Abstract

CO2 is now considered as a novel heat transmission fluid to extract geothermal energy. It can achieve the goal of energy exploitation and CO2 geological sequestration. Taking Zhacanggou as research area, a “Three-spot” well pattern (one injection with two production), “wellbore–reservoir” coupled model is built, and a constant injection rate is set up. A fully coupled wellbore–reservoir simulator—T2Well—is introduced to study the flow mechanism of CO2 working as heat transmission fluid, the variance pattern of each physical field, the influence of CO2 injection rate on heat extraction and the potential and sustainability of heat resource in Guide region. The density profile variance resulting from temperature differences of two wells can help the system achieve “self-circulation” by siphon phenomenon, which is more significant in higher injection rate cases. The density of CO2 is under the effect of both pressure and temperature; moreover, it has a counter effect on temperature and pressure. The feedback makes the flow process in wellbore more complex. In low injection rate scenarios, the temperature has a dominating impact on the fluid density, while in high rate scenario, pressure plays a more important role. In most scenarios, it basically keeps stable during 30-year operation. The decline of production temperature is <5 °C. However, for some high injection rate cases (75 and 100 kg/s), due to the heat depletion in reservoir, there is a dramatic decline for production temperature and heat extraction rate. Therefore, a 50-kg/s CO2 injection rate is more suitable for “Three-spot” well pattern in Guide region.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Research background

There are many EGS practical projects worldwide, such as the Soultz (Gérard et al. 2006) in France, Ogachi in Japan (Kaieda 2012) and Cornubian in UK (Beamish and Busby 2016).

And many corresponding researches have been performed, and Tom Schintgen combined different types of information necessary for a first qualitative assessment of deep geothermal reservoirs in Luxembourg (Schintgen 2015). And in Germany, the maximum potential for geothermal power and the hydromechanical interaction has been analyzed by Jain et al. (2015) and Schill et al. (2016). Some other details could be seen from Breede et al. (2013).

Brown (2000) set forward the concept of CO2-EGS, replacing water with CO2 as the working flow for enhanced geothermal system (EGS). It makes use of strong mobility of CO2 that helps to extract more heat and fulfills the need of CO2 geological storage. Combining geothermal heat extraction and CO2 storage, the original carbon capture and storage (CCS) is turned into carbon capture, utilization and storage (CCUS), which enhances the feasibility and cost-effectiveness of CO2 storage underground and solves the key economic difficulty regarding engineering application. According to Randolph and Saar, when it comes to selecting the geothermal reservoir, there should be a shift from fissured formations such as volcanic rocks to porous ones such as sedimentary rocks to avoid fractures-led earthquakes and to improve engineering security. In addition, porous formations are more widespread in nature and feature huge heat storage (Randolph and Saar 2011).

Based on simulation experiments, Pruess (2006) built a 2D “Five Spots” model for quantitative studies about flow and heat transmission of CO2-EGS and compared the pros and cons of CO2 and water as the heat-conducting fluid for EGS. In 2008, Pruess extended the 2D model into a 3D one, with a focus on the moving attributes of CO2 in the reservoir. The initial CO2 saturation at the reservoir is 1. Due to high density of the cold CO2 injected, it flowed from the bottom reservoir to the production well and formed heat breakthroughs at an early stage at the bottom of the well, leading to lower temperature of the production fluid in a short time. As a result, Pruess (2008) suggested that the reservoir top should be used as the production wellhead.

Atrens and others utilized MATLAB to study CO2-EGS and found that its net power generation was on par with traditional EGS, but CO2-EGS design was simpler. They also pointed out that the thermal dynamics and economic model of CO2-EGS remain to be proved (Atrens et al. 2009). Atrens et al. (2010) used radiation capacity (the biggest work done by thermodynamic system to move from a given state to equilibrium with surrounding media) as the reference variable and compared the heat extraction capacity of water and CO2 as heat-conducting fluids. They found that the radiation capacity of CO2-EGS was lower than of traditional EGS mainly due to two reasons: (1) heat capacity of CO2 is lower and heat extracted by unit mass of CO2 is far lower than of water (2) as CO2 is transmitted in the wellbore, the temperature gets lower due to Joule–Thompson effect.

Pan and others used TOUGH software (Pruess et al. 1999) and drift-flux model (Zuber and Findlay 1965) to develop the coupled wellbore–reservoir simulation software (Pan and Oldenburg 2014; Pan et al. 2011) for studying CO2 leakage and geothermal energy extraction.

Guide Basin is rich in HDR but poor in water resources. There are considerable advantages to using CO2 as the working fluid to utilize HDR resources. Hence, the paper focuses on setting up a coupled wellbore–reservoir model with the T2Well simulator, given that granite thermal storage at Zhacanggou of Guide is based on man-made storage. During the functioning period of CO2-EGS system, the coupled heat flow transmission process and changing patterns of heat extraction rates are studied based on different injection rates in order to evaluate the impact of injection rates on heat extraction rate and system sustainability.

Modeling and simulation planning

Geologic conditions for thermal reservoirs

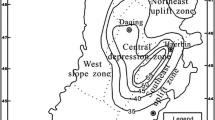

Zhacanggou is a valley before low- and medium-height mountains, situated 15 km southwest of Guide County. The basin foundation consists of ancient layers from the Triassic Age and granites of the Indo-Chinese Epoch, piling up with mudstones, silty clay, sandstone and glutenite formations and Quaternary system loose strata from the Miocene and Pliocene Series of the Paleogene and Neogene Systems in the Cenozoic Erathem. The depth of the stones ranges from 1400 to 1700 m. HDR DR1 well stands at the convergence of northwest ruptures and northeast ruptures, revealing rather complete granite bodies 2800 m below. The temperature at 3050 m below is recorded at 151.34 °C (see Fig. 1). (Report from Environmental and Geological Exploration Bureau of Qinghai Province.)

To meet CO2-EGS needs, reservoirs are used to set up fracking rock bodies to improve the penetration and porous level to build and artificial flowing channel. The paper treats the granite heat storage after reservoir modification as the target man-made reservoir.

Setting up the model

With reference to HDR development projects in the USA and Japan and geologic conditions in Zhacanggou, the researchers have three wells (one for injection and two for extraction) deployed alongside the long axis of HDR structures within 1 square km. The well in the middle is for injection, and two production wells are built 500 m away from the injection well at two sides (see Fig. 2a). The production well 500 m away from the injection well is defined as the water border. In the past research, “Five-spot” is a classic well pattern. However, it is an idealized model, in a reality project, it is too expensive to build a well group, so a more realistic pattern is chosen for this study. The paper assumes that geothermal reservoir is a porous medium of 100 m in depth and the parameters are shown in Table 1. The initial reservoir pressure is still water pressure with the temperature of 151.34 °C. Since the paper focuses on the impact of different CO2 injection on heat extraction, the initial CO2 is saturated. Due to symmetry of the region, the paper only studies one-fourth of the area (with injection and productivity being one-fourth) and makes model-based analysis. At the lateral side of the model are water- and heatproof borders with the bottom and top of waterproof and thermal conductive borders. The heat flow calculation could reference to (Vinsome and Westerveld 1980). For the wellbores, there are one-dimensional stable flows inside and their heat transfer with outside rocks resembles that of bottom and top plates, hence the same calculation methods.

Irregular 2D model (see Fig. 2b) is set up. The sizes of grid blocks range from 0.1 m for those near the wellbore to 50 m for those farther away, which helps to offer an accurate picture of the changes in the flow fields (see Fig. 2b). The wellbore is set as one-dimensional vertical model. The bottom is 3000 m from the ground, and the depth is divided into 30 grid blocks with the lower part connected with the reservoir. Based on geologic information about the research field, parameters of man-made heat storage are set (Table 2). Since the paper focuses on the impact of different injection rates on heat extraction system, five scenarios are set, i.e., 5, 25, 50, 75 and 100 kg/s.

Simulation method

The research adopts the coupled wellbore–reservoir software T2Well as the simulator. T2Well is developed based on the multiphase liquid simulation application Tough2. ECO2N state equation is used to simulate multiphase flows of CO2 and water under high temperature.

T2Well takes wellbores and reservoirs as a whole, and different governing equations are applied for two subdomains. The traditional multiphase Darcy’s law is applied for the reservoir; in the wellbore, 1D conservation of momentum is applied. The primary variable of multiphase mixture velocity is used for calculation, and the drift-flux model (Zuber and Findlay 1965) is used to obtain different phases of rate, and the parameter for drift-flux model is taken from Shi (2005). Based on the conservation of energy, kinetic energy and gravitational energy are ignored due to slow flow rate in the reservoir. In the wellbore, kinetic energy and gravitational potential energy need to be considered. The flow between wellbore and reservoir is described as Darcy’s flow. The governing equation is shown in Table 3 and the meanings of symbols are explained in “Appendix”.

Results and discussions

Wellbore

CO2 has high coupling attributes when it flows in the wellbores and reservoirs. The interactions have tremendous and complex impacts on CO2 heat extraction system as a working medium, and the impact is closely related to the injection rate.

The changing patterns concerning the injection wellhead and temperatures and pressures of the well bottoms are illustrated in Fig. 3. Except for the scenario of 5 kg/s, the pressure is kept at around 11.5 Mpa during the entire production and the injection pressure increases with bigger flows. 5 kg/s corresponds to bigger injection pressure. Under certain conditions, low flow volume requires more injection pressure. This is due to the fact that with lower rate, more heat is absorbed from the external rocks, thereby reducing the density and strengthen the buoyancy. Compared with high flow rate, low rate makes the injection more difficult.

For the injection well bottom, the pressure is positively correlated with flow volume (Fig. 3c); yet for the production well bottom, there is an inverse correlation which is close to the arithmetic sequence and remains basically stable. This is because liquid flow at the reservoir is governed by Darcy’s law and the pressure difference serves as the only driving force. In the reservoir, despite different rates of CO2, the density and dynamic viscosity are on the same level and can be regarded as arithmetic sequences. For temperature at the well bottom, the slower the injection into the well, the more heat that can be absorbed from the outside and the higher bottom temperature (Fig. 4).

It can be viewed that for the production wellhead, the temperature increases with the growing volume. The wellhead temperature in the 5 kg/s low volume scenario is much lower than in other scenarios. This is due to slow rate that leads to much heat radiation to the outside world. The same thing happens to the pressure of wellhead, and the pressure in the 5 kg/s scenario is much lower than in others. For higher rates (75 and 100 kg/s), the temperature and pressure for the wellhead register marked declines in the later stage (Fig. 5). This is due to heat loss at the reservoir. Lower temperature leads to higher density which reduces the pressure at the wellhead. CO2 density is affected by temperature and pressure with complex functional relationship as shown in Fig. 5. It is noteworthy that in any condition, the pressure of production wellhead is higher than that of the injection well, which indicates siphoning in the system. In addition, such a phenomenon has a far-reaching impact on the high flow rate scenario. The key factor of siphoning is the contractibility of CO2. CO2 density has strong reliance on temperature. Compared with injection well, CO2 temperature is higher in the production wells with lower density and stronger buoyancy. Therefore, the gravitational pressure difference in the production wells is much lower than in injection wells. When the pressure difference becomes large enough, the pressure of production wells might be higher than that of injection wells. At that time, no external equipment is needed for the operation of the cycle.

Besides discussions about parametric changes on the head and bottom of the well, analysis about changes of pressure, temperature and density inside the wellbore, in Fig. 7, helps the further understanding about coupled wellbore–reservoir system. In the injection well, CO2 flows from the head to the bottom. This is not an iso-enthalpy process. Fluid absorbs heat from surrounding rocks, and at the same time, gravity does positive work to the fluid, increasing the internal energy of the fluid and thus heating CO2 during its flow (Fig. 7b). The rate of 5 kg/s excluded, as CO2 goes deeper, and its temperature has a similar changing trend and is hardly influenced by time. But when the flow rate is 5 kg/s, the slow flow rate makes CO2 absorb more heat from rocks, leading to a far higher temperature than at other rates. Temperature dramatically changes with CO2 density (Fig. 6c). When CO2 flows at a high rate (all but 5 kg/s), density increases as pressure goes up. Compression effect always plays a dominant role in this process. At the rate of 5 kg/s, when CO2 is at a relatively shallow depth, density increases as pressure goes up, where compression effect plays a dominant role. But as CO2 gets deeper, temperature effect, in turn, plays a decisive role, cutting down the density and inducing expansion. After 30 years, in the system, heat exchange between the wall and surrounding rocks gets weaker, and density increases slightly.

In the production well, due to the high temperature of fluid, there also exists heat exchange between fluid and surrounding rocks. Moreover, internal energy transforms into gravitational potential energy, reducing the energy of fluid. Besides, with the Joule–Thompson effect, temperature of fluid drops with pressure. Taking all these factors into consideration, temperature of fluid largely declines from the head to the bottom. In the primary period (0.3 year), pressure distributions are basically the same in different situations. But at the low rate of 5 kg/s, the temperature is more drastically declined than at other rate, which causes a large difference of density changes. In cases other than 5 kg/s, expansion effect is the major effect, and from the head to the bottom, with the influence of both decreased pressure and increased temperature, density declines. At the rate of 5 kg/s, compression effect plays a dominant role, and from the head to the bottom, density increases. As time goes by, in the system, heat exchanges between fluid and surrounding rocks decrease, so that fluid is less compressed and the temperature drops, as is shown in Fig. 8a.

Therefore, CO2 density can be both influenced by temperature and pressure. Whether in the injection well or the production well, influence of temperature and pressure goes always the opposite. For fluid flowing at a high rate (25–100 kg/s), it is changes of pressure that plays a major role. However, for fluid flowing at a low rate, due to its larger heat exchanges with surrounding rocks, changes of temperature have bigger impact on density. Feedback from CO2 density to temperature and pressure makes this system even more complicated.

To study deeper about changes of pressure inside the wellbore, the author introduces Table 4 to show the pressure loss in the production well after the system has been running for 30 years. Pressure loss includes gravity loss and non-gravity loss. Non-gravity loss includes friction loss and compression or expansion loss caused by changes of density. The pressure loss due to compression or expansion is usually little. The friction takes a large proportion of non-gravity pressure loss. It can be seen that besides the column of 5 kg/s, gravity loss increases with the flow rate, because the higher the rate is, the more the heat will be lost, and as temperature drops, density increases. At the rate of 5 kg/s, high density is not caused by high flow rate, but large heat dissipation capacity. In non-gravity loss, friction loss takes the most part. It is positively related to the flow rate. Therefore, the higher the rate is, the non-gravity loss will be.

Even within the narrowest flowing range based on the rate of 5 kg/s (with heat conductive material or small caliber), there may have a problem of too low temperature. Another problem-inducing factor is heat loss in the later period. The energy extraction rate per unit and the amount of flow are both in nonlinear relations with flow rate. It is also to notice that if the parameter of reservoir and wellbore is different from what the author has given in this thesis, then the relation between special points and value of ground heating system based on CO2 and the amount of flow may also be different. But the nonlinear relation and the wellbore–reservoir-dominated effect will not be changed. Optimized designs of CO2-based systems are expected.

Reservoirs and heat extraction efficiency

Figure 9 shows that at the rate of 5 and 50 kg/s, after 30 years, how the temperature and pressure are distributed in the system. In the circulation of heat-conducting fluid, if a quarter of the area between the injection well and production well as monitoring area is taken, it can be seen that with the complex effect of cycle power, buoyancy and gravity, gas distribution is shaped in oral. The figs of flow field are shown in Fig. 10.

Heat extraction efficiency at different amount of flow is shown in Fig. 11. The calculation method is shown in formula 1. F represents mass flow, and h represents enthalpy of fluid. It can be inferred that heat extraction goes up with the amount of flow. At high flow rates (75 and 100 kg/s), large heat loss makes heat extraction decline drastically in the later period. And at flow rate below 50 kg/s, heat extraction is stable. Therefore, according to the author, the rate of 50 kg/s is better for the stable running of geothermal energy extraction systems in Guide.

Conclusion

In this thesis, the author, after studying about the hot dry rocks in Guide, establishes a 2D wellbore–reservoir system to analyze how flow rate could affect the flow of CO2 as a working fluid, changes in physical fields and the maximum heat extraction capacity in Guide. The conclusions are as follows.

Pressure in the production well is always higher than that in the injection well, so siphonage could be used in heat extraction. Moreover, at high flow rate, pressure is low, which means it may be “more difficult to inject” a small amount of gas. This is due to the compressibility of CO2, which makes its density sensitive to temperature and pressure. At low flow rates, CO2 absorbs more heat from surrounding rocks. The density is low while the buoyance is high. This indicates that at high flow rate, it is more feasible to use siphonage for heat extraction.

In the injection well, in most of the cases (except 5 kg/s), fluid is compressed and density increases with pressure. Only at a low rate (5 kg/s) does density declines as temperature goes up and remains at an expansion status. However, things go opposite in the production well. In most of the cases, density drops as pressure goes down, and only at the rate of 5 kg/s does density increases as temperature declines. Therefore, at low rates, temperature is the major factor affecting fluid density, and at high rates, pressure has a larger impact on density.

At low rates, after 30 years, the system and the temperature remain relatively stable. At high rates (75 and 100 kg/s), the reservoir has large heat loss, so that the production temperature and heat extraction efficiency decrease a lot. Therefore, in Guide, it is more suitable to keep the rate at 50 kg/s in Three-Point CO2 geothermal heat extraction.

References

Atrens AD, Gurgenci H, Rudolph V (2009) CO2 thermosiphon for competitive geothermal power generation. Energy Fuels 23:553–557

Atrens AD, Gurgenci H, Rudolph V (2010) Electricity generation using a carbon-dioxide thermosiphon. Geothermics 39:161–169

Beamish D, Busby J (2016) The Cornubian geothermal province: heat production and flow in SW England: estimates from boreholes and airborne gamma-ray measurements. Geotherm Energy 4:1

Breede K, Dzebisashvili K, Liu X, Falcone G (2013) A systematic review of enhanced (or engineered) geothermal systems: past, present and future. Geotherm Energy 1:1

Brown D (2000) A hot dry rock geothermal energy concept utilizing supercritical CO2 instead of water. In: Proceedings, twenty-fifth workshop on geothermal reservoir engineering, Stanford University, Stanford, CA

Gérard A, Genter A, Kohl T, Lutz P, Rose P, Rummel F (2006) The deep EGS (enhanced geothermal system) project at Soultz-sous-Forêts (Alsace, France). Geothermics 35:473–483

Jain C, Vogt C, Clauser C (2015) Maximum potential for geothermal power in Germany based on engineered geothermal systems. Geotherm Energy 3:1

Kaieda H (2012) Ogachi EGS reservoir analysis. Trans GRC 36:487–492

Pan L, Oldenburg CM (2014) T2Well—an integrated wellbore–reservoir simulator. Comput Geosci 65:46–55

Pan L, Oldenburg CM, Wu Y-S, Pruess K (2011) T2Well/ECO2N Version 1.0: multiphase and non-isonthermal model for coupled wellbore–reservoir flow of carbon dioxide and variable salinity water, LBNL-4291E. Lawrence Berkeley National Laboratory, Berkeley

Pruess K (2006) Enhanced geothermal systems (EGS) using CO2 as working fluid—a novel approach for generating renewable energy with simultaneous sequestration of carbon. Geothermics 35:351–367

Pruess K (2008) On production behavior of enhanced geothermal systems with CO2 as working fluid. Energy Convers Manag 49:1446–1454

Pruess K, Oldenburg C, Moridis G (1999) TOUGH2 user’s guide, version 2.0, Report LBNL-43134. Lawrence Berkeley National Laboratory, Berkeley

Randolph JB, Saar MO (2011) Coupling carbon dioxide sequestration with geothermal energy capture in naturally permeable, porous geologic formations: implications for CO2 sequestration. Energy Procedia 4:2206–2213

Schill E, Meixner J, Meller C, Grimm M, Grimmer JC, Stober I, Kohl T (2016) Criteria and geological setting for the generic geothermal underground research laboratory, GEOLAB. Geotherm Energy 4:1–30

Schintgen T (2015) Exploration for deep geothermal reservoirs in Luxembourg and the surroundings-perspectives of geothermal energy use. Geotherm Energy 3:1

Shi H, Holmes JA, Durlofsky LJ, Aziz K, Diaz L, Alkaya B, Oddie G (2005) Drift-flux modeling of two-phase flow in wellbores. SPE J 10(01):24–33

Vinsome P, Westerveld J (1980) A simple method for predicting cap and base rock heat losses in thermal reservoir simulators. J Can Pet Technol 19:87–90

Zuber N, Findlay JA (1965) Average volumetric concentration in two-phase flow systems. J Heat Transf 87:453–468

Acknowledgements

The authors wish to thank Dr Guanhong Feng. This project is supported by the Chinese Academy of Geological Sciences Fund (No. YK201611) and the Chinese Academy of Geological Sciences Hydrogeological Environment Geology Institute Fund (No. SK201408).

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is part of a Topical Collection in Environmental Earth Sciences on “Subsurface Energy Storage II”, guest edited by Zhonghe Pang, Yanlong Kong, Haibing Shao, and Olaf Kolditz.

Appendix

Appendix

\(\kappa\)—component | \(\mathop M\nolimits^{\kappa }\)—κ component |

F κ—flow or heat flux | V n —grid cell volume |

Γ n —grid cell surface area | q κ—source sink term of κ component |

ϕ—porosity | β—phase state |

S β —saturation of β phase | ρ β —density of β phase |

X κ β —mass fraction of component in κ and β phase | u β —rate of β phase |

λ—heat conductivity | C R—heat capacity ratio of rock |

μ β —kinetic viscosity of β phase | k—absolute permeability of rock |

k rβ —relative permeability of β phase | ∇P β —effective pressure gradient of β |

g—acceleration of gravity | C 0—shape parameter |

u m —mixing rate | u d —drift rate |

ρ m —mixing density | ρ * m —average rate of mending (ρ * m = S G C 0 ρ G + (1 − S G C 0)ρ L ) |

Rights and permissions

About this article

Cite this article

Liu, Y., Wang, G., Yue, G. et al. Impact of CO2 injection rate on heat extraction at the HDR geothermal field of Zhacanggou, China. Environ Earth Sci 76, 256 (2017). https://doi.org/10.1007/s12665-017-6551-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-017-6551-7