Abstract

The co-utilization pentose and hexose in lignocellulosic biomass hydrolysate is the core for economically fermentative production of the second-generation bioethanol as sustainable biofuel candidate. In this study, S. cerevisiae was co-cultured with S. stipitis for highly effective bioethanol production from pentose and hexose enriched lignocellulose hydrolysate. Results indicated that the co-culturing process could be divided into two phases (a twin-consortium phase and a second phase with xylose conversion by S. stipitis). Under the optimized condition (S. cerevisiae/S. stipitis inoculum ratio of 20/80 (v/v), overall inoculation size of 10% (v/v), and ventilation volume of 0.01 vvm), the highest ethanol yield of 0.39 g/g (of monomer sugars) can be achieved. Dynamics of the S. stipitis and S. cerevisiae abundance were further investigated, which revealed that the flora of S. cerevisiae contains a large part in the twin-consortium phase, while the S. stipitis flora gradually increased with the lengthen of fermentation period, and finally became the predominated strain after used up the glucose consumption in corn stover hydrolysate.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

A Statement of Novelty

Twin-consortium of S. cerevisiae and S. stipitis was applied to produce bioethanol from glucose and xylose containing hydrolysate. For the first time, the interspecies relationship of the consortium was revealed by the dynamic abundance of the flora. Mass balance shows that 130.7 g ethanol can be obtained from 1 kg of corn stover based on the co-culturing process.

Introduction

Due to environmental protection issues and the unstable fossil fuel supplementation, the production of bioethanol from lignocellulosic biomass has received widespread attention [1]. Unfortunately, the production of lignocellulosic ethanol has long been criticized by the low economic feasibility, owing to the obstacles such as the resistance of lignocellulose matrix and the difficulties in utilizing pentose, the second-largest monomer sugar in hydrolysate that is degraded from hemicellulose fraction in raw biomass materials [2, 3].

To solve the technical barriers of biomass resistance, a pretreatment step for effective delignification of biomass material is required before the saccharification and fermentation carried out [4]. Among different types of pretreatment strategies, organic alkaline fractionation is a promising way because valuable technical lignin can be co-generated as by-product. Besides, residual organics in the pulping liquor can be recycled, which causing little negative influences to the environment [4, 5]. More importantly, hemicellulose can be recycled under high efficiency in pulp when adopting the organic alkaline fractionation, thereby improving the overall cellulosic sugars yield [6, 7].

As for the selection of suitable microorganisms for ethanol fermentation, S. cerevisiae is commonly used in industry, owing to its superiorities of high robustness, high ethanol tolerance, high ethanol yield, and high hexose conversion rate [8]. However, a fatal problem is that the wild S. cerevisiae cells cannot metabolize xylose [9, 10]. Although various genetic methods have been applied to construct the pentose pathways for xylose catabolism in S. cerevisiae [11, 12], difficulties such as carbon catabolite repression, inhibition of lignocellulose-derived inhibitors, and redox imbalance, are still needs to be overcome [13].

Except for S. cerevisiae, there are also other types of microorganisms that could directly utilize xylose as carbon source for bioethanol fermentation. Nonetheless, the fermentation performances are generally behind the S. cerevisiae-based processes [14]. In recent researches, several species, such as E. coli, S. stipitis, P. tannophilus and C. shehatae [15,16,17], are potentially used for ethanol fermentation. Among them, S. stipitis has the highest capacity of transforming xylose into ethanol [18]. However, the theoretical ethanol yield by S. stipitis is far lower than that of S. cerevisiae (0.35–0.44 g/g vs. 0.51 g/g) [19].

In order to effectively utilize xylose in lignocellulosic hydrolysate and maximize the overall bioethanol yield, in previous works, several co-culturing processes based on S. cerevisiae and another microorganism that can be effectively metabolism xylose were constructed [20, 21]. For instance, Wang et al. [22] constructed co-culturing process that based on ethanologenic E. coli and S. cerevisiae, the ethanol yield reached 0.45 g/g of total monomer sugars in lignocellulosic hydrolysate. Hickert et al. [23] co-cultured C. shehatae with S. cerevisiae in rice hull hydrolysate, an ethanol yield of 0.48 g/g was realized. Qian et al. [24] came up with the co-culturing process of S. cerevisiae and P. tannophilus using softwood hydrolysate as substrates, which also outputted bioethanol effectively with relatively high yield.

As for co-culturing process of S. cerevisiae and S. stipitis, simultaneous saccharification and co-fermentation (SSF) was carried out, and 15.2 g/L of ethanol can be obtained [25]. Delgenes et al. [26] co-cultured S. stipitis and respiratory deficient mutant of S. cerevisiae in continuous fermentation process. An ethanol yield of 0.43 g/g was realized. Kordowska-wiater and Targonski [27] constructed the co-culturing process using the restricted catabolite repressed mutant S. stipitis and respiratory deficient mutant S. cerevisiae. 0.45 g/g of ethanol yield was achieved after 120 h of fermentation. Besides, co-immobilization of S. cerevisiae and catabolite repressed S. stipitis mutant was also suggested in ever reports [28, 29].

Nonetheless, despite the wildly application of the co-culturing processes to improve the ethanol production from the sugar mixture and realistic lignocellulose hydrolysate, studies focused on the relationships between S. cerevisiae and S. stipitis, are still limited [30, 31]. Whether synergetic and competition effect between the two microorganisms in the co-culturing process should be clarified. Hence, further analysis is required to comprehensively understanding the microflora mechanism of the co-culturing system based on the ethanologenic strains.

In the current work, in order to boosting ethanol production from the enzymatic hydrolysis of the organic alkaline fractionated corn stover pulp, co-culturing process was performed using S. cerevisiae and S. stipitis. In the first part of the manuscript, the co-culturing process was constructed and the key parameters including the inoculum size, inoculum rate, and aeration rate were optimized. In the second part, the symbiotic relationship between the strains was further revealed by presenting the dynamics of the abundance. Results obtained in current work are attractive, which helps to clarify the synergetic effect of the S. cerevisiae and S. stipitis in co-culturing system for second-generation ethanol production.

Materials and Methods

Raw Material

Corn stover was purchased from a local farm in Qinhuangdao, Hebei province, China. Cellulase (Ctec 2) with 145 ± 5 FPU/mL activity was obtained from Novozymes. Other chemicals were purchased from Beijing Chemical Work. The contents of glucan, xylan, and lignin in the raw corn stover were 34.65 wt%, 21.37 wt%, and 20.51 wt%, respectively.

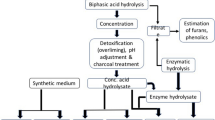

Pretreatment and Enzymatic Hydrolysis

Corn stover was squeezed by grinding disc extrusion. Then, the dried biomass was crushed, and the straw with ~ 40 meshes were selected. Organic alkaline fractionation was conducted using ethylenediamine (EDA)/water binary solution according to similar method described in previous research [7]. Generally, 10% (w/v) of corn stover bagasse was mixed with the pulping liquor that contains 2% (v/v) of ethylenediamine and 98% (v/v) of water. The reaction was carried out in a 2 L of reactor with 1 L of working volume at 120 ℃ for 1 h. The rotation rate was 500 rpm. After solid–liquid separation and washing by deionized water, the solid fraction was dried out at 105 ℃.

As for the enzymatic hydrolysis, 10% (w/v) of solid to liquid ratio was adapted. In this process, the dried corn stover pulp was mixed with 0.05 M citrate buffer (pH 4.7). Then, the slurry was maintained at 50 °C and 180 rpm for 72 h, with cellulase dosage of 15 FPU/g. pH of the liquid fraction after hydrolysis was adjusted to 5.5 by 30% ammonium hydroxide before inoculation.

After fractionized by dilute organic alkaline, the recovery rate of the corn stover pulp was 60.6 ± 0.5 wt%. For 10% (w/v) of solid loading, the concentration of glucose and xylose in corn stover hydrolysate were 40.2 ± 0.5 g/L and 15.1 ± 0.3 g/L, respectively.

Co-culturing Process

S. cerevisiae M3013 and S. stipitis CBS6054 were laboratory stored. The stock culture was preserved in 30% (v/v) glycerol at − 80 ℃. The strains were growing on YPD agar plates that contain (in w/v): 2% of glucose, 2% of peptone, 1% of yeast extract, and 2% of agar. Temperatures for mono-culturing of S. cerevisiae and S. stipitis were 30 ℃ and 28 ℃, respectively.

The corn stover hydrolysate and the synthetic medium were adopted in the co-culturing processes. Except for monomer sugars, the nutrients were as followed (g/L): (NH4)2SO4 5 g/L, KH2PO4 3 g/L, MgSO4·7H2O 4 g/L, CaSO4·2H2O 0.5 g/L, and K2SO4 4 g/L. The mediums were autoclaved at 116 ℃ for 25 min before inoculation. After cooling down to the room temperature, 1% (v/v) microelements solution (EDTA·2Na·2H2O 3.321 g/L, ZnSO4·7H2O 0.9 g/L, MnCl2·4H2O 0.241 g/L, CoCl2·6H2O 0.06 g/L, CuSO4·5H2O 0.06 g/L, Na2MoO4·H2O 0.08 g/L, CaCl2 0.6796 g/L, FeSO4·7H2O 0.6 g/L, H3BO3 0.2 g/L, KI 0.02 g/L) were additionally supplemented to the medium.

Both the co-culturing and the mono-culturing processes were carried out in 100 mL anaerobic non-baffled Erlenmeyer flasks with 50 mL of working volume. The inoculation size for mono-culturing was 10% (v/v). For the co-culturing of S. cerevisiae and S. stipitis, different S. cerevisiae/S. stipitis ratios (0/100, 5/95, 20/80, 40/60, 60/40, 80/20, and 100/0, in v/v) were adapted, with overall inoculation sizes of 5% (v/v) or 10% (v/v). During the fermentation process, the temperature was kept at 28 °C. In order to evaluate the impact of aeration rate on co-culturing process, fermentation was also carried out in a 5 L bioreactor with 2.5 L of working volume [32]. The agitation rate was maintained at 250 rpm, and the effect of aeration rate (0 vvm, 0.1 vvm and 0.03 vvm) on fermentation performances were investigated.

Analytical Method

The cells concentration was determined by a spectrophotometer detector (TU-1901) at 600 nm. Glucose, xylose, and ethanol concentration in broth were quantitatively detected by Aminex HPX-87H column (7.8 × 300 mm) that was equipped in a high-performance liquid chromatography (HPLC, Agilent Technologies 1200 Series, USA). A refractive index detector was used [11, 33]. All experiments were performed in triplicate and standard deviation test was adopted.

High-Throughput Sequencing

After centrifugation at 5000 rpm for 5 min, the strains in samples of fermentation were washed by buffer and deionized water. Then, the precipitated strains from co-culturing process were quickly frozen by liquid nitrogen for high-throughput sequencing (Majorbio, Shanghai, China). Samples were extracted by Yeast Genome Extraction Kit (Biomed, Beijing, China) to obtain the whole genome DNA of the strains in the co-culturing process. Then, the designated ITS2 sequencing region was selected, and the ITS3F forward primer 5ʹ-GCATCGATGAAGAACGCAGC-3ʹ and the ITS4R reverse primer 5ʹ-TCCTCCGCTTATTGATATGC-3ʹ with barcode were synthesized [34]. Using TransGen AP221-02: TransStart Fastpfu DNA Polymerase for PCR amplification by following stpes: 3 min at 95 °C, number of cycles × 34 (30 s at 95 °C, 30 s at annealing temperature, 45 s at 72 °C), 10 min at 72 °C, and 10 °C until halted by user. S. cerevisiae was amplified to a 420 bp fragment, and S. stipitis was amplified to a 381 bp fragment. PCR products were detected and quantified by QuantiFluor™ -ST blue fluorescence quantification system (Promega, Wisconsin, America), and were mixed according to the sequencing volume requirements.

The Illumina official adapter sequence was added to the outer end of the target area by PCR, and the PCR product was cut and recovered using AxyPrepDNA Gel Recovery Kit (AXYGEN, America), eluted with Tris–HCl buffer, detected by 2% agarose electrophoresis, and denatured by sodium hydroxide to produce single-stranded DNA fragments to construct the Miseq library and Miseq sequence [35]. The PE reads obtained by MiSeq sequencing were divided, spliced by controlling quality, and sequence denoised (DADA2/Deblur) was also conducted. Amplicon Sequence Variant (ASV) represented sequence and abundance information was adopted for a statistical or visual analysis.

Results and Discussion

Proven of the Synergetic Effect of the Co-culturing Process

Firstly, the synergetic effect of the co-culturing process was investigated. To clarify the beneficial effect of the co-culturing system, the mono-culturing of S. cerevisiae and S. stipitis were carried out, and these systems were treated as the control groups. The inoculation size was 10% (v/v).

Generally, compared with the relatively lower ethanol yield of the mono-culturing of S. stipitis and S. cerevisiae, the co-culturing process exhibited higher ethanol yield (Fig. S1 and Table 1). Ethanol concentration in the end of co-culturing process reached 15.36 g/L, which was 1.05 and 1.24 times of the mono-culturing of S. stipitis and S. cerevisiae, respectively. As expected, xylose concentration almost did not change in the S. cerevisiae mono-culturing process, because the wild yeast strain cannot utilize xylose as carbon source. In addition, xylose consumption rate of the co-culturing process was similar to the mono-culturing of S. stipitis. Therefore, the metabolism of xylose by S. stipitis in the co-culturing process was not inhibited by S. cerevisiae. However, because of the relatively high sugars concentration and the presence of inhibitors in initial substrate, only 64.84% and 58.89% of xylose was consumed in the mono-culturing of S. stipitis and the co-culturing processes. The above results indicated the co-culturing of S. stipitis and S. cerevisiae outperformed the mono-culturing processes when using the corn stover hydrolysate that containing xylose and glucose.

Optimization of the Co-culturing Process

To further improve the ethanol fermentation performances by co-culturing process, parameters including the sugar concentration in substrate, the inoculation size, and the inoculate ratio of the two strains were optimized. Firstly, a medium with relatively high monosaccharide concentration was considered, because higher sugars content in substrate would increase the final bioethanol production in broth, and consequently save more energy in downstream process [36, 37]. However, since S. stipitis exhibited poor sugar and ethanol resistances, the high concentration of sugar and ethanol in medium might negatively influenced on the xylose consumption rate of S. stipitis in the co-culturing process [38, 39]. In contrast to the results obtained from the synthesized medium containing 20 g/L of xylose, ethanol productivity of S. stipitis mono-culturing process was reduced by 8.33% when using the synthetic medium containing 30 g/L of xylose (Fig. 1). As expected, the higher xylose containing substrate (> 60 g/L of xylose) exhibited poorer ethanol fermentation performance because of the inhibition of S. stipitis in co-culturing process, though S. cerevisiae exhibited higher sugar and ethanol tolerances.

The influence of inoculation size and ratio on co-culturing was further investigated. Similar to the phenomenon in literature, S. cerevisiae and S. stipitis were competing for glucose in hydrolysate as sole carbon source at the beginning of fermentation [40]. The highest glucose consumption rate of 2.47 g/L h can be realized with inoculation size of 10% (v/v) and S. cerevisiae/S. stipitis ratio of 60/40 (Fig. S2). Besides, although xylose can be utilized by S. stipitis, glucose was preferer as the carbon source when both glucose and xylose were abundantly provided in substrate (Table 1). For instance, xylose cannot be completely utilized by S. stipitis when up to 84 g/L of monomer sugars containing in substrate. Only 0.36 g/g of ethanol yield can be obtained when the total inoculation size was 5% (v/v) and S. cerevisiae/ S. stipitis ratio of 60/40. Therefore, xylose conversion was far behind the glucose conversion when inoculating the two strains together. This phenomenon might be attributed to the low S. stipitis concentration in the co-culturing process, owing to the inhibition of S. stipitis growth by excessive ethanol production [41].

The co-culturing performances were further evaluated using the synergetic substrate with lower sugars concentration in substrate (40 g/L glucose and 15 g/L xylose). As shown in Fig. 2, glucose was completely consumed within 24 h in all the tested groups, while xylose (Table 2) concentration in broth was slowly decreased after 24 h of cultivation. This can be explained by the slowly metabolism of xylose by S. stipitis until the glucose used up [42]. With the increasement of S. cerevisiae ratio in the inoculum, the average glucose consumption rate was increased. The increasement of S. stipitis ratio in inoculum promoted the conversion of xylose in substrate. However, xylose cannot be used up after 168 h of inoculation with a size of 5% (v/v), no matter the change of S. cerevisiae/S. stipitis ratio.

Co-culturing of S. stipitis and S. cerevisiae using the synthetic medium contain 40 g/L and 15 g/L of glucose and xylose. Impact of differences inoculation size and inoculation ratio on ethanol fermentation performances were analyzed. a Glucose consumption and b xylose consumption under overall 5% (v/v) of inoculum size. c Glucose consumption and d xylose consumption under overall 10% (v/v) of inoculum size. Fermentation performances under e the overall inoculum size of 5% (v/v) and f the overall inoculum size of 10% (v/v)

Xylose was completely utilized by S. stipitis when the inoculation size was 10% (v/v) and S. cerevisiae/S. stipitis ratio of 20/80 and 5/95. However, the initial inoculation size of S. stipitis was too low to fully utilized xylose in other conditions. On conditions of 20/80 and 10% (v/v) of the inoculation ratio and size, 20.7 g/L of ethanol can be obtained, with yield of 0.43 g/g (of total monomer sugar). The effective utilization of xylose in higher total inoculation size might be attributed to the higher initial base number, which facilitated the growth of S. stipitis in the exponential growth stage [43]. Nevertheless, xylose consumption by S. stipitis under higher inoculation size was still far behind the consumption of glucose. In fact, xylose-specific transporter, and the corresponding enzymes in S. stipitis were oxygen-dependent and highly competitive for oxygen in the co-culture flora [44, 45]. Hence, we hypothesize that a microaerophilic condition was required for the biotransformation of xylose by S. stipitis.

The impact of ventilation volume on ethanol fermentation was investigated. As expected, the ventilation volume was one of the pivotal factors which affected the co-culturing process (Fig. 3). Ethanol yield and xylose consumption were much sensitive than other parameters to the fluctuant of aeration rate. Under 0.03 vvm, the glucose and xylose consumption rates were significantly increased to 2.79 g/L h and 0.23 g/L h. Nevertheless, ethanol yield was only 0.37 g/g under 0.03 vvm, owing to the synergistic effect of evaporating the product and promoting the TCA cycle for cell growth [46, 47]. Comparatively, 0.01 vvm was a suitable aeration rate for the co-culturing process. 98.52% of initial monomer sugars can be assumed within 100 h. At the same time, ethanol concentration and yield reached 22.97 ± 0.48 g/L and 0.44 g/g, respectively (Table S1).

Co-culturing Using Lignocellulose Hydrolysate as Substrate

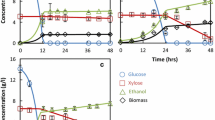

Co-culturing of S. cerevisiae/S. stipitis using lignocellulose hydrolysate as substrate. Figure 4 described the time course of the co-culturing process. Similar to the kinetics using the synthetic medium, a clear bi-phasic fermentation process has emerged. For the first phase, glucose can be utilized by twin-consortium with relatively high conversion rate, while in the second phase, the residual xylose was slowly converted into ethanol. In this process, glucose in corn stover hydrolysate was completely consumed within 24 h, while xylose was almost used up after 96 h of fermentation. Ethanol production and yield of 20.97 g/L and 0.39 g/g were obtained, which were lower than the results using synthetic medium. This can be explained by the inhibitions from organic acids, furans and phenolic compounds that were remained in hydrolysate [48]. However, the consumption rate of sugars in lignocellulosic hydrolysate was similar to the result using synthetic medium.

It worthy to be noted here that the co-culturing of S. cerevisiae/S. stipitis was as comparable as other co-culturing systems for cellulosic bioethanol production reported in previous literatures. As it is illustrated in Table 3, the co-culturing process had competitiveness in terms of pretreatment methods, fermentation scale, economic feasibility, and technical indicators. Moreover, the monomer sugars in the hydrolysate without detoxification and exogenous nutrients can be directly converted into bioethanol by the co-culturing process under high efficiency.

Dynamic of the Abundance of S. stipitis and S. cerevisiae

In order to ascertain the competition or symbiotic relationships between S. stipitis and S. cerevisiae in the co-culturing process, it is necessary to further clarify the growth status of each strain. For the first time, high-throughput sequencing, and bioinformatics ASV analysis were adopted to investigate the relative dynamic abundance of S. cerevisiae and S. stipitis in co-culturing system using lignocellulose hydrolysate as substrate (20/80 of S. cerevisiae/S. stipitis ratio was adopted) (Fig. 5).

In the co-culturing phase (within 24 h of calculation), compared with S. stipitis, S. cerevisiae showed stronger preference for glucose, and soon became the predominated strain in co-culturing system. The growth rate of S. cerevisiae was much higher than that of S. stipitis. The relative abundance of S. cerevisiae reached the maximum value of 82.91% at 24 h. In contrast, S. stipitis had poor robustness and competitiveness for glucose catabolism in the twin-consortium phase. It took longer period for S. stipitis to adapted stress of the environment. In the early stage of competition, S. stipitis did not make good use of glucose and was not growing as strong as the mono-culturing process, which affected xylose utilization.

In the second phase, with the lengthen of fermentation, carbon source competition was gradually disappearing because S. cerevisiae could not utilize xylose. S. stipitis was gradually adapted to environment and rapidly grew in this phase. Consequently, the abundance of S. stipitis was gradually increased, while residual xylose in broth started converted into ethanol. Finally, at 96 h, the cells concentration of S. stipitis was almost equal to that of S. cerevisiae.

Mass Balance

Mass balance of the co-culturing of S. cerevisiae/S. stipitis for conversion organic alkaline fractionated corn stover was evaluated. As can be seen from Fig. 6, 606 g of corn stover pulp can be recovered from 1 kg of dried raw material. After enzymatic hydrolysis, the lignocellulose hydrolysate with 243.6 g of glucose and 91.5 g of xylose was co-cultured with S. cerevisiae and S. stipitis, which eventually output 130.7 g of bioethanol.

Future works would be down to reveal the flora relationships between the two strains by transcriptomics and metabolomics analysis. In order to improve the overall yield of ethanol from monomer sugar in hydrolysate, metabolic engineering would be also adopted to modify the microorganisms by weakening the competition and strengthen the symbiotic relationship.

Conclusions

S. cerevisiae/S. stipitis co-culturing process can be applied for bioethanol fermentation using the lignocellulose hydrolysate as substrate, with advantages of high sugars conversion (95.97%) and ethanol yield (0.39 g/g total monomer sugars). The ethanol fermentation performance was greatly influenced by initial sugar concentration in substrate, the inoculation size, and the aeration rate. Moreover, high-throughput sequencing and dynamic abundance revealed the competition of the strains during the co-culturing process.

Data Availability

The data that support the findings of this study were available from the corresponding author upon reasonable request.

Code Availability

Not applicable.

References

Zhou, Z., Lei, F., Li, P., Jiang, J.: Lignocellulosic biomass to biofuels and biochemicals: a comprehensive review with a focus on ethanol organosolv pretreatment technology. Biotechnol. Bioeng. 115, 2683–2702 (2018). https://doi.org/10.1002/bit.26788

Zhang, C., Wen, H., Chen, C., Cai, D., Fu, C., Li, P., Qi, P., Tan, T.: Simultaneous saccharification and juice co-fermentation for high-titer ethanol production using sweet sorghum stalk. Renew. Energ. 134, 44–53 (2018). https://doi.org/10.1016/j.renene.2018.11.005

Su, C., Qi, L., Cai, D., Chen, B., Chen, H., Zhang, C., Si, Z., Wang, Z., Li, G., Qin, P.: Integrated ethanol fermentation and acetone-butanol-ethanol fermentation using sweet sorghum bagasse. Renew. Energ. 162, 1125–1131 (2020). https://doi.org/10.1016/j.renene.2020.07.119

Zhang, J., Cai, D., Qin, Y., Liu, D., Zhao, X.: High value-added monomer chemicals and functional bio-based materials derived from polymeric components of lignocellulose by organosolv fractionation. Biofuels Bioprod. Bioref. 14, 371–401 (2019). https://doi.org/10.1002/bbb.2057

Xu, L., Li, W., Xin, J., Zhang, S., Li, B., Yuan, Y.: Ethylenediamine enhances ionic liquid pretreatment performance at high solid loading. ACS Sustain. Chem. Eng. (2020). https://doi.org/10.1021/acssuschemeng.0c03884

Chen, H., Huo, W., Wang, B., Wang, Y., Wen, H., Cai, D., Zhang, C., Wu, Y., Qin, P.: L-lactic acid production by simultaneous saccharification and fermentation of dilute ethylediamine pre-treated rice straw. Ind. Crop. Prod. 141, 111749 (2019). https://doi.org/10.1016/j.indcrop.2019.111

Qin, L., Li, X., Zhu, J., Li, W., Xu, H., Guan, Q., Zhang, M., Li, B., Yuan, Y.: Optimization of ethylenediamine pretreatment and enzymatic hydrolysis to produce fermentable sugars from corn stover. Ind. Crop. Prod. 102, 51–57 (2017). https://doi.org/10.1016/j.indcrop.2017.03.0

Farias, D., Filho, F.M.: Co-culture strategy for improved 2G bioethanol production using a mixture of sugarcane molasses and bagasse hydrolysate as substrate. Biochem. Eng. J. 147, 29–38 (2019). https://doi.org/10.1016/j.bej.2019.03.02

Kim, S.R., Park, Y.C., Jin, Y.S., Seo, J.H.: Strain engineering of Saccharomyces cerevisiae for enhanced xylose metabolism. Biotechnol. Adv. 31, 851–861 (2013). https://doi.org/10.1016/j.biotechadv.2013.03.004

Ko, J.K., Um, Y., Woo, H.M., Kim, K.H., Lee, S.M.: Ethanol production from lignocellulosic hydrolysates using engineered Saccharomyces cerevisiae harboring xylose isomerase-based pathway. Bioresour. Technol. 209, 290–296 (2016). https://doi.org/10.1016/j.biortech.2016.02.124

Li, Y., Wang, M., Chen, Y., Wang, M., Fan, L., Tan, T.: Engineered yeast with a CO2-fixation pathway to improve the bio-ethanol production from xylose-mixed sugars. Sci. Rep. 7, 43875 (2017). https://doi.org/10.1038/srep43875

Borgström, C., Wasserstrom, L., Almqvist, H., Broberg, K., Klein, B., Noack, S., Lidé, G., Gorwa-Grauslund, M.F.: Identification of modifications procuring growth on xylose in recombinant Saccharomyces cerevisiae strains carrying the weimberg pathway. Metab. Eng. 55, 1–11 (2019). https://doi.org/10.1016/j.ymben.2019.05.010

Brandt, B.A., Jansen, T., Görgens, J.F., van Zyl, W.H.: Overcoming lignocellulose-derived microbial inhibitors: advancing the Saccharomyces cerevisiae resistance toolbox. Biofuels Bioprod. Bioref. 13, 1520–1536 (2019). https://doi.org/10.1002/bbb.2042

Parra-Ramírez, D., Martinez, A., Cardona, C.A.: Technical and economic potential evaluation of the strain Escherichia coli MS04 in the ethanol production from glucose and xylose. Bioch. Eng. J. 140, 123–129 (2018). https://doi.org/10.1016/j.bej.2018.09.015

Jeffries, T.W., Jin, Y.S.: Ethanol and thermotolerance in the bioconversion of xylose by yeast. Adv, Appl, Microbio 47, 221–268 (2000). https://doi.org/10.1016/S0065-2164(00)47006-1

Mei, G.Y., Bajwa, P.K., Dashtban, M., Ho, C.Y., Lee, H.: Transfer of plasmid into the pentose-fermenting yeast Pachysolen tannophilus. J. Microbiol. Methods. 148, 97–103 (2018). https://doi.org/10.1016/j.mimet.2018.03.013

Yuvadetkun, P., Reungsang, A., Boonmee, M.: Comparison between free cells and immobilized cells of Candida shehatae in ethanol production from rice straw hydrolysate using repeated batch cultivation. Renew. Energy. 115, 634–640 (2018). https://doi.org/10.1016/j.renene.2017.08.033

Jeffries, T.W., Grigoriev, I.V., Grimwood, J., Laplaza, J.M., Aerts, A., Salamov, A., Schmutz, J., Lindquist, E., Dehal, P., Shapiro, H., Jin, Y.S., Passoth, V., Richardson, P.M.: Genome sequence of the lignocellulose-bioconverting and xylose-fermenting yeast Pichia stipitis. Nat. Biotechnol. 25, 319–326 (2007). https://doi.org/10.1038/nbt1290

Qin, L., Dong, S., Yu, J., Ning, X., Xu, K., Zhang, S., Li, B., Li, J., Yuan, Y., Li, C.: Stress-driven dynamic regulation of multiple tolerance genes improves robustness and productive capacity of Saccharomyces cerevisiae in industrial lignocellulose fermentation. Metab. Eng. 60, 160–170 (2020). https://doi.org/10.1016/j.ymben.2020.06.003

Singh, A., Bajar, S., Bishnoi, N.R.: Enzymatic hydrolysis of microwave alkali pretreated rice husk for ethanol production by Saccharomyces cerevisiae Scheffersomyces stipitis and their co-culture. Fuel 116, 699–702 (2014). https://doi.org/10.1016/j.fuel.2013.08.072

Chen, Y.: Development and application of co-culture for ethanol production by co-fermentation of glucose and xylose: a systematic review. J. Ind. Microbiol. Biotechnol. 38, 581–597 (2010). https://doi.org/10.1007/s10295-010-0894-3

Wang, L., York, S.W., Ingram, L.O., Shanmugam, K.T.: Simultaneous fermentation of biomass-derived sugars to ethanol by a co-culture of an engineered Escherichia coli and Saccharomyces cerevisiae. Bioresour. Technol. 273, 269–276 (2018). https://doi.org/10.1016/j.biortech.2018.11.016

Hickert, L.R., da Cunha-Pereira, F., de Souza-Cruz, P.B., Rosa, C.A., Ayub, M.A.Z.: Ethanogenic fermentation of co-cultures of Candida shehatae HM 52.2 and Saccharomyces cerevisiae ICV D254 in synthetic medium and rice hull hydrolysate. Bioresour. Technol. 131, 508–514 (2013). https://doi.org/10.1016/j.biortech.2012.12.135

Qian, M., Tian, S., Li, X., Zhang, J., Pan, Y., Yang, X.: Ethanol production from dilute-acid softwood hydrolysate by co-culture. Appl. Biochem. Biotechnol. 134, 273–284 (2006). https://doi.org/10.1385/abab:134:3:273

Suriyachai, N., Weerasaia, K., Laosiripojana, N., Champreda, V., Unrean, P.: Optimized simultaneous saccharification and co-fermentation of rice straw for ethanol production by Saccharomyces cerevisiae and Scheffersomyces stipitis co-culture using design of experiments. Bioresour. Technol. 142, 171–178 (2013). https://doi.org/10.1016/j.biortech.2013.05.003

Delgenes, J.P., Escare, M.C., Laplace, J.M., Moletta, R., Navarro, J.M.: Biological production of industrial chemicals, i.e. xylitol and ethanol, from lignocelluloses by controlled mixed culture systems. Ind. Crop. Prod. 7, 101–111 (1998). https://doi.org/10.1016/s0926-6690(97)00038-1

Kordowska-wiater, M., Targonski, Z.: Ethanol fermentation on glucose/xylose mixture by co-cultivation of restricted glucose catabolite repressed mutants of Pichia stipitis with respiratory deficient mutants of Saccharomyces cerevisiae. Acta. Microbiol. Pol. 51, 345–352 (2002)

Okuofu, S.I., Bhagwat, P., Gerrano, A.S., Singh, S., Pillai, S.: Simultaneous saccharification and bioethanol production from underutilized biomass, cowpea haulm using co-cultures of Saccharomyces cerevisiae (BY4743) and Scheffersomyces stipitis (PsY633). Biomass Convers. Bior. 1, 196 (2021). https://doi.org/10.1007/s13399-021-01368-2

De Bari, I., De Canio, P., Cuna, D., Liuzzi, F., Capece, A., Romano, P.: Bioethanol production from mixed sugars by Scheffersomyces stipitis free and immobilized cells, and co-cultures with Saccharomyces cerevisiae. New Biotechnol. 30, 591–597 (2013). https://doi.org/10.1016/j.nbt.2013.02.003

Wen, Z., Wu, M., Lin, Y., Yang, L., Lin, J., Cen, P.: Artificial symbiosis for acetone-butanol-ethanol (ABE) fermentation from alkali extracted deshelled corn cobs by co-culture of Clostridium beijerinckii and Clostridium cellulovorans. Microb. Cell Fact. 13, 92 (2014). https://doi.org/10.1186/s12934-014-0092-5

Mithra, M.G., Padmaja, G.: Improvement in ethanol yield from lignocellulo-starch biomass using Saccharomyces cerevisiae alone or its co-culture with Scheffersomyces stipitis. Curr. Biotechnol. 9, 57–76 (2020). https://doi.org/10.2174/2211550109666200311111119

Papini, M., Nookaew, I., Uhlén, M., Nielsen, J.: Scheffersomyces stipitis: a comparative systems biology study with the crabtree positive yeast Saccharomyces cerevisiae. Microb. Cell Fact. 11, 136 (2012). https://doi.org/10.1186/1475-2859-11-136

Li, Y., Lu, Y., Zhang, Z., Mei, S., Tan, T., Fan, L.: Co-fermentation of cellulose and sucrose/xylose by engineered yeasts for bioethanol production. Energy Fuel 31, 4061–4067 (2017). https://doi.org/10.1021/acs.energyfuels.7b00032

Toju, H., Tanabe, A.S., Yamamoto, S., Sato, H.: High-coverage ITS primers for the DNA-based identification of ascomycetes and basidiomycetes in environmental samples. PLoS ONE 7, e40863 (2012). https://doi.org/10.1371/journal.pone.0040863

Nilsson, R.H., Anslan, S., Bahram, M., Wurzbacher, C., Baldrian, P., Tedersoo, L.: Mycobiome diversity: high-throughput sequencing and identification of fungi. Nat. Rev. Microbiol. 17, 95–109 (2019). https://doi.org/10.1038/s41579-018-0116-y

Mukasekuru, M.R., Kaneza, P., Sun, H., Sun, F.F., He, J., Zheng, P.: Fed-batch high-solids enzymatic saccharification of lignocellulosic substrates with a combination of additives and accessory enzymes. Ind. Crop. Prod. 146, 112156 (2020). https://doi.org/10.1016/j.indcrop.2020.11215

Molaverdi, M., Karimi, K., Mirmohamadsadeghi, S., Galbe, M.: High titer ethanol production from rice straw via solid-state simultaneous saccharification and fermentation by Mucor indicus at low enzyme loading. Energ. Convers. Manage. 182, 520–529 (2019). https://doi.org/10.1016/j.enconman.2018.12.0

Du Preez, J.C., Bosch, M., Prior, B.A.: Temperature profiles of growth and ethanol tolerance of the xylose-fermenting yeasts Candida shehatae and Pichia stipitis. Appl. Microbiol. Biotechnol. 25, 521–525 (1987). https://doi.org/10.1007/bf00252010

Liang, M., Kim, M.H., He, Q.P., Wang, J.: Impact of pseudo-continuous fermentation on the ethanol tolerance of Scheffersomyces stipitis. J. Biosci. Bioeng. 116, 319–326 (2013). https://doi.org/10.1016/j.jbiosc.2013.03.016

Nguyena, D.T.T., Praveen, P., Loh, K.C.: Co-culture of Zymomonas mobilis and Scheffersomyces stipitis immobilized in polymeric membranes for fermentation of glucose and xylose to ethanol. Biochem. Eng. J. 145, 145–152 (2019). https://doi.org/10.1016/j.bej.2019.02.019

Zhu, Y., Wu, L., Zhu, J., Xu, Y., Yu, Y.: Transcriptome and metabolome analysis of Pichia stipitis to three representative lignocellulosic inhibitors. Archives Microbiol. (2018). https://doi.org/10.1007/s00203-018-1600-5

Demeke, M.M., Dietz, H., Li, Y., Foulquie-Moreno, M.R., Mutturi, S., Deprez, S., Den Abt, T., Bonini, B.M., Liden, G., Dumortier, F., Verplaetse, A., Boles, E., Thevelein, J.M.: Development of a D-xylose fermenting and inhibitor tolerant industrial Saccharomyces cerevisiae strain with high performance in lignocellulose hydrolysates using metabolic and evolutionary engineering. Biotechnol. Biofuels 6, 89 (2013). https://doi.org/10.1186/1754-6834-6-89

Sreemahadevan, S., Singh, V., Roychoudhury, P.K., Ahammad, S.Z.: Mathematical modeling, simulation and validation for co-fermentation of glucose and xylose by Saccharomyces cerevisiae and Scheffersomyces stipitis. Biomass Bioenergy 110, 17–24 (2018). https://doi.org/10.1016/j.biombioe.2018.01.0

Weierstall, T., Hollenberg, C.P., Boles, E.: Cloning and characterization of three genes (SUT1-3) encoding glucose transporters of the yeast Pichia stipitis. Mol. Microbiol. 31, 871–883 (1999). https://doi.org/10.1046/j.1365-2958.1999.01224.x

Slininger, P.J., Thompson, S.R., Weber, S., Liu, L.Z., Moon, J.: Repression of xylose-specific enzymes by ethanol in Scheffersomyces (Pichia) stipitis and utility of repitching xylose-grown populations to eliminate diauxic lag. Biotechnol. Bioeng. 108, 1801–1815 (2011). https://doi.org/10.1002/bit.23119

Wang, Y., Liu, J., Cai, D., Zhao, G.: Co-generation of ethanol and l-lactic acid from corn stalk under a hybrid process. Biotechnol. Biofuels 11, 331 (2018). https://doi.org/10.1186/s13068-018-1330-6

Dai, Z., Huang, M., Chen, Y., Siewers, V., Nielsen, J.: Global rewiring of cellular metabolism renders Saccharomyces cerevisiae crabtree negative. Nat. Commun. 9, 3059 (2018). https://doi.org/10.1038/s41467-018-05409-9

Lyu, G., Yoo, C.G., Pan, X.: Alkaline oxidative cracking for effective depolymerization of biorefining lignin to mono-aromatic compounds and organic acids with molecular oxygen. Biomass Bioenergy 108, 7–14 (2018). https://doi.org/10.1016/j.biombioe.2017.10.046

Costa, C.E., Romaní, A., Cunha, J.T., Johansson, B., Domingues, L.: Integrated approach for selecting efficient Saccharomyces cerevisiae for industrial lignocellulosic fermentations: Importance of yeast chassis linked to process conditions. Bioresour. Technol. 227, 24–34 (2017). https://doi.org/10.1016/j.biortech.2016.12.016

Wang, Z., Dien, B.S., Rausch, K.D., Tumbleson, M.E., Singh, V.: Improving ethanol yields with deacetylated and two-stage pretreated corn stover and sugarcane bagasse by blending commercial xylose-fermenting and wild type Saccharomyces yeast. Bioresour. Technol. 282, 103–109 (2019). https://doi.org/10.1016/j.biortech.2019.02.123

Sasakia, K., Tsuge, Y., Sasaki, D., Teramura, H., Inokuma, K., Hasunuma, T., Ogino, C., Kondo, A.: Mechanical milling and membrane separation for increased ethanol production during simultaneous saccharification and co-fermentation of rice straw by xylose-fermenting Saccharomyces cerevisiae. Bioresour. Technol. 185, 263–268 (2015). https://doi.org/10.1016/j.biortech.2015.02.11

Cunha, J.T., Romaní, A., Costa, C.E., Sá-Correia, I., Domingues, L.: Molecular and physiological basis of Saccharomyces cerevisiae tolerance to adverse lignocellulose-based process conditions. Appl. Microbiol. Biot. 103, 159–175 (2019). https://doi.org/10.1007/s00253-018-9478-3

Acknowledgements

This work was supported in part by the National Key Research and Development Program of China (Grant No. 2018YFB1501702), Natural Science Foundation of China (Grant No. 22078018), Key Research and Development Program of Hebei Province (Grant No. 21327316D), and Bingtuan Science and Technology Program (Grant No. 2022DB025).

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

YW: methodology, formal analysis, investigation, writing—original draft, review and editing. JW: investigation, review and editing; KW: resources, review and editing; CS: writing—review and editing. CC: investigation, review and editing. ZC: review and editing. DC: conceptualization of idea, project leader, funding acquisition, supervision, writing—review and editing. SC: review and editing. HC: funding acquisition and supervision. PQ: writing—review and editing, funding acquisition and co-supervision.

Corresponding author

Ethics declarations

Conflict of interest

These authors declare that they are no conflict of competing interest to declare.

Ethical Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wu, Y., Wen, J., Wang, K. et al. Understanding the Dynamics of the Saccharomyces cerevisiae and Scheffersomyces stipitis Abundance in Co-culturing Process for Bioethanol Production from Corn Stover. Waste Biomass Valor 14, 43–55 (2023). https://doi.org/10.1007/s12649-022-01861-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-01861-3