Abstract

The Standard Penetration Test (SPT) is one of the most frequently applied tests during the geotechnical investigation of soils. Due to its usefulness, the development of empirical equations to predict mechanical and compressibility of soil parameters from the SPT blow count has been an attractive subject for geotechnical engineers and engineering geologists. The purpose of this study is to perform regression analyses between the SPT blow counts and the pressuremeter test parameters obtained from a geotechnical investigation performed in a Mersin (Turkey) city sewerage project. In accordance with this purpose, new empirical equations between pressuremeter modulus (E M) and corrected SPT blow counts (N 60) and between limit pressure (P L) and corrected SPT blow counts (N 60) are developed in the study. When developing the empirical equations, in addition to the SPT blow counts, the role of moisture content and the plasticity index of soils on the pressuremeter parameters are also assessed. A series of simple and nonlinear multiple regression analyses are performed. As a result of the analyses, several empirical equations are developed. It is shown that the empirical equations between N 60 and E M, and N 60 and P L developed in this study are statistically acceptable. An assessment of the prediction performances of some existing empirical equations, depending on the new data, is also performed in the study. However, the prediction equations proposed in this study and the previous studies are developed using a limited number of data. For this reason, a cross-check should be applied before using these empirical equations for design purposes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

There are many direct procedures for determining the strength of rocks and soils (i.e., in situ plate loading test, dilatometer test, pressuremeter, flat jack test), but these procedures are both expensive and time consuming, and they require sophisticated testing equipment and skilled technical personnel. Due to the difficulties encountered during in situ tests, various empirical equations have been developed correlating in situ tests, laboratory tests and the geomechanical properties of the soil or rock. Numerous indirect equations have been proposed for predicting the deformation modulus of rock masses in the literature (e.g., Kayabasi et al. 2003; Gokceoglu et al. 2003; Sonmez et al. 2006). Recently, Lee et al. (2010) evaluated the deformation modulus of cemented sand using the cone penetration and dilatometer tests. According to their findings (Lee et al. 2010), the deformation modulus of cemented sands is underestimated when using the empirical relations previously suggested for uncemented sands. Thus, to obtain acceptable empirical equations for the deformability parameters of soils, new empirical equations are necessary, although it is possible to find various empirical equations developed for in situ and laboratory tests applied to soils (for e.g. Akça 2003; Sharma and Singh 2008). However, there is no commonly used empirical equation between the Standard Penetration Test (SPT) and the Menard pressuremeter test (MPT) parameters. Various tests have been carried out on Leucate and Dunkerque sands, and correlations performed by Cassan 1968–1969 have described an N/P L ratio of approximately 5 × 10−2 (Blow count/kPa) (Baquelin et al. 1978). Other studies have been carried out on the Devonian marl of Monmouthshire (G.B.) (Hobbs and Dixon 1969) and on the silty sands of the Blois region (Waschkowski 1974). A comparison shows that the coefficients proposed by different researchers have large scattering. The ratio of N/P L varies between 2 × 10−2 (Blow count/kPa) and 5 × 10−2 (Blow count/kPa). This is mainly due to the reaming effect. As a provisional recommendation, it is proposed that the ratio of N/P L should be equal to 2 × 10−2 (Blow count/kPa) for sands (Baquelin et al. 1978). No relationship is proposed for clays due to the very large scatter obtained from the SPT blow counts (Waschkowski 1974; Baquelin et al. 1978). However, the graphs of the abovementioned empirical approaches (Cassan 1968–1969; Hobbs and Dixons 1969; Waschkowski 1976) were given by Baquelin et al. (1978), and the statistical correlations, equations and regression constants were not given by the same authors (Baquelin et al. 1978). In this study, to evaluate these studies with same data on the graph, regression analyses are carried out, and the regression constants are determined (Table 1).

A linear correlation is determined between log P L and Log N, and between Log E M and Log N using the results of a pressuremeter test and SPT applied to a completely weathered granite of the northern and central parts of Hong Kong and the southern part of the Kowloon Peninsula (Chiang and Ho 1980). The relationship between the corrected SPT blow count (N cor) and the pressuremeter parameters (E M and P L) were investigated, and acceptable equations were obtained for sandy, silty clayish soils (Table 2) (Yagiz et al. 2008). Recently, Bozbey and Togrol (2010) studied the correlations between SPT and pressuremeter parameters. The authors (Bozbey and Togrol 2010) emphasised many difficulties arising from the disturbance of the soil, the drainage conditions and the level of strain during the drilling and testing processes. The proposed empirical equations for sandy and clayish soils have high coefficients of determination (Table 2).

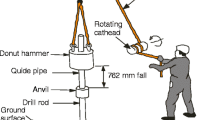

For foundation design analysis, pressuremeter tests and SPTs are widely applied in boreholes. The pressuremeter test is employed to determine the deformability and the strength parameters of stiff soil to soft rock. The concept of inflating a balloon-like device in soil and measuring deformability was proposed by Köegler in 1933 (Baquelin et al. 1978). Later, in 1957, Louis Menard developed a device called the Menard Pressuremeter (Baquelin et al. 1978). The Menard pressuremeter consists of three parts: the probe, the control unit, and tubing (Fig. 1a). Menard Deformation Modules (E M) and Limit Pressure values (P L) are determined from graphs obtained from the measurements (Fig. 1b). Both E M and P L parameters are used for the calculation of the settlement and bearing capacity, respectively, of foundation soil. For this test, various standards are recommended by ASTM (the ASTM Standard D 4719-87), Eurocode Standards (ENV 1997-3), French Standards (AFNOR NF P 94-110-1) (APAGEO 2006) and Turkish Standards (TSENV 1997-3). The SPT (Fig. 1c) was developed in 1927 (Bowles 1988). The related standards for SPT are ASTM D 1586 (Bowles 1988), BS 1377, Eurocode Standards (ENV 1997-3), and TS 5744 (Turkish Standard). SPT is a dynamic test performed for the determination of the strength parameters of silty, sandy and clayish soils and heavily weathered rock units. Raw blow counts (N) are obtained from the SPT. Then, groundwater correction, rod energy ratio correction, rod length correction, sample barrel correction and borehole diameter correction are applied, and the corrected blow count (N 60) is obtained. Pressuremeter test equipment is sophisticated and expensive. However, SPT is a practical test and is used widely. Both tests have an important intersection in application area. Thus, the estimation of the pressuremeter modulus and the limit pressure from SPT blow counts is useful to investigators. Estimating SPT blow counts from pressuremeter parameters may also be possible.

The application direction of the pressuremeter test is horizontal in a vertical borehole, whereas the SPT is applied vertically to the ground surface in a borehole. This direction difference does not create a problem for isotropic soil conditions. Several authors (Leischner 1966; Shields and Bauer 1975) have emphasised that in situ tests in vertical and horizontal boreholes give similar values of stiffness. Lee and Rowe (1989) determined that anisotropy has little influence on the settlement of vertical loading to the ground surface. Considering the results of these studies, it is possible to say that the vertical loading condition of the SPT results and the horizontal loading condition of the pressuremeter test may have little effect on the results. This effect could be eliminated with the requirement of the compared tests if the tests were applied at relatively similar depths.

In this study, data from an investigation of the foundation of a sewerage station in Mersin City (Turkey) are employed. The project site is located in the east of Mersin city, Turkey (Fig. 2). The location plan and a sketch of the drill holes are shown in Fig. 2. A total of 20 boreholes having a depth of 258.20 m in total were drilled according to the purpose of the investigation. Both pressuremeter tests and SPTs were applied in all of the boreholes. In total, 115 SPT and 69 pressuremeter tests were performed in the boreholes. The number of cases obtained from both the pressuremeter tests and SPTs is 52. The logs of the boreholes are given in Appendix A. Measurements show that groundwater level in the study area is at a depth of approximately 1.5 m from the surface. Groundwater corrections and other related corrections are applied on the SPT blow counts, and the N 60 values are determined. A series of laboratory tests are also performed on both disturbed and undisturbed soil samples to determine the properties of the foundation soil.

In situ testing

Pressuremeter tests were carried out using a GA-type Menard Pressuremeter. The diameter of the test zone was 66 mm. A pressuremeter probe with a diameter of 60 mm was inserted into the test zone, the selected pressures were applied, and the corresponding volumetric deformation values were recorded. To determine the soil elasticity parameters, these tests were applied at each 1-m zone. A total of 69 pressuremeter tests were completed. Pressure-volumetric deformation graphs were drawn, and Menard Deformation Modules (E M) and Limit Pressure Values (P L) were determined from these graphs. These values were correlated with the SPT results in the present study. The histograms of the E M, P L and SPT (N cor) values are given in Fig. 3. The mean value of the pressuremeter modulus (E M) is determined as 19.42 MPa. The minimum pressuremeter modulus value is 2.45 MPa, and its maximum value is 37.8 MPa. The other parameter obtained from the pressuremeter tests is the limit pressure. The mean, minimum and maximum values of the limit pressure (P L) are 1.57 MPa, 0.42 MPa, and 2.8 MPa, respectively. Baquelin et al. (1978) described the degree of soil consolidation with the E M/P L ratio as given in Table 3. The mean value of the E M/P L obtained in this study is approximately 12, which means that the foundation soil is normally consolidated. Clarke (1995) described soil consistency while considering the E M/P L ratio. According to this classification, ratio ranges between 10 and 20 correspond to stiff to very stiff consistency, while a range of 8–10 corresponds to a soft to firm consistency. When considering this classification, the investigated clayish foundation soil can be classified as stiff to very stiff consistency with an E M/P L ratio of 12. As mentioned previously, the tests were performed at each 1-m zone. However, conducting the SPT and the pressuremeter tests in the same borehole sometimes resulted in revision of the test zones. To avoid disturbing the soil, an approximately 1-m level difference was kept between the levels of SPT and the pressuremeter tests. The disturbed samples obtained from the SPT split barrel were transported to the EIE soil laboratory daily. The corrected SPT blow count (N 60) values vary from 6 to 29. According to the mean value of N 60 values (19), the clayish foundation material has a very stiff consistency with a 1.5–3.0 kg/cm2 unconfined compressive strength (Terzaghi and Peck 1968).

A series of undrained uniaxial strength tests were performed on the drill core using a hand penetrometer at the drilling site. Each uniaxial strength test value was obtained by averaging five different values taken from the same level of the drill core. A total of 105 records from different boreholes were taken and evaluated. The hand penetrometer test results can be summarised as having minimum, maximum and mean values of 0.24, 5, and 3.07 kg/cm2, respectively, with a standard deviation of 1.02 kg/cm2. These results showed that the clayish foundation soil material has a very stiff or hard stiff consistency (Craig 1987).

To determine the permeability coefficient of soil, constant head permeability tests, following ASTM standards (ASTM 1994), were applied in the four boreholes. According to the test results, the foundation material (clayish soil) is completely impermeable.

Laboratory testing

Laboratory tests were applied on both disturbed (SPT samples) and undisturbed samples taken from the boreholes. All of the samples were labelled and transported to the laboratory daily. The type and number of the laboratory tests applied could be summarised as follows: bulk unit weight (N = 38); sieve test (N = 43); Atterberg limits (N = 42); natural moisture content test (N = 105); direct shear test (CU) (N = 38); consolidation test (N = 14); and triaxial compression test (N = 3). All of the samples were collected and tested in accordance with the procedures suggested by ASTM (1994).

The bulk unit weight of fine-grained samples changes between 16.8 and 19.7 kN/m3 with a mean of 18.22 kN/m3 and a standard deviation of 0.79 kN/m3. According to the grain size distribution curves (Fig. 4), the soil samples employed consist of 74.9% fine-grained material (<#200 sieve) and 39.5% clay-sized material (USBR 1974). The fine-grained material is mainly high plastic clay (CH); the exceptions are 13 samples that are medium plastic clay (CL), closer to the 50% LL line, and 8 samples that are high plastic silt (MH) or high plastic organic material (OH) (Fig. 5). The liquid limits (LLs) vary between 45.5 and 82.9%, while the plastic limits (P L) change between 3.5 and 52.5%. The mean values of the liquid and plastic limits are 59.81 and 23.44%, respectively. The plasticity index (PI) ranges between 26.7 and 46.0% with a standard deviation of 6.4%. Clayish soil can be classified as plastic to highly plastic soil (Leonards 1962). The majority of the test results show that the liquid limit is greater than 50%, which indicates the presence of montmorillonitic clays, according to Means and Parcher (1963). The results of the natural moisture content tests show minimum, maximum, and mean values of 21, 55 and 34%, respectively, with a standard deviation of 8.19%. The mean activity of the clayish foundation soil is 1.46 with a minimum value 0.76 and a maximum value of 2.82. According to the activity classification proposed by Seed et al. (1964), the soil samples are active clay with a mean value of 1.46. Skempton (1953) classified soils according to activity. The activity value of montmorillonite changes between 1 and 7. The Ca montmorillonite amount increases to approximately 1; the Na montmorillonite amount increases with an increasing activity value to 7; the activity of illites is between 0.5 and 1; and the activity of kaolinite is near 0.5 (Mitchell 1975). According to this classification, the foundation soil can be classified as Ca montmorillonite. In addition, the X-ray analysis is applied on the specimen from the clayey soil studied. The results of the X-ray analysis show that the specimen is dominantly formed by the montmorillonite rich in calcium. The results obtained from both activity assessments and X-ray analysis show a good accordance.

The mean results of the values determined in situ and in the laboratory are shown as depth versus parameters (Fig. 6). As can be seen in Fig. 5, the SPT, E M, P L, C (Cohesion) and Ø (internal friction angle) values show a similar trend, while the moisture content (w %) and plasticity index (PI %) values exhibit an inverse trend. A clear influence of the moisture content on the pressuremeter parameters and penetration resistance is observed.

Regression analysis

Regression analyses have been used for a long time in environmental geology and geotechnics (e.g., Apte et al. 1999; Uddameri 2007; Benavente et al. 2007; Sivrikaya 2008; Iphar et al. 2008; Gunaydin 2009; Yagiz et al. 2009; Yagiz and Gokceoglu 2010; Chen-Chang et al. 2011). To conduct a safe regression analysis, our first condition was to have comparable data, which were obtained from the same borehole with testing levels at a range of 2 m. Fifty-two of 113 SPT data and 52 of 69 pressuremeter test data were selected as comparable data in this manner (Table 4). As a first stage, regression analyses were performed to obtain empirical relations between the pressuremeter modulus (E M) and the corrected SPT blow counts (N 60). The results of the regression analysis are shown in Table 5. The equation with the highest coefficient of the regression between N 60 and E M is represented by a power function (Fig. 7, Eq. 1). For a diagnostic check of this regression model, a residual analysis is applied (Fig. 8). According to this analysis, the Durbin Watson value is obtained as 2.238, and hence, the data exhibit no autocorrelation problem and no alternating variance problem.

The same procedures are applied for SPT (N 60) values versus Limit Pressure (P L) values (Table 6). The highest coefficient of the regression between SPT and P L is represented by a power function (Fig. 9, Eq. 2). A diagnostic check is also applied for this model. The Durbin Watson value is calculated as 2.1 (Fig. 10). Other problems, such as autocorrelation and alternating variance, are not encountered.

The root mean square error (RMSE) indices and values accounted for (VAF) are calculated to qualify the prediction performance of the equations for simple regression analysis, as performed by previous researchers (Alvarez Grima and Babuska 1999; Finol et al. 2001; Gokceoglu 2002; Gokceoglu and Zorlu 2004; Zorlu et al. 2008; Yagiz et al. 2009; Dagdelenler et al. 2011). An excellent prediction is represented with 0 in RMSE values and 100% in VAF values. The RMSE and VAF indices for each equation are tabulated in Table 7. According to these results (Table 7), the equation developed from this study gives the closest RMSE value to 0 and VAF value to 100%. The equation proposed by Bozbey and Togrol (2010) gives the second-best results, but the equation proposed by Yagiz et al. (2008) also gives acceptable results. The measured and estimated pressuremeter modulus values are shown in Fig. 11. The visual trend of empirical equations proposed by Yagiz et al. (2008) and Bozbey and Togrol (2010) yielded close results.

Using the N 60 values and the previously proposed equations for P L, the P L values are predicted. Figure 12 shows a correlation graph of all the empirical equations. The RMSE indices for each equation are calculated to make a relative comparison for the prediction performances of the existing equations (Table 8). According to these results, the equation proposed by Bozbey and Togrol (2010) and Waschkowski (1976) gives the second-best results, following the equation proposed in this study. It is possible to state that the other empirical equations also give acceptable results when considering the RMSE and VAF indices given in Table 8.

There is a problem in correlating the pressuremeter parameters with SPT due to the scattering of the pressuremeter parameters corresponding to the same SPT blow counts (Table 4). This problem can be explained by the behaviour of the soil under the test time; that is, the soil has a time for deformation during the pressuremeter test, but the soil could not deform due to the sudden falling of the hammer and the driving of a head in the soil. Therefore, the measured blow counts are of the resistance of the soil, not its deformability and plasticity during the application of the SPT test. A pressuremeter test takes at least 10 min, depending on the increasing pressure on the test material. The selected pressures are applied on borehole walls with time intervals. Thus, the stress strain and the strength behaviour of the material are characterised. The behaviour of the test material is much better determined by the pressuremeter test than the SPT. Both the moisture content and plasticity index results of the SPT samples, N 60 values, pressuremeter modulus (E M) and limit pressure values are graphed, and the curves of each parameter are inspected with a trendline (Fig. 13). The plasticity index (PI), E M and P L values show the same trend, while the moisture content values trend inversely with respect to other parameters. As the moisture content increases, the other correlated parameters generally decrease. The small changes of moisture content causes sudden changes of the pressuremeter parameter and plasticity index values; the SPT blow count trend line, however, is not influenced, and it trends smoothly.

The purpose of a pressuremeter test is to obtain the relationship between the applied pressure and deformation of the soil, whereas a SPT aims to determine the stiffness of the soils. Considering the characteristics of these tests, it is possible to state that the pressuremeter test is much more sensitive than the SPT in clayey soil. The moisture content variation influences the pressuremeter test results more rapidly than the SPT blow counts. These differences arise from the test time differences between tests. During SPT, clayey soil does not have enough time to deform. A pressuremeter test result is easily affected from the variation of consistency, and it produces more scattered data. These scattered data allow a detailed inspection of the material. The direct determination of elastic parameters from pressure–deformation curves also has an advantage with the pressuremeter test compared with the SPT. Long-term deformation properties of clayey soils are important for engineering structures; hence, the pressuremeter test in clayey soils for geotechnical investigations can be advised.

In the second stage of the statistical studies, the relations between the pressuremeter parameters (E M and P L) with the SPT and moisture content are evaluated together. The first step is to define the SPT and the w% as the function of pressuremeter parameters:

A simple regression analysis between the measured pressuremeter modulus (E M) with the moisture content (w%) gives Eq. (5) with a logarithmic relationship (Fig. 14). The nature of this relationship shows that the non-linear multiple regression is more suitable than the linear multiple regression. Similar procedures were followed by Yagiz et al. (2009); Gokceoglu et al. (2009) and Dagdelenler et al. (2011) when developing multiple regression equations.

The combination of Eqs. 1 and 5 can be defined as follows:

A, B, C and D are the coefficients of the nonlinear multiple regression equation. The following equation for predicting the pressuremeter modulus is obtained by applying a nonlinear regression analysis using a statistical computer programme (SPSS 2002);

The coefficient of determination (R 2) between E M(measured) and E M(predicted) from Eq. (6) is 0.72, which is nearly the same coefficient of determination as Eq. (1) (Fig. 15).

The correlation of the measured limit pressure (P L) and the moisture content (w %) gives the following equation (Fig. 16):

The combination of Eqs. 2 and 8 can be expressed with the following equation:

A, B, C, D and E are the coefficients of the equations. Eq. (10) is obtained by employing a nonlinear statistical regression analysis.

The P L(predict) data derived from Eq. (10) and the P L (measured) values correlated with the basic regression analysis results in a regression coefficient (R 2) of 0.77, which is nearly the same as the coefficient of determination of Eq. (2) (Fig. 17).

The third stage of the statistical studies was the incorporation of the plasticity index data into the equations. The correlation of pressuremeter parameters (E M and P L) with the SPT blow counts, moisture content and plasticity index data comprises this step. For this purpose, the pressuremeter parameters are defined as a function of three variables as follows:

First, the plasticity index is correlated with the measured pressuremeter modulus data, and Eq. (13) has a coefficient of determination (R 2) equal to 0.56 (Fig. 18).

The combination of Eqs. (1), (5) and (13) results in Eq. (14), where A, B, C, D, E and F are the coefficients of the equation.

Performing the nonlinear analysis with three variables versus the measured pressuremeter modulus gives Eq. (15):

The coefficient of determination (R 2) between E M(measured) and E M(predicted) from Eq. (15) is 0.79, which is greater than the coefficients of determination of Eqs (1) and (5) (Fig. 19).

Second, the measured limit pressure (P L) is correlated with the plasticity index (PI) values. Eq. (16), with a logarithmic relationship, is determined from simple regression analysis (Fig. 20).

The combination of Eqs. (2), (10) and (16) results in the following equation:

A, B, C, D, E and F are the coefficients of Eqs. (2), (10) and (16). Performing a nonlinear analysis with three variables versus the measured limit pressure (P L) gives Eq. (18):

The coefficient of determination (R 2) between P L(measured) and P L(predicted) from Eq. (18) is equal to 0.84, which is greater than the coefficients of determination of Eqs. (2) and (10) (Fig. 21).

Table 9 summarises the empirical equations derived in this study. The value of regression coefficients approaches 1 when the plasticity index and moisture content parameters are added to the limit pressure equation, but the same results cannot be derived for the equations of the pressuremeter modulus. The high regression coefficients in all the equations are noteworthy. In fact, the main parameter controlling E M and P L is the N 60. The increase in input parameters does not dramatically increase the model performance. However, the deformability and strength parameters of soils are strongly affected by their physical states. For this reason, the multiple regression equations, including moisture content and the plasticity index, are important because they represent the physical state of the soils. In practical use, the simple regression equation including only N 60 can be used. However, if the user has additional parameters, such as the moisture content and the plasticity index, then the results can be controlled by employing the multiple regression equations.

Results and discussions

SPT and the pressuremeter test are widely used in in situ borehole tests. Both tests can be applied to fine-grained soils. The pressuremeter test can also be applied in other soils and in poor to good quality rocks. The main role of an engineer is to solve the problems in the most scientifically and economically sound way. Therefore, a determination of the necessary parameters from the applied tests is both scientific and economic for an engineer. The main purpose of this study is to propose empirical equations between N 60 and E M and N 60 and P L as well as to test other empirical equations related to this subject.

In this study, data obtained from a geotechnical investigation of a sewerage station foundation in Mersin (south of Turkey) were used. The foundation area consists of mainly clayey soils. A series of boreholes were drilled, and in situ and laboratory tests were performed. The SPT and pressuremeter test data, which were obtained from the same borehole and at approximately the same metres of depth, were correlated statistically. Regression analyses between E M and N 60 and P L and N 60 were performed, and significant results were obtained with high regression coefficients. The regression analyses were carried out in three steps. In the first step, E M and N 60 as well as P L and N 60 values were correlated, and a good prediction performance was determined. The relationships between moisture content (w%), plasticity index (PI) and pressuremeter parameters were determined with simple regression analysis. In the second step of the regression analysis, the moisture contents were added to the equations as a second variable with N 60 values, which resulted in a better performance relative to the first step of the statistical analysis. In the third step, the PI values were also added in the equations, and empirical equations estimating pressuremeter parameters from N 60 values, moisture content (w%) and the plasticity index (PI,%) were developed. All of the derived equations have high regression coefficients. The performance of previous empirical equations was also tested with the SPT blow counts of this study, and the estimated E M and P L values of the previous equations were correlated with the measured E M and P L values of this study. The results were also found to be within acceptable limits.

During the correlation of results obtained from two different tests, one must be aware of the following disadvantages: errors arising from technicians (during boring and testing); differences of testing equipment; calibration differences of testing equipment; mistakes in the evaluation of test results; and the different conditions of the soils and boreholes. Another main disadvantage is the scarcity of data. Despite these disadvantages, the empirical equations in this study result in high regression coefficients. To interpret one empirical equation as the general equation, countless data must be correlated. As mentioned previously, all of the SPT and pressuremeter data should be obtained from nearly the same level, and the same lithologies must be grouped. The same statistical analysis must be carried out on these numerous parameters by a group of experts, and a general equation that could be acceptable by all engineers must be evaluated. Otherwise, every project could produce independent empirical equations derived from their own data correlations.

The empirical equations presented in this study do not represent a general correlation equation between SPT and pressuremeter tests because the amount of data obtained was limited due to the majority of the soils only being a part of the CH group. The deformational and mechanical parameters of the soils are considerably controlled by the mineralogical and textural characteristics and the water content. Depending on the water content, the physical state of a clayey soil can change. For the characterization of the physical state of the clayey soil employed in the present study, the PI and water content are used as the input parameter during the multiple regression analyses. However, even with the limitations of the approach, the empirical equations introduced in this study may be useful for the preliminary design stages of civil engineering projects. If pressuremeter parameters are needed and only SPT blow counts are in hand, all empirical equations can be used, and the E M and P L values can be derived or vice versa. However, the obtained results would not correspond to the exact values of the in situ pressuremeter parameters or the SPT blow counts. The parameters calculated with these empirical equations could be used to obtain advance information about soil conditions.

References

Akça N (2003) Correlation of SPT-CPT data from United Arab Emirates. Eng Geol 67:219–231

Alvarez Grima M, Babuska R (1999) Fuzzy model for the prediction of unconfined compressive strength of rock samples. Int J Rock Mech Min Sci 36:339–349

APAGEO (2006) Menard Pressuremeter (G Type) operating instructions. 2006 edition

Apte MG, Price PN, Nero AV, Revzan K (1999) Predicting New Hampshire indoor radon concentrations from geologic information and other covariates. Env Geol 37:181–194

ASTM (American society for testing and materials) (1994) Annual book of ASTM Standards, Section 4, Construction, V. 0408 Soil and Rock; Building Stones. ASTM Publication, Pennsylvania, p 978

Baquelin F, Jezequel JF, Shields DH (1978) The pressuremeter and foundation engineering. Trans Tech Publications, Clausthal-Zellerfeld

Benavente D, Cueto N, Martinez–Martinez J, García Del Cura MA, Cañaveras JC (2007) The influence of petrophysical properties on the salt weathering of porous building rocks. Environ Geol 52:197–206

Bowles JE (1988) Foundation analysis and design, 4th edn. McGraw-Hill International Editions, Tokyo

Bozbey İ, Togrol E (2010) Correlation of standard penetration test and pressuremeter data: a case study from Istanbul, Turkey. Bull Eng Geol Environ 69:505–515

British Standard 1377 (1975) Method of test for soils for civil engineering purposes. British Standard Institution, London

Cassan M (1968–1969) “Les essays in situ en mècanique des sols”- Construction, No.10, Octobre ’68, pp 337–347; No. 5, Mai ’69, pp 178–187; No. 7–8, Julliet-Aoǔt ’69, pp 244–256

Chen-Chang L, Cheng-Haw L, Hsin-Fu Y, Hung-I L (2011) Modeling spatial fracture intensity as a control on flow in fractured rock. Environ Earth Sci 63:1199–1211

Chiang YC, Ho YM, (1980) Pressuremeter method for foundation design in Hong Hong. In: International proceedings of sixth Southeast Asian conference on soil engineering, vol 1, pp 31–42

Clarke BG (1995) Pressuremeters in geotechnical design (1. Edition). Chapman and Hall, London

Craig RF (1987) Soil mechanics. Department of Civil Engineering, 4th edn. University of Dundee, Longman, England

Dagdelenler G, Sezer EA, Gokceoglu C (2011) Some non-linear models to predict the weathering degrees of a granitic rock from physical and mechanical parameters. Expert Syst Appl 38:7476–7485

ENV (Eurocode 7) (1997) Geotechnical design-Part 3: design assisted by field testing

Finol J, Guo YK, Jing XD (2001) A rule based fuzzy model for the prediction of prediction of petrophysical rock parameters. J Petr Sci Eng 29:97–113

Gokceoglu C (2002) A fuzzy triangular chart to predict the uniaxial compressive strength of the Ankara agglomerates from their petrographic composition. Eng Geol 66(1–2):39–51

Gokceoglu C, Zorlu K (2004) A fuzzy model to predict the uniaxial compressive strength and the modulus of elasticity of a problematic rock. Eng Appl Artif Intell 17(1):61–72

Gokceoglu C, Sonmez H, Kayabasi A (2003) Predicting deformation moduli of rock masses. Int J Rock Mech Min Sci 41(2):337–341

Gokceoglu C, Sonmez H, Zorlu K (2009) Estimating the uniaxial compressive strength of some clay bearing rocks selected from Turkey by nonlinear multivariable regression and rule-based fuzzy models. Expert Syst 26(2):176–190

Gunaydin O (2009) Estimation of soil compaction parameters by using statistical analyses and artificial neural networks. Environ Geol 57:203–215

Hobbs N-B, Dixon J-C (1969) In situ testing for Bridge Foundations in the Devonian Marl. In: Proceedings of the Conference on in situ investigations in soils and rocks, British Geotechnical Society, London, May 13–15, pp 31–38

Iphar M, Yavuz M, Ak H (2008) Prediction of ground vibrations resulting from the blasting operations in an open-pit mine by adaptive neuro-fuzzy inference system. Env Geol 56:97–107

Kayabasi A, Gokceoglu C, Ercanoglu M (2003) Estimating the deformation modulus of rock masses:a comparative study. Int J Rock Mech Min Sci 40(1):55–63

Lee KM, Rowe RK (1989) Deformation caused by surface loading and tunneling: the role of elastic anisotropy. Geotechnique 39(1):125–140

Lee MJ, Hong SJ, Choi YM, Lee W (2010) Evaluation of deformation modulus of cemented sand using CPT and DMT. Eng Geol 115:28–35

Leischner W (1966) Die bautechnische Baugrundbeurteilung mittels horizontaler Belastungsversuche im Bohrloch nach dem Koglerverfahren, Der Bauingenier, 12

Leonards GA (1962) Foundation Engineering. McGraw Hill, Tokyo, p 113

Means RE, Parcher JW (1963) Physical Properties of Soils. In: Charls E (ed) Merril Publ Comp, Columbia, p 467

Mitchell JK (1975) Fundamentals of soil behaviour. Wiley, Newyork, p 422

Seed HB, Woodward RJ, Lundgren R (1964) Fundamental Aspects of the Atterberg Limits. J Soil Mech Found Div, ASCE, 90(SM6):75–105

Sharma PK, Singh TN (2008) A correlation between P-wave velocity, impact strength index, slake durability index and uniaxial strength index. Bull Eng Geol Environ 67:17–22

Shields DH, Bauer GH (1975) Determination of the modulus of deformation of sensitive clay using laboratory and in situ tests. In: Proceedings of the ASCE Special Conference on in situ measurement of soil properties, Raleigh, vol 1, pp 395–421

Sivrikaya O (2008) Models of compacted fine-grained soils used as mineral liner for solid waste. Environ Geol 53:1585–1595

Skempton AW (1953) The colloidal activity of clays. In: 3rd International Conference on Soil Mechanics and Foundation Engineering, Switzerland, vol 1, p 57

Sonmez H, Gokceoglu C, Nefeslioglu HA, Kayabasi A (2006) Estimation of rock modulus. Int J Rock Mech Min Sci 43(2):224–235

SPSS (2002) Statistical Package for the Social Sciences (v.11.5). SPSS Inc, Chicago

Terzaghi K, Peck RB (1968) Foundation design and construction. Pitman, London

Türk Standartları Enstitüsü (TSE) (1988) In situ measurement methods of the properties of foundation soils in civil engineering (in Türkish)

Türk Standartları Enstitüsü (TSE) (1997) Jeoteknik Tasarım Bölüm 3, Arazi Deneyleri Yardımıyla Tasarım (TS ENV 1997-3, Eurocode 7), (in Turkish)

Uddameri V (2007) Using statistical and artificial neural network models to forecast potentiometric levels at a deep well in South Texas. Environ Geol 51:885–895

USBR (United States Dep. Int. Bur. Reclamation) (1974) Earth manual. A Water Resources Technical Publication, Denver, p 810

Waschkowski E (1974) “Pénétrométrétres dynamiques”- Comtes rendus des Journées des Laboratoires des Ponts et Chausssées. Saint-Brieue. 19-21 Novembre, pp 1–37. Not Published

Waschkowski E (1976) “Comparaisons entre les résultats des essais pressiométriques et le SPT”- Rapport de Recherche du Laboratorie Régional des Ponts et Chaussées de Blois, F.A.E.R. 1.05.23.5, Juin. Not Published

Yagiz S, Gokceoglu C (2010) Application of fuzzy inference system and nonlinear regression models for predicting rock brittleness. Expert Syst Appl 37:2265–2272

Yagiz S, Akyol E, Sen G (2008) Relationship between the standart penetration test and the pressuremeter test on sandy silty clays: a case study from Denizli. Bull Eng Geol Environ 67:405–410

Yagiz S, Gokceoglu C, Sezer E, Iplikci S (2009) Application of two non-linear prediction tools to the estimation of tunnel boring machine performance. Eng Appl Artif Intell 22:818–824

Zorlu K, Gokceoglu C, Ocakoglu F, Nefeslioglu HA, Acikalin S (2008) Prediction of uniaxial compressive strength of sandstones using petrography-based models. Eng Geol 96(3/4):141–158

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kayabasi, A. Prediction of pressuremeter modulus and limit pressure of clayey soils by simple and non-linear multiple regression techniques: a case study from Mersin, Turkey. Environ Earth Sci 66, 2171–2183 (2012). https://doi.org/10.1007/s12665-011-1439-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12665-011-1439-4