Abstract

Phenolic compounds are considered as a serious organic pollutant containing in many industrial effluents particularly vulnerable when the plant discharge is disposed on land. In the present study, the phenol removal potential of peat soil as adsorption media was investigated as the adsorption process are gaining popular for polishing treatment of toxic materials in industrial wastewater. Batch experiments were performed in the laboratory to determine the adsorption isotherms of initial concentrations for 5, 8, 10, 15, and 20 mg/L and predetermined quantity of peat soil with size ranges between 425 and 200 μm poured into different containers. The effects of various parameters like initial phenol concentration, adsorbent quantity, pH, and contact time were also investigated. From experimental results, it was found that 42 % of phenol removal took place with optimized initial phenol concentration of 10 mg/L, adsorbent dose of 200 g/L, solution pH 6.0 for the equilibrium contact time of 6 h. The result exhibits that pseudo-first-order (R 2 = 0.99) and Langmuir isotherm models are fitted reasonably (R 2 = 0.91). Adams–Bohart, Thomas, Yoon–Nelson, and Wolborska models were also investigated to the column experimental data of different bed heights to predict the breakthrough curves and to determine the kinetic coefficient of the models using nonlinear regression analysis. It was found that the Thomas model is the best fitted model to predict the experimental breakthrough curves with the highest coefficient of determination, R 2 = 0.99 and lowest root mean square error and mean absolute performance error values.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Phenolic compounds are very poisonous organic substances that enter the aquatic environment through direct discharge from industrial sources such as coke ovens in steel plants, oil refineries, phenolic resin manufacturing units, and pharmaceutical and pesticide manufacture industries (Li et al. 2001). In the USEPA list, the priority pollutants are described in their frequency of occurrence where metals (antimony, arsenic, beryllium, cadmium, chromium, copper, lead, mercury, nickel, selenium, silver, thallium, and zinc) are on the top and phenols constituted the 54th of the 126 priority pollutants. However, phenols are also common contaminant and emanated from many industries as mentioned above and even at very low concentration phenol imparts psychological and health impact in the human body due to which it is included in the USEPA priority list. It causes several dreaded acute and chronic toxic effects on human health (including a wide range of symptoms: headache, vomiting, fainting, liver and kidney damage, and other mental disorders) (ATSDR 1998). As per the WHO (1997), 0.002 mg/L is the permissible limit for phenol concentration in potable water. Hence, the removal of phenol from wastewater is of outmost importance.

The groundwater quality in a nearby locality of coke oven plant situated in Durgapur, West Bengal, India was contaminated with phenol and other pollutants due to land discharge of wastewater from the plant and subsequent migration of pollutants through subsurface soil media to the groundwater. It is a great concern on the groundwater contamination due to phenolic pollutants in that particular site. The fact has been reported by Pal et al. (2011). In this context, a scientific study is very much necessary to explore the capacity of neighboring deposits of soil for decontamination of phenolic compound and subsequent liner system design. Keeping in view of such examination, a research study is undertaken in achieving the desired objectives.

Several methods have so far been proposed for removal of phenol, e.g., biological oxidation, thermal liquid phase oxidation, photochemical conversion, catalytic oxidation, physical adsorption, and solvent extraction system (Mitra and Pal 1994). Among all of the methods, low-cost physical adsorption process considered to be one of the sustainable technologies for removal of phenol from aqueous solutions containing moderate or low concentrations for economic consideration. The investigation had already been carried out for removal of phenol from aqueous solutions by low cost adsorbents such as saw dust (Singh and Mishra 1990; Sivanandam and Anirudhan 1995), charcoal (Bhat et al. 1983), activated carbon, bagasse ash and wood charcoal (Mukherjee et al. 2007), fly ash, and bentonite (Viraraghavan and Maria Alfaro 1998).

Earlier Viraraghavan and Maria Alfaro (1998) carried out a research investigation to observe the adsorption capacity of peat soil for removal of phenol for low level of initial concentration (1.0 mg/L). They obtained 41.6 % removal efficiency between the pH level 4–5. In a separate study, Taha et al. (2003) conducted a batch adsorption study with a wide variation of initial phenol concentration (0.8–100 mg/L) by using granite residual soil and they found that about 50 % removal could be possible. They have also evaluated some kinetic parameters and isotherm constants using Langmuir and Freundlich models. Phenolic adsorption by natural soil was studied experimentally with batch and fixed bed column tests by some other investigator also (Yong et al. 1997; Nayak and Singh 2007; Froehner et al. 2009; Belarbi and Al-Malack 2010).

A number of mathematical models ware developed till date to study the nature of the adsorption process namely Langmuir, Freundlich, Redlich–Peterson for adsorption isotherm study and pseudo-first-order, pseudo-second-order, inter particle diffusion models for kinetics studies. The linear least square regression method is frequently used in fitting the experimental adsorption data with the models to estimate the coefficients of the model equations. However, this method requires transformation of the nonlinear model equations to linear form. This linearization approach results in alteration of the error structures, violation of the error variance, and normality assumptions of the standard least squares (Ratkowsky 1990; Ho 2006a) and leading to bias in the fitted parameter values between linear and non-linear versions of the model equations (Ho 2006b). The non-linear regression method does not require for transformation of nonlinear model equations to linear form and thus same error structure can be maintained (Ho 2004).

Hong et al. (2009) used nonlinear regression analysis tool to determine different isotherm parameters of Langmuir, Freundlich, and Redlich–Peterson model for adsorption of methylene blue onto bentonite at different temperatures. They successfully used R 2 value of the nonlinear method in fitting the isotherm models with the experimental data. Redlich–Peterson isotherm model provided the best fit with highest R 2 (0.998) value. EI-Khaiary et al. (2010) compared the linear and non-linear regression methods using kinetic adsorption data for determination of pseudo-second-order kinetic parameters. They concluded that the nonlinear regression adequately predicts the pseudo-second-order kinetic equation and more accurately estimate the kinetic parameters in comparison to the linear regression method.

In case of design of liner thickness in waste landfill site and to generate breakthrough curves, the continuous fixed-bed column studies are to be performed in the laboratory. However, the requisite experiments are complex, time dependent and necessitate close surveillance. Various researchers namely Adams–Bohart, Thomson, Yoon–Nelson, Wolborska, etc., have developed mathematical model for the prediction of breakthrough curves. Non-linear regression equations are often preferred to estimate the model parameters.

The significance of the present investigation is to incorporate batch, kinetic adsorption experimental data of phenol-peat soil system in various adsorption-isotherm-kinetic order model as feasibility study to investigate the attenuation behavior of the soil to mitigate phenolic pollution in the surrounding soil environment. Limited literatures and research reports are available in this context covering all kind of kinetic models specially on nonlinear analysis of adsorption data for examining soil as a material for attenuation of phenol transmission through soil.

The objective of the present investigation was to evaluate the isotherm, kinetics, and breakthrough curves for adsorption of phenol onto peat soil. The peat soil was collected as adsorption media for removal of phenol from aqueous medium from a nearby pond of the existing contaminated site. The effect of various operational parameters namely initial phenol concentration, adsorption dosage, pH, and contact time on adsorption efficiency was also studied. The mathematical models were used to analyze the experimental data and the model parameters were estimated using nonlinear regression analysis. An error analysis was also performed to test the accuracy of the models used.

Materials and methods

Experimental procedure

Analysis of soil samples

The peat samples were collected from the benthal layer of a nearby pond of National Institute of Technology campus, Durgapur, West Bengal, India. The samples were brought to the Soil Mechanics and Foundation Engineering Laboratory of National Institute of Technology, Durgapur, West Bengal, India for determining the physico-chemical properties as per the guidelines given in Bureau of Indian Standards (IS 2720). First, the soil was oven-dried at 103 °C temperature for 24 h for evaporating out the moisture content in it to dryness and then it was stored in desiccator until use. The physico-chemical properties of soil and its grain size distribution are shown in Table 1 and Fig. 1, respectively. The results given in the Table 1 are average of three replicates. The grain size distribution of soil was determined by hydrometer (Make-Testing Instruments Mfg. Co. Pvt. Ltd., India) and sieve analyses (Make-Geologists Syndicate Pvt. Ltd., India). The specific gravity, natural moisture content, liquid limit, and pH of soil was measured by pycnometer (Make-Testing Instruments Mfg. Co. Pvt. Ltd., India), Digital moisture meter (Model M-3A, make-Advance Research Instruments Co., India), Casagrande apparatus (Make-Aimil Ltd., India), and Digital pH meter (Model-pH 1100, make-EUTECH, Singapore), respectively. The total porosity of the soil was calculated using the following equation:

where n = total porosity of the soil sample, ρ b = bulk density of undisturbed soil sample in g/cc, and G s = specific gravity of the soil.

Cation exchange capacity of the soil was determined using the BaCl2 extraction method. The soil surface area was calculated by using the ethylene glycol monoethyl ether method (Cerato and Lutenegger 2002).

The mineralogical composition of peat soil was determined by X-ray diffraction analysis for the qualitative evaluation of the common and predominant phases within the soil. The analysis was carried out using a PANalytical XPert Pro Basic X-ray diffractometer with a Cu-anode. The diffractometer was operated at 40 kV and 40 mA for 1 h over the range of 2θ from 0° to 80° and the identification was carried out using high score plus software. Figure 2 shows the X-ray diffraction pattern for particle size ≤425 μm, which was taken as test soil in the present experiment. It was found that the peat soil composed of aluminum phosphate, hematite, magnesium oxide, calcium oxide, and large characteristic peaks of quartz (SiO2).

Batch experiments

The stock solution of phenol of strength 10,000 mg/L was prepared by diluting the 1 gm solid phenol supplied by Merck Chemical Limited, India in 100 mL double distilled water. The stock solution was then diluted to prepare various initial intermediate concentrations (C 0) ranging between 5 and 20 mg/L. The pH of the phenol solution was adjusted to a constant value either by adding 1 N HCl or 1 N NaOH solution. All chemicals and reagents used were AR grade. The pH was measured by a digital pH meter. The batch adsorption test was done in the laboratory by adding varying amount of peat soil (particle sizes 425–200 μm) ranges between 5 and 25 g in a series of 250 ml glass stoppered flasks filled with 100 ml synthetic phenol solution. The concentration of phenol solution varies between 5 and 20 mg/L. The glass stoppered flasks were then placed in an orbital rotary shaker (Remi make, India) and agitated at a speed of 150 rpm until the equilibrium condition reached. The treated solutions were then filtered through 0.22 μm filter paper and the residual phenol concentration were determined spectrophotometrically after developing color using 0.3 ml each of potassium ferricyanide and 4-amino antipyrine solution. The pH of the solution was adjusted to 7.0 ± 0.2. The solution was then allowed to stand for 10–15 min for full color development. The residual concentration was measured by UV/Vis spectrophotometer (Model-UV-2300, make-TECHCOMP, Shanghai, China) at a wavelength of 500 nm in a 5 cm cell. Water quality parameters and phenol estimation were done in accordance with ‘standard methods’ (APHA-AWWA-WPCF 1998).

The percentage of phenol adsorbed by the peat soil was calculated by the following equation.

where C 0 and C e are the initial and equilibrium concentration of phenol in mg/L.

Isotherm experiments

Adsorption isotherm experiments were performed in a series of 250 mL capacity glass stoppered flasks containing 100 mL of different initial concentration (5–20 mg/L) of phenol solutions. The adsorbent dosage was maintained at a constant level for each set of experiment. After equilibrium, the solutions were filtered and analyzed for residual phenol concentration.

The equilibrium phenol adsorption capacity (q e, mg/kg) was calculated by the following Eq. 3.

where V = volume of solution in ml, M = mass of adsorbent (peat soil) in gm.

Kinetic studies

Different amount of adsorbents (5–25 g) were taken into a stoppered glass flask containing 100 ml synthetic phenol solution with initial phenol concentration ranging from 5 to 20 mg/L. The solution containing the adsorbent was agitated in the shaker for different time intervals. The residual concentration of phenol after each hour interval was determined using UV/VIS spectrophotometer.

The amount of phenol adsorption with time, q t (mg/kg), was calculated by the following equation,

where C t = residual concentration of phenol with time.

Effect of adsorbent dosage, initial adsorbate concentrations, pH, and contact times

Different amount of peat soil (5–25 g) was taken as adsorbent to study their effect on the removal of phenol from aqueous solution. The experiment was conducted to determine the pH range at which maximum adsorption of phenol would take place. The initial concentration of phenol was varied to study their effect on adsorption.

Column adsorption studies

Column adsorption experiments were conducted in a column of internal diameter of 2.5 cm and height of 30 cm made of perspex sheet. The peat soil having a particle size range in between 425 and 200 μm was used to pack the columns for three different bed heights of 5, 10, and 15 cm each. The glass wools were placed at the top and bottom of the soil media for uniform distribution of flow. The aqueous solution of phenol of initial concentration of 10 mg/L and initial solution pH 6 was allowed to feed through the soil media under down flow mode at a constant flow rate of 1 mL/min. The constant flow was maintained with the help of a peristaltic pump. Before adsorption experiment, the soil beds were saturated with distilled water for 24 h. The desired influent phenol concentration and solution pH was the optimized values as evaluated in the batch process. The effluent samples were collected at specified time intervals for determination of residual phenol concentrations from the bottom of the column through a sampling port.

Theoretical models

Isotherm model

The adsorption isotherm study is useful to determine the adsorptive potential of soil for removal of phenol from wastewater. The Langmuir, Freundlich, and Redlich–Peterson isotherm models were tested for fitting with kinetic equilibrium experimental data.

Langmuir model (1918) was based on the assumption that the adsorption energy is constant and independent of surface coverage, adsorption occurs on a finite number of identical sites and maximum adsorption occurs when the surface is covered by a monolayer of adsorbate. The Langmuir isotherm equation is expressed as:

where Q max is maximum adsorption capacity at monolayer (mg/kg); b is constant related to the free energy of adsorption and a measure of affinity of binding sites (L/mg).

The Freundlich model (1926) was based on the assumption that adsorption occurs on a heterogeneous surface. The isotherm equation is expressed as follows:

where k f adsorbent capacity (mg/kg) and n adsorbent intensity (L/mg), respectively.

The Redlich–Peterson (1959) isotherm model has combined features of both Langmuir and Freundlich isotherms and expressed as follows:

where k R (L/kg), α R (L/mg) are Redlich–Peterson isotherm constants and β varies between 0 (Henry’s law equation) and 1 (Langmuir form).

Kinetic model

The adsorption kinetics describe the adsorption efficiency and solute uptake rate, which in turn governs the residence time of adsorption reaction (Srihari and Das 2009). The kinetics of adsorption of phenol onto peat soil were nonlinearly analyzed using pseudo-first-order, pseudo-second-order, and inter particle diffusion models.

Pseudo first-order kinetic model: a widely used Lagergren equation was applied to study the pseudo first-order kinetics (Tseng et al. 2003; Azizian 2004)

Integrating Eq. 8 between the limits from t = 0 to t = t and from q t = 0 to q t = q t

where q e and q t are the amounts of phenol adsorbed at equilibrium and at time t in mg/, respectively, k 1 is the first-order rate constant (h−1kg).

Pseudo second-order kinetic model: the adsorption data were analyzed by second order kinetic model (Tseng et al. 2003; Azizian 2004)

Integrating above equation, we get

where k 2 is the second-order rate constant (kg/mg h).

Inter particle diffusion model: Weber and Morris (1963) developed the inter particle diffusion model to describe the diffusion mechanism and rate controlling steps that affects the adsorption process. According to this theory, the inter particle diffusion equation is expressed as follows:

where k P is inter particle diffusion rate constant (mg/kg h1/2); C is intercept (mg/kg).

The kinetic coefficients were obtained by fitting the model with the test data and using a nonlinear regression analysis. The value of C gives an idea about the boundary layer thickness. The higher value of C means a higher contribution of surface sorption in rate controlling step.

Column breakthrough model

In the present study, four mathematical models such as Adams–Bohart, Thomas, Yoon–Nelson, and Wolborska models were considered to predict the dynamic behavior of the column and also to estimate some kinetic parameters of the models. The models are summarized below.

Adams–Bohart model

This model was established based on surface reaction theory and it assumed that equilibrium is not instantaneous; therefore, the rate of the sorption is proportional to the fraction of sorption capacity still remains on the sorbent (Goel et al. 2005). The expression of the model is:

where c 0 is influent solute concentration (mg/L); c is effluent solute concentration (mg/L); k BA is kinetic constant (L/mg h); q BA is maximum volumetric sorption capacity (mg/L); v is linear flow rate (cm/h); and H is bed depth of soil in column (cm).

Thomas model

The Thomas model is widely used to explain the dynamic behavior of adsorption in the fixed bed column. It is based on the assumption that the adsorption process follows Langmuir kinetics of adsorption–desorption with no axial dispersion. The model behavior matches with the second-order reversible reaction kinetics (Thomas 1944). The expression for the model for an adsorption column is given by the following equation:

where k Th is Thomas rate constant (L/mg h); Q is flow rate (L/h); m is mass of the soil bed (g); c 0 is initial influent concentration (mg/L); q Th is maximum concentration of the solute in the solid phase (mg/g).

Yoon–Nelson model

Yoon and Nelson (1984) have developed a relatively simple model for a single component system. The following expression represents the model:

where k YN is rate constant (h−1); τ is time required for 50 % solute adsorbance (h).

Wolborska model

Wolborska (1989) proposed a model that describes adsorption dynamics using mass transfer phenomenon for the diffusion mechanism for low concentration range of breakthrough curves. The equation of the model is represented as follows:

where β a is kinetic coefficient of external mass transfer (h−1); q w is maximum volumetric sorption capacity (mg/L); and the other symbols have their usual meaning.

The experimental data are fitted with all the four models as described above to determine the model kinetic parameters using nonlinear regression analysis in SPSS 17 statistical software. The model performance was evaluated using R 2, root mean square error (RMSE), and mean absolute performance error (MAPE) values as suggested by different investigators (Yilmaz and Yüksek 2009; Cabalar et al. 2010; Jalalifar et al. 2011). These predictive indices were calculated by using the following equations:

where y pre and y exp are the predicted and measured values of the phenol concentration ratio (c/c 0), respectively; \( \overline{y} \) term represents the average values of related y; n is the total number of observations.

Results and discussions

Adsorption isotherms

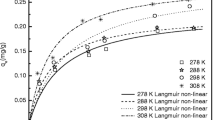

The experimental data were plotted according to the above mentioned three isotherm models and shown in Fig. 3. The coefficient of the models, R 2, RMSE, and MAPE values are also determined using nonlinear regression analysis and exhibited as summarized form in Table 2.

It can be observed from Fig. 3 and Table 2, all the isotherm models are reasonably fitted to the test data with higher coefficients of determinations and lower error values. However, the Langmuir isotherm model fits best as per the highest R 2 (0.91), lower RMSE (1.6625) and MAPE (13.15 %) values. The test results indicated that the phenol adsorbs onto peat soil as a monolayer adsorption. The shape of the Langmuir isotherm was estimated by the dimensionless separation factor (R L) using the following equation:

where c 0 and b having usual meaning described earlier. The calculated R L = 0.57 (0 < R L < 1) indicates that the phenol adsorption process on peat soil is favorable.

Effect of adsorbent dosage

The amount of phenol removal from the synthetic solution as a function of adsorbent dosage are plotted in Fig. 4. The adsorbent dosage were varied from 50 to 250 g/L for an initial phenol concentration of 10 mg/L. It is evident from the Fig. 4 that the phenol removal was found to be increased with the increase in adsorbent dosage up to a certain limit and then leveled off. It can be attributed from the trend of plotting that with the increased amount of adsorbent dosage, the surface area of the adsorbent increases resulting in a higher percentage of phenol removal. After reaching limiting equilibrium condition, an overlapping of active sites prevailed at higher dosage and with the decrease in effective surface area resulting in the conglomeration of exchanger particles (Tahir 2005). In the present work, it is observed that the maximum phenol removal efficiency is achieved at 200 g/L adsorbent dose with a 6 h contact time. Hence, 200 g/L was considered as optimum adsorbent dose and to be used for further study.

Effect of initial phenol concentration

The effect of initial phenol concentration on phenol removal is shown in Fig. 5. In this experiment, the initial phenol concentration was varied from 5 to 20 mg/L for an optimum adsorbent dose of 200 g/L. From the Fig. 5, it was observed that the percentage removal of phenol increases with the increase in phenol concentration up to 10 mg/L and then decreases. Due to the increase of initial phenol concentration higher amount of phenol adsorbed on the surface of adsorbent because of the higher concentration gradient. The large amount of adsorbed phenol is thought to have an inhibitory effect on further adsorption on adsorbent surface. Hence 10 mg/L of initial phenol concentration was considered to be optimum condition in the present study.

Effect of contact time on adsorption

To explore the removal efficiency of adsorbent accurately, it is important to consider sufficient contact time for the experimental solution to attain equilibrium. The effect of contact time on the removal of phenol by peat soil at optimized initial phenol concentration (10 mg/L) for varying adsorbent dosage are plotted in Fig. 6. It was observed from Fig. 6 that the phenol removal efficiency gradually ascending with increasing contact time up to 6 h. A further increase in contact time shows a negligible effect on the amount of phenol adsorbed. Thus, adsorbent–adsorbate reaction attains equilibrium at a contact time of 6 h.

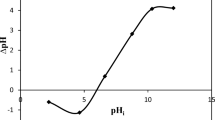

Effect of pH on phenol removal

The effect of pH on phenol removal by peat soil was investigated by varying pH of the solution in between two and ten. The test results are shown in Fig. 7. The removal of phenol at pH lower than 2.0 is found to be marginal and less perhaps due to high H+ concentration retards the adsorption process. The removal efficiency increases with the increase of pH from 2 to 6 and then found to be decreased with further increase of pH in the solution. So, pH 6 was considered as optimum pH level in the present study. A similar observation was reported by Viraraghavan and Maria Alfaro (1998) in their study on phenol adsorption using soil media.

Adsorption kinetics

Kinetic studies were conducted in a series of 250 ml glass stoppered flask with 100 mL solution with initial phenol concentration of 10 mg/L and the adsorbent dose of 200 g/L at pH 6 for an equilibrium time of 6 h.

Phenol adsorption on peat soil with respect to reaction time was analyzed using the three kinetic models mentioned above. The results as shown in Figs. 8 and 9 are for pseudo-first-order, pseudo-second-order and inter particle diffusion model, respectively. Table 3 exhibits the adsorption kinetic parameters. According to R 2, RMSE, and MAPE values, it can be depicted that the pseudo-first-order kinetic model (R 2 = 0.99, RSME = 0.7977, and MAPE = 6.25 %) explains the experimental data better than pseudo-second-order kinetic model (R 2 = 0.98, RSME = 1.0609, and MAPE = 5.46 %) and inter particle diffusion model (R 2 = 0.70, RSME = 3.8513, and MAPE = 20.85 %).

From the Fig. 9, it can be attributed that external surface adsorption or instantaneous adsorption occurs up to 2.5 h1/2 and thereafter adsorption becomes gradual. This indicated that the inter particle diffusion is rate controlled but there was some control of boundary layer as it can be seen from the value of C.

Application of mathematical models for prediction of breakthrough curves and determination of model kinetic parameters

The experimental results as obtained in adsorption columns of three different soil bed heights (5, 10, and 15 cm) at an initial influent concentration (10 mg/L) and initial solution pH (6.0) were applied to the four mathematical models (Adams–Bohart, Thomas, Yoon–Nelson, and Wolborska) and the corresponding kinetic coefficients were determined using nonlinear regression analysis. The predicted and experimental breakthrough curves with respect to bed height are shown in Fig. 10 and Table 4 illustrates the values of kinetic coefficients for each model used. To assess the prediction performance each model, the values of R 2, RMSE, and MAPE are also depicted in Table 4. Higher values of R 2 and lower values of RMSE, MAPE indicate a good fit of the model. By comparing the statistical parameters in Table 4, it is clear that the Thomas model adequately reproduces the experimental results for different bed height used.

Comparison of the predicted and experimental breakthrough curves obtained in adsorption columns at different bed heights at an influent phenol concentration of 10 mg/L, initial solution pH 6.0 and flow rate 1 ml/min according to studied models for phenol adsorption by peat soil. a Bed height = 5 cm; b bed height = 10 cm; c bed height = 15 cm

Conclusions

The present investigation demonstrated that peat soil can be used as adsorbent for removal of phenolic compound in contaminated groundwater. Under optimized condition, 42 % removal could be obtained for a soil dose of 200 g/L with an initial concentration of 10 mg/L of phenol. The equilibrium time of batch study was found to be 6 h at optimum pH level of 6.0. Kinetic analysis was performed with different nonlinear equations as proposed by various scientists and adsorption trend followed pseudo first order reaction kinetics. In the column experiment breakthrough time was found to be 6 h for smaller height of soil bed, however, the removal was significantly improved at greater height. The column experiment data were fitted in Adams–Bohart, Thomas, Yoon–Nelson, and Wolborska model to determine the kinetic parameter of the models using nonlinear regression technique. The Thomas model was found best fit for the column breakthrough results based on the highest coefficient of determination, R 2 = 0.99 and lower error values. The experimental results were also analyzed using Langmuir and Freundlich and Redlich–Peterson isotherms. Most of the isotherm models are reasonably agreeable to the test data with higher coefficients of determinations and lower error values. However, the Langmuir isotherm model provided the best fit of the test data based on the highest coefficient of determination, R 2 (0.91), lower RMSE (1.6625), and MAPE (13.15 %) values which signifies a monolayer adsorption phenomenon exists between peat soil and solute as phenol. The adsorption capacity of peat soil was determined as 42.624 mg/kg. It is also suggested that necessary laboratory and pilot plant scale studies would be undertaken in future to validate the different parameters as considered to apply in real life wastewater.

References

APHA-AWWA-WPCF (1998) Standard methods for the examination of water and wastewater, 20th edn. American Public Health Association, Washington

ATSDR (1998) Toxicological profile for phenol. Agency for toxic substances and disease registry, US Department of Health and Human Services, Public Health Service, Atlanta, GA

Azizian S (2004) Kinetic models of sorption: a theoretical analysis. J Colloid Interface Sci 276:47–52

Belarbi H, Al-Malack MH (2010) Adsorption and stabilization of phenol by modified local clay. Int J Environ Res 4(4):855–860

Bhat DJ, Bhargava DS, Panesar PS (1983) Effect of pH on phenol removal in moving media reactor. Indian J Environ Health 25:261–267

Cabalar AF, Cevik A, Gokceoglu C, Baykal G (2010) Neuro-fuzzy based constitutive modeling of undrained response of Leighton Buzzard sand mixtures. Expert Syst Appl 40:14–33

Cerato AB, Lutenegger AJ (2002) Determination of surface area of fine-grained soils by the ethylene glycol monoethyl ether (EGME) method. Geotech Test J 25(3):1–7

El-Khaiary MI, Malash GF, Ho YS (2010) On the use of linearized pseudo-second-order kinetic equations for modeling adsorption systems. Desalination 257:93–101

Freundlich H (1926) Colloid and capillary chemistry. Matheun and Co. Ltd., London

Froehner S, Martins RF, Furukawa W, Errera MR (2009) Water remediation by adsorption of phenol onto hydrophobic modified clay. Water Air Soil Pollut 199:107–113

Goel J, Kadirvelu K, Rajagopal C, Kumar Garg V (2005) Removal of lead (II) by adsorption using treated granular activated carbon: batch and column studies. J Hazard Mater 125(1–3):211–220

Ho YS (2004) Selection of optimum sorption isotherm. Carbon 42:2115–2116

Ho YS (2006a) Isotherms for the sorption of lead onto peat: comparison of linear and nonlinear methods. Pol J Environ Stud 15:81–86

Ho YS (2006b) Second-order-kinetic model for the sorption of cadmium onto tree fem: a comparison of linear and nonlinear methods. Water Res 40:119–125

Hong S, Wen C, He J, Gan F, Ho YS (2009) Adsorption thermodynamics of methylene blue onto bentonite. J Hazard Mater 167:630–633

IS 2720: Part 22: 1972 methods of test for soils: determination of organic matter

IS 2720: Part 2: 1973 methods of test for soils: determination of water content

IS 2720: Part III: Sect. 2: 1980 test for soils: determination of specific gravity—Sect. 2: fine, medium and coarse grained soils

IS 2720: Part 1: 1983 methods of test for soils: preparation of dry soil samples for various tests

IS 2720 : Part 4 : 1985 Methods of Test for Soils : Grain Size Analysis

IS 2720: Part 5: 1985 method of test for soils: determination of liquid and plastic limit

IS 2720: Part 26: 1987 method of test for soils: determination of pH value

Jalalifar H, Mojedifar S, Sahebi AA, Nezamabadi-pour H (2011) Application of the adaptive neuro-fuzzy interface system for prediction of a rock engineering classification system. Comput Geomech 38(6):783–790

Langmuir I (1918) Adsorption of gasses on plane surfaces of glass, mica and platinum. J Am Chem Soc 40:1361–1403

Li Ping, Xiu Guohua, Jiang Lei (2001) Competitive adsorption of phenolic compounds onto activated carbon fibers in fixed bed. J Environ Eng (ASCE) 127(8):730–734

Mitra PP, Pal TK (1994) Treatment of effluent containing phenol and catalytical conversion. Int Chem Eng 41(1):26–30

Mukherjee SN, Kumar S, Mishra AK, Fan M (2007) Removal of phenols from water environment by activated carbon, bagasse ash and wood charcoal. Chem Eng J 129:133–142

Nayak PS, Singh BK (2007) Removal of phenol from aqueous solutions by sorption on low cost clay. Desalination 207:71–79

Pal S, Adhikari K, Ghosh S, Mukherjee SN (2011) Characterization of subsurface water near an industrial wastewater disposal site. Int J Earth Sci Eng 04(06):437–441

Ratkowsky DA (1990) Handbook of nonlinear regression models. Marcel Dekker Inc., New York

Redlich O, Peterson DL (1959) A useful adsorption isotherm. J Phys Chem 63:1024

Singh DK, Mishra A (1990) Removal of phenolic compound from water using chemical treated saw dust. Indian J Environ Health 32:345–351

Sivanandam AV, Anirudhan TS (1995) Phenol removal from aqueous system by sorption on jack wood sawdust. Indian J Chem Technol 2:137

Srihari V, Das A (2009) Adsorption of phenol from aqueous media by an agro-waste (Hemidesmus indicus) based activated carbon. Appl Ecol Environ Res 7(1):13–23

Taha MR, Leng TO, Mohamad AB, Kadhum AAH (2003) Batch adsorption tests of phenol in soils. Bull Eng Geol Environ Earth Environ Sci 62:251–257

Tahir H (2005) Comparative trace metal contents in sediments and liquid wastes from tanneries and the removal of chromium using zeolite 5A. Electr J Agric Food Chem 4(4):1021–1032

Thomas HC (1944) Heterogeneous ion exchange in a flowing system. J Am Chem Soc 66(10):1664–1666

Tseng RL, Wu FC, Juang RS (2003) Liquid-phase adsorption of dyes and phenols using pinewood based activated carbons. Carbon 41:487–495

Viraraghavan T, Maria Alfaro F (1998) Adsorption of phenol from wastewater by peat, fly ash and bentonite. J Hazard Mater 57:59–70

Weber WJ, Morris JC (1963) Kinetics of adsorption on carbon from solution. J Sanit Eng Div 89:31–60

WHO (1997) Guidelines for drinking-water quality, health criteria and other supporting information. vol 2, World Health Organization, Geneva

Wolborska A (1989) Adsorption on activated carbon of p-nitrophenol from aqueous solution. Water Res 23:85–91

Yilmaz I, Yüksek AG (2009) Prediction of strength and elasticity modulus of gypsum using multiple regression, ANN, ANFIS models and their comparison. Int J Rock Mech Min Sci 46(4):803–810

Yong RN, Desjardins S, Farant JP, Simon P (1997) Influence of pH and exchangeable cation on oxidation of methylphenols by a montmorillonite clay. Appl Clay Sci 12:93–110

Yoon YH, Nelson JH (1984) Application of gas adsorption kinetics. Part 1. A theoretical model for respirator cartridge service time. Am Ind Hyg Assoc J 45:509–516

Acknowledgments

The authors are thankful to the Director, National Institute of Technology, Durgapur-713209, West Bengal, INDIA, for providing necessary assistance for carrying out the present research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pal, S., Mukherjee, S. & Ghosh, S. Nonlinear kinetic analysis of phenol adsorption onto peat soil. Environ Earth Sci 71, 1593–1603 (2014). https://doi.org/10.1007/s12665-013-2564-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12665-013-2564-z