Abstract

Purpose

The yield of levan extracted from microbial fermentation broth is low, so in vitro catalytic synthesis of levan by levansucrase is expected to be one of the industrial production approaches of levan.

Methods

The recombinant plasmid pET-28a-AcmA-Z constructed in a previous study was used to produce levansucrase. The effects of temperature, pH, and metal ions on the levan formation activity of the levansucrase were investigated. The polymer was analyzed by means of HPIC, FTIR, and NMR techniques.

Results

The recombinant levansucrase could be easily purified in one step and the purified enzyme had a single band clearly visible in SDS-PAGE. The conditions for enzymatic reactions were optimal at pH 5.2 and 40 ℃, and the activity of enzymes was stimulated by K+ and Ca2+. The yield of levan biosynthesis from 10% (w/v) sucrose with 6.45 U/g sucrose of levansucrase was 30.6 g/L. The molecular weight of the levan was approximately 1.56 × 106 Da, as measured by GPC. HPIC analysis showed that the monosaccharide composition of the levan was fructose and glucose. The results of FTIR and NMR analysis indicated that the polymer produced by the recombinant levansucrase was β-(2,6) levan.

Conclusions

The results of this study provide a basis for the large-scale production of levan by enzymatic methods.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Statement of Novelty

Levan-type fructan has great potential for development and utilization in biomedical, food and pharmaceutical fields. The content of levan in microorganisms and plants is low and difficult to extract, while the levan synthesized by levansucrase using sucrose as substrate is easier to purify and operate. Therefore, levan production by enzymatic method may be an effective choice to solve the problem of low yield of wild strains. This study not only measured the levan formation activity of levansucrase but also provided insight into the molecular structure information on biosynthesized product. Our research provides a promising candidate for industrial production levan.

Introduction

Levan is a fructan biopolymer, consisting of repeating fructose subunits with a glucose residue at the reducing end. Levan's fructose chain is formed by β-(2,6) glycosidic bonds with some β-(2,1) linked branch chains [1–3]. Due to its excellent biocompatibility, biodegradability, renewability, eco-friendliness, and human compatibility, levan has a wide range of applications in the fields of food, pharmaceuticals and cosmetics [4, 5]. In the food industry, levan is used as a stabilizer, encapsulating agent, water-holding agent, surface-finishing agent, thickener, emulsifier, flavor carrier, and prebiotic sweetener [6]. In addition, levan can also increase the shelf life of food and be used as a fat substitute [7]. In the field of pharmaceuticals, levan can be used as a plasma substitute [4] and have anti-hyperglycemia, anti-diabetes, anti-oxidation, anti-virus [8], cholesterol-lowering [9], anti-tumor [10] and immunomodulatory bioactivities. For example, levan produced by levansucrase from Leuconostoc mesenteroides NTM048 can induce IgA production in rats [11]. In the field of cosmetics, levan plays an important role in cell proliferation, skin moisturizing and skin irritation-alleviating as a mixed ingredient [1, 12], because it can protect plant cells by storing water and controlling the active ingredient in a fixed area during the growth of plant cells.

Levan is naturally produced by plants or microorganisms. Microbial levans have a much larger molecular weight (2 to 100 MDa) than plant-produced levans (2 to 33 KDa) and have more branches [13]. Due to the low content of levan in plants and the high cost of natural extraction and separation, levan is not suitable for industrial production. It is a good choice to synthesize levan by microorganisms. To date, the production of levan is mainly biosynthesized by levansucrase using sucrose as a substrate. Levansucrase catalyzes hydrolysis, transglycosylation, and polymerization reactions in the formation of levan [14]. Many microorganisms can produce levan, such as Zymomonas [5], Halomonas [15], Bacillus [16], Acetobacter xylinum [17], Pseudomonas [18] and Leuconostoc mesenteroides [19], but most of their production is too low to meet commercial needs. Therefore, levan production by enzymatic methods may be an effective choice to solve the problem of low yield of wild strains.

In this study, the preconstructed genetically engineered bacterium Escherichia coli BL21 was used to produce levansucrase (GenBank MT038999). The effects of temperature, pH, and metal ions on activitiy of the purified recombinant enzyme were investigated to evaluate its potential to synthesize levan. The polymer was analyzed by means of high-performance ion chromatography (HPIC), Fourier transform infrared (FTIR), and nuclear magnetic resonance (NMR) techniques. The structure of the biosynthetic product was determined to be levan-type fructan.

Materials and Methods

Materials

E. coli strains DH5α and BL21 were cultivated aerobically at 37 °C in lysogeny broth (LB). Restriction endonucleases, Prime STAR Max DNA Polymerase, and DNA Ligation Kit were obtained from TaKaRa Biotechnology Co., Ltd. (Dalian, China) or New England BioLabs (Beijing, China). The DNA primers and Plasmid Mini Kit were obtained from Shanghai Sangon Biological Engineering Technology & Services Co., Ltd. (Shanghai, China). All other reagents were of analytical grade and were commercially available unless otherwise indicated.

Gene Cloning, Expression and Purification of the Recombinant Levansucrase

In a previous study, a levansucrase expression system using E. coli BL21 as the host was constructed [20]. The recombinant genetically engineered bacterium were harvested by centrifugation at 12,000 rpm for 20 min at 4 °C, and the precipitate was washed twice with 50 mM Tris–HCl buffer (pH 7.0) and subsequently disrupted by ultrasonic oscillation. The cellular debris and unbroken cells were separated by centrifugation at 12,000 rpm for 25 min at 4 °C, and we collected the supernatant. Then, we purified the supernatant (crude enzyme) by the Gram-positive enhancer matrix (GEM) purification method in one step. The essence of GEM is peptidoglycan, which can bind to recombinant levansucrase with the AcmA label. The preparation method of GEM particles mainly refers to the literature of Zhao [21]. Equal parts of GEM particles were combined with the Acma-labeled recombinase, centrifuged at 4 °C and 12,000 rpm for 30 min to collect the precipitate and dissolved in the constant volume of Tris–HCl (pH 7.2) buffer solution. SDS-PAGE was carried out on a SE 250 electrophoretic device (GE Healthcare, USA) using a 12% separation gel and 5% stacked gels under a constant 100 mV current. Proteins in the gel were stained with Coomassie blue G-250 and destained with double distilled water. After SDS-PAGE, the correct expression of the enzyme was confirmed.

Measurement of the Levan Formation Activity of Levansucrase

To determine the levan formation activity, 1 mL 5% phenol and 5 mL concentrated sulfuric acid were added to the reaction system (2 mL 10% sucrose solution and 20 μL purified enzyme at pH 5.2 and 55 °C). The solution was placed at room temperature for 20 min, and then the absorbance was measured at 490 nm by a UV–VIS spectrophotometer (MAPADA, V-1800).

Effect of Temperature, pH, and Metal Ions on the Levan Formation Activity of the Recombinant Levansucrase

The optimum temperature for the activity of levansucrase was measured at 20.0–60.0 °C in pH 5.2 sodium acetate-acetate buffer using sucrose as the substrate (10% w/v), and the optimum pH for enzyme activity was tested at pH 4.6–5.6. The effect of metal ions was detected by preprocessing the levansucrase and sucrose (10% w/v) in the sodium acetate-acetate buffer (pH 5.2) containing 5 mM or 50 mM K+, Ca2+, Cu2+, Mg2+, Fe2+, Fe3+, Ba2+, Zn2+, Ni2+ and Mn2+ at 40 °C for 2 h. All the experiments were performed in triplicate, and the error was expressed as the standard deviation of the three measurements.

Determination of Kinetic Parameters

Kinetic parameters of the levansucrase reactions were determined by varying the sucrose concentration (0.0078–0.125 M) at 40 °C and pH 5.2. We used the DNS (3,5-dinitrosalicylic acid) method to determine the released total reducing sugar concentrations [22]. Data were fitted to the standard Michaelis—Menten formula.

Preparation and Purification of Levan

The crude polysaccharide solution after the enzyme reaction was centrifuged at 4 °C and 8, 000 rpm for 30 min. Three times the volume of precooled 95% (v/v) ethanol was added to the supernatant, and the polysaccharide was precipitated overnight at 4 °C. Then, the polysaccharide was centrifuged according to the above conditions and redissolved in an appropriate amount of ultrapure water. The redissolved solution was dialyzed with ultrapure water at 4 °C for 72 h in a dialysis bag with a cutoff of 14 kDa, and the water was changed every 8 h. Finally, the polysaccharide sample was obtained by lyophilization.

Monosaccharide Composition Analysis

In this study, high-performance ion chromatography (HPIC, ThermoFisher ICS5000) was used to determine the monosaccharide composition. The 13 kinds of monosaccharide standard (fucose, rhamnose, arabinose, galactose, glucose, xylose, mannose, fructose, ribose, galacturonic acid, glucuronic acid, guluronic acid, and mannuronic acid) were prepared into 10 mg/mL standard solution, respectively. Four mg of the sample was put into an ampoule bottle, and 1 mL 2 mol/L trichloroacetic acid was added to it. The ampoule bottle filled with the solution was put into an oven for hydrolysis for 2 h at 100 °C. The acid hydrolysis solution (200 µL) was transferred to a 1.5 mL Eppendorf tube for nitrogen blowing and drying, and 1 mL water was added for vortex mixing. The solution was centrifuged at 12, 000 rpm for 5 min. The supernatant was added to the IC for analysis. The detector used for ion chromatography analysis was an electrochemical detector. The chromatographic column type was a DionexCarbopacTMPA20 (3*150), and the detection temperature was 30 °C. Mobile phase: A: H2O; B: 250 mM NaOH; C: 50 mM NaOH & 500 mM NaOAC. The flow rate was 0.3 mL/min and the injection volume was 5 µL.

Levan Structural Characterization and Identification Methods

Molecular Weight and Purity of Levan

The average molecular weight and purity of the levan were determined by gel permeation chromatography (GPC, Waters 1515) with a Waters 2414 Refractive Index Detector. The Ultrahydrogel 120, 250 and 500 PKGD columns were eluted with 0.1 M NaNO3 at a flow rate of 1 mL/min. Samples (25 mg/L, 50 μL) were injected into the column. Polyethylene glycol (PEG) standard compounds (Mp 330,000, 176,000, 82,500, 44,000, 25,300, 20,600, 12,600, 7130, 4290, 1400, 633, 430 KDa) were provided by Polymer Standards Service-USA Inc [23] .

Scanning Electron Microscope (SEM) of Levan

The surface morphology of the levan was obtained by Scanning Electron Microscope (SEM, SU8020). Freeze-dried pure levan was fixed to the SEM stubs with double-faced adhesive tape and coated with conductive gold in an ion sputtering apparatus. The microstructures of samples with different magnifications were observed at an accelerating voltage of 10 kV. In this study, SEM images of levan samples at magnifications of 400 × , 1000 × , and 2000 × were obtained.

Atomic Force Micrograph (AFM) of Levan

The surface morphology and roughness of levan were obtained by Atomic force micrograph (AFM, Bruker Multimode8) analysis. The levan solution with a concentration of 1 mg/mL was prepared and stirred continuously for 1 h at 40 °C in an airtight bottle. Once cooled to room temperature, 5 μL of levan solution was absorbed into the mica sheet. The AFM images of levan were obtained in tapping mode after drying at room temperature.

Fourier-Transform Infrared Spectroscopy (FT-IR)

Fourier-transformed infrared spectroscopy is a common method for the determination of functional groups present in levan. The levan and KBr powder were thoroughly mixed in a ratio of 1:100 to make a 1 mm thick KBr pellet. The absorption spectrum of levan was recorded on a Thermo IS5 instrument (America) in the region of 4000–400 cm−1.

Nuclear Magnetic Resonance Spectroscopy (NMR)

The 1H and 13C NMR spectrum of the levan solution were recorded using a Bruker 600 M spectrometer (Switzerland). Purified and freeze-dried levan (20 mg) was dissolved in D2O [24], dissolving and lyophilizing repeatedly to realize the exchange of H and D. The prepared sample was sealed in an NMR tube. All experiments were performed at room temperature and all the data were analyzed with MestRenova software.

Results and Discussion

Purification of the Recombinant Levansucrase

As shown in Fig. 1, the purified enzyme had a single band clearly visible at approximately 75 kDa on SDS-PAGE, indicating that no impurities were introduced in the purification process. GEM particle purification is a promising method that can save purification time, simplify operation and reduce activity loss compared with traditional purification methods [21].

Effect of Temperature, pH, and Metal Ions on the Levan Formation Activity of the Recombinant Levansucrase

The levan biosynthesis ability of the recombinant enzyme was evaluated at various temperatures, ranging from 20 to 60 °C. As shown in Fig. 2A, the optimum activity temperature of the recombinase was 40 °C, and the activity of the recombinase was severely inhibited when temperatures below 30 °C and above 55 °C. Levansucrase from Bacillus methylotrophicus SK 21.002 showed the highest levan production at around 37 °C [25]. A lower optimum temperature for levan formation of 15 ℃ was reported for levansucrase from Halomonas smyrnensis AAD6T [26].

The effect of pH on the levan biosynthesis ability of the recombinant enzyme was studied at different pH values (4.6–5.6). The highest levan formation activity of the enzyme was obtained at pH 5.2. As shown in Fig. 2B, the activity was rather sensitive to pH, which was only high at pH 5.2 but decreased sharply when pH was below 5.0 or above 5.4. The optimum pH for levan synthesis was lower than that of levansucrase from Leuconostoc mesenteroides B-512 FMC [27] and levansucrase from Brenneria goodwinii [28], and their optimum pH values were 6.2 and 6.0, respectively. The optimal pH for most levansucrases is between 5.0 and 6.5 [29].

The effects of different concentrations and different kinds of metal ions on the levan formation activity of levansucrase were determined at pH 5.2 and 40 °C (Fig. 2C). Fifty mM Ca2+ and K+ increased the activity to around 130% of the initial relative activity. However, metal ions such as Cu2+, Fe3+ and Zn2+ had an obvious inhibitory effect on the enzyme activity indicating that the recombinase was sensitive to the presence of Cu2+, Fe3+ and Zn2+. Levansucrase from Bacillus methylotrophicus SK 21.002 was tested for its effects on metal ions on levan biosynthesis. 20 mM Mg2+ increased the enzyme activity to 115% of the initial relative activity, while Cu2+, Fe2+, and Zn2+ had a strong inhibitory effect on the enzyme activity [25]. Hg2+ and Ag+ decreased the activity of levansucrase from Leuconostoc Mesenteroides B-512 FMC by 92% and 86%, respectively, while Zn2+, Fe2+ and Cu2+ slightly inhibited the activity of levansucrase [27].

Levan biosynthesis was carried out from 10% (w/v) sucrose at pH 5.2 and 40 °C using the recombinant levansucrase of 6.45 U/g sucrose. The highest production reached 30.6 g/L after 2 h, which was higher than 15 g/L for Erwinia herbicolaand [30] and lower than 36 g/L for B. polymyxa (NRRL B-18475) [31].

Enzyme Kinetics

Different concentrations of sucrose solution were prepared with sodium acetate-acetate buffer. The reaction rate of levansucrase with different concentrations of sucrose solution was determined according to the method described in Sect. 2.5. According to the regression equation (Fig. 3), the Michaelis constant of levansucrase to sucrose was 25.63 mM. The Km value of the enzyme in this study was similar to the Km value (24 mM) of the levansucrase from Leuconostoc mesenteroides NTM048 [11]. Moreover, the Km value was much lower than that of levansucrase from Halomonas smyrnensis AAD6T (104.79 ± 4.17 mM) [26]. Therefore, the affinity of levansucrase from different microbial sources to sucrose is very different.

Monosaccharide Composition Analysis

Monosaccharide composition analysis usually requires hydrolysis of polysaccharides or oligosaccharides with appropriate acids before derivatization for gas chromatography (GC) and high-performance liquid chromatography (HPLC) analysis, or high-performance ion chromatography (HPIC) analysis without derivatization. The resulting chromatogram is shown in Fig. 4. By comparing the retention time of sample monosaccharides with that of standard monosaccharides, it was determined that the sample polysaccharide was composed of fructose, glucose and galactose, which accounted for 81.6%, 16.6% and 1.9%, respectively. The monosaccharide composition of polysaccharides is related to many factors: for example, the hydrolysis temperature of the sample can affect the extraction of ketose. When the temperature was 30–70 °C, the free fructose was relatively stable; when the temperature rose to 120 ℃, the free fructose would rapidly degraded to 80% [32].

Molecular Weight and Purity of Levan

Gel permeation chromatography is the most commonly used method to detect the purity and molecular weight of polysaccharides. The molecular weight of levan was obtained by comparing the retention time of levan with the standard substance with different molecular weights. The retention time of levan was 16.667 min and it has a single elution peak in gel permeation chromatography (Fig. 5), indicating that the polymer is a homogeneous component. Based on the linear regression curve of PEG standards, the average molecular weight of levan was calculated to be 1.56 × 106 Da. In general, the molecular weight of polysaccharides is related to many factors, including strain type, fermentation conditions, medium composition, and extraction method. Malang et al. [33] showed that levans synthesized by raffinose as a carbon source in W. confusa E5/2–1 have a higher molecular weight than levans synthesized from sucrose. Levan produced by Bacillus subtilis was reported to have two levan distributions: a high molecular weight levan (2.3 × 106 Da) and a low molecular weight levan (7.2 × 103 Da) [34]. The molecular weight of levan in this study is between the two. Levan with different molecular weights has different applications in medicine, cosmetics and food. For example, levan with a low Mw produced from Z. Mobilis had a stronger antibacterial inhibition in vitro, while levan with a high Mw produced from Bacillus subtilis NRC1aza had the strongest DPPH free radical scavenging activity [35].

SEM Analysis

A scanning electron microscopy analysis was performed to observe the microstructure and surface morphology of the levan, which can help in understanding the physical properties of the levan. The surface morphology micrographs of levan at 400 × , 1000 × , 2000 × are shown in Fig. 6. As observed by SEM images, levan in this study had a highly branched and porous structure. It was supposed that levan with a highly branched and porous structure was conducive to the formation of hydrated polymers and was most likely to be used in the foods and cosmetics industries as a texturing, thickening, stabilizing, and water-binding agent [36–38]. In addition, SEM images indicated that levan had a sheet-like smooth and glossy surface, which has the potential to prepare plasticized films [39]. The partial microstructure of the levan in this study was similar to the microstructure of glucan produced by Leuconostoc pseudomesenteroides XG5, which had a smooth and glittering surface and high branched structure [38], but there were a little differences between levan from Bacillus mojavensis and Brenneria sp. EniD312 exhibited a uniform porous network [7, 40].

AFM Analysis

AFM is a useful tool for characterizing polymer morphology with high resolution and simple operation, and was developed on the basis of SEM. The topographical AFM images of levan exhibited many ellipsoidal or spheroidal particles and spike-like lumps (Fig. 7), which indicated that polysaccharides had a strong affinity with water molecules [40–42]. The maximum peak height of rounded lumps was 55.7 nm, the average roughness was 3.41 nm and the mean roughness was 1.48 nm. The maximum height of levan was much higher than the height of a single polysaccharide chain(0.1–1 nm) suggesting that the tightly packed molecular structure formed in AFM images may be caused by the intermolecular and intramolecular aggregation of levan [36]. A similar result was reported for the EPS polymer from Lactobacillus sakei L3 [43] but different from Lactobacillus reuteri E81 glucan, which had the tangled networks [44], and Mesona blumes gum EPS polymer, which had an irregular shape like the worm [45].

FT-IR Analysis

Fourier-transformed infrared spectroscopy was used to determine the glycosidic bond configuration and the functional groups on the sugar chain by using the relative vibrations within the molecule and molecular rotation information to analyze the structure of polysaccharides. Figure 8 showed the FT-IR spectrum of purified levan. The wide and strong peak at 3304 cm−1 was caused by the stretching vibration of O–H [25, 46], indicating the existence of intermolecular hydrogen bonding. The weak peaks at 2931 cm−1 and 2887 cm−1 were the results of C–H stretching vibration and bending vibration respectively [47]. The strong absorption peak at 1644 cm−1 was caused by the O–H bending vibration, which might be caused by the presence of water in the sample [48]. The absorption peaks at 1122 cm−1 and 1009 cm−1 were caused by C–O–C stretching vibrations [49], which are the characteristic peaks of carbohydrates. The absorption peaks at 923 cm−1 and 809 cm−1 represent the symmetric stretching vibration of furanose and the D-type C-H bending vibration of furanose respectively, which are typical signal peaks of furanose [14, 50]. Thus, it was proven that a furan ring was contained in the polysaccharide structure. Preliminary analysis showed that the polysaccharide was composed of D-furanose.

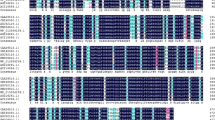

NMR Analysis

Further analysis of the structure of purified polysaccharides was obtained by 1H and 13C NMR spectra (Fig. 9). The 13C NMR spectra had several signals in the anomeric carbon signal region (95–110 ppm). The peak at 96.31 ppm may be a signal for ɑ-glucose C1 [51]. Two peaks at 104.19 and 103.65 ppm were derived from the β-fructose C2 signal [52]. Major signals in the ring carbon signal region (50–85 ppm) at around 59.88, 76.28, 75.18, 80.27 and 63.36 ppm were attributed to the fructose groups C1, C3, C4, C5 and C6, respectively. Among them, the signal at 63.36 ppm (C6) confirmed the presence of the fructose β-(2,6)-linkage [53]. The carbon chemical shifts of levan produced by levansucrase reported in other literatures are shown in the table below, which are similar to the six signals in this paper.

According to the 1H NMR spectra, the signal at 4.70 ppm was due to D2O. The signals of 5.33 and 5.15 ppm in the anomeric proton region can be attributed to the characteristic signal of ɑ-glucose H1 [39]. Seven major proton signals were observed at 4.10 ppm (H3), 4.01 ppm (H4), 3.87 ppm (H5), 3.82 ppm (H6a), 3.68 ppm (H1a), 3.60 ppm (H1b), and 3.48 ppm (H6b). All of them were in the ring proton region (3.4–4.2 ppm), indicating the presence of fructose in the polysaccharide [50]. The ratio of peak areas was approximately 1:1:1:1:1:1, which indicated the same amount of every kind of H atom. No galactose residue signal was found in the spectrum, which may be due to the low content of galactose residues, resulting in too little signal accumulation. All the information indicated that the polysaccharide synthesized by levansucrase was β-(2,6) levan.

Conclusion

In this study, levan was synthesized in vitro with recombinant levansucrase from the Bacillus subtilis ZW019 strain. The yield of levan reached 30.6 g/L. The synthesized levan has a molecular weight of 1.56 × 106 Da, and its structure is β-(2,6) fructose, containing a furan ring. The results indicated that the genetically engineered E. coli strain could express levansucrase efficiently, and the recombinant levansucrase could be easily purified in one step. Moreover, the recombinant levansucrase showed high catalytic activity in vitro, and the composition and structure of the synthesized levan were highly similar to those of natural levan. In the future, we will further study the biological function of the levan synthesized by enzymatic methods and then explore the application way of the levan.

Data Availability

All data included in this study are available upon request by contact with the corresponding author.

References

Bouallegue, A., Casillo, A., Chaari, F., Cimini, D., Corsaro, M.M., Bachoual, R., Ellouz-Chaabouni, S.: Statistical optimization of levan: Influence of the parameter on levan structure and angiotensin I-converting enzyme inhibitory. Int. J. Biol. Macromol. 158, 945–952 (2020)

Jathore, N.R., Bule, M.V., Tilay, A.V., Annapure, U.S.: Microbial levan from Pseudomonas fluorescens: Characterization and medium optimization for enhanced production. Food Sci. Biotechnol. 21, 1045–1053 (2012)

Xavier, J.R., Ramana, K.V.: Optimization of Levan Production by Cold-Active Bacillus licheniformis ANT 179 and Fructooligosaccharide Synthesis by Its Levansucrase. Appl. Biochem. Biotechnol. 181, 986–1006 (2017)

Barone, J.R., Medynets, M.: Thermally processed levan polymers. Carbohydr. Polym. 69, 554–561 (2007)

Chiang, C.J., Wang, J.Y., Chen, P.T., Chao, Y.P.: Enhanced levan production using chitin-binding domain fused levansucrase immobilized on chitin beads. Appl. Microbiol. Biotechnol. 82, 445–451 (2009)

Jang, K.H., Song, K.B., Kim, C.H., Chung, B.H., Kang, S.A., Chun, U.H., Choue, R.W., Rhee, S.K.: Comparison of characteristics of levan produced by different preparations of levansucrase from Zymomonas mobilis. Biotechnol. Lett. 23, 339–344 (2001)

Haddar, A., Hamed, M., Bouallegue, A., Bastos, R., Coelho, E., Coimbra, M.A.: Structural elucidation and interfacial properties of a levan isolated from Bacillus mojavensis. Food Chem. 343, 128456 (2021)

Esawy, M.A., Ahmed, E.F., Helmy, W.A., Mansour, N.M., El-Senousy, W.M., El-Safty, M.M.: Production of levansucrase from novel honey Bacillus subtilis isolates capable of producing antiviral levans. Carbohydr. Polym. 86, 823–830 (2011)

Yamamoto, Y., Takahashi, Y., Kawano, M., Iizuka, M., Matsumoto, T., Saeki, S., Yamaguchi, H.: In vitro digestibility and fermentability of levan and its hypocholesterolemic effects in rats. J. Nutr. Biochem. 10, 13–18 (1999)

Srikanth, R., Reddy, C.H., Siddartha, G., Ramaiah, M.J., Uppuluri, K.B.: Review on production, characterization and applications of microbial levan. Carbohydr. Polym. 120, 102–114 (2015)

Ishida, R., Sakaguchi, K., Matsuzaki, C., Katoh, T., Ishida, N., Yamamoto, K., Hisa, K.: Levansucrase from Leuconostoc mesenteroides NTM048 produces a levan exopolysaccharide with immunomodulating activity. Biotechnol. Lett. 38, 681–687 (2016)

Abdel-Fattah, A.M., Gamal-Eldeen, A.M., Helmy, W.A., Esawy, M.A.: Antitumor and antioxidant activities of levan and its derivative from the isolate Bacillus subtilis NRC1aza. Carbohydr. Polym. 89, 314–322 (2012)

Esawy, M., Ahmed, E., Helmy, W., Mansour, N., El-Senousy, W., El-Safty, M.: Antiviral Levans from Bacillus spp. Isolated from Honey, The Complex World of Polysaccharides. (2012)

Ni, D., Xu, W., Bai, Y., Zhang, W., Zhang, T., Mu, W.: Biosynthesis of levan from sucrose using a thermostable levansucrase from Lactobacillus reuteri LTH5448. Int. J. Biol. Macromol. 113, 29–37 (2018)

Poli, A., Kazak, H., Gürleyendağ, B., Tommonaro, G., Pieretti, G., Öner, E.T., Nicolaus, B.: High level synthesis of levan by a novel Halomonas species growing on defined media. Carbohydr. Polym. 78, 651–657 (2009)

Shih, I.-L., Chen, L.-D., Wu, J.-Y.: Levan production using Bacillus subtilis natto cells immobilized on alginate. Carbohydr. Polym. 82, 111–117 (2010)

Srikanth, R., Siddartha, G., Sundhar Reddy, C.H., Harish, B.S., Janaki Ramaiah, M., Uppuluri, K.B.: Antioxidant and anti-inflammatory levan produced from Acetobacter xylinum NCIM2526 and its statistical optimization. Carbohydr. Polym. 123, 8–16 (2015)

Khandekar, S., Srivastava, A., Pletzer, D., Stahl, A., Ullrich, M.S.: The conserved upstream region of lscB/C determines expression of different levansucrase genes in plant pathogen Pseudomonas syringae. BMC Microbiol. 14, 79 (2014)

Morales-Arrieta, S., Rodriguez, M.E., Segovia, L., Lopez-Munguia, A., Olvera-Carranza, C.: Identification and functional characterization of levS, a gene encoding for a levansucrase from Leuconostoc mesenteroides NRRL B-512 F. Gene 376, 59–67 (2006)

Wang, J., Xiao, H., Zhao, F., Zhao, B., Xu, M., Zhou, Z., Han, Y.: A fructan sucrase secreted extracellular and purified in one-step by gram-positive enhancer matrix particles. Processes. 19, 95 (2021)

Zhao, F., Song, Q., Wang, B., Han, Y., Zhou, Z.: Purification and immobilization of the soluble and insoluble portions of recombinant lipase by gram-positive enhancer matrix (GEM) particles. Int. J. Biol. Macromol. 145, 1099–1105 (2020)

Miller, G.L.: Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31(3), 426–428 (1959)

Zheng, J., Sun, K., Hu, A., Gao, J., Sun, P., Gao, X., Zhang, F.: Purification, structure and properties of polysaccharides from lumpfish cartilage. Fine Chem. 36, 66–73 (2019)

Ruhmkorf, C., Bork, C., Mischnick, P., Rubsam, H., Becker, T., Vogel, R.F.: Identification of Lactobacillus curvatus TMW 1.624 dextransucrase and comparative characterization with Lactobacillus reuteri TMW 1.106 and Lactobacillus animalis TMW 1.971 dextransucrases. Food Microbiol. 34, 2–61 (2013)

Zhang, T., Li, R., Qian, H., Mu, W., Miao, M., Jiang, B.: Biosynthesis of levan by levansucrase from Bacillus methylotrophicus SK 21002. Carbohydr. Polym. 101, 975–981 (2014)

Kirtel, O., Menendez, C., Versluys, M., Van den Ende, W., Hernandez, L., Toksoy Oner, E.: Levansucrase from Halomonas smyrnensis AAD6T: first halophilic GH-J clan enzyme recombinantly expressed, purified, and characterized. Appl. Microbiol. Biotechnol. 102, 9207–9220 (2018)

Kang, H.K., Seo, M.Y., Seo, E.S., Kim, D., Chung, S.Y., Kimura, A., Day, D.F., Robyt, J.F.: Cloning and expression of levansucrase from Leuconostoc mesenteroides B-512 FMC in Escherichia coli. Biochim. Biophys. Acta. 1727, 5–15 (2005)

Liu, Q., Yu, S., Zhang, T., Jiang, B., Mu, W.: Efficient biosynthesis of levan from sucrose by a novel levansucrase from Brenneria goodwinii. Carbohydr. Polym. 157, 1732–1740 (2017)

Belghith, K.S., Dahech, I., Belghith, H., Mejdoub, H.: Microbial production of levansucrase for synthesis of fructooligosaccharides and levan. Int. J. Biol. Macromol. 50, 451–458 (2012)

Shih, I.-L., Yu, Y.-T., Shieh, C.-J., Hsieh, C.-Y.: Selective production and characterization of levan by Bacillus subtilis (Natto) takahashi. J. Agric. Food Chem. 53, 8211–8215 (2005)

Hangit, Y.W., Clarke, M.A.: Production and characterization of microbial levan. J. Agric. Food Chem. 38, 393–396 (1990)

Dong, C.X., Zhang, L.J., Xu, R., Zhang, G., Zhou, Y.B., Han, X.Q., Zhang, Y., Sun, Y.X.: Structural characterization and immunostimulating activity of a levan-type fructan from Curcuma kwangsiensis. Int. J. Biol. Macromol. 77, 99–104 (2015)

Malang, S.K., Maina, N.H., Schwab, C., Tenkanen, M., Lacroix, C.: Characterization of exopolysaccharide and ropy capsular polysaccharide formation by Weissella. Food Microbiol. 46, 418–427 (2015)

Raga-Carbajal, E., Carrillo-Nava, E., Costas, M., Porras-Dominguez, J., Lopez-Munguia, A., Olvera, C.: Size product modulation by enzyme concentration reveals two distinct levan elongation mechanisms in Bacillus subtilis levansucrase. Glycobiology 26, 377–385 (2016)

Porras-Dominguez, J.R., Avila-Fernandez, A., Miranda-Molina, A., Rodriguez-Alegria, M.E., Munguia, A.L.: Bacillus subtilis 168 levansucrase (SacB) activity affects average levan molecular weight. Carbohydr. Polym. 132, 338–344 (2015)

Sun, N., Liu, H., Liu, S., Zhang, X., Chen, P., Li, W., Xu, X., Tian, W.: Purification, preliminary structure and antitumor activity of exopolysaccharide produced by Streptococcus thermophilus CH9. Molecules 23, 2898 (2018)

Yang, Y., Feng, F., Zhou, Q., Zhao, F., Du, R., Zhou, Z., Han, Y.: Isolation, purification and characterization of exopolysaccharide produced by Leuconostoc pseudomesenteroides YF32 from soybean paste. Int. J. Biol. Macromol. 114, 529–535 (2018)

Salama, B.M., Helmy, W.A., Ragab, T.I.M., Ali, M.M., Taie, H.A.A., Esawy, M.A.: Characterization of a new efficient low molecular weight Bacillus subtilis NRC16 levansucrase and its levan. J. Basic. Microb. 59, 1004–1015 (2019)

Feng, F., Zhou, Q., Yang, Y., Zhao, F., Du, R., Han, Y., Xiao, H., Zhou, Z.: Characterization of highly branched dextran produced by Leuconostoc citreum B-2 from pineapple fermented product. Int. J. Biol. Macromol. 113, 45–50 (2018)

Xu, W., Liu, Q., Bai, Y., Yu, S., Zhang, T., Jiang, B., Mu, W.: Physicochemical properties of a high molecular weight levan from Brenneria sp. Eni D312. Int. J. Biol. Macromol. 109, 810–818 (2018)

Ahmed, Z., Wang, Y., Anjum, N., Ahmad, A., Khan, S.T.: Characterization of exopolysaccharide produced by Lactobacillus kefiranofaciens ZW3 isolated from Tibet kefir – Part II. Food Hydrocoll. 30, 343–350 (2013)

Wang, B., Song, Q., Zhao, F., Xiao, H., Zhou, Z., Han, Y.: Purification and characterization of dextran produced by Leuconostoc pseudomesenteroides PC as a potential exopolysaccharide suitable for food applications. Process Biochem. 87, 187–195 (2019)

Wang, B., Song, Q., Zhao, F., Zhang, L., Han, Y., Zhou, Z.: Isolation and characterization of dextran produced by Lactobacillus sakei L3 from Hubei sausage. Carbohydr. Polym. 223, 115111 (2019)

İspirli, H., Sagdic, O., Yılmaz, M.T., Dertli, E.: Physicochemical characterisation of an α-glucan from Lactobacillus reuteri E81 as a potential exopolysaccharide suitable for food applications. Process Biochem. 79, 91–96 (2019)

Tao, F., Biao, G., Yu, J., Ning, Z.: Isolation and characterization of an acidic polysaccharide from Mesona Blumes gum. Carbohydr. Polym. 71, 159–169 (2008)

Moussa, T.A.A., Al-Qaysi, S.A.S., Thabit, Z.A., Kadhem, S.B.: Microbial levan from Brachybacterium phenoliresistens: Characterization and enhancement of production. Process Biochem. 57, 9–15 (2017)

Yu, X., Li, L., Zhang, J., Shen, Z., Zhu, C., Wang, P., Jiang, X.: Structural analysis of macromolecular levan produced by Bacillus megaterium GJT321 based on enzymatic method. Int. J. Biol. Macromol. 93, 1080–1089 (2016)

Hao, L., Sheng, Z., Lu, J., Tao, R., Jia, S.: Characterization and antioxidant activities of extracellular and intracellular polysaccharides from Fomitopsis pinicola. Carbohydr. Polym. 141, 54–59 (2016)

Ragab, T.I.M., Shalaby, A.S.G., El Awdan, S.A., El-Bassyouni, G.T., Salama, B.M., Helmy, W.A., Esawy, M.A.: Role of levan extracted from bacterial honey isolates in curing peptic ulcer. In vivo. Int. J. Biol. Macromol. 142, 564–573 (2020)

Cai, G., Liu, Y., Li, X., Lu, J.: New Levan-Type Exopolysaccharide from Bacillus amyloliquefaciens as an Antiadhesive Agent against Enterotoxigenic Escherichia coli. J. Agric. Food Chem. 67, 8029–8034 (2019)

Kabli, M., Yilmaz, M.T., Taylan, O., Kaya, Y., İspirli, H., Basahel, A., Sagdic, O., Dertli, E.: An integrated neural-fuzzy methodology for characterisation and modelling of exopolysaccharide (EPS) production levels of Leuconostoc mesenteroides DL1. Comput. Ind. Eng. 148, 1–11 (2020)

Nasir, D.Q., Wahyuningrum, D., Hertadi, R.: Screening and characterization of levan secreted by halophilic bacterium of Halomonas and Chromohalobacter genuses originated from bledug kuwu mud crater. Procedia Chem. 16, 272–278 (2015)

Mamay, D., Wahyuningrum, R.: Hertadi, isolation and characterization of levan from moderate halophilic bacteria Bacillus licheniformis BK AG21. Procedia Chem. 16, 292–298 (2015)

Acknowledgements

This work was financially supported by the Key Technology R&B Program of Tianjin,China (19YFZCSN00100).

Author information

Authors and Affiliations

Contributions

JW: conceptualization, methodology, investigation, writing—original draft. XX: conceptualization, methodology, investigation, writing—original draft. FZ: investigation, writing—review and editing, formal analysis. NY: investigation, formal analysis. ZZ: supervision, software. YH*: resources, supervision, project administration, funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest and unanimously approve publication of the manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, J., Xu, X., Zhao, F. et al. Biosynthesis and Structural Characterization of Levan by a Recombinant Levansucrase from Bacillus subtilis ZW019. Waste Biomass Valor 13, 4599–4609 (2022). https://doi.org/10.1007/s12649-022-01814-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-01814-w