Abstract

High amounts of granitic powders are produced in the granite industry in Galicia (NW Spain), whose accumulation could pose environmental threats, at least locally. Due to its natural alkalinity, the powder could be used to correct the acidity of soils or mining residues, where it would act at the same time as a source of plant nutrients. A greenhouse experiment was conducted to test the growth of Italian ryegrass on an acid soil amended with different rates of granitic powder (2.5, 5 and 10 %). Soil amended with lime or with lime in combination with P–K fertilizer, and the granitic powder alone, was used for comparison, with the unamended soil as control. After a growth period of 14 weeks, the plants were completely removed and washed; dry weight yield was recorded for roots and shoots, and their contents in nutrients and heavy metals were determined. Cation exchange capacity (CEC), pH, total C and N, nutrient elements and heavy metals were also determined in soil samples. The addition of granitic powder ameliorated the soil conditions for plant growth, with increments in soil pH, CEC and available nutrients, as well as a reduction of aluminium saturation. As a consequence, a significant increment in plant yield at increasing granitic powder rates was observed in comparison to the other amendments (up to 75 % higher than in the soil without amendment). The results of this study allow considering granitic powder as a suitable alternative to the traditional lime-based amendments for acid soils.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The granite industry in Spain is one of the most important in Europe, and more than 90 % of the national production is located in the small region of Galicia (NW Spain). In recent years, there has been a large expansion of the granite processing industry in this region, and the export of granite blocks has been superseded by the export of manufactured products. During the production process of granite blocks, a waste known as granitic powder or granite dust is produced in the form of a slurry formed by water, rock particles, and remains of calcium hydroxide and other additives included in the abrasive mixture. The slurry is collected in a deposit from which it is pumped into settlement tanks. Afterwards, the thick slurry is transported to storage ponds where it is air-dried before dumping. The disposal of this waste is a serious problem for the production companies because of the large volume generated. The volume of wastes produced and the practice of dumping them directly onto soil produces the sealing of potentially productive soils, and even if no further chemical risks exist in this case, this is a significant problem of environmental degradation in mining areas.

Until now, no viable way for reusing the granite powder has been developed. However, previous studies have revealed that crushed rocks may provide a source of nutrient elements that are released to the soil, and their use is especially recommended in highly weathered soils under tropical or humid environments (Gillman 1980; Chesworth et al. 1983, 1989; Leonardos et al. 1987; Sanz-Scovino and Rowell 1988; Bakken et al. 1997, 2000; Harley and Gilkes 2000; Suzi and Othon 2006). Granitic powder could act as a long term fertilizer thanks to its mineral constituents, primarily mica, which could provide nutrients during its weathering. Moreover, the natural alkalinity of grinded rock is enhanced by the remains of the Ca(OH)2 employed during the cutting process (Barral Silva et al. 2005). In this sense, it can be hypothesised that it might constitute an effective alternative to traditional liming materials for correcting the acidic pH of agricultural and forest soils, as well as in restoring mine soils, by combining its liming effect with the potential capacity to act as a source of nutrients. This potential application has especial relevance in the region of Galicia (NW Spain), where acid soils with a low nutrient status predominate, as a consequence of the siliceous nature of the geological substrata and high rainfall (Guitián and Muñoz 1960; Muñoz and Guitián 1962). Consequently they are poor in basic cations, such as Ca or Mg, and present high Al saturation which can reach phytotoxic levels. To counteract this effect, agricultural soils are routinely limed to maintain the pH within a range suitable for growing crops. Other essential elements as P or K are poorly available in these soils, mainly due to their fixation on soil components (Trasar-Cepeda et al. 1990). Furthermore, large extensions of mine soils exist in Galicia affected by acidity as a result of sulphide oxidation, whose restoration usually requires the addition of amendments to correct acidity. These materials are associated with lignite deposits (Leirós et al. 1995; Monterroso and Macías 1998) or originated from the exploitation of pyritic materials and other metal sulphides (Calvo and Pérez 1994). Then, two important advantages would be derived from the reuse of granitic powder as a soil amendment: (1) saving costs by reducing lime requirements in agricultural areas or in restoration labours, and (2) reducing soil degradation in non-cultivated areas.

The aim of the present study is to investigate the possibilities for the reutilization of this material as an amendment and fertilizer in acid agricultural or forest soils. To meet this objective, a greenhouse experiment was conducted, where the effects of the addition of different rates of granite powder on the plant productivity of an acid soil were studied. The results were also compared to those obtained using of lime as a fertilizer (with or without addition of P and K fertilizer).

Materials and methods

Granitic powder

The granitic powder used in the experiment was provided by the Centro Tecnolóxico do Granito de Galicia in Porriño (province of Pontevedra, Galicia, Spain). This kind of materials has been previously characterised (Barral Silva et al. 2005). The industries in this area mainly use local adamellitic granites, with quartz, abundant biotite and equivalent proportions of potassium feldspar and plagioclase, as well as granodiorites and biotite–amphibole granites, with less potassium feldspar than plagioclase, and biotite as the principal mica (IGME 1981). The granite powder was air-dried and sieved using a 2 mm mesh sieve; the fraction retained on the mesh was negligible. The general analyses were carried out according to the methods described by Guitián and Carballas (1976). The pH was measured in water and in 0.1 M KCl (1:2.5 powder:solution ratio), and the electrical conductivity (at 25 °C) in an aqueous extract (1:1 powder:solution ratio). Textural analysis was carried out by the international method, quantifying the sand (>50 μm), silt (2–50 μm) and clay (<2 μm) fractions. To determine the total content of those constituents of the granite powder that were expected to have a pH buffering effect or pose an environmental risk, the ground samples (<50 μm) were digested with HNO3, HF and H3BO3 in pressure digesters at 120 °C. Ca, Mg, Fe, Al, Mn, Cu, Zn, Pb, Cr and Ni were measured in the extracts by flame atomic absorption spectrometry, and Na and K by emission spectrometry (Varian SpectraAA 220FS).

Soil

The soil used for the pot experiment was taken from the topsoil (0-10 cm of the Ah horizon) of a Cambic Umbrisol (alumic, pachic) (FAO 2006) developed on granite, under heath vegetation and collected in Monte Meda, 20 km south of Santiago de Compostela (Galicia, NW Spain). This soil is representative of the natural soils of Galicia developed over granitic materials, which are characterised by a high organic C content, with high acidity, low effective cation exchange capacity (ECEC), high Al saturation, and deficiency of most major nutrients (Macías and Calvo 2001). The soil was characterised using the methods described by Guitián and Carballas (1976); it had a loamy sand texture (71 % sand, 16 % silt, 13 % clay), acidic pH (pH in water 4.6; pH in KCl 4.0), a high total organic carbon concentration (52.5 g kg−1), and a high value for exchangeable Al (2.8 cmolc kg−1), which dominated the exchange complex (85 % Al saturation). Regarding the mineralogy, the main crystalline minerals on the clay fraction are degraded micas (illite), gibbsite, kaolinite and interlayered mica-vermiculite with minor amounts of hydroxyaluminic vermiculites (Calvo et al. 1981).

Greenhouse experiment

Pot experiments were conducted to test the effects of the granitic powder on the fertility of the soil. For the experiments, the following treatments were assayed:

-

(S) Control. Soil without any treatment.

-

(L) Soil limed with CaCO3. 92 mg kg−1 of Ca (about 2.3 t ha−1 of CaCO3). The quantity of lime was calculated to reduce Al saturation of the exchange complex to values under 60 %, which is regarded as the limit for Al toxicity in soils (Mombiela and Mateo 1984).

-

(LF) Soil limed and fertilized with PO4H2K. The same rate of lime as in the L treatments, plus 192 mg kg−1 of PO4H2K (44 mg kg−1 of K and 55 mg kg−1 of P, roughly equivalent to about 100 kg ha−1 of P2O5 and 66 kg ha−1 of K2O, usual rates employed in cultivated soils in the area).

-

(SG) Increasing quantities of the granite powder were added to the soil: SG1 (25 g kg−1), SG2 (50 g kg−1), SG3 (100 g kg−1). These quantities are roughly equivalent to additions of about 25, 50 and 100 t ha−1 of granite powder, respectively, considering its incorporation to soil to a depth of 10 cm.

-

(G) Granitic powder without any treatment, aiming to test if this material was capable of sustaining vegetation by itself.

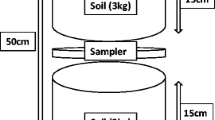

For each treatment, three pots containing 1,100 g of amended or unamended soil were prepared and transferred to the greenhouse. The pots were maintained at field capacity during 15 days before sowing, in order to facilitate the interaction of the components and the beginning of nutrient solubilisation. The pots were then sown with Lolium multiflorum Lam. (three seeds cm−2). Throughout the 14 weeks of the experiment, the moisture of all pots was maintained near field capacity using deionised water. The first harvest was done 6 weeks after sowing; plant shoots were cut at 4 cm from the surface and dry weights were recorded. Finally, after 14 weeks in the greenhouse, plants were entirely harvested, separating the above ground plant material and the roots. The roots were carefully washed with deionised water, and plant material was oven-dried (70 °C, 48 h) and weighed. At the end of the experiment, the soil of the pots was homogenised and air-dried before the analyses.

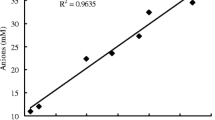

Soil analysis

The following physicochemical analyses were carried out in the soils: total C and N were determined in a LECO-SC32 analyzer. pH was determined in a water suspension and in 0.1 M KCl, using a 1:2.5 sample:solution ratio (Guitián and Carballas 1976). Exchangeable base cations were extracted with 1 M NH4Cl (Peech et al. 1947), and exchangeable Al was extracted in 0.1 M KCl (Lin and Coleman 1960). The effective cation exchange capacity (ECEC) was estimated as exchangeable base cations plus Al. Available Ca, Mg and K were extracted in 1 M NH4AcO at pH 7, which extracts the elements present in the soil solution, in exchangeable sites and associated to carbonates (Guitián and Carballas 1976). Al, Ca, Mg and K were measured in the extracts using flame atomic absorption/emission spectroscopy (VARIAN FS220). Available P was extracted in 0.5 M NaHCO3 following the method of Olsen and Sommers (1982), with colorimetric determination of the phosphomolybdic complex (VARIAN CARY100). Available Fe, Mn, Cu, Zn, Ni, Cr and Pb were extracted using an NH4AcO + EDTA solution (Lakanen and Erviö 1971), and measured in the extracts by atomic absorption spectroscopy (VARIAN FS220).

Plant analysis

To determine major and trace elements, the plant material was digested with concentrated HNO3 and H2O2. The digested material was filtered by ashless filter paper (Whatman nº40) and Ca, Mg, Fe, Mn, Al, Cr, Cu, Ni, Pb and Zn were measured using flame atomic absorption spectroscopy, and Na and K by flame atomic emission spectroscopy (VARIAN FS220).

Statistical analysis

The data were treated by analysis of variance (ANOVA) using the SPSS 13.0 statistical software package and significant differences were assessed by the Duncan’s test at p < 0.05. The results of the granite powder alone (G) were excluded from the statistical analysis, as it was not properly a treatment and it was only included for comparative reasons.

Results and discussion

Properties of the granitic powder

The granitic powder presented low electrical conductivity and alkaline pH (Table 1), which in a previous work was attributed mainly to the natural composition of the powders and not to the additives (Barral Silva et al. 2005). Given that the granitic powder is produced from the abrasion and crushing of the rock during cutting and polishing, we can assume that the value obtained for the pH will be similar to that of the abrasion pH, defined as the pH of a suspension of the finely ground material in distilled water. The abrasion pH is related, on one hand, to the chemical and mineralogical composition of the material, and on the other, to the physicochemical behaviour of the new surfaces created during the grinding process. The abrasion pH of rocks is usually alkaline because grinding produces an increase in the surface area that favours the dissolution of cations from mineral crystalline networks. The high pH values of the powder samples reflect the predominance of unweathered primary minerals, as confirmed by mineralogical analysis, which indicates that the mineral constituents of the powders are the main components of the granites from which they are produced, with a predominance of alkaline and calcoalkaline feldspars and slightly lower amounts of quartz and micas (Barral Silva et al. 2005).

The texture is silty loam, with the silt fraction representing almost 80 %. The predominance of silt in the granitic powder is common to other wastes originating during rock sawing: for example, this fraction lies between 46 and 69 % in processing fines from dolomite (Fraser and McBride 2000), and up to 80 % for slate processing fines (Paradelo et al. 2008). The composition of the powder is coincident with that typical of the granitic rocks from which it is originated (Taboada et al. 1990a, b), except for the concentrations of Ca, Fe and some trace elements which are higher in the granite powder. The differences found are explained by the use of metal fillings as abrasive products during the cutting process, and the addition of calcium hydroxide to avoid the appearance of iron oxide stains on the stone (Barral Silva et al. 2005). In comparison with the mean composition of natural soils developed over granites (Macías and Calvo 2008), the granitic powder has higher concentrations for Mn, Cu, Cr and Ni, also attributable to metal fillings employed during the cutting process.

The analysis of the composition of the granitic powder allowed making an estimation of its potential nutrient supply capacity in the different treatments assayed in the greenhouse experiment (Table 2). At the rates employed in this study, the granite powder provides high amounts of K and Ca, although its actual nutrient supply capacity will be strongly dependant upon the solubility of the forms in which the elements are present. Thus, it is expected that Ca presents a higher solubility than K and Mg, as an important fraction of it comes from the addition of Ca(OH)2.

Soil properties after the greenhouse experiment

Table 3 shows the pH values, C and N concentrations, and CEC of the soils after the greenhouse experiment, 14 weeks after seeding. The granitic powder produced a decrease of the total C and N concentrations of the soil, as expected having in mind that it was largely devoid of these elements. It can also be seen that the soil pH (in either water or KCl) was increased by approximately 0.3 pH units after the addition of CaCO3 (L) or CaCO3 and H2PO4K (LF), whereas the incorporation of the granite powder produced a stronger acidity correction. Thus, its addition at 50, 100 or 200 t ha−1 rates produced pH increments of 0.9, 1.2 and 1.8 pH units, respectively, bringing the soil pH to values considered optimum for plant growth. Concomitantly to the pH increment, both the exchangeable Al and Al saturation decreased in all treatments. In this sense, the granite powder was more effective than lime at the rates employed, and a progressive reduction of exchangeable Al was observed at increasing rates of granite powder. This acid-neutralizing effect of silicate rocks has already been pointed by other researchers (Sanz-Scovino and Rowell 1988; Hinsinger et al. 1996; Priyono and Gilkes 2008), and it has been investigated in detail for several granite powders by Barral Silva et al. (2005), who found that their acid-neutralizing capacity to pH 4.5 varied between 5 and 61 cmol H+ kg−1. In particular, the granitic powder employed for this study had the highest ANC value among all (61 cmol H+ kg−1). Also in this case, the presence of Ca(OH)2 in the composition of the powder have surely increased its acid neutralization potential.

The exchange complex was strongly dominated by Ca in the soil treated with granite powder, and by Al in the other treatments. The addition of CaCO3 (L), or CaCO3 and H2PO4K (LF), increased the exchangeable Ca, but did not affect the other exchangeable bases. In turn, the granite powder increased the exchangeable Ca, as well as Na, K and Mg, proportionally to the rate added. The highest increment due to the addition of the granite powder was that for Ca, followed by K, leading to the increment of the ECEC despite the reduction in exchangeable Al. These results are not totally coincident with those previously reported by other researchers. For example, Hinsinger et al. (1996) did not observe that soil exchangeable Na, Ca and Mg were affected by a 20 t ha−1 granite powder application, although a significant increase in exchangeable K was seen in nine out the 20 soils studied. The disagreement with our results can be attributed to the fact that, in our case, the granite powder presented an additional Ca source incorporated during rock processing, but also to differences in the properties of the soils studied.

Regarding the availability of plant nutrients (Table 4), after the plant growth experiment the soil available Ca concentrations were higher in all the treatments with respect to the control soil. The available Mg concentrations increased in the soil amended with the granite powder at any rate, but no effect was observed in the treatments with lime, whereas available K was only higher than the control at the two highest rates of granite powder. Finally, the granite powder did not affect the P availability in the soil. Although a significant increment of available P was observed in the soil amended with lime plus phosphate, it is surprising that this treatment did not achieve a greater increment of the P concentration, what can be attributed to the P-fixation problems common to many Galician soils (García-Rodeja et al. 1987; Trasar-Cepeda et al. 1990). When these results are compared to the potential nutrient supply of the granite powder deduced from their total nutrient concentrations (Table 2), it is evidenced the low availability of K, whereas a high percentage of the total Ca and Mg added was still available after the plant growth period. Other authors (Sanz-Scovino and Rowell 1988; Bakken et al. 1997, 2000) have already observed low availability of the K supplied as crushed rock products, although differences may exist depending on the K-bearing mineral: thus, biotite is a better K supplier than feldspar (Bakken et al. 2000). It has to be remarked the special behaviour observed for Mg, whose available concentration was higher in the soils amended with granite powder than in the granite powder itself. This fact could be explained as a consequence of the differences in pH between the soil and the powder. It is likely that most Mg remains unavailable in the granite powder, at pH 9.5, due to its low solubility at that alkaline pH; however, when added to the soil, a fraction of the total Mg will be available after dissolution at the acidic pH of the mixture, especially if it exists in the form of carbonates.

The potential negative effects derived from the application of granitic powder to soil must also be considered, and thus the concentrations of potentially toxic elements have been studied (Table 5). Overall, the treatments with lime reduced the total concentrations of the seven elements studied. In the treatments with granite powder, only Cu was increased, while the other total elements were not affected or they even decreased. None of the metals exceeded the concentrations considered to be phytotoxic (Kabata-Pendias and Pendias 1984). The treatments with lime did not produce any effect on the availability of heavy metals (Table 6), as indicated by their extractability in EDTA. In turn, the addition of the granite powder slightly increased the available Fe, Mn, Cu, and Ni concentrations, in general proportionally to the rate employed.

Plant properties after the greenhouse experiment

Table 7 shows the plant productivity of the soils in the greenhouse experiment. In the first harvest of aerial material, after 6 weeks of plant growth, significant differences already existed for plant productivity. The soils amended with granitic powder had higher productivities than the control soil and the soils amended with lime or lime plus phosphate, whose productivity was not statistically different. By the end of the experiment, similar results were obtained for the aerial part, with statistically significant differences between the soils amended with granitic powder and all the other treatments, and a progressive increment of productivity with the three rates of granitic powder. Regarding the root system, the soils amended with granitic powder or lime plus phosphate improved the results of the control, whereas the soil receiving only lime did not. The better results for plant productivity obtained in the soils amended with the granitic powder are presumably a consequence of the parallel improvements in pH, and available nutrients, as well as the reduction of exchangeable Al.

Table 8 shows the composition of the root material by the end of the experiment. The two treatments with lime had little or no effect on the composition in this case, whereas the granite powder induced an increment on the root uptake of Ca, Cu, Ni, and Fe, and a decrease in the root uptake of Zn and Al. Table 9 shows the composition of the aerial plant material (shoots) at the end of the experiment. The two treatments with lime, containing or not inorganic fertilizer, had little or no effect on the plant composition, except for Ca, whose uptake was increased. In turn, the granite powder induced an increment on the plant uptake of K, Mg and Mn, while it decreased the absorption of Zn, Fe and Al. It can be seen that the shoots had higher K, Ca, Mg, Mn and Pb concentrations than the roots in all treatments, whereas the Fe, Al, Zn and Ni concentrations were lower in the shoots. The addition of the granite powder also induced an increase of the ratios shoot/root for K and Mn with respect to the non-amended soil. The contrary was true for Ca, Ni, Fe, and Al, whereas for the other elements there was not a consistent effect compared to the results of the non-amended soil.

Ryegrass, as most monocotyledons, has a low demand for Ca, and a tissue Ca content of 0.7 g kg−1 may be enough for optimal growth (Marschner 1995). Thus it can be seen than Ca supply was sufficient in all treatments. Magnesium requirements for optimal plant growth are in the range 0.15–1.35 % of the dry weight of the vegetative parts (Marschner 1995), and it can be seen that plants grown in the soil treated with lime and lime plus fertilizer were close to deficiency. The addition of granite powder, in turn, produced Mg concentrations in plant tissue that are indicative of optimum Mg supply. Requirements for K are higher than for Ca and Mg, reaching 2–5 % of the dry weight of the vegetative parts. The same as for Mg, the addition of the granitic powder led to plant K concentrations indicative of optimum supply, whereas the plants grown in the other treatments presented concentrations which could not be sufficient. These results globally agree with those reported in the literature, where several authors observed the K-supply capacity of granitic powder by increments in tissue concentration (Swanback 1950; Coroneos et al. 1996; Hinsinger et al. 1996), although comparisons shall be with caution because of differences in the properties of the soils used in each study.

Conclusions

A greenhouse pot experiment was conducted to test the effects of the addition of different rates of granitic powder to an acid soil, in comparison with those of lime, with or without addition of P and K fertilizer. The results showed a significant increase in plant yield with increasing granitic powder doses in comparison to the other amendments, as well as an amelioration of the soil chemical conditions for plant growth. The granite powder corrected the acidic pH of the soil, increased available Ca, Mg and K, but not P, had no negative effects on the concentrations of potentially toxic elements, and increased plant productivity as well as plant uptake of major nutrients. Overall, the results of the greenhouse experiment demonstrated that the addition of the granitic powder not only increased the productivity of the soil, but also produced plants without nutrient deficiencies or toxicity due to trace elements. This study allows us to consider the granitic powder as a suitable alternative to the traditional lime-based amendments for acid soils, what should contribute to saving costs by reducing lime requirements in agricultural areas or in restoration labours, and reducing soil degradation due to uncontrolled dumping of these wastes.

References

Bakken AK, Gautneb H, Myhr K (1997) The potential of crushed rocks and mine tailings as slow-releasing K fertilizers assessed by intensive cropping with Italian ryegrass in different soil types. Nutr Cycl Agroecosyst 47:41–48

Bakken AK, Gautneb H, Sveistrup T, Myhr K (2000) Crushed rocks and mine tailings applied as K fertilizers on grassland. Nutr Cycl Agroecosyst 56:53–57

Barral Silva MT, Silva Hermo B, García-Rodeja E, Vázquez Freire N (2005) Reutilization of granite powder as an amendment and fertilizer for acid soils. Chemosphere 61:993–1002

Calvo R, Pérez JL (1994) Soils affected by acid mine waters in Galicia (NW Spain). Water Air Soil Pollut 73:247–263

Calvo RM, Guitián F, Macías F (1981) Aspectos geoquímicos de la alteración de un granito de 2 micas en Galicia. Acta Científica Compostelana 18:287–313

Chesworth W, Macías-Vázquez F, Acquaye D, Thompson E (1983) Agricultural alchemy: stones into bread. Episodes 1983(1):3–7

Chesworth W, Van Straaten P, Semoka JMR (1989) Agrogeology in East Africa: the Tanzania–Canada Project. J Afr Earth Sci 9:357–362

Coroneos C, Hisinger P, Gilkes RJ (1996) Granite powder as a source of potassium for plants: a glasshouse bioassay comparing two pasture species. Fert Res 45:143–152

FAO (2006) World Reference Base for Soil Resources 2006. Food and Agriculture Organization of the United Nations, Rome

Fraser J, McBride RA (2000) The utility of aggregate processing fines in the rehabilitation of dolomite quarries. Land Degrad Dev 11:1–17

García-Rodeja E, Silva B, Macías F (1987) Andosols developed from non-volcanic materials in Galicia, NW Spain. J Soil Sci 38:573–591

Gillman GP (1980) The effect of crushed basalt scoria on the cation exchange properties of a highly weathered soil. Soil Sci Soc Am J 44:465–468

Guitián F, Carballas T (1976) Técnicas de análisis de suelos. Ed. Pico Sacro, Santiago de Compostela

Guitián F, Muñoz M (1960) Efecto del encalado en los suelos ácidos. An Edafol Agrobiol 19:261–270

Harley AD, Gilkes RJ (2000) Factors influencing the release of plant nutrient elements from silicate rock powders: a geochemical overview. Nutr Cycl Agroecosyst 56:11–36

Hinsinger P, Bolland MDA, Gilkes RJ (1996) Silicate rock powder: effect on selected chemical properties of a range of soils from Western Australia and on plant growth as assessed in a glasshouse experiment. Fert Res 45:69–79

IGME (Instituto Geológico y Minero de España) (1981) Mapa Geológico 1:50.000. IGME, Madrid, Spain

Kabata-Pendias A, Pendias H (1984) Trace elements in soils and plants. CRC Press, Boca Raton

Lakanen E, Erviö R (1971) A comparison of eight extractants for the determination of plant-available micronutrients in soils. Acta Agric Fenn 123:223–232

Leirós MC, Varela MC, Gil F, Trasar MC, Seoane S (1995) Los suelos de la mina. In: Guitián F (ed) Recuperación de las escombreras de la mina de lignitos de Meirama (A Coruña). Universidad de Santiago-Lignitos de Meirama, Santiago de Compostela, pp 125–158

Leonardos OH, Fyfe WS, Kronberg BI (1987) The use of ground rocks in laterite systems: an improvement to the use of conventional soluble fertilizers? Chem Geol 60:361–370

Lin C, Coleman NT (1960) The measurement of exchangeable aluminium in soils and clays. Soil Sci Soc Am Proc 24:444–446

Macías F, Calvo R (2001) Los suelos. In: Precedo Ledo A, Sancho Comíns J (eds) Atlas de Galicia. Consellería de Presidencia, Xunta de Galicia, Santiago de Compostela, pp 173–217

Macías F, Calvo R (2008) Niveles genéricos de referencia de metales pesados y otros elementos traza en suelos de Galicia. Consellería de Medio Ambiente e Desenvolvemento Sostible, Xunta de Galicia, Santiago de Compostela

Marschner H (1995) Mineral nutrition of higher plants, 2nd edn. Academic Press, London

Mombiela FA, Mateo ME (1984) Necesidades de cal para praderas en terrenos “a monte”. I) su relación con el Al cambiable en suelos sobre granitos y pizarras de Galicia. An INIA 25:129–143

Monterroso C, Macías F (1998) Drainage waters affected by pyrite oxidation in a coal mine in Galicia (NW Spain). Composition and mineral stability. Sci Total Environ 216:121–132

Muñoz M, Guitián F (1962) La necesidad de cal en los suelos de cultivo gallegos. An Edafol Agrobiol 21:473–480

Olsen SR, Sommers LE (1982) Phosphorus. In: Page AL (ed) Methods of Soil Analysis. Part 2. Chemical and microbiological properties. American Society of Agronomy, Madison, pp 403–430

Paradelo R, Moldes AB, Barral MT (2008) Characterization of slate processing fines according to parameters of relevance for mine spoil reclamation. Appl Clay Sci 41:172–180

Peech M, Alexander LT, Dean LA, Reed JF (1947) Methods of soil analysis for soil fertility investigations. USDA Circular

Priyono J, Gilkes RJ (2008) High-energy milling improves the effectiveness of silicate rock fertilizers: a glasshouse experiment. Commun Soil Sci Plant Anal 39:358–369

Sanz-Scovino JI, Rowell DL (1988) The use of potassium fertilizers in the savannah of Colombia. Fert Res 17:71–83

Suzi T, Othon T (2006) The use of rocks to improve family agriculture in Brazil. An Acad Bras Cienc 78:721–730

Swanback TR (1950) Granite stone meal as a source of potash for tobacco. Conn AES Bull 536:1–14

Taboada TM, Romero R, García Paz C (1990a) Weathering evolution of a biotite granite (El Pindo, Galicia, NW Spain). In: 2nd international symposium on geochemistry of the Earth’s surface and of mineral formation, Aix-en-Provence, pp 130–132

Taboada TM, Romero R, García Paz C (1990b) Relaciones entre dos índices de alteración: el índice de Parker y el pH de abrasión. In: Actas XVII Congreso Nacional de la Ciencia del Suelo, Badajoz, pp 75–78

Trasar-Cepeda MC, Gil-Sotres F, Guitián-Ojea F (1990) Relation between phosphorus fractions and development of soils from Galicia (NW Spain). Geoderma 27:139–150

Acknowledgments

This study was carried out as part of a research project developed through an agreement between the Universidad de Santiago de Compostela and the Asociación de Graniteros de Galicia, and was funded by the Consellería de Industria e Comercio of the Xunta de Galicia.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Silva, B., Paradelo, R., Vázquez, N. et al. Effect of the addition of granitic powder to an acidic soil from Galicia (NW Spain) in comparison with lime. Environ Earth Sci 68, 429–437 (2013). https://doi.org/10.1007/s12665-012-1747-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12665-012-1747-3