as a new class of heterogeneous catalyst in various chemical transformations. For example, Goswami et al. successfully used copper nanoparticles supported over nanocellulose as effective catalyst in the C–N coupling reactions involving open chain as well as cyclic secondary amines and electron deficient vinylic compounds [40]. Choudhary et al. used chromium(III)-doped layered double-hydroxide supported copper nanoparticles for the oxidation of alcohols and hydrocarbons [41]. Shen et al. showed a new strategy of controlling catalytic activity and selectivity of Cu nanoparticles for the ammonia borane-initiated hydrogenation reaction. CuNPs are active and selective for chemoselective reduction of nitrostyrene to vinylaniline under ambient conditions [42]. Pei et al. showed porous carbon-supported copper nanoparticles as an efficient catalyst for the dimethyl carbonate synthesis [43]. Diacon et al. successfully demonstrated supported CuO nanoparticles catalyst for controlled radical polymerization reaction and block-copolymer synthesis [44]. The low cost and high efficiency associated with the Cu NPs make them promising candidate in organic synthesis [45, 46].

1,2,3-Triazoles are important class of organic compounds and possesses several biological activities [47,48,49,50,51,52,53,54,55,56,57]. Apart from their biological activity, triazole compounds find application in the polymer and material science [58,59,60,61,62,63,64,65,66,67]. Due to the enormous use of triazole compounds, development of methodology for the synthesis of this moiety is of significant importance. The thermal 1,3-dipolar cycloaddition of azide and alkyne developed by Huisgen [68] was used for synthesis of 1,2,3-triazole. Later, Wang et al. [69] and Chouaib et al. [70] reported that use of copper salts as catalysts allowing the product formation in milder reaction condition, better yield, exclusive regioselectivity (1,4-disubstituted triazole), and having broad substrate scope. Nowadays, the synthesis of 1,2,3-triazoles by using heterogeneous catalyst is getting more attention [71, 72]. Nasrollahzadeh et al. reported that the biosynthesized CuNPs using plant extract is highly active for the Huisgen [3 + 2] cycloaddition of azides and alkynes at room temperature giving high yield of products [73]. Recently, the same research group reported excellent activity of CuNPs for 1,3-diploar cycloaddition using Et3N as base at room temperature [74].

The heterogeneous catalysts have several advantages over homogenous catalysts since in the former case, lower catalyst loading is required, recyclability of catalyst, simple operation, and easier separation. Use of plant extract for the synthesis of the heterogeneous catalyst makes the process more attractive from the green chemistry perspective. Our group is actively involved in the synthesis of different heterogeneous catalyst systems and using them in carrying out important organic reactions [75,76,77,78].

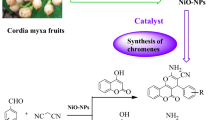

In this work, we have reported the synthesis of copper oxide nanoparticles (CuONPs) using plant extract of Colocasia esculenta leaves which is abundantly available in North-East India for the first time. The leaves were thrown as waste after cultivation. We have further demonstrated the use of the synthesized CuONPs as catalyst for the synthesis of 1,2,3-triazoles using one-pot multi-component reaction of organic halide, sodium azide, and alkynes in water as solvent. Multi-component reactions are those reactions in which three or more reagents react together in a single step to give the product. They are more advantageous than conventional reactions as they require less number of steps, reduced purification steps, energy efficient, and require shorter time [79,80,81,82,83,84].

2 Materials and Methods

2.1 Plant Sample Preparation

Colocasia esculenta leaves were collected from Kokrajhar, Assam, India. The leaves were dried at 50 °C for 3 h and then followed by grinding using mortar pestle to make powder form.

2.2 Synthesis of Nanoparticles

The biosynthesis of the CuONPs is described using the schematic diagram. (Fig. 1). The different phytochemicals present in the plants are believed to help act as capping agent in stabilizing the nanoparticle. For the synthesis of CuONPs, 5-gm powder of Colocasia esculenta leaves was added to 100 mL hot water (Milli Q water) at 70 °C and after 30 min, filtration was done. The 5 mL aqueous extract was added in 45 mL of 1 mM Cu(NO3)2.3H2O solution at 50 °C, and the process was continued under magnetic stirring for 2 h. The mixture was then centrifuged to separate larger particles and prevent agglomeration. After Uv-vis spectrophotometric analysis, the sample was freeze dried. The solid was washed three times with cold water and dried under vacuum to obtain 120 mg of the product which was used for further analysis [85]. The amount of copper in the catalyst was calculated with the help of atomic absorption spectroscopy (AANALYST 700, Perkin Elmer) which is found to be 2.26 wt%.

2.3 Characterization

The UV-Vis spectra of the samples were analyzed using spectrophotometer (Lamda-35, PerkinElmer, USA) to confirm the formation of CuONPs, and for the crystallinity, X-Ray diffractometer was used (Rigaku pro analytical X-ray diffractometer) using wavelength at 1.514 × 10-10 m for 2Ɵ 10 to 80 °C. For the surface morphological studies, transmission electron microscope (TEM) was used (JSM-100CX, Jeol). Chemical bonding study of synthesized CuONPs was carried out using FT-IR (IRAffinity-1, Shimardzu, Tokyo, Japan). The elemental analysis was done with energy dispersive spectrophotometer (EDX). The particle size distribution and zeta-potential analysis were done using dynamic light scattering (DLS) Nano-ZS instrument (Malvern Instruments Ltd., Malvern, UK). X-ray photoelectron spectroscopy study was carried out in Thermo Scientific, ESCALAB Xi+ instrument.

3 Results and Discussion

3.1 UV-Vis Spectroscopy

According to the method described by Jadhav et al. [86] with some minor modification, optical properties of synthesized nanoparticles were analyzed using a spectrophotometer (Lambda 35; Perkin Elmer, USA). Initially, the formation of CuONPs was confirmed by visual observation when the color changed from greenish-blue to brown. Figure 2a shows the UV-Vis spectrum of the synthesized CuO nanoparticles showing a peak at 300 nm.

3.2 Fourier Transformed Infrared Spectroscopy Analysis

FT-IR analysis was carried out on bio-synthesized CuONPs using a spectrophotometer (IRAffinity-1, Shimardzu, Tokyo, Japan) in the spectral region of 4000–500 cm−1 using a resolution of 4 cm−1 and 64 coadded scans. The colloidal NPs solution was freeze-dried in the form of powder and palletized with KBr for FT-IR studies [87]. The representative FT-IR spectrum is shown in Fig. 2b. The presence of bands at 616 cm−1 and 996 cm−1 indicates different modes of bending vibration of the Cu–O bond [88]. Other notable peaks which are observed at 1146 cm−1 (C–O stretch), 1624 cm−1 (C=O stretch and N–H bending), 1714 cm−1 (CH3CO group), and 3244 cm−1 (O–H stretch) are probably due to the organic matter present on the surface of the copper nanoparticles [89].

3.3 Dynamic Light Scattering Studies (DLS)

Dynamic light scattering (DLS) study was carried on the bio-synthesized copper oxide nanoparticles using Zetasizer Nano (Nano ZS; Malvern Instruments, UK). From particle size analysis study, it was confirmed that the average particle size of the bio-synthesized CuONPs is below 100 nm (Fig. 2c). The zeta potential measurement was also carried out, and the net zeta potential value on the CuONPs is − 15.8 mV depicting a negative surface charge on the nanoparticles (Fig. 2d).

3.4 Transmission Electron Microscopy Studies

Synthesized CuONPs using plant extract were analyzed using transmission electron microscopy (TEM). Representative TEM image is shown in Fig. 3a. It is clear from the images that majority of the particles are of sizes below 100 nm. The corresponding EDX studies also carried out and are shown in Fig. 3b. The EDX spectrum clearly shows the nanoparticles are copper oxide. It needs to be mentioned here that EDX studies could not be done along with TEM as the sample was prepared in Cu grids. Hence, EDX measurement was done in SEM set-up with prior Au coating before EDX measurement. Hence, EDX spectrum shows the presence of Au along with Cu and O.

3.5 X-ray Photoelectron Spectroscopy Studies

XPS measurement was carried out on bio-synthesized CuONPs. The survey scan (Fig. 4a) and the high-resolution Cu 2p spectra were obtained. The spectra are referenced to the C 1 s peak at 284.17. Cu2p core level spectrum (Fig. 4b) reveals that the Cu(2p3/2) and Cu(2p1/2) peaks centered at 934.15 and 953.26 eV (with splitting of 19.2 eV), respectively, were attributed to the presence of the Cu2+ chemical state as an indication for the formation of CuO nanoparticles.

a XPS spectrum and b Cu2p core level spectrum of bio-synthesized CuONPs. Moreover, the satellite peaks of the Cu(2p3/2) and Cu(2p1/2) at 942.2 and 962.4 eV, respectively which is 9 eV higher than the main spin orbit component further confirms the presence of Cu2+ chemical state [90, 91]. For lager figure, please see electronic supporting information

3.6 Catalytic Activity: Application of the CuONP in the Synthesis of 1,2,3-triazoles

We then explored the catalytic activity of our CuONP catalyst for carrying out the multi-component reaction of benzyl chloride, sodium azide, and phenyl acetylene for synthesis of 1,2,3-triazoles. The reaction of sodium azide and organic halide produces the required organic azide in situ and thus the isolation and purification step could be avoided. We have screened different solvents for the reaction, and water is found to give best yield. The reaction gave no product in the absence of catalyst (entry 8, Table 1). After screening several conditions, we observed that the reaction gave best yield of product at 70 °C using 15 mg of catalyst for 6 h (entry 3, Table 1). Reducing the amount of catalyst (entries 1 and 2, Table 1) lowers the yield whereas increasing the catalyst loading to 20 mg (entry 4, Table 1) did not improve the yield further. Interestingly, the use of 15 mg of the catalyst contains very low amount of copper (0.535 mol%, 0.00535045 mmol) which is enough to complete the reaction in 6 h. Increasing the reaction time beyond 6 h also did not improve the yield. Use of solvents other than water lowers the yield (entries 9–12, Table 1). When 1:1 mixture of water:ethanol was used as solvent, the reaction gave lower yield (entry 13, Table 1). Use of simple copper salt gave very low yield of the product (entries 14–15, Table 1). The turnover number (TON) for the optimized reaction is 177.6 based on the moles of phenyl acetylene consumed per mole of catalyst. The corresponding turnover frequency (TOF) is 29.6 h−1.

After having the optimized conditions in hand, we looked for the substrate scope of the reaction. Use of different acyl (3b, Scheme 1), alkyl (3c, Scheme 1), allyl (3d, Scheme 1), aryl (3e, Scheme 1), and aralkyl (3f, Scheme 1) halides gave good yield of products when reacted with phenyl acetylene. Use of 1-hexyne as terminal alkyne also gave good yield of products (3g, 3h, Scheme 1). Thus, the catalyst has good substrate scope.

Substrate scope of the reaction. All the reactions were performed by using corresponding halides (1.1 mmol), sodium azide (1.2 mmol), alkyne (1.0 mmol), H2O (2 mL), catalyst (15 mg) at 70 °C for 6 h. aThe corresponding azides were prepared according to the procedure by McNulty et al. [92] and then reacted with alkynes to get the required triazole products

A plausible mechanism is proposed based on the literature reports (Scheme 2). The terminal alkyne reacts with the nanoparticle catalyst forming the copper acetylide. This then undergoes cycloaddition reaction with the inorganic azide counterpart which is formed in situ from the reaction of the corresponding organic halide and sodium azide to furnish the 1,2,3-triazole products.

The efficiency of the catalyst developed by us is compared with some previously reported catalyst systems (Table 2) for synthesis of 1,2,3-triazoles. 1The advantages of the catalyst are the use of waste plant product and green protocol for synthesis of catalyst, cost-effective, low catalyst loading, good yield of products, etc.

3.7 Recycle Studies

To find out the reusability and stability of the catalyst, the recycling experiments for preparation of 1,2,3-triazole reaction of benzyl chloride, sodium azide, and phenyl acetylene were conducted for three consecutive cycles under the identical reaction condition. The catalyst was easily separated by centrifuge after the reaction and washed with ethyl acetate. The catalyst was dried in oven and reused for next reaction. The reactants were taken with respect to the amount of the catalyst recovered after each reaction cycle. The corresponding yields over the each three subsequent cycles were 92, 89, and 87% for first, second, and third, respectively. The decrease in yield of product could be explained by leaching of metal. The stability of the reused catalyst was determined by EDX and FT-IR analysis. It is clear from the FT-IR analysis of the reused catalyst that characteristics peak at ~ 600 cm−1 and ~ 996 cm−1 indicating different modes of bending vibration of the Cu–O bond is intact in the reused catalyst. Other notable peaks are also present. Similarly, the EDX data of fresh and reused catalyst clearly shows even after several cycles the chemical composition (Cu and O) of the catalyst remains almost same (see the electronic supporting information for detailed EDX and FT-IR data of the catalyst after each recycle). Thus, even after several cycles of the use of catalyst, the catalyst is stable. This demonstrates the versatility of the catalyst which could be reused for several times.

4 Conclusion

In summary, we have developed a greener method for the synthesis CuONPs from plant extract of Colocasia esculenta leaves which are considered as waste product after cultivation. 1,2,3-Triazole compounds are known to have several biological activity and present in many important organic compounds. Due to the various advantages such as low catalyst loading, reusability, cost-effectiveness, and easily separable from reaction mixture, the use of heterogenous copper catalyst for the click reaction is highly desirable. The nanoparticles we have synthesized showed good activity when used in the click reaction of organic azide and alkyne giving the 1,2,3-triazoles products in excellent yields. We have performed the reaction in water which is environmentally benign and abundant. The reaction is carried out in one-pot multi-component approach which is advantageous. The substrate scope is good, and the catalyst could be used in the synthesis of different triazoles giving high yield of products. In addition, the catalyst can be reused, and recycle studies revealed yields over each of the three cycles which were 92, 89, and 87% for first, second, and third, respectively. The process is simple, cost-effective, high yielding and environmentally benign demonstrating that it could be used by the industries and academic laboratories. We believe that our method would significantly augment the repertoire of the methods available for the synthesis of important 1,2,3-trazoles by copper-catalyzed nanoparticles. The use of the waste and non-toxic plant material is also advantageous for the synthesis of nanoparticle.

5 Experimental Section

5.1 General Procedure for the Synthesis of Triazoles

To a mixture of organic halide (1.1 mmol), NaN3 (1.2 mmol) and the alkyne (1.0 mmol) in 2 mL water was added to the catalyst (15 mg). The reaction was then heated at 70 °C for 6 h. The reaction was then cooled to room temperature and the water layer was extracted with ethyl acetate (2 × 5 mL). The combined organic layer was washed with brine and dried over anhydrous Na2SO4. The organic layer was filtered, and solvent was removed under reduced pressure in a rotary evaporator. The crude product was then purified by column chromatography using silica gel (100–200 mesh), and ethyl acetate–hexane as eluent.

5.2 The Representative Example of the Synthesis of 3a

To a mixture of benzyl chloride (1.1 mmol, 139 mg), NaN3 (1.2 mmol, 78 mg) and phenyl acetylene (1.0 mmol, 102 mg) in 2 mL water was added 15 mg of catalyst. The reaction mixture was then heated at 70 °C for 6 h. After the completion of the reaction (monitored by TLC), the reaction mixture was brought to room temperature and extracted with ethyl acetate (2 × 5 ml). The combined organic layer was washed with brine and treated with anhydrous Na2SO4 and concentrated in a rotary evaporator under reduced pressure. The crude product was purified by column chromatography using silica gel (100–200 mesh), and ethyl acetate–hexane as eluent. White solid, (223 mg, yield-95%); mp: 128–130 °C; IR (cm−1): 3135, 3036, 2923, 2852, 1607, 1466, 1354, 1220, 1194, 1158, 1074, 1048, 809, 766, 727, 581, 507; 1H NMR (600 MHz, CDCl3): δ 7.80 (d, J = 7.2 Hz, 2H), 7.67 (s, 1H), 7.40–7.26 (m, 8H), 5.58 (s,2H); 13C NMR (150 MHz,CDCl3): 148.4, 134.9, 130.8, 129.4, 129.0, 128.4, 128.3, 125.9, 119.7, 54.4; HRMS (ESI) exact mass was calculated for C15H13N3 [M + H]+: 236.1188; Found: 236.1191.

References

Rasouli, R., Barhoum, A., & Uludag, H. (2018). A review of nanostructured surfaces and materials for dental implants: surface coating, patterning and functionalization for improved performance. Biomaterials Science, 6, 1312–1338. https://doi.org/10.1039/c8bm00021b.

Kaur, A., & Gupta, U. (2009). A review on applications of nanoparticles for the preconcentration of environmental pollutants. Journal of Materials Chemistry, 19, 8279–8289. https://doi.org/10.1039/b901933b.

Gupta, R., & Xie, H. (2018). Nanoparticles in daily life: applications, toxicity and regulations. Journal of Environmental Pathology, Toxicology and Oncology, 37, 209–230. https://doi.org/10.1615/jenvironpatholtoxicoloncol.2018026009.

Khan, I., Saeed, K., & Khan, I. (2019). Nanoparticles: Properties, applications and toxicities. Arabian Journal of Chemistry, 12, 908–931. https://doi.org/10.1016/j.arabjc.2017.05.011.

Ramos, A. P., Cruz, M. A. E., Tovani, C. B., & Ciancaglini, P. (2017). Biomedical applications of nanotechnology. Biophysical Reviews, 9, 79–89. https://doi.org/10.1007/s12551-016-0246-2.

Samadishadlou, M., Farshbaf, M., Annabi, N., Kavetskyy, T., Khalilov, R., Saghfi, S., Akbarzadeh, A., & Mousavi, S. (2018). Magnetic carbon nanotubes: preparation, physical properties, and applications in biomedicine. Artificial Cells, Nanomedicine, and Biotechnology, 46, 1314–1330. https://doi.org/10.1080/21691401.2017.1389746.

Paramasivam, G., Kayambu, N., Rabel, A. M., Sundramoorthy, A. K., & Sundaramurthy, A. (2017). Anisotropic noble metal nanoparticles: synthesis, surface functionalization and applications in biosensing, bioimaging, drug delivery and theranostics. Acta Biomaterialia, 49, 45–65. https://doi.org/10.1016/j.actbio.2016.11.066.

Balantrapu, K., & Goia, D. V. (2009). Silver nanoparticles for printable electronics and biological applications. Journal of Materials Research, 24, 2828–2836. https://doi.org/10.1557/jmr.2009.0336.

Hola, K., Markova, Z., Zoppellaro, G., Tucek, J., & Zboril, R. (2015). Tailored functionalization of iron oxide nanoparticles for MRI, drug delivery, magnetic separation and immobilization of biosubstances. Biotechnology Advances, 33, 1162–1176. https://doi.org/10.1016/j.biotechadv.2015.02.003.

Shi, D., Sadat, M. E., Dunn, A. W., & Mast, D. B. (2015). Photo-fluorescent and magnetic properties of iron oxide nanoparticles for biomedical applications. Nanoscale, 7, 8209–8232. https://doi.org/10.1039/c5nr01538c.

Ling, D., Lee, N., & Hyeon, T. (2015). Chemical synthesis and assembly of uniformly sized iron oxide nanoparticles for medical applications. Accounts of Chemical Research, 48, 1276–1285. https://doi.org/10.1021/acs.accounts.5b00038.

Lin, A. Y., Young, J. K., Nixon, A. V., & Drezek, R. A. (2014). Encapsulated Fe3O4/Ag complexed cores in hollow gold nanoshells for enhanced theranostic magnetic resonance imaging and photothermal therapy. Small, 10, 3246–3251. https://doi.org/10.1002/smll.201303593.

Wang, X., Liu, H., Chen, D., Meng, X., Liu, T., Fu, C., Hao, N., Zhang, Y., Wu, X., Ren, J., & Tang, F. (2013). Multifunctional Fe3O4@P(St/MAA)@Chitosan@Au core/shell nanoparticles for dual imaging and photothermal therapy. ACS Applied Materials & Interfaces, 5, 4966–4971. https://doi.org/10.1021/am400721s.

Gupta, A. K., Naregalkar, R. R., Vaidya, V. D., & Gupta, M. (2007). Recent advances on surface engineering of magnetic iron oxide nanoparticles and their biomedical applications. Nanomedicine, 2, 23–39. https://doi.org/10.2217/17435889.2.1.23.

Ullah, M. W., Shi, Z., Shi, X., Zeng, D., Li, S., & Yang, G. (2017). Microbes as structural templates in biofabrication: study of surface chemistry and applications. ACS Sustainable Chemistry & Engineering, 5, 11163–11175. https://doi.org/10.1021/acssuschemeng.7b0276.

Makarov, V. V., Love, A. J., Sinitsyna, O. V., Makarova, S. S., Yaminsky, I. V., Taliansky, M. E., & Kalinina, N. O. (2014). "Green" nanotechnologies: synthesis of metal nanoparticles using plants. Acta Naturae, 6, 35–44. https://doi.org/10.32607/20758251-2014-6-1-35-44.

Shah, M., Fawcett, D., Sharma, S., Tripathy, S., & Poinern, G. (2015). Green synthesis of metallic nanoparticles via biological entities. Materials, 8, 7278–7308. https://doi.org/10.3390/ma8115377.

Husseiny, M. I., El-Aziz, M. A., Badr, Y., & Mahmoud, M. A. (2007). Biosynthesis of gold nanoparticles using Pseudomonas aeruginosa. Spectrochimica Acta Part A, 67, 1003–1006. https://doi.org/10.1016/j.saa.2006.09.028.

Guilger-Casagrande, M., & de Lima, R. (2019). Synthesis of silver nanoparticles mediated by fungi: a review. Frontiers in Bioengineering and Biotechnology, 7, 287. https://doi.org/10.3389/fbioe.2019.00287.

Ovais, M., Khalil, A. T., Ayaz, M., Ahmad, I., Nethi, S. K., & Mukherjee, S. (2018). Biosynthesis of metal nanoparticles via microbial enzymes: a mechanistic approach. International Journal of Molecular Sciences, 19, 4100. https://doi.org/10.3390/ijms19124100.

Das, S. K., Dickinson, C., Lafir, F., Brougham, D. F., & Marsili, E. (2012). Synthesis, characterization and catalytic activity of gold nanoparticles biosynthesized with Rhizopus oryzae protein extract. Green Chemistry, 14, 1334–1322. https://doi.org/10.1039/c2gc16676c.

Deljou, A., & Goudarzi, S. (2016). Green extracellular synthesis of the silver nanoparticles using thermophilic Bacillus Sp. AZ1 and its antimicrobial activity against several human pathogenetic bacteria. Iranian Journal of Biotechnology, 14, 25–32. https://doi.org/10.15171/ijb.1259.

Choi, Y., & Lee, S. Y. (2020). Biosynthesis of inorganic nanomaterials using microbial cells and bacteriophages. Nature Reviews Chemistry, 4, 638–656. https://doi.org/10.1038/s41570-020-00221-w.

Gahlawat, G., & Choudhury, A. R. (2019). A review on the biosynthesis of metal and metal salt nanoparticles by microbes. RSC Advances, 9, 12944–12967. https://doi.org/10.1039/C8RA10483B.

Akhtar, M. S., Panwar, J., & Yun, Y.-S. (2013). Biogenic synthesis of metallic nanoparticles by plant extracts. ACS Sustainable Chemistry & Engineering, 1, 591–602. https://doi.org/10.1021/sc300118u.

Ahmed, S., Ahmad, M., Swami, B. L., & Ikram, S. (2016). A review on plants extract mediated synthesis of silver nanoparticles for antimicrobial applications: a green expertise. Journal of Advanced Research, 7, 17–28. https://doi.org/10.1016/j.jare.2015.02.007.

Iravani, S. (2011). Green synthesis of metal nanoparticles using plants. Green Chemistry, 13, 2638–2650. https://doi.org/10.1039/c1gc15386b.

Gour, A., & Jain, N. K. (2019). Advances in green synthesis of nanoparticles. Artificial Cells, Nanomedicine, and Biotechnology, 47, 844–851. https://doi.org/10.1080/21691401.2019.1577878.

Parandhamana, T., Dey, M. D., & Das, S. K. (2019). Biofabrication of supported metal nanoparticles: exploring the bioinspiration strategy to mitigate the environmental challenges. Green Chemistry, 21, 5469–5500. https://doi.org/10.1039/c9gc02291k.

Drishya, S., Namitha, T. R., Johnson, S. P., Vimala, J., & Paulson, M. (2020). Synthesis of silver and copper oxide nanoparticles using Myristica fragrans fruit extract: antimicrobial and catalytic applications. Sustainable Chemistry and Pharmacy, 16, 100255. https://doi.org/10.1016/j.scp.2020.100255.

Rabiee, N., Bagherzadeh, M., Kiani, M., Ghadiri, A. M., Etessamifar, F., Jaberizadeh, A. H., & Shakeri, A. (2020). Biosynthesis of copper oxide nanoparticles with potential biomedical applications. International Journal of Nanomedicine, 15, 3983–3999. https://doi.org/10.2147/IJN.S255398.

Ohemeng, P. O., Dankyi, E., Darko, S., Yaya, A., Salifu, A. A., Ahenkorah, C., & Apalangya, V. A. (2020). Iron and silver nanostructures: biosynthesis, characterization and their catalytic properties. Nano-Structures & Nano-Objects, 22, 100453. https://doi.org/10.1016/j.nanoso.2020.100453.

Xie, H., Lee, J. Y., Wang, D. I. C., & Ting, Y. P. (2007). Silver nanoplates: from biological to biomimetic synthesis. ACS Nano, 1, 429–439. https://doi.org/10.1021/nn7000883.

Jia, L., Zhang, Q., Li, Q., & Song, H. (2009). The biosynthesis of palladium nanoparticles by antioxidants in Gardenia jasminoides Ellis: long lifetime nanocatalysts forp-nitrotoluene hydrogenation. Nanotechnology, 20, 385601–385610. https://doi.org/10.1088/0957-4484/20/38/385601.

Song, J. Y., Kwon, E. Y., & Kim, B. S. (2010). Biological synthesis of platinum nanoparticles using Diopyros kaki leaf extract. Bioprocess and Biosystems Engineering, 33, 159–164. https://doi.org/10.1007/s00449-009-0373-2.

Mishra, K., Basavegowda, N., & Lee, Y. R. (2015). Biosynthesis of Fe, Pd, and Fe-Pd bimetallic nanoparticles and their application as recyclable catalysts for [3 + 2] cycloaddition reaction: a comparative approach. Catalysis Science & Technology, 5, 2612–2621. https://doi.org/10.1039/c5cy00099h.

Simsikova, M., Bartos, M., Cechal, J., & Sikola, T. (2016). Decolorization of organic dyes by gold nanoflowers prepared on reduced graphene oxide by tea polyphenols. Catalysis Science & Technology, 6, 3008–3017. https://doi.org/10.1039/c5cy01836f.

Vishveshvar, K., Krishnan, M. V. A., Haribabu, K., & Vishnuprasad, S. (2018). Green synthesis of copper oxide nanoparticles using Ixiro coccinea plant leaves and its characterization. BioNanoScience, 8, 554–558. https://doi.org/10.1007/s12668-018-0508-5.

Saravanakumar, K., Shanmugam, S., Varukattu, N. B., Ali, D. M., Kathiresane, K., & Wang, M.-H. (2019). Biosynthesis and characterization of copper oxide nanoparticles from indigenous fungi and its effect of photothermolysis on human lung carcinoma. Journal of Photochemistry and Photobiology. B, 190, 103–109. https://doi.org/10.1016/j.jphotobiol.2018.11.017.

Goswami, M., & Das, A. M. (2018). Synthesis of cellulose impregnated copper nanoparticles as an efficient heterogeneous catalyst for C-N coupling reactions under mild conditions. Carbohydrate Polymers, 195, 189–198. https://doi.org/10.1016/j.carbpol.2018.04.033.

Choudhary, A., Sharma, N., Sharma, C., Jamwal, B., & Paul, S. (2019). Synergistic effect of Cr3+ on layered double hydroxide supported Cu0 nanoparticles for the oxidation of alcohols and hydrocarbons. ChemistrySelect, 4, 5276–5283. https://doi.org/10.1002/slct.201803829.

Shen, M., Liu, H., Yu, C., Yin, Z., Muzzio, M., Li, J., Xi, Z., Yu, Y., & Sun, S. (2018). Room-temperature chemoselective reduction of 3-nitrostyrene to 3-vinylaniline by ammonia borane over cu nanoparticles. Journal of the American Chemical Society, 140, 16460–16463. https://doi.org/10.1021/jacs.8b11303.

Pei, Y., Zhao, J., Shi, R., Wang, X., Li, Z., & Ren, J. (2019). Hierarchical porous carbon-supported copper nanoparticles as an efficient catalyst for the dimethyl carbonate synthesis. Catalysis Letters, 149, 3184–3193. https://doi.org/10.1007/s10562-019-02884-7.

Diacon, A., Rusen, E., Mocanu, A., & Nistor, L. C. (2017). Supported Cu0 nanoparticles catalyst for controlled radical polymerization reaction and block-copolymer synthesis. Scientific Reports, 7, 10345–10355. https://doi.org/10.1038/s41598-017-10760-w.

Ojha, N. K., Zyryanov, G. V., Majee, A., Charushin, V. N., Chupakhin, O. N., & Santra, S. (2017). Copper nanoparticles as inexpensive and efficient catalyst: a valuable contribution in organic synthesis. Coordination Chemistry Reviews, 353, 1–57. https://doi.org/10.1016/j.ccr.2017.10.004.

Gawande, M. B., Goswami, A., Felpin, F.-X., Asefa, T., Huang, X., Silva, R., Zou, X., Zboril, R., & Varma, R. S. (2016). Cu and Cu-Based nanoparticles: synthesis and applications in catalysis. Chemical Reviews, 116, 3722–3811. https://doi.org/10.1021/acs.chemrev.5b00482.

Yi, G., Son, J., Yoo, J., Park, C., & Koo, H. (2018). Application of click chemistry in nanoparticle modification and its targeted delivery. Biomaterials Research, 22, 13. https://doi.org/10.1186/s40824-018-0123-0.

Agalave, S. G., Maujan, S. R., & Pore, V. S. (2011). Click chemistry: 1,2,3-triazoles as pharmacophores. Chemistry, an Asian Journal, 6, 2696–2718. https://doi.org/10.1002/asia.201100432.

Nwe, K., & Brechbiel, M. W. (2009). Growing applications of “click chemistry” for bioconjugation in contemporary biomedical research. Cancer Biotherapy & Radiopharmaceuticals, 24, 289–302. https://doi.org/10.1089/cbr.2008.0626.

Hou, J., Liu, X., Shen, J., Zhao, G., & Wang, P. G. (2012). The impact of click chemistry in medicinal chemistry. Expert Opinion on Drug Discovery, 7, 489–501. https://doi.org/10.1517/17460441.2012.682725.

Kalesh, K. A., Shi, H., Ge, J., & Yao, S. Q. (2010). The use of click chemistry in the emerging field of catalomics. Organic & Biomolecular Chemistry, 8, 1749–1762. https://doi.org/10.1039/b923331h.

Tron, G. C., Pirali, T., Billington, R. A., Canonico, P. L., Sorba, G., & Genazzani, A. A. (2008). Click chemistry reactions in medicinal chemistry: applications of the 1,3-dipolar cycloaddition between azides and alkynes. Medicinal Research Reviews, 28, 278–308. https://doi.org/10.1002/med.20107.

Mamidyala, S. K., & Finn, M. G. (2010). In situ click chemistry: probing the binding landscapes of biological molecules. Chemical Society Reviews, 39, 1252–1261. https://doi.org/10.1039/b901969n.

Wang, X., Huang, B., Liu, X., & Zhan, P. (2016). Discovery of bioactive molecules from CuAAC click-chemistry-based combinatorial libraries. Drug Discovery Today, 21, 118–132. https://doi.org/10.1016/j.drudis.2015.08.004.

Meghani, N. M., Amin, H. H., & Lee, B. J. (2017). Mechanistic applications of click chemistry for pharmaceutical drug discovery and drug delivery. Drug Discovery Today, 22, 1604–1619. https://doi.org/10.1016/j.drudis.2017.07.007.

Chuprakov, S., Kwok, S. W., & Fokin, V. V. (2013). Transannulation of 1-sulfonyl-1,2,3-triazoles with heterocumulenes. Journal of the American Chemical Society, 135, 4652–4655. https://doi.org/10.1021/ja400350c.

Zibinsky, M., & Fokin, V. V. (2013). Sulfonyl-1,2,3-triazoles: convenient synthones for heterocyclic compounds. Angewandte Chemie, International Edition, 52, 1507–1510. https://doi.org/10.1002/anie.201206388.

Thirumurugan, P., Matosiuk, D., & Jozwiak, K. (2013). Click chemistry for drug development and diverse chemical-biology applications. Chemical Reviews, 113, 4905–4979. https://doi.org/10.1021/cr200409f.

Haas, K. L., & Franz, K. J. (2009). Application of metal coordination chemistry to explore and manipulate cell biology. Chemical Reviews, 109, 4921–4960. https://doi.org/10.1021/cr900134a.

Jewett, J. C., & Bertozzi, C. R. (2010). Cu-free click cycloaddition reactions in chemical biology. Chemical Society Reviews, 39, 1272–1279. https://doi.org/10.1039/b901970g.

Huo, J., Hu, H., Zhang, M., Hu, X., Chen, M., Chen, D., Liu, J., Xiao, G., Wang, Y., & Wen, Z. (2017). A mini review of the synthesis of poly-1,2,3-triazole-based functional materials. RSC Advances, 7, 2281–2287. https://doi.org/10.1039/c6ra27012c.

Qin, A., Lam, J. W. Y., & Tang, B. Z. (2010). Click polymerization. Chemical Society Reviews, 39, 2522–2544. https://doi.org/10.1039/b909064a.

Kantheti, S., Narayana, R., & Raju, K. V. S. N. (2015). The impact of 1,2,3-triazoles in the design of functional coatings. RSC Advances, 5, 3687–3708. https://doi.org/10.1039/c4ra12739k.

Debets, M. F., van Berkel, S. S., Dommerholt, J., Dirks, A. J., Rutjes, F. P. J. T., & van Delft, F. L. (2011). Bioconjugation with strained alkenes and alkynes. Accounts of Chemical Research, 44, 805–815. https://doi.org/10.1021/ar200059z.

Binder, W. H., & Kluger, C. (2006). Azide/alkyne-“click” reactions: applications in material science and organic synthesis. Current Organic Chemistry, 10, 1791–1815. https://doi.org/10.2174/138527206778249838.

Hu, M. H., Chen, X., Chen, S. B., Ou, T. M., Yao, M., Gu, L. Q., Huang, Z. S., & Tan, J. H. (2015). A new application of click chemistry in situ: development of fluorescent probe for specific G-quadruplex topology. Scientific Reports, 5, 17202. https://doi.org/10.1038/srep17202.

Golas, P. L., & Matyjaszewski, K. (2010). Marrying click chemistry with polymerization: expanding the scope of polymeric materials. Chemical Society Reviews, 39, 1338–1354. https://doi.org/10.1039/b901978m.

Huisgen, R. (1984). In A. Padwa (Ed.), 1,3-Dipolar cycloaddition chemistry (pp. 1–176). New York: Wiley.

Wang, W., Wei, F., Ma, Y., Tung, C., & Xu, Z. (2016). Copper(I)-catalyzed three-component click/alkynylation: one-pot synthesis of 5-Alkynyl-1,2,3-triazoles. Organic Letters, 18, 4158–4416. https://doi.org/10.1021/acs.orglett.6b02199.

Chouaib, K., Romdhane, A., Delemasure, S., Dutartre, P., Elie, N., Touboul, D., & Jannet, H. B. (2016). Regiospecific synthesis by copper- and ruthenium-catalyzed azide-alkyne 1,3-dipolar cycloaddition, anticancer and anti-inflammatory activities of oleanolic acid triazole derivatives. Arabian Journal of Chemistry, 12, 3732–3742.

Chetia, M., Gehlot, P. S., Kumar, A., & Sarma, D. (2018). A recyclable/reusable hydrotalcite supported copper nano catalyst for 1,4-disubstituted-1,2,3-triazole synthesis via click chemistry approach. Tetrahedron Letters, 59, 397–401. https://doi.org/10.1016/j.tetlet.2017.12.051.

Chetia, M., Ali, A. A., Bhuyan, D., Saikia, L., & Sarma, D. (2015). Magnetically recoverable chitosan-stabilised copper-iron oxide nanocomposite material as an efficient heterogeneous catalyst for azide-alkyne cycloaddition reactions. New Journal of Chemistry, 39, 5902–5907. https://doi.org/10.1039/c5nj00754b.

Nasrollahzadeh, M., & Sajadi, S. M. (2015). Green synthesis of copper nanoparticles using Ginkgo biloba L. leaf extract and their catalytic activity for the Huisgen [3 + 2] cycloaddition of azides and alkynes at room temperature. Journal of Colloid and Interface Science, 457, 141–147. https://doi.org/10.1016/j.jcis.2015.07.004.

Nasrollahzadeh, M., Ghorbannezhad, F., Issaabadi, Z., & Sajadi, S. M. (2019). Recent developments in the biosynthesis of cu-based recyclable nanocatalysts using plant extracts and their application in the chemical reactions. Chemical Record, 19, 601–643. https://doi.org/10.1002/tcr.201800069.

Kalita, P., Pegu, C. D., Dutta, P., & Baruah, P. K. (2014). Room temperature solvent free aza-Michael reactions over nano-cage mesoporous materials. Journal of Molecular Catalysis A: Chemical, 394, 145–150. https://doi.org/10.1016/j.molcata.2014.06.031.

Baruah, P. K., Dutta, P., & Kalita, P. (2015). Cage like al-kit-5 mesoporous materials for C-C bond formation reactions under solvent free conditions. Catalysis Letters, 145, 2037–2045. https://doi.org/10.1007/s10562-015-1611-7.

Dutta, P., Kalita, P., & Baruah, P. K. (2016). Room temperature ring opening of epoxides over triflic acid functionalized cage like mesoporous materials. ChemistrySelect, 1, 1650–1657. https://doi.org/10.1002/slct.201600500.

Kalita, P., Dutta, P., & Baruah, P. K. (2018). Conversion of fructose and xylose into platform chemicals using organo-functionalized mesoporous material. ChemistrySelect, 3, 10971–10976. https://doi.org/10.1002/slct.201801315.

Singh, M. S., & Chowdhury, S. (2012). Recent developments in solvent-free multicomponent reactions: a perfect synergy for eco-compatible organic synthesis. RSC Advances, 2, 4547–4592. https://doi.org/10.1039/c2ra01056a.

Paprocki, D., Madej, A., Koszelewski, D., Brodzka, A., & Ostaszewski, R. (2018). Multicomponent reactions accelerated by aqueous micelles. Frontiers in Chemistry, 6, 502. https://doi.org/10.3389/fchem.2018.00502.

Haji, M. (2016). Multicomponent reactions: a simple and efficient route to heterocyclic phosphonates. Beilstein Journal of Organic Chemistry, 12, 1269–1301. https://doi.org/10.3762/bjoc.12.121.

Estevez, V., Villacampa, M., & Menendez, J. C. (2014). Recent advances in the synthesis of pyrroles by multicomponent reactions. Chemical Society Reviews, 43, 4633–4657. https://doi.org/10.1039/c3cs60015g.

Graebin, C. S., Ribeiro, F. V., Rogerio, K. R., & Kummerle, A. E. (2019). Multicomponent reactions for the synthesis of bioactive compounds: a review. Current Organic Synthesis, 16, 855–859. https://doi.org/10.2174/1570179416666190718153703.

Neochoritis, C. G., Zhao, T., & Domling, A. (2019). Tetrazoles via multicomponent reactions. Chemical Reviews, 119, 1970–2042. https://doi.org/10.1021/acs.chemrev.8b00564.

Manjari, G., Saran, S., Arun, T., Rao, A. V. B., & Devipriya, S. P. (2017). Catalytic and recyclability properties of phytogenic copper oxide nanoparticles derived from Aglaia elaeagnoidea flower extract. Journal of Saudi Chemical Society, 21, 610–618. https://doi.org/10.1016/j.jscs.2017.02.004.

Jadhav, M. S., Kulkarni, S., Raikar, P., Barretto, D. A., Vootla, S. K., & Raikar, U. S. (2018). Green biosynthesis of CuO Ag-CuO nanoparticles from Malus domestica leaf extract and evaluation of antibacterial, antioxidant and DNA cleavage activities. New Journal of Chemistry, 42, 204–213. https://doi.org/10.1039/c7nj02977b.

Cerník, M., & Padil, V. V. T. (2013). Green synthesis of copper oxide nanoparticles using gum karaya as a biotemplate and their antibacterial application. International Journal of Nanomedicine, 8, 889–898. https://doi.org/10.2147/ijn.s40599.

Raul, P. K., Senapati, S., Sahoo, A. K., Umlong, I. M., Devi, R. R., Thakur, A. J., & Veer, V. (2014). CuO nanorods: a potential and efficient adsorbent in water purification. RSC Advances, 4, 40580–40587. https://doi.org/10.1039/c4ra04619f.

Sundar, S., Venkatachalam, G., & Kwon, S. J. (2018). Biosynthesis of copper oxide (CuO) nanowires and their use for the electrochemical sensing of dopamine. Nanomaterials, 8, 823–839. https://doi.org/10.3390/nano8100823.

Karle, S., Rogalla, D., Ludwig, A., Becker, H.-W., Dirk, A., Grafen, W. M., Ostendorfd, A., & Devi, A. (2017). Synthesis and evaluation of new copper ketoiminate precursors for a facile and additive-free solution-based approach to nanoscale copper oxide thin films. Dalton Transactions, 46, 2670–2679. https://doi.org/10.1039/c6dt04399b.

Mo, L., & Kawi, S. (2014). An in situ self-assembled core-shell precursor route to prepare ultrasmall copper nanoparticles on silica catalysts. Journal of Materials Chemistry A, 2, 7837–7844. https://doi.org/10.1039/c3ta14592a.

McNulty, J., & Keskar, K. (2012). Discovery of a robust and efficient homogeneous Silver(I) catalyst for the cycloaddition of azides onto terminal alkynes. European Journal of Organic Chemistry, 2012, 5462–5470. https://doi.org/10.1002/ejoc.201200930.

Bagdi, P. R., Basha, R. S., Baruah, P. K., & Khan, A. T. (2014). Copper oxide nanoparticle mediated ‘click chemistry’ for the synthesis of mono-, bis- and tris-triazole derivatives from 10,10-dipropargyl-9-anthrone as a key building block. RSC Advances, 4, 10652–10659. https://doi.org/10.1039/C3RA44869J.

Maleki, A., Panahzadeh, M., & Eivazzadeh-keihan, R. (2019). Agar: a natural and environmentally-friendly support composed of copper oxide nanoparticles for the green synthesis of 1,2,3-triazoles. Green Chemistry Letters and Reviews, 12, 395–406. https://doi.org/10.1080/17518253.2019.1679263.

Iniyavan, P., Balaji, G. L., Sarveswari, S., & Vijayakumar, V. (2015). CuO nanoparticles: synthesis and application as an efficient reusable catalyst for the preparation of xanthene substituted 1,2,3-triazoles via click chemistry. Tetrahedron Letters, 56, 5002–5009. https://doi.org/10.1016/j.tetlet.2015.07.016.

Alonso, F., Moglie, Y., & Radivoy, G. (2015). Copper nanoparticles in click chemistry. Accounts of Chemical Research, 48, 2516–2528. https://doi.org/10.1021/acs.accounts.5b00293.

Acknowledgments

The authors acknowledge the Dept. of Chemistry, Gauhati University, India, and Sophisticated Analytical Instrument Facility (SAIF), NEHU, Shillong, India, for TEM and EDX analysis of the samples.

Funding

This study is financially supported by DST, Govt. of India (Grant No. SB/FT/CS-100/2012).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Research Involving Humans and Animals Statement

Not applicable

Consent for Publication

All authors have approval for final version of the article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

ESM 1

The characterization data including 1H & 13C NMR and IR spectra of the synthesized 1,2,3-triazoles are provided. XPS spectra of the catalyst is provided. The IR and EDX data of the fresh catalyst and after each reaction cycle is also provided. (PDF 2307 kb)

Rights and permissions

About this article

Cite this article

Barman, K., Dutta, P., Chowdhury, D. et al. Green Biosynthesis of Copper Oxide Nanoparticles Using Waste Colocasia esculenta Leaves Extract and Their Application as Recyclable Catalyst Towards the Synthesis of 1,2,3-triazoles. BioNanoSci. 11, 189–199 (2021). https://doi.org/10.1007/s12668-021-00826-5

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12668-021-00826-5