Abstract

Bentonite has been studied extensively because of its strong adsorption capacity. The Gaomiaozi (GMZ) bentonite is selected as the first choice of Chinese buffer materials for the high-level radioactive waste repository. The adsorption of Cd(II) on the GMZ bentonite as a function of contact time, pH, ionic strength, bentonite content, and Cd(II) concentration was studied by using batch technique. The adsorption process achieved equilibrium within 50 min, and the adsorption capacity of Cd(II) by the raw GMZ bentonite was about 3.16 mg/g under the given experimental conditions. The adsorption ability of the GMZ bentonite increases with increasing pH at 2–12 but decreases with increasing ionic strength from 0.01 to 0.1 M KNO3. The uptake of Cd(II) on this bentonite increases in response to an increase of the bentonite content. Chemisorption was considered to be a key of process and adsorption mechanism could be concluded to be complexation, ion exchange, and electrostatic interaction. The equilibrium adsorption data were fitted to the second-order kinetic equation. Furthermore, the Langmuir adsorption isotherm model was used for the description of the adsorption process very well.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Heavy metal pollution on the planet earth has been observed in sediment lakes(Verta et al. 1989), soil profiles (Sterckeman et al. 2000), ice cores (Barbante et al. 2004), or other valuable archives (Nriagu 1996). There are hundreds of sources of heavy metal pollution, including the coal, natural gas, paper, and chlor-alkali industries (McDonald and Grandt 1981; Alloway 1995). Among these metals, cadmium and cadmium compounds have been found to be very toxic and long-term exposure to cadmium can cause serious damage to human health (Hasan et al. 2006). Take itaiitai as an example: this disease was found in residents of the cadmium(Cd)-polluted Jinzu River basin in Toyama Prefecture, Japan, and has been generally recognized as a toxic compound since 1950s (Kim and Lee 1998). As cadmium and cadmium compounds could not be degraded biologically, the control of Cd(II) pollution has special importance for all organism benefit from water.

The conventional methods for heavy metal removal from water and wastewater include oxidation, reduction, precipitation, and ion exchange/adsorption. Among those various methods ion exchange/adsorption is the most effective and economical (Zhu et al. 2008). The use of various adsorbents such as phosphogypsum (Nilgün and Hasan 2008), resin (Xiong et al. 2009), active carbon (Amir et al. 2009), and peat (Balasubramanian et al. 2009) have been reported to remove cadmium from aqueous solutions. However, most of these techniques have some disadvantages such as complicated treatment process, high cost, and energy use. For adsorption treatment methods, the main disadvantage is the high price of the adsorbents, which increases the cost of wastewater treatment. Thus, adsorbents with low cost and high efficiency for Cd(II) adsorption should be developed. Clay minerals have great potential as inexpensive and efficient adsorbents due to their large quantities, chemical and mechanical stability, high specific surface area, and structural properties (Baeyens and Bradbury 1997; Barbier et al. 2000; Abollino et al. 2003; Babel and Kurniawan 2003; Zhu et al. 2008). In recent years, the adsorption of Cd(II) by several clay minerals as adsorbents has led to much work on their adsorption properties for Cd(II) (Barbier et al. 2000; Adebowale et al. 2006; Sharma 2008; Sim et al. 2009).

Because of higher specific surface area and cation exchange capacity, bentonite (mainly montmorillonite) is the most preferable clay mineral in the decontamination and treatment of heavy metal ions (Abollino et al. 2003) and is also considered as the first choice of buffer/backfill material in the disposal of radioactive nuclear waste (Hoda et al. 2009). The adsorption of heavy metal ions on bentonite has been studied extensively in the past decade (Saleh et al. 2005; Lacin et al. 2005; Xu et al. 2008; Hoda et al. 2009). The results show that the adsorption of heavy metal ions on clay minerals increases with increasing pH values, and the adsorption is dominated by outer-sphere complexation or ion exchange at low pH and by inner-sphere complexation or precipitation at high pH (Wang et al. 2009a). However, there are still few references, focusing on the effect of the pH values and the ionic strength on Cd(II) adsorption on bentonite (Gonzalez Pradas et al. 1994; Bereket et al. 1997; Lacin et al. 2005), that need to be studied.

The Gaomiaozi (GMZ) bentonite has been extracted from the northern Chinese Nei Mongolia autonomous region, 300 km northwest from Beijing (Fig. 1). There are 160 million tons with 120 million tons Na-bentonite reserves in the deposit and the mine area is about 72 km2. The GMZ bentonite has been selected as the candidate of buffer/backfill material for the nuclear waste repository of China. Some authors (Yu 2006; Wen 2006; Ye et al. 2007) reported the high swelling and sealing ability of the GMZ bentonite, and others (Yang et al. 2009; Li et al. 2009; Wang et al. 2009b) studied the adsorption capacity of this bentonite for Pb(II), Cu(II), and Ni(II). However, the adsorption capacity of Cd(II) on this bentonite has not been studied in detail. The objectives of the present work are to (a) study the effect of contact time, pH, ionic strength and bentonite content on the adsorption of Cd(II) on the GMZ bentonite; (b) determine the Cd(II) adsorption isotherms and simulate the experimental data with the Langmuir and Freundlich adsorption models; (c) compare the results with the adsorption results of other bivalent ions on the GMZ bentonite or other Cd(II) adsorption results on other bentonite materials; and (d) discuss the adsorption mechanism of Cd(II) on the GMZ bentonite.

Materials and methods

Bentonite

GMZ bentonite samples were obtained from Gaomiaozi county (Nei Mongolia, China). The used GMZ bentonite presents a grain size no more than 160 μm as shown in Fig. 2. The mineralogical composition of the GMZ bentonite has been quantitatively analyzed using the X-ray diffraction method (Wen 2008). The bulk composition was determined as follows (in mass): montmorillonite, 75.4%; quartz, 11.7%; cristobalite, 7.3%; feldspar, 4.3%; kaolinite, 0.8%; calcite, 0.5%. It appears that the proportion of montmorillonite is dominant in the GMZ bentonite, with a high smectite content of 75.4%.

Grain size distribution of the GMZ bentonite used for the experiment (Qian 2007)

The bulk chemical component of the GMZ bentonite was analyzed using the X-ray fluorescence spectrometry as follows (in mass): SiO2, 67.43%; Al2O3, 14.20%; TFe2O3, 2.40%; Na2O, 1.75%; CaO, 1.13%; K2O, 0.73%; FeO, 0.29%; TiO2, 0.12%; MgO, 0.10%; P2O5, 0.02%; MnO, 0.02%. Besides that the GMZ bentonite also contains some lanthanon, like La, Ce, Nd, etc.

The adsorption capacity of adsorbent is mainly controlled by its cation exchange capacity (CEC) and specific surface area (SSA). The CEC of the GMZ bentonite is 77.3 mmol/100 g and the SSA is 570 m2/g (Wen 2006).

Adsorption experiments

All experiments were performed under aerobic conditions and with chemicals of analytical purity. The adsorption capacity of Cd(II) on the GMZ bentonite was investigated using batch technique in polyethylene centrifuge tubes sealed with screw-cap under ambient conditions. In all experiments, no attempt was made to exclude air. The stock solutions of the GMZ bentonite and KNO3 were pre-equilibrated for 24 h and then the Cd stock solution was added to achieve the desired concentration of the different components. A stock solution of CdCl2 (100 mg/L) was prepared by dissolving Cd in HCl. The pH values of the system were adjusted by adding negligible volumes of 0.01 or 0.1 M HCl, 0.01 or 0.1 M KOH to achieve the desired values. The ionic strengths were adjusted with 0.1 or 1 M KNO3 solution to the desired values. The experimental conditions such as contact time, pH, ionic strength, bentonite content, and Cd(II) concentration were selected on the previous works related to the adsorption of the bivalent heavy metal ions on the GMZ bentonite (Yang et al. 2009; Li et al. 2009; Wang et al. 2009b) and the adsorption of Cd(II) on clay mineral (Gonzalez Pradas et al. 1994; Bereket et al. 1997; Lacin et al. 2005). The GMZ bentonite content of the system studied was 5.0 g/L. After the suspensions were shaken for 24 h, the solid and the liquid phases were separated by centrifugation at 400 rpm for 40 min.

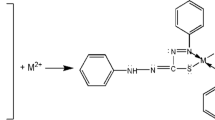

The concentration of Cd(II) was analyzed by spectrophotometry at a wavelength of 228.8 nm using Cd Chlorophosphonazo-III complex. All experimental data were the average of duplicate or triplicate determinations. The relative uncertainties of the data amount to 5%.

The amount of Cd(II) adsorbed on the GMZ bentonite, derived from the initial and the equilibrium concentrations, C 0 and C e, could be expressed as Eq. 1:

The removal or uptake efficiency (%) of Cd(II) by the GMZ bentonite is calculated from the difference between the initial and the final concentrations using the equation

where q e (mg/g) is the amount concentration of Cd(II) on the GMZ bentonite, C 0 (mg/L) is the initial concentration of Cd(II) in suspension, C e (mg/L) is the concentration of Cd(II) in supernatant after centrifugation, m (g) is the mass of the adsorbent, and V (L) is the volume of the Cd(II) solution.

Results and discussion

Effect of the contact time

The uptake of Cd(II) by the GMZ bentonite is examined at different time intervals and the results are shown in Fig. 3.

As can be seen from the Fig. 3a, during the first 50 min of the experiment, the concentration of Cd(II) adsorbed on the GMZ bentonite increases with the prolonged time. From 50 to 220 min, no significant change of Cd(II) concentration is observed. The results indicate that the adsorption equilibrium is reached after only 50 min. Similarly, the adsorption of Cu(II) or Pb(II) on the GMZ bentonite also occurs quickly and 4 h are enough to achieve the adsorption equilibrium (Li et al. 2009; Wang et al. 2009a, b). The literature shows that the Cd(II) adsorption is demonstrated to be a fast process where >95% of the adsorption took place within the first 10 min and equilibrium is attained within 1 h (Statillan-Medrano and Jurinak 1975). Thus, in the following experiments, 24 h were selected to ascertain the equilibrium of Cd(II) adsorption to the GMZ bentonite. The fast adsorption of those heavy metals on bentonite suggested that the uptake of those heavy metals from solution to bentonite was mainly dominated by chemical adsorption rather than physical adsorption (Li et al. 2009). In this experiment the amount of Cd(II) adsorbed on the GMZ bentonite, q e, and the equilibrium concentration, C e, amount to 3.16 mg/g and 4.19 mg/L, respectively, with an initial concentration of C 0 = 20 mg/L.

The pseudo-second-order equation is often successfully used to describe the kinetics of the adsorption process. Its expression is as follows:

where k 2 (g mg−1 min−1) is the second-order rate constant and q t (mg/g) denotes the amount of Cd(II) adsorbed at time t (min). This equation can be integrated for the boundary conditions t = 0 (q e = 0) to (q t = q e) and then liberalized, leading to Eq. 4 (Ho and Mckay 1998):

By plotting t/q t versus t, a straight line is obtained with the slope of 1/k 2 q 2e and intercept of 1/q e (Fig. 3b). The values of k 2 and q e are given in Table 1. High correlation coefficient indicates the applicability of the pesudo-second-order rate model to describe the adsorption process.

Effect of pH

As pH is an important factor affecting the uptake of cations from aqueous solutions, the dependence of Cd(II) uptake on aqueous pH is studied (Fig. 4). The uptake efficiency increases abruptly from about 35 to 80% as pH increases from 2 to 4 and then increases gradually with increasing pH at 4–8. Above pH 8, its effect on the uptake becomes insignificant and reaches a plateau. A maximum uptake on the GMZ bentonite of 96.7% is observed at pH 12 and an initial concentration of 10 mg/L.

As can be seen in Fig. 4, Cd(II) adsorption on the GMZ bentonite increases from about 35% at pH 2 to about 90% at pH 8 and then maintains a high level. The pH effect on the Cd(II) adsorption is the same as that on the bivalent metal ions (such as Pb(II), Ni(II) and Cu(II)) adsorption by the GMZ bentonite (Wang et al. 2009a, b; Yang et al. 2009; Li et al. 2009). In addition, the pH effect on the Cd(II) ion uptake is the same as that on the metal ions adsorption by clay minerals (Bradl 2004; Nilgün and Hasan 2008; Amir et al. 2009). In general, an increase of the solution pH induces increasing in the adsorption of Cd(II), but the degree of increase varies for various adsorbents. For example, by increasing the solution pH from 1.0 to 10.0, the extent of adsorption increases from 4.3 to 29.5% for kaolinite, and 74.7–94.5% for montmorillionite (Bhattacharyya and Gupta 2008). The results comply with complexation and adsorption of Cd(II) on the GMZ bentonite surface increasing with pH while leveling off at high values due to the negatively charged surface of the GMZ bentonite. The adsorption of Cd(II) on the GMZ bentonite may be attributed to electrostatic and/or Coulombic attraction (Ren et al. 2007).

The negative surface (≡S) groups of the GMZ bentonite contribute to the adsorption as

The adsorption of Cd(II) may also be attributed to the ion exchange between surface hydroxyl groups and Cd(II) as follows:

With increasing pH the number of negatively charged ≡SO− groups and the hydrolysis of Cd(II) increases, which leads to an increase of Cd(II) adsorption (Zhao et al. 2008). The strong pH-dependent adsorption indicates that the adsorption is dominated by surface complexation according to the surface complexation model (Baeyens and Bradbury 1997; Wen et al. 1998; Chen and Wang 2007; Xu et al. 2008).

Effect of ionic strength

In this study, the effect of initial ionic strength on Cd(II) adsorption on the GMZ bentonite is achieved by varying the concentration of additive KNO3 from 0.01 to 0.1 M. As shown in Fig. 5, the adsorption of Cd(II) onto the GMZ bentonite is obviously affected by ionic strength. The adsorption decreases with increasing KNO3 concentration, which suggests that the K+ greatly affects Cd(II) adsorption. The uptake of Cd(II) from aqueous solution changes from about 82 to 20% when the concentration ranges of KNO3 are from 0.01 to 0.1 M, respectively. A reasonable explanation is there is a competitive adsorption between Cd(II) and K+. At a lower ionic strength, more function groups are available for Cd(II) uptake, the effect of K+ is insignificant and when the ionic strength is high, the competition between Cd(II) and K+ for the available sites becomes important, resulting in low Cd(II) uptake. Similar results have been reported by Wang et al. (2009a, b) for Pb(II) ion uptake using the GMZ bentonite. The ionic strength-dependent adsorption indicated that cation exchange partly contributes to the adsorption (Baeyens and Bradbury 1997; Wang and Liu 2004). Generally, cation exchange is influenced by ionic strength whereas surface complexation is affected by pH values obviously (Zhao et al. 2008).

Effect of bentonite content

The dependence of Cd(II) adsorption on bentonite content is studied by varying the amount of the GMZ bentonite from 2.5 to 25 g/L while keeping all other variables [pH, contact time and concentration (10.0 mg/L)] constant. The results are presented in Fig. 6, which indicates that the uptake efficiency of Cd(II) from solution to the GMZ bentonite increases with increasing bentonite content. Similar conclusions have been drawn by Li et al. (2009) for Cu(II) adsorption on the GMZ bentonite. This can be attributed to the fact that the higher content of bentonite in the solution results in greater availability of exchangeable sites for the ions (Vijaya et al. 2008), and thereby enhances the adsorption of Cd(II) from solution to the solid.

On the other hand, increase in the GMZ bentonite content leads to a decrease in the specific Cd(II) uptake. Similar results have been found for Pb(II) on the MX-80 bentonite (Xu et al. 2008), that is, an increase in bentonite content reduces the amount of metal recovered per dry weight unit of solid soil used. These results suggest that high bentonite content is not necessary to produce a high adsorption yield because the results obtained with 10 g of the GMZ bentonite are similar to those obtained with a 2.5 times greater content.

Adsorption isotherms

The general adsorption isotherms that can be used for describing the adsorption include the Langmuir, Freundlich and Brunauer–Emmett–Teller (BET) type (Metcalf Eddy Inc 1991). The adsorption data were analyzed using Freundlich (Freundlich 1906) and Langmuir models (Langmuir 1918).

The Langmuir model can be written as

or, in linear form

where q e is the amount of solute adsorbed per unit weight of adsorbent after equilibrium (mg/g), C e is the equilibrium concentration of metal ions remaining in the bulk solution (mg/L), Q 0 and b are Langmuir constants related to adsorption capacity and adsorption energy, respectively. Q 0, the maximum adsorption capacity, is the amount of metal ions at complete monolayer coverage (mg/g), and b (L/mg) is a constant related to the heat of adsorption [b ∝ exp(−∆G/RT), where ∆G is the Gibbs free energy change (kJ/mol), R is the universal gas constant (8.31 J/mol/K), T is the absolute temperature in Kelvin (K)]. The constants of the Langmuir isotherm can be obtained by plotting C e/q e versus C e.

The Freundlich model can be represented by the following equation:

or, in linear form

where k F is the constant indicative of the relative adsorption capacity of the adsorbent (mg1−1/nL1/n/g) and 1/n is the constant indicative of the intensity of the adsorption. The constants of the Freundlich isotherm can be obtained by plotting log q e versus log C e.

The adsorption isotherm of Cd(II) on the GMZ bentonite is shown in Fig. 7. The experimental data are fitted by Langmuir and Freundlich adsorption models, separately.

Values of the Langmuir and Freundlich constants for Cd(II) are given in Table 2 with Pb(II), Cu(II), and Ni(II) adsorption on the GMZ bentonite studied by other authors (Li et al. 2009; Wang et al. 2009a; Yang et al. 2009). Correlation values (R 2) presented in Table 2 indicate that the adsorption data for heavy metals including Cd(II), Pb(II), Cu(II), and Ni(II) removal fit with the Langmuir isotherm very well.

The linear plot of C e/q e versus C e with R 2 = 0.982 is shown in Fig. 8. From the slope of Fig. 8, the maximum adsorption capacity of bentonite for Cd(II) calculates to 42.4 mg/g under the given experimental conditions. It can be seen from Table 2 that the Langmuir capacity (Q 0) of the GMZ bentonite is in the order of Cd(II) > Pb(II) > Ni(II) > Cu(II).

The linear plot of logq e versus logC e with R 2 = 0.972 is shown in Fig. 9. The magnitude of the constant k F provides quantitative information on the relative adsorption affinity towards the adsorbed cations, and the magnitude of constant 1/n is an indicator of linearity of adsorption (Xu et al. 2008). The large value of k F indicates that bentonite has a high adsorption affinity towards Cd(II). The value of 0.1 < 1/n < 1 shows favorable adsorption of cadmium ions onto adsorbent (Amir et al. 2009).

Conclusions

In this study, the adsorption capacity of Cd(II) on the GMZ bentonite was studied by batch tests conducted under various experimental conditions such as contact time, pH, ionic strength, and bentonite content. The equilibrium batch experiment data demonstrated that the GMZ bentonite is effective adsorbent for the uptake of Cd(II) from aqueous solution with the maximum uptake capacity of 3.16 mg/g under the given experimental conditions. The adsorption achieves the equilibration rapidly and it is strongly dependent on pH and ionic strength. The adsorption process is pseudo-second-order reaction following the Langmuir isotherm adsorption. Chemisorption was considered to be a key of process and adsorption mechanism could be concluded to be complexation, ion exchange, and electrostatic interaction. The results obtained in this study make the GMZ bentonite a promising candidate for adsorption, immobilization, and pre-concentration of heavy metal ions from large volumes of solutions.

References

Abollino O, Aceto M, Malandrino M, Sarzanini C, Mentasti E (2003) Adsorption of heavy metals on Na-montmorillonite: effect of pH and organic substances. Water Res 37:1619–1627

Adebowale KO, Unuabonah IE, Olu-Owolabi BI (2006) The effect of some operating variables on the adsorption of lead and cadmium ions on kaolinite clay. J Hazard Mater 134:130–139

Alloway BJ (1995) Heavy metals in soils, 2nd edn. Chapman and Hall, Glasgow

Amir FT, Tahereh K, Mansooreh S (2009) Adsorption of cadmium from aqueous solutions on sulfurized activated carbon prepared from nut shells. J Hazard Mater 165:1159–1164

Babel S, Kurniawan TA (2003) Low-cost adsorbents for heavy metals uptake from contaminated water: a review. J Hazard Mater 97:219–243

Baeyens B, Bradbury MH (1997) A mechanistic description of Ni and Zn sorption on Na-montmorillonite. Part I: titration and sorption measurements. J Contam Hydrol 27:199–222

Balasubramanian R, Perumal SV, Vijayaraghavan K (2009) Equilibrium isotherm studies for the multicomponent adsorption of lead, zinc and cadmium onto Indonesian peat. Ind Eng Chem Res 48:2093–2099

Barbante C, Schwikowski M, Döring T, Gäggeler HW, Schotterer U, Tobler L, van de Velde K, Ferrari C, Cozzi G, Turetta A, Rosman K, Bolshov M, Capodaglio G, Cescon P, Boutron C (2004) Historical record of European emissions of heavy metals to the atmosphere since the 1650s from alpine snow/ice cores drilled near Monte Rosa. Environ Sci Technol 38:4085–4090

Barbier F, Duc G, Petit-Ramel M (2000) Adsorption of lead and cadmium ions from aqueous solution to the montmorillonite/water interface. Colloids Surf A Physicochem Eng Asp 166:153–159

Bereket G, Aroguz AZ, Ozel MZ (1997) Removal of Pb(II), Cd(II), Cu(II), and Zn(II) from aqueous solutions by adsorption on bentonite. J Colloid Interface Sci 187:338–343

Bhattacharyya KG, Gupta SS (2008) Adsorption of a few heavy metals on natural and modified kaolinite and montmorillonite: a review. Adv Colloid Interface Sci 140:114–131

Bradl HB (2004) Adsorption of heavy metal ions on soils and soils constituents. J Colloid Interface Sci 277:1–18

Chen CL, Wang XK (2007) Influence of pH, soil humic/fulvic acid, ionic strength and foreign ions on sorption of thorium(IV) onto g-Al2O3. Appl Geochem 22:436–445

Freundlich H (1906) Uber die adsorption in losungen. Z Phys Chem 57:387–470

Gonzalez Pradas E, Villafranca Sanchez M, Canton Cruz F, Socias Viciana M, Fernandez Perez M (1994) Adsorption of cadmium and zinc from aqueous solution on natural and activated bentonite. J Chem Technol Biotechnol 59:289–295

Hasan S, Krishnaiah A, Ghosh K, Viswanath DS, Boddu VM, Smith ED (2006) Adsorption of divalent cadmium (Cd(II)) from aqueous solutions onto chitosan-coated perlite beads. Ind Eng Chem Res 45:5066–5077

Ho YS, McKay G (1998) Kinetic models for the sorption of dye from aqueous solution by wood. Process Saf Environ Prot 76:183–191

Hoda O, Hassan A, Abdelhakium D (2009) Adsorption of 60C o radionuclides from aqueous solution by raw and modified bentonite. Appl Clay Sci 44:21–26

Kim HG, Lee SB (1998) Effects of organic matter on cadmium adsorption in soil. J KSEE 20(1):1–8

Lacin O, Bayrak B, Korkut O, Sayan E (2005) Modeling of adsorption and ultrasonic desorption of cadmium(II) and zinc(II) on local bentonite. J Colloid Interface Sci 292:330–335

Langmuir I (1918) The adsorption of gases on plane surfaces of glass, mica and platinum. J Am Chem Soc 40:1362–1403

Li J, Hu J, Sheng G, Zhao G, Huang Q (2009) Effect of pH, ionic strength, foreign ions and temperature on the adsorption of Cu(II) from aqueous solution to GMZ bentonite. Colloids Surf A Physicochem Eng Asp 349:195–201

McDonald DG, Grandt AF (1981) Limestone-lime treatment of acid mine drainage-full scale. EPA Project Summary. EPA-600/S7-81-033

Metcalf Eddy Inc (1991) Wastewater engineering: treatment, disposal and reuse, 3rd edn. Irwin/McGraw-Hill, Boston

Nilgün B, Hasan C (2008) Adsorption of cadmium from aqueous solution by phosphogypsum. Chem Eng J 140:247–254

Nriagu JO (1996) A history of global metal pollution. Science 272:223–224

Qian LX (2007) A fundamental Study of GMZ bentonite as buffer material in deep geological disposal for high-level radioactive waste. Dissertation, Tongji University (in Chinese)

Ren A, Yu S, Han J, Chang P, Chen C, Chen J, Wang X (2007) A comparative study of Pb2+ sorption onto MX-80 bentonite, LA bentonite, γ-Al2O3 and SiO2. J Radioanal Nucl Chem 272:3–10

Saleh K, Suzelle B, Maria E, Li W (2005) Effect of Pb and Cd on Cu adsorption by sand-bentonite liners. Can J Civ Eng 32:241–249

Sharma YC (2008) Thermodynamics of removal of cadmium by adsorption on an indigenous clay. Chem Eng J 145:64–68

Sim JH, Seo HJ, Kim CG (2009) Physicochemical characteristics for adsorption of MTBE and cadmium on clay minerals. Environ Earth Sci 59:537–545

Statillan-Medrano J, Jurinak JJ (1975) The chemistry of lead and cadmium in soil: solid phase formation. Soil Sci Soc Am J 39:851–856

Sterckeman T, Douay F, Proix N, Fourrier H (2000) Vertical distribution of Cd, Pb and Zn in soils near smelters in the North of France. Environ Pollut 107:377–389

Verta M, Tolonen K, Simola H (1989) History of heavy metal pollution in Finland as recorded by lake sediments. Sci Total Environ 87–88:1–18

Vijaya Y, Popuri SR, Boddu VM, Krishnaiah A (2008) Modified chitosan and calcium alginate biopolymer sorbents for removal of nickel (II) through adsorption. Carbohydr Polym 72:261–271

Wang XK, Liu XP (2004) Effect of pH and concentration on the diffusion of radiostrontium in compacted bentonite-a capillary experimental study. Appl Radiat Isot 61:1413–1418

Wang SW, Dong YH, He ML, Chen L, Yu XJ (2009a) Characterization of GMZ bentonite and its application in the adsorption of Pb from aqueous solutions. Appl Clay Sci 43:164–171

Wang SW, Hu J, Li JX, Dong YH (2009b) Influence of pH, soil humic/fulvic acid, ionic strength, foreign ions and addition sequences on adsorption of Pb(II) onto GMZ bentonite. J Hazard Mater 167:44–51

Wen ZJ (2006) Physical property of china’s buffer material for high-level radioactive waste repositories. Chin J Rock Mech Eng 25:794–800 (in Chinese)

Wen ZJ (2008) Selection and basic properties of the buffer material for high-level radioactive waste repository in China. Acta Geol Sinica 82:1050–1055

Wen X, Du Q, Tang H (1998) Surface complexation model for the heavy metal adsorption on natural sediment. Environ Sci Technol 32:870–875

Xiong CH, Xiong CP, Yao CP (2009) Study on the adsorption of cadmium(II) from aqueous solution by D152 resin. J Hazard Mater 166:815–820

Xu D, Xu XL, Tan XL, Chen CL, Wang XK (2008) Adsorption of Pb(II) from aqueous solution to MX-80 bentonite: effect of pH, ionic strength, foreign ions and temperature. Appl Clay Sci 41:37–46

Yang S, Li J, Lu Y, Chen Y, Wang X (2009) Sorption of Ni(II) on GMZ bentonite: Effects of pH, ionic strength, foreign ions, humic acid and temperature. Appl Radiat Isot 67:1600–1608

Ye WM, Schaze S, Qian LX, Wang J, Arifin (2007) Characteristics of swelling pressure of densely compacted gaomiaozi bentonite GMZ01. Chin J Rock Mech Eng 26:3861–3865

Yu C (2006) Volume change behavior and its micro-structural mechanical of unsaturated GMZ bentonite. Dissertation, Tongji University (in Chinese)

Zhao DL, Feng SJ, Chen CL, Chen SH, Xu D, Wang XK (2008) Adsorption of thorium(IV) on MX-80 bentonite: effect of pH ionic strength and temperature. Appl Clay Sci 41:17–23

Zhu SJ, Hou B, Xue YJ (2008) Kinetic and isothermal studies of lead ion adsorption onto bentonite. Appl Clay Sci 40:171–178

Acknowledgments

Financial supports from Natural Science Foundation of China (No.40802064, 41030748), Shanghai Leading Academic Discipline Project (No.B308), Scientific Research Fund of Hunan Provincial Education Department (No.09B006) and Kwang-Hua Fund for College of Civil Engineering, Tongji University are acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, YG., Ye, WM., Yang, XM. et al. Effect of contact time, pH, and ionic strength on Cd(II) adsorption from aqueous solution onto bentonite from Gaomiaozi, China. Environ Earth Sci 64, 329–336 (2011). https://doi.org/10.1007/s12665-010-0850-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12665-010-0850-6