Abstract

A new site-specific vibration prediction equation was developed based on site measurement performed in a sandstone quarry. Also, several vibration prediction equations were compiled from the blasting literature and used to predict ground vibration for the studied quarry. By this way, site-specific equation created by regression analysis and the equations obtained from the blasting literature were compared in terms of prediction accuracy. Some of the equations obtained from the literature made better predictions than the site-specific equation created for the studied quarry. The prediction equations were grouped, and the effects of the rock formation and mine type on the prediction accuracy were investigated. Suitable error measures for evaluation of ground vibration prediction were examined in detail. A new general prediction equation was created using site factors (K, β) of the examined studies. The general equation was created using 17 prediction equations reported by blast researchers. Prediction capability of the general equation was found to be strong. Diversity of the blast data is one of the strongest features of the general equation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Ground vibration is the one of the most important adverse effects of rock blasting. Effect of the ground vibration may reach long distances. Blast researchers focus on prediction of ground vibration to take precautions to reduce high vibration levels. Blast vibration has a site-specific character, and generally, it is represented using peak particle velocity (ppv). Site measurements are performed by blast seismographs and researchers try to establish a site-specific prediction equation to forecast ground vibrations. The coefficients of prediction equation reflect rock mass characteristics in general terms. However, there are various opinions on the character of vibration prediction equation.

The scaled distance approach is the first step to create a vibration prediction formula. The vibration measurement distance (D)—the distance between seismograph and blast point—and maximum instantaneous charge (W) are recorded. Maximum instantaneous charge is the weight of explosive detonating in a minimum 8 ms delay period. A ratio called scaled distance is created.

where SD is scaled distance; D is the distance between the blast and the station (m), and W is the maximum charge per delay (kg).

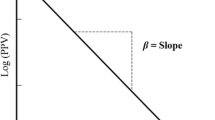

Regression analysis between ppv and scaled distance forms the predictor equation. The most used prediction equation was created by the researchers of US Bureau of Mines (USBM). It is presented as follows:

This is a vibration propagation equation, and K and β are empirical constants (Jimeno et al. 1995). K is particle velocity (y axis) intercept, and β is curve slope (Rosenthal and Morlock 1987). Regression coefficients (K and β) characterize rock mass properties. Blast researchers named the constants as site factors, site constant or site-specific constant (Rai and Singh 2004; Khandelwal and Singh 2007; Görgülü et al. 2013). Some researchers indicated that K and β mainly reflect influence of the local geology and rock mass on vibration attenuation (Morhard et al. 1987; Kahriman 2002; Gonzalez-Nicieza et al. 2014). On the other hand, some other researchers stated that K and β reflect influence of the blast geometry and explosive properties in addition to rock mass characteristics (Konya and Walter 1990; Persson et al. 1994; Nateghi 2012). Rosenthal and Morlock (1987) and Hustrulid (1999) emphasize that K and β are highly site specific and K constant can range from as low as 20 up to 1000 or more. The slope β is normally not lower than −1.1, and it is not higher than −2.4. According to the Adhikari et al. (2004), the site constants K and β are not really constants; they are simply regression coefficients. If a few sets of data for a given site are deleted, the values of the constants change. Adhikari et al. (2004) claimed that the variation in K and β are not significant only when size of data sets is large and contain very small to very large particle velocity or scaled distance. This situation may be the reason why there is no a strong relationship between site constants K − β and rock properties such as compressive strength, tensile strength or density.

As seen above, blast researchers have different ideas on the site factors. In this paper, the site-specific character of blast vibration prediction is investigated. The aim of this contribution is to examine the applicability of a site-specific vibration prediction equation which is created for a particular rock formation to a different mining site. At the same time, the influence of the change of blasthole diameter on vibration prediction accuracy is investigated. This paper also focuses on the possibility of the creation of a general equation to use in the absence of vibration monitoring. Additionally, suitable error measures for ground vibration prediction are analyzed.

In the following pages, site measurements performed in a sandstone quarry are explained and a new site-specific vibration prediction equation is introduced. The researches related to blast vibration prediction are discussed, and 18 vibration prediction equations compiled from the blasting literature are examined. These equations are used to predict ground vibration for the studied sandstone quarry. By this way, a site-specific equation created by regression analysis and the equations obtained from the blasting literature are compared. Accuracy of the equations is examined by several error measures. In the last part of the paper, a new general prediction equation is introduced based on the site constants derived from the blasting literature.

Site measurements and site-specific vibration prediction equation

The field investigations were performed at a sandstone quarry of Cendere Basin located in the northern Istanbul. The Akdaglar Quarry produces aggregate for concrete and asphalt plants. Current production capacity of the quarry is about 4000 ton/day. The rock structure is referred to as Trakya formation. The formation substantially contains sandstone layers. Additionally, thin layered shale and limestone are observed. Trakya formation is formed by carboniferous aged, fragmented sediments. It was deformed, folded and fragmented by joint systems in different locations during Hercynian and Alpine Orogenesis period. The thicknesses of the sediments are between 5 and 50 cm. In some parts, especially for sandstones, the thickness reaches 50–100 cm (Tugrul and Undul 2006). The rock of the quarry is sandstone that contains sixty percent silicium. The density of the rock is 2.70 g/cm3. The Mohs hardness value is 5–6. The average porosity is 1.03%. The average compressive strength is 829 kg/cm2, and the average tensile strength is 57.08 kg/cm2. The Young’s Modulus is 17 GPa.

The diameter of the drill holes is 89 mm in the quarry. ANFO (blasting agent) and emulsion explosive (priming) are used in the blasting operations. The blastholes are initiated by millisecond electrical detonators. In each blast, between 2 and 4 rows, each of which has 10–40 holes, are detonated. The number of the holes that are initiated instantaneously varies between 3 and 6. The weight of the maximum instantaneous charge is between 74 and 227 kg. Totally, 41 blast data were measured to create a vibration prediction equation. Table 1 shows measured ppv and scaled distance values for each blast.

The graph of the relationship between ppv and scaled distance is presented in Fig. 1. Equation (3) shows the prediction equation created by regression analysis based on the USBM approach.

The strength of the developed equation can be examined by regression statistics (Table 2). In Table 2, R 2 is the percent of variance in the dependent variable (ppv) explained by the independent variable (SD). An R 2 value close to 1 also indicates importance of regression. In this case, a value of 0.788 indicates that 78.8% of the ppv variability is explained by the linear regression (SPSS Base 19 2010). The F test is applied to test the significance of the regression model. If the significance value of the F statistic is <0.05, it means that the variation explained by the model is not due to chance (Montgomery et al. 2006). The significance value approximates to zero. That indicates the importance of the developed prediction equation.

The selected researches on blast-induced ground vibration

Several vibration prediction equations were compiled from the blasting literature and used to predict ground vibration for the studied Cendere Region sandstone quarry. By this way, the site-specific equation created by regression analysis (Eq. 3) and the equations obtained from the blasting literature were compared in terms of prediction accuracy. A conservative literature research was performed to increase reliability of this study:

-

Relatively, recent papers were used to compile ground vibration; equations 15 out of 18 examined papers were published after 2004.

-

Only the studies published in indexed journals were considered. Most of these journals are core publications in the fields of mining, earth science or vibrations.

-

Only relatively successful predictor equations were considered. For that purpose, the correlation coefficients of the predictive equations or the authors’ interpretations were strictly examined.

Totally, 18 studies related to blast vibration prediction were evaluated to form a research database. Table 3 is a summary table for examined blast researches. In the table, all available data—blast parameters, explosive type, rock formation and site factors used to predict ground vibration—are presented for each study. All the site factors given in Table 3 were obtained by regression analysis based on USBM approach. The studies presented in Table 3 were conducted in various parts of the world. Quarry blasts were examined by 7 researchers (Birch and Pegden 2000; Adhikari et al. 2004; Kahriman 2004; Rai and Singh 2004; Giraudi et al. 2009; Mesec et al. 2009; Gonzalez-Nicieza et al. 2014). Four researchers investigated coal mine blasts (Pal Roy 1991; Kahriman 2002; Singh and Roy 2008; Khandelwal 2010). Ak et al. (2009) worked in a Magnesite Mine. Alipour and Ashtiani (2011), Ghasemi et al. (2013) and Faramarzi et al. (2014) investigated copper mine blasts. Görgülü et al. (2013) studied in a boron mine. Hole diameter varied between 64 and 311 mm. Burden is between 1.5 and 8 m. Spacing between holes is 2–11 m (Table 3). Bench height is 2–40 m. Stemming length is between 1.7 and 8 m. The blast studies presented in Table 3 were performed in sandstone, limestone, shale, marlstone, andesite, granodiorite and complex mixed rock formations. The variety of the blast parameters and rock formation is an important element that increases the reliability of this study.

Evaluation of prediction accuracy

Forecast error measurements for blast-induced ground vibration

Generally, researchers use a few error measures to evaluate the accuracy of vibration prediction equations. In this paper, measurement of accuracy is discussed in detail to abstain a crude examination. Additionally, the most appropriate error measures for vibration prediction are investigated. Forecast error measures may be divided into 4 main groups: absolute error, percentage error, symmetric error and scaled error. All error measures are given in Table 4. Absolute error is very popular in the blasting literature (Khandelwal 2010; Ghasemi et al. 2013; Alipour and Ashtiani 2011; etc.). They are simple and easy to use. Shcherbakov et al. (2013) report that the main drawback of absolute error is the scale dependency. Also extreme values in the data highly influence the results. Makridakis and Hibon (1995) indicate that root-mean-square error (RMSE) provides a quadratic loss function and it is also measures the uncertainty in prediction. Percentage errors are relative measures that express errors as a percentage of the measured actual data (Table 4). They provide information about magnitude of the errors. Percentage errors are easily and intuitively interpretable. Median absolute percentage error (MdAPE) is not influenced by extreme values. (Makridakis and Hibon 1995). However, according to Armstrong and Collopy (1992), mean absolute percentage error (MAPE) puts heavier penalty on forecasts that exceed the actual value than those that are less than the actual value. This observation led to the use of the so-called symmetric error measures (Hyndman and Koehler 2006). The symmetric error group contains symmetric mean absolute percentage error (sMAPE) and symmetric median absolute percentage error (sMdAPE). The problem of asymmetry of percentage errors and its possible influence by outliers can be corrected by dividing the forecasting error by the average of predicted and actual value (Makridakis and Hibon 1995). However, if the actual value is equal to predicted but with opposite sign, or both of these values are zero, division by zero error occurs (Shcherbakov et al. 2013). The scaled error group contains mean absolute scaled error (MASE) and root-mean-square scaled error (RMSSE). Hyndman and Koehler (2006) claimed that scaled errors are symmetrical and resistant to extreme values. They are clearly independent of the scale of the data.

None of the error measures is superior on all criteria (Armstrong and Collopy 1992). Each error measure has a disadvantage (Shcherbakov et al. 2013). Quality and type of the data may affect the efficiency of error measures. Makridakis and Hibon (1995) also indicate that choosing an error measure also depends on the person using it. Statisticians and engineers with a quantitative background have no problem using mean absolute error (MAE), mean absolute scaled error (MASE), symmetric median absolute percentage error (sMdAPE). However, measures intended for the general public may be limited to those having common sense meaning [for example, mean absolute percentage error (MAPE)].

Additionally, Variance account for (VAF), correlation, standard error of estimate and “Number of Prediction Error ≤2 mm/s” were used as error measures (Table 4). Contrary to other error measures, the higher the VAF the better the model performs. “Number of Prediction Error ≤2 mm/s” is the indicator of the accurate prediction capability of the models.

Comparison of the vibration prediction equations by error measures

All calculated error values for the vibration prediction equations are presented in Table 5. From this point forward, Eq. (3) created for the Cendere region sandstone quarry is called “current study.” According to MAE values, the equations created by Birch and Pegden (2000), Kahriman (2002), Adhikari et al. (2004), Ak et al. (2009), Mesec et al. (2009) and Khandelwal (2010) made better predictions than the equation created by the current study (Eq. 3). MAPE is 27.68 for the current study. Lowest percentage errors are obtained by Rai and Singh’s (2004) equation created for dolomite formation. MAPE, MdAPE and RMSPE values of this equation are 26.99, 25.63 and 31.86, respectively (Table 5). Also, Rai and Singh’s (2004) equation for limestone made better predictions than the current study (Eq. 3) in terms of percentage error. Percentage errors of the equations created by Birch and Pegden (2000) and Faramarzi et al. (2014) are also promising. sMAPE of the current study is 26.51 (Table 5). This is the best symmetric error value. sMAPE of the equation of Ak et al. (2009) is very close to the current study (Eq. 3), 26.59. sMAPE of Birch and Pegden’s (2000) equation is 26.92. However, in terms of sMdAPE, 5 equations perform better than the current study (Eq. 3). sMdAPE is 23.91 for the current study. It is 21.70 for the Kahriman’s (2002) equation. sMdAPE values for the Khandelwal’s (2010) and Birch and Pegden’s (2000) equations are 21.92 and 22.91, respectively (Table 5). MASE and RMSSE values of the current study (Eq. 3) are 0.40 and 0.54, respectively. Six equations show better performance than that of the current study (Eq. 3) according to scaled error values (Table 5). MASE value for Mesec et al.’s (2009) equation is 0.38. MASE is 0.39 for the equations created by Birch and Pegden (2000), Adhikari et al. (2004) and Ak et al. (2009).

Correlation and standard error of estimates for the current study (Eq. 3) are 0.833 and 4.5763, respectively. Best correlation value is 0.861 for the equation developed by Ghasemi et al. (2013). However, Ghasemi et al.’s (2013) equation does not make good predictions according to the calculated error measures (Table 5). “Number of prediction error ≤2 mm/s” is 15 for current study. The equations created by Rai and Singh (2004) and Faramarzi et al. (2014) predict 18 blasts with an error lower than 2 mm/s. “Number of prediction error ≤2 mm/s” is 17 for the equation developed by Ak et al. (2009). Also, the equations created by Birch and Pegden (2000) Kahriman (2002) and Mesec et al. (2009) are very promising (Table 5). Highest variance account for value is obtained by Adhikari et al.’s (2004) equation. VAF is 62.24 for the current study. The predictions of 13 equations have a higher VAF than the current study. It is concluded that apparently some of the equations gathered from the blasting literature made better predictions than that of the current study (Eq. 3).

Generally, the results of percentage error measures are in accordance with the results of absolute error measures. However, the relationship between percentage error and number of prediction error ≤2 mm/s is stronger than that of absolute error measures and number of prediction error ≤2 mm/s. MAE and MAPE values for Rai and Singh’s (2004) equation for dolomite are 4.03 and 26.99, respectively. This equation makes 19 predictions with an error lower than 2 mm/s. MAE and MAPE values for the equation developed by Mesec et al. (2009) are 3.51 and 29.96, respectively. Equation created by Mesec et al. (2009) predicts 14 blasts with an error lower than 2 mm/s. Correlation and standard error of estimate values of predictor equations are very similar (Table 5). Therefore, it is relatively difficult to interpret these error measures. Scaled error values are lower than 0.40 for successful predictor equations (predictor equations with an MAE lower than 4). Scaled error values are easy to interpret and can be recommended to evaluate accuracy of blast vibration prediction. For particular cases, magnitude of symmetric error may lead to difficulty in interpretation. Absolute errors, scaled errors and “Number of prediction error ≤2 mm/s” values are in accordance with each other for the equations created by Kahriman (2004) and Görgülü et al. (2013). However, even though prediction accuracy is almost similar for Kahriman’s (2004) and Görgülü et al. (2013) equations, symmetric error values are 90.55 and 56.81, respectively. VAF is 70 or more for successful predictions. Nevertheless, VAF is not a precise error measure for some cases. For example, Pal Roy’s (1991) equation made better predictions than Birch and Pegden’s (2000) equation. However, VAF value is 69.46 for Birch and Pegden’s (2000) equation and 65.19 for Pal Roy’s (1991) equation (Table 5).

The effect of mine type on the prediction accuracy

The prediction equations were grouped to investigate the effect of the rock formation and mine type on the prediction accuracy. Quarry blasts are generally performed by small diameter holes in low benches. Weight of explosive charge per hole is low. Therefore, burden, spacing and stemming length are smaller in comparison with open-pit blasts. Site measurements of the current study were also performed in a quarry. Figure 2 shows the prediction error of the equations which were developed based on quarry blasts. In the investigated quarries, generally, hole diameter is lower than 150 mm. Figure 3 presents the error of the equations which were developed for non-quarry open-pit blasts. Except Alipour and Ashtiani’s (2011) study, the researchers examined the blasts performed by large diameter holes. For example, particularly for the studies conducted by Singh and Roy (2008) and Khandelwal (2010), hole diameters are between 270 and 300 mm. MAE and “Number of Prediction Error ≤2 mm/s” were used for the comparison of the equations. As seen in Figs. 2 and 3, it is not possible to recognize a significant difference between the two groups. There is no any apparent relationship between prediction accuracy and mine type (operational size).

The effect of rock formation on the prediction accuracy

Figures 4 and 5 are created to examine effect of the rock formation on the accuracy of prediction equations. MAPE and “Number of Prediction Error ≤2 mm/s” were used for the comparison of the equations. Figure 4 is created for the equations developed based on the blasts performed in limestone formations. The aim of the Fig. 4 is to diagnose error pattern of the equations developed for similar formation. Figure 5 shows the error of the equations developed based on the blasts performed in various rock formations except limestone. There are no similarities among the equations created for limestone in terms of error rates. It is not possible to recognize any error pattern.

Site measurements of the current study were performed in a sandstone quarry. A hypothesis may be proposed that an equation created for sandstone formation may be applicable to another sandstone operation. Four out of the 16 studies listed in Table 3 were performed in sandstone or dominantly sandstone formations. Figure 6 shows prediction performance of the equations developed for sandstone. MASE and “Number of Prediction Error ≤2 mm/s” are used for the comparison. The equations created for sandstone formation are relatively successful. MASE value of 3 out of 4 equations is lower than 5 mm/s. However, at this stage, there are only 4 blasts to examine. More investigations are needed to conclude that an equation created for a particular rock formation can be also used for similar formations.

A new general prediction equation

Different equations developed for various mines were used to predict blast vibration in a sandstone quarry. Most of the equations made successful prediction. At this stage, a new general predictor equation may be created using site factors (K, β) of the examined studies given in Table 3. The new general equation relies on blast data collected from various mines and rock formations. In the absence of monitoring, the general equation may be used to predict ground vibration. As seen in Table 3, the K and β constants of Singh and Roy’s (2008) and Ghasemi et al.’s (2013) equations are very close to the limit values that were mentioned in the introduction. Therefore, these two extremum cases were dropped to increase stability of the general equation. The general equation was constructed using 17 cases. The mean K value is 427.074, and mean β value is −1.485. The general prediction equation was formed as follows:

The general predictor equation was applied to measured blast data presented in Table 1. Figure 7 shows comparison of general predictor equation and Eq. (3) created by the measured data given in Table 1. In Fig. 7, the vertical axis shows the predicted ppv and the horizontal axis shows the actual ppv. The calculated error measures are also shown in Fig. 7. It is apparent that the general equation shows considerable promise. The prediction accuracy of the general predictor equation is higher than that of Eq. (3) in terms of the most error measures.

In the second stage, the blasts that were not included among the 41 blast data given in Table 1 were used to analyze the prediction capability of the developed predictor equations. General predictor equation (Eq. 5) and Eq. (3) were applied to 19 test blasts (Fig. 8). In Fig. 8, vertical axis shows the measured ppv and the horizontal axis shows blast number. Both general equation and Eq. (3) seem to make similar predictions particularly for the blasts 8, 13, 14, 15 and 19. Prediction errors exceed 5 mm/s for the blasts 12, 13, 15 and 18. MAE is 3.67 for Eq. (5). It is 3.88 for Eq. (3). MAPE, sMAPE and MASE values of the general equation are 33.92, 32.00 and 0.40, respectively. MAPE is 34.44 for Eq. (3). sMAPE and MASE values of Eq. (3) are 32.24 and 0.42, respectively. “Number of prediction error ≤2 mm/s” is 8 for Eq. (5). The equation created by the current study (Eq. 3) predicts 6 blasts with an error lower than 2 mm/s. General equation produced promising results for the test blasts. In the absence of monitoring, it may be helpful for site engineers. The general equation was created using diverse research data coming from various rock formations (Table 3). The blast data come from various mines those use different hole diameters and operational parameters. Therefore, it is believed that the general equation can be applied to most of the mining projects.

Conclusions

Vibration prediction equations reported in the literature were investigated to understand the site-specific character of vibration prediction. Applicability of a site-specific vibration prediction equation to a different mining site was examined. Many blast studies realized in different parts of the world were compiled. Site measurement was performed in a sandstone quarry, and a site-specific vibration prediction equation was created. The vibration prediction equations compiled from the literature were applied to measured data in the sandstone quarry. Some of the equations obtained from the literature made better predictions than the site-specific equation created for the studied quarry. Without any doubt, rock mass parameters affect the magnitude and propagation of blast-induced vibration. However, as indicated in this paper, blast researchers have different ideas about the definitions of constants of the vibration prediction equation. Thus, the parameters that have influence on the formation of the prediction equations should be reconsidered.

The prediction equations compiled from the blasting literature were grouped to investigate the effect of the operational size on the prediction accuracy. The prediction equations were divided into two groups as the equations developed for the blasts performed by small diameter holes and the equations developed for large diameter blast holes. It is concluded that there is no apparent relationship between operational size and prediction accuracy. Also, the vibration prediction equations were grouped as the equations developed for limestone formations and the equations developed for non-limestone formations. The aim of the examination was to diagnose error pattern of the equations developed for similar formations. There are no similarities among the equations created for limestone in terms of error rates. The equations created for sandstone formation were relatively successful in predicting vibrations for the studied sandstone quarry. However, at this stage, only 4 blasts were examined. In the future, attempts may be made to investigate applicability of site-specific vibration prediction equations to similar formations.

Error measures for blast vibration were discussed in detail. In rock blasting literature error measures for blast vibrations have been performed in a crude, highly simplified manner. Generally, absolute error measures are used in the blasting literature. In this research, scaled error measures and percentage error measures were found to be quite useful for evaluation of vibration prediction in addition to absolute errors. Different error measures provide different perspectives. In the future, application of different error measures, as done in this paper, will help understand which error measures are most suitable for evaluation of blast vibration prediction.

A new general equation was created for vibration prediction. The general equation will be helpful for site engineers in the absence of monitoring. This equation may also be used for pre-estimation before vibration monitoring. Prediction capability of the general equation was found to be strong. The general equation was created using 17 prediction equations reported by blast researchers. Diversity of the blast data and rock formation are the strongest features of the new equation. Like all new scientific approaches, the developed general equation should be further tested in prospective trials in various mines and rock formations. Application of the general equation to new blasts will test the reliability of it.

This study may be considered a strong introduction for investigation of the site-specific character of ground vibration. In the future, attempts may be made to increase the number of inspected predictor equations. As a part of a Ph.D. thesis, the blast literature may be reviewed and symposium proceedings may be examined to find more studies related to vibration prediction. However, in that situation, researchers should be selective and consider the reliability of blast data. Also, new investigations may be performed to add site-specific modifier parameters to the conventional vibration prediction equations. Future researchers may use the research methodology presented in this paper along with new studies reported in the literature when they become available.

References

Adhikari GR, Theresraj AI, Venkatesh HS, Balachander R, Gupta RN (2004) Ground vibration due to blasting in limestone quarries. Fragblast 8:85–94. doi:10.1080/13855140412331336160

Ak H, Iphar M, Yavuz M, Konuk A (2009) Evaluation of ground vibration effect of blasting operations in a magnesite mine. Soil Dyn Earthq Eng 29:669–676. doi:10.1016/j.soildyn.2008.07.003

Alipour A, Ashtiani M (2011) Fuzzy modeling approaches for the prediction of maximum charge per delay in surface mining. Int J Rock Mech Min 48:305–310. doi:10.1016/j.ijrmms.2010.11.010

Armstrong JS, Collopy F (1992) Error measures for generalizing about forecasting methods: empirical comparisons. Int J Forecast 8:69–80. doi:10.1016/0169-2070(92)90008-W

Birch WJ, Pegden M (2000) Improved prediction of ground vibrations from blasting at quarries. Trans Inst Min Metall (Sect A: Min Technol) 109:102–106. doi:10.1179/mnt.2000.109.2.102

Faramarzi F, Ebrahimi FMA, Mansouri H (2014) Simultaneous investigation of blast induced ground vibration and airblast effects on safety level of structures and human in surface blasting. Int J Min Sci Technol 24:663–669. doi:10.1016/j.ijmst.2014.07.006

Ghasemi E, Ataei M, Hashemolhosseini H (2013) Development of a fuzzy model for predicting ground vibration caused by rock blasting in surface mining. J Vib Control 19:755–770. doi:10.1177/1077546312437002

Giraudi A, Cardu M, Kecojevic V (2009) An assessment of blasting vibrations: a case study on quarry operation. Am J Environ Sci 5:467–473. doi:10.3844/ajessp.2009.467.473

Gonzalez-Nicieza C, Álvarez-Fernandez MI, Alvarez-Vigil AE, Arias-Prieto D, López-Gayarre F, Ramos-Lopez FL (2014) Influence of depth and geological structure on the transmission of blast vibrations. B Eng Geol Environ 73:1211–1223. doi:10.1007/s10064-014-0595-7

Görgülü K, Ercan A, Demirci A, Koçaslan A, Dilmaç MK, Yüksek AG (2013) Investigation of blast-induced ground vibrations in the Tulu boron open pit mine. B Eng Geol Environ 72:555–564. doi:10.1007/s10064-013-0521-4

Hustrulid W (1999) Blasting principles for open pit mining—general design concepts. Theoretical foundations. A.A Balkema, Roterdam

Hyndman RJ, Koehler AB (2006) Another look at measures of forecast accuracy. Int J Forecast 22:679–688. doi:10.1016/j.ijforecast.2006.03.001

Jimeno CL, Jimeno EL, Carcedo FJA (1995) Drilling and blasting of rocks. A. A Balkema, Brookfield Publication, Rotterdam

Kahriman A (2002) Analysis of ground vibrations caused by bench blasting at can open-pit lignite mine in Turkey. Environ Geol 41:653–661. doi:10.1007/s00254-001-0446-2

Kahriman A (2004) Analysis of parameters of ground vibration produced from bench blasting at a limestone quarry. Soil Dyn Earthq Eng 24:87–892. doi:10.1016/j.soildyn.2004.06.018

Khandelwal M (2010) Evaluation and prediction of blast-induced ground vibration using support vector machine. Int J Rock Mech Min 47:509–516. doi:10.1016/j.ijrmms.2010.01.007

Khandelwal M, Singh TN (2007) Evaluation of blast-induced ground vibration predictors. Soil Dyn Earthq Eng 27:116–125. doi:10.1016/j.soildyn.2006.06.004

Konya CJ, Walter EJ (1990) Surface blast design. Prentice Hall, New Jersey

Makridakis S, Hibon M (1995) Evaluating accuracy (or error) measures. INSEAD Working Paper Series No. 18/TM:1-31

Mesec J, Vrkljan D, Ester Z (2009) Allowed quantity of explosive charge depending on the distance from the blast. Geotech Geol Eng 27:431–438. doi:10.1007/s10706-008-9243-y

Montgomery DC, Peck EA, Vining GG (2006) Introduction to linear regression analysis. Wiley, NJ

Morhard RC, Chiappetta RF, Borg DG (1987) Explosives and rock blasting. Atlas Powder Co., Dallas

Nateghi R (2012) Evaluation of blast induced ground vibration for minimizing negative effects on surrounding structures. Soil Dyn Earthq Eng 43:133–138. doi:10.1016/j.soildyn.2012.07.009

Pal Roy P (1991) Vibration control in an opencast mine based on improved blast vibration predictors. Min Sci Technol 12:157–165. doi:10.1016/0167-9031(91)91642-U

Persson PA, Holmberg R, Lee J (1994) Rock blasting and explosives engineering. CRC Press, Boca Raton

Rai R, Singh TN (2004) A new predictor for ground vibration prediction and its comparison with other predictors. Indian J Eng Mater S 11:178–184

Rosenthal MF, Morlock GL (1987) Blasting guidance manual. Office of Surface Mining Reclamation and Enforcement, US Department of the Interior, USA

Shcherbakov MV, Brebels A, Shcherbakova NL, Tyukov AP, Janovsky TA, Kamaev VA (2013) A survey of forecast error measures. World Appl Sci J 24:171–176. doi:10.5829/idosi.wasj.2013.24.itmies.80032

Singh PK, Roy MP (2008) Characterization of blast vibration generated from open-pit blasting at surface and in belowground openings. Min Technol Trans Inst Min Metall Sect A 117:122–127. doi:10.1179/037178409X405750

SPSS Base 19 (2010) SPSS Inc, Chicago

Tugrul A, Undul O (2006) Engineering geological characteristics of Istanbul greywackes. In: Proceedings of the 10th international association for engineering geology and the environment (IAEG) congress, Nottingham, 6–10 Sept, Paper no. 395

Acknowledgements

This study was supported by the Research Fund of the Istanbul Technical University (Project Name: The effects of the variations in blast design and initiation systems on blast induced ground vibrations. No: 38511). The authors are grateful to the Research Fund of the Istanbul Technical University for their financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hudaverdi, T., Akyildiz, O. Investigation of the site-specific character of blast vibration prediction. Environ Earth Sci 76, 138 (2017). https://doi.org/10.1007/s12665-017-6456-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-017-6456-5