Abstract

Olive mill wastewaters (OMW) are effluents originated from olive oil extraction. As an oil-rich residue, OMW is a potential source of lipase-producing microorganisms and a complex medium potentially suitable for lipase production. The aim of the present study was to isolate yeasts with the ability to produce extracellular lipases from OMW. Thirty-two yeast isolates were obtained and screening for esterase/lipase activity using rapid plate detection methods allowed the selection of five isolates. Subsequently, extracellular lipolytic activity was determined in shake-flasks, and the best activity was found in the isolate JT5 (0.85 U/mL). This isolate was identified as Magnusiomyces capitatus by DNA sequencing. Growth and lypolytic activities by M. capitatus JT5 were assessed in undiluted OMW, and optimization of lipase production was achieved by a positive interaction of two factors (oxygen availability and nitrogen concentration). The highest lipase activity (1.4 U/mL) was obtained at NH4Cl concentration of 2.8 g/L and kLa of 0.65 min−1. The growth of M. capitatus JT5 in a stirred tank bioreactor, using undiluted OMW, allowed the improvement of lipase production (up to 3.96 U/mL) by increasing olive oil concentration in the medium, under the selected conditions of nitrogen concentration and oxygen availability. This study highlighted the isolate M. capitatus JT5 as a lipase-producing microorganism that is able to grow in undiluted OMW under controlled conditions. Results obtained in shake-flasks have been reproduced satisfactorily in the stirred tank bioreactor.

Graphic Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

A new lipase-producing yeast was isolated from olive mill wastewater. The use of undiluted waste can further contribute for water savings and to a more economical bioprocess for lipases production.

Introduction

Lipases (triacylglycerol acylhydrolases; EC 3.1.1.3) are an important group of enzymes with a variety of applications in food, dairy, detergent, pharmaceutical industries, and in the field of bioenergy [1,2,3,4]. In the last decade, particular attention has been given to the use of lipases as hydrolytic enzymes that catalyse the hydrolysis of triacylglycerols (TAGs) and the esterification of vegetable oil wastes, being an environmentally friendly process to produce FAME (fatty acid methyl ester), i.e. biodiesel [5,6,7].

Lipases have been found in many species of animals, plants, and microorganisms [4]. However, microbial lipases have gained special industrial attention due to their broad substrate specificity, selectivity and stability [8] and now constitute the most important group of biocatalysts for biotechnological applications [9, 10]. Fungi are the preferred microorganisms as industrial lipases producers, because they usually produce extracellular enzymes, which facilitate the extraction of the fermentation medium. Fungal lipase production has been widely studied, mainly by genus Geotrichum [11,12,13,14], Penicillium [15,16,17], and Fusarium [18, 19]. Amongst the most used commercial lipase-producing yeasts are Yarrowia lipolytica [20,21,22,23,24] and species belonging to the genus Candida, mainly C. rugosa, C. cylindracea and C. antarctica [4, 23, 25]. This popularity in industry has caused a demand for new sources of lipases with alternative catalytic characteristics, which stimulates the isolation and selection of new strains. Lipase-producing microorganisms have been found in different habitats such as vegetable oil processing factories, dairy plants, and soil contaminated with oil and industrial wastes, among others [26]. All these habitats have in common a significant source of residual nutrients (lipids) that can serve as growth media for those particular microorganisms. Although considerable progress has been made over the recent years towards developing cost-effective systems for lipases, the high cost of production of this enzyme remains the major challenge associated with large-scale industrial applications. In order to turn the lipase production as economically viable, solid residues from agro-industry have been used as low cost culture media and cheaper substrates alternatives. However, liquid effluents such as olive mill wastewater and palm oil mill effluents showed potential to be used for lipase production [4, 20, 27, 28].

Olive mill wastewater (OMW), annually produced in large amounts in the Mediterranean basin, can be regarded as a resource containing simple and complex sugars, proteins, and mineral elements, and could be utilized for fermentative production processes [27, 29]. In addition, OMW contains lipids and residual oil, making this effluent either a suitable growth medium for lipase-producing microorganisms [6, 13, 30,31,32]. There are several studies regarding the ability of yeast strains to grow in OMW and lipase production. The main microorganisms referred in literature are Yarrowia lipolytica, Candida cylindracea, and Candida rugosa [22,23,24, 27, 29,30,31] as belonging to culture collections.

Besides its potential as a liquid growth medium, it is also highly expected that native microbiota with lipolytic properties could also be found and isolated from this effluent. Consequently, OMW can be used as a source of lipase-producing yeasts. Therefore, the aim of this study was to isolate lipase-producing yeasts from OMW and the highest producing isolate was further selected for identification and to evaluate its ability to grow and to produce extracellular lipases in OMW.

Then, the optimization of lipase production by M. capitatus JT5 using undiluted OMW as growth substrate was assessed. The effect of the nitrogen concentration and oxygen availability on lipase and biomass produced by M. capitatus JT5 grown in shake flasks was studied, using the Doehlert distribution experimental design. M. capitatus JT5 cells stress physiological response was analysed under different growth conditions, using flow cytometry. Further, M. capitatus JT5 was grown on a medium culture containing OMW, in a stirred tank bioreactor, and the effect of olive oil (by addition to the OMW based medium) on the lipase production was assessed.

Materials and Methods

Microorganisms and Culture Conditions

Isolates of Magnusiomyces capitatus JT5 were kept at a Culture Collection of Microorganisms (CCM at LNEG, Lisbon, Portugal). The isolate was maintained at + 4 °C on Yeast Malt Agar (YMA, Difco) plates and sub-cultured every 3 weeks. For inoculum preparation, one colony of the YMA plate was suspended in 50 mL of YEP medium containing peptone (1%, w/v), yeast extract (1%, w/v) and glucose (2%, w/v). Incubations were carried out at 30 °C at 150 rpm for 24 h.

Yarrowia lipolytica NRRL Y-323, used for comparison tests of lipolytic activity, was collected from CCM (LNEG, Lisbon, Portugal). All strains used and isolated in this study were maintained at + 4 °C on Potato Dextrose Agar (PDA, Difco) and sub-cultured monthly.

Sampling and Characterization of Olive Mill Wastewater

OMW used in this work was collected from a three-phase olive mill located in the south region of Portugal (Algarve, during the last month of olive oil production campaign). Due to the high concentration of suspended solids, a preliminary step of filtration with normal gauze and centrifugation (8600 g, 15 min) was performed prior to its use as culture medium.

OMW was characterized for Chemical Oxygen Demand (COD, g/L), total and volatile suspended solids (TSS and VSS, g/L), and nitrates (g/L), according to Standard Methods [33]. The total phenolic content (TPh) was determined using the Folin–Ciocalteau colorimetric method and expressed as caffeic acid equivalents [34]. The nitrates determination (NO3) was performed by the method “Nitrate Cell Test 1.14542” (Spectroquant Merck) in a HACH DR/2010 spectrophotometer (USA). The content of ammonium (NH4+) was measured using an ion selective electrode (Crison, Spain). Total lipids (g/L) content was determined gravimetrically after petroleum ether extraction. Reducing sugars were measured using 3,5-dinitrosalicylic acid (DNS) method [35] and were expressed as glucose (g/L).

Isolation and Screening of Esterase/Lipase-Producing Yeasts

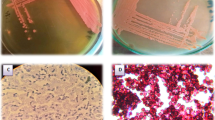

Serial dilutions (10−1 up to 10−5) of the OMW sample were prepared, 0.1 mL of each was spread on Nutrient Agar (NA, Difco) plates in triplicate, and incubated at 30 °C during 48 h. Yeast colonies were selected, isolated from the agar plates and subcultured in the selective media Yeast Malt Agar (YMA, Difco), Cook Rose Bengal Agar (CRBA, Difco) and Potato Dextrose Agar (PDA, Difco), all supplemented with a final concentration of 35 µg mL−1 of chlortetracycline to prevent bacterial growth. The plates were incubated at 30 °C during 48 h, and isolates were examined under phase contrast microscopy, 1000× (microscope Olympus BX51) for morphological characterization according to Kurtzman et al. [36]. Thirty-two yeast colonies were morphologically selected, picked from the plates and re-streaked on YMA as often as necessary to ensure purity. The yeast isolates were screened for esterase/lipase activity through rapid plate detection experiments. Three different media were used for that purpose: Tween 20 agar [37], Tributyrin agar [38], and Phenol-red (0.01%) supplemented with olive oil (1 g/L) in agar plates [39]. The esterase/lipase activity was registered after 48 h-72 h at 30 °C, as positive (++, +), weak (w) or negative (−) result.

Selection of Yeasts for Extracellular Lipase Activity

In order to determine extracellular lipase activity, selected yeast isolates were grown overnight in 50 mL of YEPD medium (1 g/L yeast extract, 2 g/L peptone and 2 g/L dextrose). Then they were inoculated (300 µL) in 100 mL of growth medium (1 g/L yeast extract, 1 g/L potassium chloride and 1 g/L magnesium sulphate) using 0.5 g/L olive oil as inducer. Cultures were performed in 500 mL-shake-flasks, for 72 h at 30 °C under continuous stirring at 180 rpm. 1 mL samples were collected every 24 h and biomass concentration was determined by filtration (0.45 μm), which were then dried to constant weight at 105 °C. The biomass was expressed as dry cell weight (DCW, g/L). The samples were then centrifuged (7500 g, 15 min) at 4 °C and the supernatant was used to determine extracellular lipase activity. All experiments were done in triplicate.

Yeast Identification

DNA from selected yeast isolate was extracted according to a standard phenol–chloroform-extraction protocol [40]. The purity and yield of the DNA was assessed spectrophotometrically (NanoDrop 2000 Spectrophotometer, Thermo Scientific, Wilmington, USA). The D1/D2 variable domains of the large-subunit rRNA gene was amplified by PCR using NL1 (5′-GCA TAT CAA TAA GCG GAG GAA AAG) and NL4 (5′-GGT CCG TGT TTC AAG ACG G) primers [41]. After initial denaturation of DNA at 94 °C for 3 min, 40 cycles of amplification with the following thermocycling program: denaturation at 94 °C for 30 s, followed by 30 s at 50 °C for primer annealing and 90 s at 72 °C for extension. Final extension at 72 °C for 4 min was used. The amplified fragment was submitted to DNA sequencing (STAB Vida, Almada, Portugal). The sequence was assembled, edited, aligned with the program MEGA5 [42] and was analysed using the BLAST tool of the Westerdijk Fungal Biodiversity Institute [http://www.westerdijkinstitute.nl/collections/BioloMICSSequences.aspx?file=all].

This isolate JT5 has been maintained in the CCM (LNEG, Lisbon, Portugal) with the reference identification 555F. The GenBank/EMBL/DDBJ accession number for the sequence of D1/D2 domains of the large subunit of the rRNA gene of isolate JT5 is MK076454.

Growth and Lipase Production by the Selected Lipolytic Isolate in OMW

Growth ability of the selected yeast isolate in OMW was evaluated. A sample of centrifuged raw OMW was diluted at 10%, 25%, 50% and 75% using YEP (yeast extract 2% and peptone 2%), autoclaved (121 °C for 20 min), and tested as culture medium. A cells suspension (20 µL), previously grown overnight in YEPD at 30 °C, was used to inoculate each assayed media (200 µL), in triplicate, in a 96-wells microplate, and then incubated in a microplate reader (Multiskan GO Microplate Spectrophotometer, Thermo Fischer Scientific, Finland), at 30 °C with shaking. Yeast growth in each condition tested was followed spectrophotometrically at 640 nm for 48 h, with 1-h interval readings, and specific growth rates were determined during the exponential growth phase.

The lipase production by the selected yeast isolate was measured during growth in undiluted OMW. Undiluted OMW was supplemented with [a] 2.0 g/L yeast extract or [b] 2.0 g/L yeast extract plus 1.0 g/L olive oil, and was adjusted for pH 6.8 before sterilization (121 °C for 20 min). Cell suspension (300 µL), previously grown in YEPD overnight, was used as inoculum. The flasks were then incubated at 30 °C, under continuous stirring at 180 rpm, for 120 h. Biomass was daily monitored. Crude cell-free extract was obtained by recovering the supernatant after spinning down cells and cell debris (7500 g, 15 min). This preparation was used to measure lipase activity.

Experimental Design in Shake-Flasks

Taking into account the results previously obtained for optimization of microbial lipase production in OMW [2, 13, 27, 29], an experimental distribution for two factors (oxygen availability and nitrogen concentration) was used to produce response surfaces according to the Doehlert uniform design [43], in undiluted OMW supplemented with yeast extract (2 g/L) and olive oil (1 g/L). Seven experiments were carried out in duplicate within an experimental domain with working volume (X1) ranging between 100 and 400 mL and ammonium chloride (NH4Cl, X2) varying between 0.2 and 2.8 g/L. Oxygen availability was tested using baffled shake flasks (1 L) containing working volume ranging between 100 and 400 mL, corresponding to a volumetric oxygen mass transfer coefficient (kLa) between 0.24 and 1.88 min−1. Cultures were incubated at 30 °C and 180 rpm for 48 h. Coded representation of factors was used for calculation purposes. The responses studied in this design were biomass concentration, lipase activity and cell integrity. The model used to express the responses was a second-order polynomial model provided by Doehlert uniform design (Eq. 1):

where Y was the response from each experiment; β were the parameters of the polynomial model; and X was the experimental factor level.

Experiments in Bench-Top Stirred Tank Bioreactor

Lipase production by M. capitatus JT5 was assessed using a 2-L bioreactor equipped with four-flat-blade impellers and two baffles. Fermentation parameters were controlled using a PT 100 temperature sensor, a double reference pH sensor (Phoenix, USA), and a dissolved oxygen sensor (Mettler Toledo, USA). The bioreactor was inoculated with 0.5% (v/v) of exponential growing cells and fermentation experiments were carried out at 30 °C, 100 rpm and 1 vvm aeration (kLa 36 min−1). According to the previous experimental design in shake-flasks, the fermentation was conducted using 1-L undiluted OMW supplemented with yeast extract (2 g/L), olive oil (1 g/L) and 2.8 g/L NH4Cl. The initial pH was adjusted to 6.1 with NaOH 0.1 M before sterilization (121 °C for 20 min). To assess the effect of oil addition a second fermentation was performed in the same conditions, with addition of 3 g/L olive oil. Biomass concentration was determined as described above. All samples were analysed in triplicate.

The volumetric oxygen mass transfer coefficient (KLa) was measured inside the reactor by using the gassing out method [44]. Nitrogen was injected in the medium until the oxygen concentration dropped near to zero. Then, the medium was stirred and aerated, and the increase in dissolved oxygen (DO) concentration with time (t) was monitored with a membrane dissolved oxygen electrode. KLa was determined according to the equation ln[(100 − OD)/100) = KLa*t.

Determination of Lipase Activity

The measurement of lipase activity was adapted from Gomes et al. [45]. A reaction mixture composed by 195 μL of substrate (2.63 mM p-nitrophenyl butyrate in sodium phosphate buffer, 0.05 M, pH 6.8, with 4% (v/v) Triton X-100) and 5 μL of sample taken from culture, was incubated in a microplate at 37 °C for 15 min. Fresh OMW medium was used as blank. The absorbance was measured at 405 nm in a microplate reader (Multiskan GO Microplate Spectrophotometer, Thermo Fischer Scientific, Finland). One unit (U) of lipase activity was defined as the amount of enzyme that produces 1 μmol of p-nitrophenol per minute under assay conditions.

Flow Cytometry

The flow cytometer (FACScalibur© Becton–Dickinson, Franklin Lakes, NJ, USA) was used to assess M. capitatus JT5 cell membrane integrity, using the fluorochrome propidium iodide (PI, Invitrogen© USA). PI cannot cross an intact cytoplasmic membrane, but enters the cell if the membrane is injured, binding to the DNA chains. The samples were centrifuged (5000 g, 10 min), the pellet was re-suspended in phosphate buffer solution (PBS, pH 7.0), and then diluted in PBS in order to obtain a cell concentration ~ 1000 events per second. Five microlitre of PI stock solution (1 mg/mL in distilled water) were added to 995 μL-diluted sample so the final PI concentration in the cell suspension was 0.5 μg/mL and the mixture was analysed in the flow cytometer. PI was excited at 488 nm and was detected in channel FL3. All data were analysed using Windows Multiple Document Interface flow cytometry (WinMDI 9.0).

Results and Discussion

Characterization of OMW

Physicochemical characteristics were determined on raw OMW: pH 4.99, chemical oxygen demand (COD) = 55.2 g/L, nitrates (NO3−) = 1.42 g/L, ammonium (NH4) = 1.7 g/L, total suspended solids (TSS) = 21.9 g/L, total phenols (TPh) = 3.97 g caffeic acid/L, lipids = 3.20 g/L, and reducing sugars = 35 g/L.

The composition of the sample used in this work falls within the range of characteristic values reported by different authors for OMW [24, 32, 46].

Isolation and Screening of Esterase/Lipase-Producing Yeasts from OMW

According to several authors, OMW usually contain a diverse microbiota that is able to grow and colonize this effluent despite its high phenolic content. This microbiota consists of several species of yeasts, filamentous fungi and bacteria. Yeasts are especially well adapted to this particular environment, since they have a better tolerance to phenolic compounds when compared to bacteria [47,48,49]. Thirty-two yeasts were isolated from the OMW sample (Table 1) and divided into three major groups (A, B and C) based on their microscopic morphology. Colonies morphology was very similar in most isolates, forming circular white colonies. In group A, the cells were small sized and round, very similar to the genus Saccharomyces, sometimes forming aggregates. In group B, cells had a larger, more rectangular shape, with frequent formation of pseudo mycelia. Group C showed cells with an elliptical shape, without aggregates or filaments.

The 32 yeast isolates were examined for their ability to produce extracellular lipases. The lipolytic activity was tested using three different detection substrates in agar plates: Tween 20; Tributyrin and Phenol-Red supplemented with olive oil. The results on extracellular esterase/lipase activity of isolated yeasts are given in Table 1. The appearance of a catalytic halo around discs is an indication of esterase/lipase activity and therefore a positive result. In the Phenol-Red test, the positive result was shown by a change of colour around the disc, while in the Tween 20 and in the Tributyrin tests, positive results were given by the formation of precipitates and the absence of turbidity, respectively. Extracellular esterase/lipase activity was detected by the hydrolysis of Tween-20 by only nine isolates (Table 1). From these isolates, only yeasts 1F, 6F, and PT3 exhibited a clear positive result in the Phenol-Red test, and yeasts PT6 and JT5 exhibited lipolytic activity in Tributyrin test. The positive results observed only on Tributyrin plates could be useful to differentiate lipase from esterase activity [38, 50, 51]. Phenol-red supplemented with olive oil was described by Singh et al. [39] as a method that could differentiate between esterases and lipases. However, this medium had shown a poor performance for the evaluation of lipolytic activity of the isolates, overall showing inconclusive results. In addition, Singh et al. [39] reported difficulties to detect individual bands on the gels due to spread of fatty acids. Since Tween 20 is generally known as a good lipase inducer, being used to increase its production in several optimization assays and also in plate detection methods for detection of esterase/lipase activity [37, 52,53,54], five isolates (1F, 6F, PT3, PT6, and JT5) were selected for further shake-flasks experiments aiming to determine extracellular lipase activity.

Extracellular Production of Lipase in Shake-Flask Experiments

The selected five yeast isolates (1F, 6F, PT3, PT6, and JT5) were then examined for their extracellular lipolytic ability in synthetic liquid medium (YEP) supplemented with 0.5 g/L olive oil, using Yarrowia lipolytica NRRL Y-323 as positive control. D’Annibale et al. [29] had previously demonstrated that olive oil was the most effective inducer in lipase production, with lipase activity measured after 96 h of incubation. As shown in Fig. 1a, the lipase activity determined in isolates 1F, PT3 and 6F was relatively low and practically inexistent in the isolate PT6. JT5 showed a maximum of lipase activity 0.85 U/mL at 96 h, which is the highest lipase activity determined and 7-fold higher than that measured for the known lipolytic yeast Y. lipolytica NRRL Y-323 (0.12 U/mL). Figure 1b shows the growth of Y. lipolytica, and isolates 1F, 6F, PT3, PT6, and JT5 in YEP with 0.5 g/L olive oil. All strains have shown good growth in synthetic medium, without need of an adaptation period, and values of biomass ranging between 4 (Y. lipolytica and JT5) and around 7 g/L (1F, 6F, PT3) were obtained. The growth of isolates PT6 and JT5 was only determined during the first 72 h, due to the occurrence of flocculation. The flocculation presented itself as small circular aggregates, floating in the medium. However, lipase production in all isolates was measured until 96 h of culture growth in order to obtain comparable data. Flocculation can be triggered by environmental factors, such as nitrogen starvation, or pH changes, so it might protect the cells in the middle of the flocs from the environment, or by genetic factors. Some authors reported that the flocculation of microbial cultures may be related to low levels of oxygen or carbon sources during the culture growth [55, 56].

a Extracellular lipase activity determined in YEP medium with 0.5 g/L olive oil for 96 h. Values represent means of three independent replicates and error bars indicate standard deviations. b Yeast growth in YEP medium with 0.5 g/L olive oil. Values represent means of three independent replicates and error bars indicate standard deviations

The best lipolytic yeast isolate (JT5) was selected for further identification.

Isolate Identification

D1/D2 of the large subunit ribosomal DNA of yeast isolate JT5 was sequenced and compared against the Westerdijk Institute database. The partial D1/D2 sequence showed 100% identity with the one from Magnusiomyces capitatus CBS 197.35, a strain recently subjected to whole-genome sequencing [57], and to other strains from the same species. It also shown 99% identity with the one from M. capitatus CBS 162.80 type strain (accession number NG_055400.1), confirming the identification at the species level.

Magnusiomyces capitatus is a yeast prevalent in geographic areas of high humidity and temperature. It can be found in diverse natural substrates including soil, fruits and dairy products. Yamada-Onodera et al. [58] had already reported this species, for biotechnological purposes, as a producer of N-benzyl-3-pyrrolidinol dehydrogenase. To current knowledge, the yeast M. capitatus has not yet been reported on the production of lipases.

Growth and Lipase Production by M. capitatus JT5 in OMW

The recalcitrant properties of the OMW have been attributed to the high concentrations of polyphenols (tannins, catechins and anthocyanins). More specifically, monomeric phenols have been directly associated with the phytotoxic and antimicrobial characteristics of this effluent [59, 60]. The ability of M. capitatus JT5 to grow in OMW was tested by using different dilutions with YEP (10 up to 75%) and comparing with growth in synthetic medium YEP. Figure 2 and Table 2 show the yeast growth and specific growth rates obtained for each tested condition. As shown in Fig. 2, final biomass concentration increased with the increase of OMW concentration in the culture medium (4.48 g/L in YEP up to 11.06 g/L in YEP + 75%-OMW) but an increase in the lag phase was also observed, varying from 7 h (YEP) to 18–21 h (YEP + 75%-OMW and 100% OMW). Additionally, M. capitatus JT5 growth rates increased with the increase in OMW concentration up to 50% (Table 2) reaching 0.38 h−1. In fact, the yeast growth seems to be enhanced by the presence of sugars and residual lipids present in the OMW. However, since the phenolic content also increase in the growth medium with the increase of OMW concentration, the results have shown that M. capitatus JT5 is able to grow in undiluted OMW but the recalcitrance of OMW affected growth profiles, with growth rates decreasing to 0.31 h−1 and 0.25 h−1 for YEP + 75%-OMW and 100% OMW, respectively. The yeasts ability to tolerate phenolic compounds was demonstrated by other authors. Ben Sassi et al. [49] showed that some strains of yeast isolates were well adapted and able to grow in undiluted OMW agar plates. Brozzoli et al. [27] found that phenolic concentration did not influence the biomass production by Candida cylindracea grown on different undiluted OMW-based media. Gonçalves et al. [61] studied the phenolic compounds toxicity to yeast strains. The results demonstrated Y. lipolytica W29 and Candida rugosa PYCC 3238 were able to grow in two different OMW-based media, without dilution, and that cell growth inhibition was not observed. These results allowed the valorization of OMW as culture based-medium with supplementation for producing extracellular lipases [23, 29, 62].

In this study, growth of M. capitatus JT5 was tested further in 100% OMW supplemented with [a] 2.0 g/L yeast extract, or [b] 2.0 g/L yeast extract and 1.0 g/L olive oil (Fig. 3a). Growth rate of 0.09 h−1 obtained for condition [b] was half the growth rate in YEP + OMW 10% (0.18 h−1), but lag phase was not observed. In both OMW media, M. capitatus JT5 reached the stationary phase after 48 h and, unlike previous growth in the YEP culture medium, it was observed that flocculation did not occurred in any of the OMW-based media. This could be attributed to additional supplementation of nitrogen source and the presence of residual nutrients in OMW that can be used during the yeast growth. Biomass concentration increased up to 12.34 g/L in the medium supplemented with yeast extract and olive oil.

a Growth of M. capitatus JT5 in the OMW-based media. Values represent means of three independent replicates and error bars indicate standard deviations. b Lipase production of M. capitatus JT5 in the OMW-based media. Values represent means of three independent replicates and error bars indicate standard deviations

As it can be shown in Fig. 3b, the maximum lipase activity achieved by M. capitatus JT5 was 0.11 U/mL after 72 h growth in the undiluted OMW based-medium supplemented with yeast extract [a]. In case of olive oil addition to OMW based-medium [b], lipase was produced earlier, after 48 h, and the maximum lipase activity increased to 0.33 U/mL. This result confirm that M. capitatus JT5 is a lipase-producing yeast and addition of olive oil as carbon source with high percentage of oleic acid, is an effective inducer to the production of lipase [29, 63].

The present study shows that OMW can be used as a good source for the isolation of lipase-producing yeasts. M. capitatus has not yet been studied and reported as a lipase producer. As far as we know, this is the first study describing M. capitatus isolation from OMW, its tolerance to this type of recalcitrant medium and ability to produce lipase in undiluted OMW with reduced nutrient supplementation. Reports in the literature [64, 65] show that lipolytic activity could be improved with additional supplementation of inorganic nitrogen sources during cell growth and the process can be optimized using a stirred tank bioreactor [27].

Optimisation of the Lipase Production in OMW in Shake-Flasks

Despite nitrogen content and oxygen availability are widely reported in the literature as influencing lipase production, the combined effect of these two key factors has not been studied yet in M. capitatus JT5. The surface response methodology according to the Doehlert distribution for those two factors was used to find the optimal conditions for lipase production and to highlight possible interactions. In addition, flow cytometry was used to assess the cell membrane integrity under all tested conditions. Table 3 shows the results obtained from the experimental design for biomass, lipase production, and the flow cytometry data, indicating the percentage of cells with intact and permeabilised membrane. The two factors taken into consideration were shaken flask working volume, as a mean to control oxygen availability in terms of the volumetric oxygen mass transfer coefficient, kLa, and nitrogen concentration through the addition of different NH4Cl amounts to the medium culture. The lowest value obtained for biomass in the experimental design was 5.06 g/L, and it was found for a tested condition corresponding to the lowest oxygen availability tested, kLa 0.24 min−1. The increase in kLa values did not affected biomass growth or lipase production. However, maintaining kLa values (0.65 or 1.47 min−1) and increasing NH4Cl concentration (0.2 up to 2.8 g/L), lipase production was increased by 11-fold (tests D and F) and ninefold (tests E and G), reaching about 1.4 U/mL. Flow cytometry was used to observe the physiological stress induced in the cells by the different tested conditions (A–G). From the analysis of Table 3, it is clear that all the cultures showed a low proportion of cells with permeabilised membrane because they were under low stress conditions, and were able to tolerate the conditions of the experimental design.

Analysis of the Polynomial Models Parameters

The data obtained from the experimental design were further used for regression analysis and the polynomial model-derived parameters (β0 to β22) are shown in Table 4. These parameters describe the relative influence of both factors individually on the responses and their interaction within the experimental domain. β0 represents the analysed response at the centre of the experimental domain. The magnitude of β1 and β2 indicates the importance of each factor (oxygen availability and nitrogen concentration, respectively) on the responses. β12 is an interaction parameter indicating how the effect of one factor depends on the level of the other factor. The values of β11 and β22 determine how the response surface folds downward (negative values) or upward (positive values) quadratically, more or less rapidly depending on the magnitude of the absolute value.

For the statistical analysis, the observations were according to the model representation of the experimental domain (Table 4). The relative effect of the two studied factors, oxygen availability (kLa) and nitrogen concentration, in biomass growth, lipase production, intact (IC) and permeabilised cells (PC) was given by the values of β parameters. The influence of the oxygen availability (β1 = 0.33) is lower than the nitrogen concentration (β2 = 0.73) in lipase production. The interaction of both factors (β12 = − 0.02) shows that these two factors act independently, since their joint action does not exhibit an improvement in lipase activity, except when these factors reach their highest value. Concerning biomass, there is a positive interaction of the two factors for biomass growth (β12 = 0.03) but the influence of oxygen availability (β1 = 1.14) has more effect on yeast growth than nitrogen concentration (β2 = − 0.42). The interaction of the two factors also has a positive response for intact membrane cells (β12 = 1.22).

Analysis of Isoresponses Surfaces Plots

Data regression transformed the statistical data into contour plots. Figure 4 presents the profiles obtained by the isoresponse contours of biomass concentration (a), lipase production (b), percentage of intact cells (c) and percentage of permeabilised cells (d) with increasing concentrations of nitrogen and oxygen on growth of M. capitatus JT5 on undiluted OMW-based medium.

The importance of oxygen availability on biomass growth is expressed by the vertical lines on the response surface in Fig. 4a, with the nitrogen concentration having insignificant influence. It becomes clear that the optimum kLa values vary between 1.0 and 1.7 min−1. In this range, the limiting nutrient is in excess and the nitrogen concentration becomes the most influent factor. The increase of kLa to highest values (which were obtained using low volumes of culture media), did not improve biomass production, meaning that a good stability for the growth of M. capitatus JT5 under the experimental domain has been achieved. This stability can be observed in the response surface in Fig. 4c, d, since there is no variation in the response of intact and permeabilised cell membranes resultant from the interaction of both factors, oxygen transfer rate (kLa) and nitrogen concentration (NH4Cl).

The response surfaces in Fig. 4b shows the variation of lipase production within the experimental domain. The increase in the NH4Cl concentration and on kLa values increased the production of lipase. However, the enzyme activity seems to be more affected by the nitrogen concentration due to the horizontal lines observed on the upper left response surface. Results show that nitrogen influenced the lipase production, as the highest lipase activity values (1.44 and 1.37 U/mL) were obtained at the highest NH4Cl concentration (2.8 g/L). It is generally known that OMW has a low content of nitrogen and it could be necessary to supplement these effluents. Fadil et al. [66] report that the low content of nitrogen and phosphate of OMW are necessary for a successful degradation of that effluent using Geotrichum sp., Aspergillus sp. and Candida tropicalis. The effect of nutrients requirement and oxygen supply has been studied on biomass growth and for the improvement of lipase production by filamentous fungi and yeast strains. D’Annibale et al. [29] described the influence of different nitrogen sources (NH4Cl, (NH4)2SO4, NaNO3 and urea) on lipase production by Candida cylindracea in OMW. The study showed that the highest lipase activity of 1.45 U/mL was achieved with the use of ammonium salts, mainly NH4Cl. Brozzoli et al. [27] also concluded that lipase production could be enhanced in nitrogen-supplemented OMW based media by C. cylindracea.

Analysis of Experimental Data

Statistical validation of the polynomial equations was made by analysis of variance (ANOVA) [67]. The adequacy of the models to fit the sets of data was performed using two statistical tests: (i) the F-test for the effectiveness of the factors which detects whether the source of variance, included in the residuals, is due to the inadequacy of the models to reproduce experimental data; and (ii) the F-test for the lack of fit, that is performed in order to detect if the origin of the variance was due to experimental errors. Table 4 shows the Fisher variation ratios and levels of confidence evaluated for each F-test.

The F-test for the effectiveness of the factors applied to biomass, lipase activity, intact and permeabilised cells showed a level of confidence at which the null hypothesis (H0) can be rejected by 0.001% for lipase activity, permeabilised cells and intact membrane cells, and 0.01% for biomass. Thus, with a good level of confidence it can be assumed that a significant amount of variance in the data has been represented by the factors in the models (i.e. the factors, as they appear in the model, do have an effect upon the responses analysed).

The F-ratio for the lack of fit also seems to be highly significant for the responses of lipase activity and biomass under study, as the null hypothesis can be rejected with levels of confidence of 0.0001 and 0.001% as shown in Table 4. Under these conditions, the alternative hypothesis (Ha) is accepted, which means that the lack of perfect prediction of the models is explained by the experimental error. All the models fit well the sets of data.

Assessment of Lipase Production in Bioreactor

The effect of increase olive oil concentration on production of lipase was evaluated in a stirred tank reactor with OMW-based medium. The fermentation was conducted using undiluted OMW-based medium supplemented with 2.8 g/L NH4Cl, according to the previous experimental design in shake-flasks. Figure 5 shows the fermentation profiles in batch conditions, during yeast growth. In Fig. 5a, it can be observed that the yeast grew rapidly (0.66 h−1) in the first 24 h reaching a biomass concentration of about 14 g/L and remained constant after that period. With the increase in the olive oil amount to 3 g/L, the growth profile was similar, reaching biomass concentration to about 13 g/L. Brozzoli et al. [27] also observed this behaviour for C. cylindracea grown in shake flasks.

Effect of olive oil addition. M. capitatus JT5 fermentation profiles obtained from batch cultures in bioreactor performed using 1-L undiluted OMW-based medium supplemented with 2.8 g/L NH4Cl: a biomass, b dissolved oxygen and pH, and c lipase activity. Values represent means of three independent replicates and error bars indicate standard deviations

Dissolved oxygen is an important parameter that provides information about the current state of fermentation (see Fig. 5b). In our study, dissolved oxygen decreased rapidly from the beginning of the fermentation, during the first 24 h to levels as 40% and 50% saturation, respectively, in media with 3 g/L olive oil and 1 g/L olive oil. Thereafter, rapidly increased and stabilized at levels of 70% and 80%, respectively. In shake-flasks experiments, oxygen was the factor with the larger influence on the biomass production. In this fermentation carried out in the stirred tank reactor, there was a drastic decrease in dissolved oxygen content coinciding with the increase in exponential phase of the yeast growth. After that, according Burkert et al. [11], the increase in oxygen concentration normally corresponds to the end of cell growth and coincides with the beginning of lipase depletion. However, in the case of lipase production by M. capitatus JT5, increase in activity was observed throughout the fermentation period. Asses et al. [13] and Alonso et al. [68] showed aeration increased oxygen transfer, which was decisive on the microbial lipase production. On the contrary, lipase activity can be reduced if anoxic conditions occurred in the early stage of yeast fermentation [23].

The effect of olive oil on the lipase activity was shown in Fig. 5c. The experimental conditions were chosen accordingly the results obtained by D’Annibale et al. [29], which showed that lipase production by C. cylindracea NRRL Y-17506 was highly stimulated by vegetable oils, and supplementing with 3 g/L of olive oil. In the current work, lipase productivities of 23.98 and 31.59 U/L h were obtained for 1 and 3 g/L of olive oil addition, respectively. In fermentation supplemented with 3 g/L olive oil, lipase production was faster since beginning, and continues after 96 h of experiment, reaching 3.96 U/mL lipase activity.

Conclusions

This study showed that OMW could be used as a source for isolation of new lipase-producing yeasts beyond its potential already confirmed as fermentation medium. The isolate JT5 selected with the best lipolytic activity was identified as M. capitatus. This isolate was able to grow and to produce lipases on undiluted OMW.

The optimization of lipase production by M. capitatus JT5 was performed in selected growth conditions using undiluted OMW supplemented with yeast extract and olive oil as inducer, using two variables: nitrogen source (NH4Cl) concentration and oxygen availability (kLa). Maximal lipase activity of 1.4 U/mL was achieved in shake-flasks using statistical design following the Doehlert distribution for these two factors. Lipase production increased with increasing of NH4Cl concentration. Under the tested conditions, biomass growth was stable as the yeast cells did not experience adverse conditions, since almost 99% of the yeast cells displayed intact membrane, as indicated by the flow cytometry analysis. Scale-up of lipase production by M. capitatus JT5 allowed reaching a maximum of 4 U/mL on the 2L-reactor and a productivity of 31.6 U/L h, under optimized conditions of aeration, NH4Cl and olive oil.

Further work focusing on lipase characterization and purification from the culture medium can contribute for the commercial exploitation of this bioprocess.

References

Ryu, H.S., Kim, H.K., Choi, W.C., et al.: New cold-adapted lipase from Photobacterium lipolyticum sp. nov. that is closely related to filamentous fungal lipases. Appl. Microbiol. Biotechnol. 70, 321–326 (2006)

Gupta, N., Shai, V., Gupta, R.: Alkaline lipase from a novel strain Burkholderia multivorans: statistical medium optimization and production in a bioreactor. Process Biochem. 42, 518–526 (2007)

Franken, L.P.G., Marcon, N.S., Treichel, H., et al.: Effect of treatment with compressed propane on lipases hydrolytic activity. Food Bioprocess Technol. 3, 511–520 (2010)

Salihu, A., Alam, M.Z., AbdulKarim, M.I., Salleh, H.M.: Lipase production: an insight in the utilization of renewable agricultural residues. Resour. Conserv. Recycl. 58, 36–44 (2012)

Yousuf, A., Sannino, F., Addorisio, V., Pirozzi, D.: Microbial conversion of olive mill wastewaters into lipids suitable for biodiesel production. J. Agric. Food Chem. 58, 8630–8635 (2010)

Gog, A., Roman, M., Toşa, M., et al.: Biodiesel production using enzymatic transesterification—current state and perspectives. Renew. Energ 39, 10–16 (2012)

Kuo, T.-C., Shaw, J.-F., Lee, G.-C.: Conversion of crude Jatropha curcas seed oil into biodiesel using liquid recombinant Candida rugosa lipase isozymes. Bioresour. Technol. 192, 54–59 (2015)

Griebeler, N., Polloni, A.E., Remonatto, D., et al.: Isolation and screening of lipase-producing fungi with hydrolytic activity. Food Bioprocess Technol. 4, 478–586 (2011)

Jaeger, K.-E., Eggert, T.: Lipases for biotechnology. Curr. Opin. Biotechnol. 13(4), 390–397 (2002)

Jaeger, K.-E., Eggert, T.: Enantioselective biocatalysis optimized by directed evolution. Curr. Opin. Biotechnol. 15(4), 305–313 (2004)

Burkert, J.F.M., Maldonado, R.R., Maugeri, F., Rodrigues, M.I.: Comparison of lipase production by Geotrichum candidum in stirring and airlift fermenters. J. Chem. Technol. Biotechnol. 80, 61–67 (2005)

Yan, J., Yan, Y.: Optimization for producing cell-bound lipase from Geotrichum sp. and synthesis of methyl oleate in microaqueous solvent. Appl. Microbiol. Biotechnol. 78, 431–439 (2008)

Asses, N., Ayed, L., Bouallagui, H., Ben Rejeb, I., et al.: Use of Geotrichum candidum for olive mill wastewater treatment in submerged and static culture. Bioresour. Technol. 100, 2182–2188 (2009)

Maldonado, R.R., Macedo, G.A., Rodrigues, M.I.: Lipase production using microorganisms from different agro-industrial by-products. Int. J. Appl. Sci. Technol. 4, 108–115 (2014)

Miranda, O.A., Salgueiro, A.A., Pimentel, M.C.B., et al.: Lipase production by a Brazilian strain of Penicillium citrinum using an industrial residue. Bioresour. Technol. 69, 145–147 (1999)

Menoncin, S., Domingues, N.M., Freire, D.M.G., et al.: Study of the extraction, concentration and partial characterization of lipases obtained from Penicillium verrucosum using solid-state fermentation of soybean bran. Food Bioprocess Technol. 3, 537–544 (2010)

Papagianni, M.: An evaluation of the proteolytic and lipolytic potential of Penicillium spp. isolated from traditional Greek sausages in submerged fermentation. Appl. Biochem. Biotechnol. 172, 767–775 (2014)

Prazeres, J.N., Cruz, J.A.B., Pastore, G.M.: Characterization of alkaline lipase from Fusarium oxysporum and the effect of different surfactants and detergents on the enzyme activity. Braz. J. Microbiol. 37, 505–509 (2006)

Oliveira, B.H., Coradi, G.V., Attili-Angelis, D., et al.: Comparison of lipase production on crambe oil and meal by Fusarium sp. (Gibberella fujikuroi complex). Eur. J. Lipid Sci. Technol. 115, 1413–1425 (2013)

De Felice, B., Pontecorvo, G., Carfagna, M.: Degradation of waste waters from olive oil mills by Yarrowia lipolytica ATCC 20255 and Pseudomonas putida. Acta Biotechnol. 17, 231–239 (1997)

Pereira-Meirelles, F.V., Rocha-Leão, N.H.M., Sant’Anna Jr., G.L.: A stable lipase from Candida lipolytica: cultivation conditions and crude enzyme characteristics. Appl. Biochem. Biotechnol. 63–65, 3–85 (1997)

Lanciotti, R., Gianotti, A., Baldi, D., et al.: Use of Yarrowia lipolytica strains for the treatment of olive mill wastewater. Bioresour. Technol. 96, 317–322 (2005)

Gonçalves, C., Oliveira, F., Pereira, C., Belo, I.: Fed-batch fermentation of olive mill wastewaters for lipase production. J. Chem. Technol. Biotechnol. 87, 1215–1218 (2012)

Moftah, O.A.S., Grbavčić, S.Ž., Moftah, W.A.S., et al.: Lipase production by Yarrowia lipolytica using olive oil processing wastes as substrates. J. Serb. Chem. Soc. 78(6), 781–794 (2013)

Larios, A., García, H.S., Oliart, R.M., Valerio-Alfaro, G.: Synthesis of flavor and fragrance esters using Candida antarctica lipase. Appl. Microbiol. Biotechnol. 65, 373–376 (2004)

Sharma, R., Chisti, Y., Chand, U.: Production, purification, characterization, and applications of lipases. Biotechnol. Adv. 19(8), 627–662 (2001)

Brozzoli, V., Crognale, S., Sampedro, I., et al.: Assessment of olive-mill wastewater as a growth medium for lipase production by Candida cylindracea in bench-top reactor. Bioresour. Technol. 100, 3395–3402 (2009)

Salihu, A., Alam, M.Z., AbdulKarim, M.I., Salleh, H.M.: Optimization of lipase production by Candida cylindracea in palm oil mill effluent based medium using statistical experimental design. J. Mol. Catal. B Enzym. 69, 66–73 (2011)

D’Annibale, A., Sermanni, G.G., Federici, F., Petruccioli, M.: Olive mill wastewaters: a promising substrate for microbial lipase production. Bioresour. Technol. 97, 1828–1833 (2006)

Crognale, S., D’Annibale, A., Federici, F., Fenice, M., et al.: Olive oil mill wastewater valorization by fungi. J. Chem. Technol. Biotechnol. 81, 1547–1555 (2006)

Lopes, M., Araujo, C., Aguedo, M., et al.: The use of olive mill wastewater by wild type Yarrowia lipolytica strains: medium supplementation and surfactant presence effect. J. Chem. Technol. Biotechnol. 84, 533–537 (2009)

Abrunhosa, L., Oliveira, F., Dantas, D., et al.: Lipase production by Aspergillus ibericus using olive mill wastewater. Bioprocess Biosyst. Eng. 36, 285–291 (2013)

APHA: Standard methods for the examination of water and wastewater, 21st edn. American Public Health Association, Washington, DC (2005)

Singleton, V.L., Rossi, J.A.: Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am. J. Enol. Viticult. 16, 144–158 (1965)

Miller, G.L.: Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31, 426–428 (1959)

Kurtzman, C.P., Fell, J.W., Boekhout, T., Robert, V.: Methods for the isolation, phenotypic characterization and maintenance of yeasts. In: Kurtzman, C.P., Fell, J.W., Boekhout, T. (eds.) The yeasts—a taxonomic study, 5th edn, pp. 87–110. Amsterdam, Elsevier (2011)

Gopinath, S.C.B., Anbu, P., Hilda, A.: Extracellular enzymatic activity profiles in fungi isolated from oil-rich environments. Mycoscience 46(2), 119–126 (2005)

Cihangir, N., Sarikaya, E.: Investigation of lipase production by a new isolate of Aspergillus sp. World J. Microbiol. Biotechnol. 20(2), 193–197 (2004)

Singh, R., Gupta, N., Goswami, V., Gupta, R.: A simple activity staining protocol for lipases and esterases. Appl. Microbiol. Biotechnol. 70, 679–682 (2006)

Cheng, H., Jiang, N.: Extremely rapid extraction of DNA from bacteria and yeasts. Biotechnol. Lett. 28, 55–59 (2006)

O’Donnell, K.: Ribosomal DNA internal transcribed spacers are highly divergent in the phytopathogenic ascomycete Fusarium sambucinum (Gibberella pulicaris). Curr. Genet. 22(3), 213–220 (1992)

Tamura, K., Peterson, D., Peterson, N., Stecher, G., et al.: MEGA5: molecular evolutionary genetics analysis using maximum likelihood, evolutionary distance, and maximum parsimony methods. Mol. Biol. Evol. 28, 2731–2739 (2011)

Doehlert, D.H.: Uniform shell designs. Appl. Stat. 19, 231–239 (1970)

Wise, W.S.: The measurement of the aeration of culture media. J. Gen. Microbiol. 5, 167–177 (1951)

Gomes, N.C., Gonçalves, C., Garcia-Roman, M., et al.: Optimization of a colorimetric assay for yeast lipase activity in complex systems. Anal. Methods 3, 1008–1013 (2011)

Gonçalves, C., Pereira, C., Alves, M., et al.: Olive mill wastewater as a renewable resource. Environ. Eng. Manag. J. 9, 319–325 (2010)

Rincón, B., Raposo, F., Borja, R., et al.: Performance and microbial communities of a continuous stirred tank anaerobic reactor treating two-phases olive mill solid wastes at low organic loading rates. J. Biotechnol. 121(4), 534–543 (2006)

Morillo, J.A., Aguilera, M., Ramos-Cormenzana, A., Monteoliva-Sánchez, M.: Production of a metal-binding exopolysaccharide by Paenibacillus jamilae using two-phase olive-mill waste as fermentation substrate. Curr. Microbiol. 53(3), 189–193 (2006)

Ben Sassi, A., Boularbah, A., Jaouad, A., et al.: A comparison of olive oil mill wastewaters (OMW) from three different processes in Morocco. Process Biochem. 41, 74–78 (2006)

Hasan, F., Shah, A.A., Hameed, A.: Methods for detection and characterization of lipases: a comprehensive review. Biotechnol. Adv. 27(6), 782–798 (2009)

Panda, T., Gowrishankar, B.S.: Production and applications of esterases. Appl. Microbiol. Biotechnol. 67(2), 160–169 (2005)

Immanuel, G., Esakkiraj, P., Jebadhas, A., et al.: Investigation of lipase production by milk isolate Serratia rubidaea. Food Technol. Biotechnol. 46(1), 60–65 (2008)

Treichel, H., de Oliveira, D., Mazutti, M.A., et al.: A review on microbial lipases production. Food Bioprocess Technol. 3(2), 182–196 (2009)

Salihu, A., Alam, M.Z., Abdulkarim, M.I., Salleh, H.M.: Suitability of using palm oil mill effluent as a medium for lipase production. Afr. J. Biotechnol. 10(11), 2044–2052 (2011)

Holmberg, S., Kielland-Brandt, M.C.: A mutant of Saccharomyces cerevisiae temperature sensitive for flocculation. Influence of oxygen and respiratory deficiency on flocculence. Carlsberg Res. Commun. 43(1), 37–47 (1978)

Sampermans, S., Mortier, J., Soares, E.V.: Flocculation onset in Saccharomyces cerevisiae: the role of nutrients. J. Appl. Microbiol. 98(2), 525–531 (2005)

Brejová, B., Lichancová, H., Brázdovič, F., et al.: Genome sequence of the opportunistic human pathogen Magnusiomyces capitatus. Curr. Genet. 65, 539–560 (2019)

Yamada-Onodera, K., Fukui, M., Tani, Y.: Purification and characterization of alcohol dehydrogenase reducing N-benzyl-3-pyrrolidinone from Geotrichum capitatum. J. Biosci. Bioeng. 103(2), 174–178 (2007)

Sayadi, S., Allouche, N., Jaoua, M., Aloui, F.: Detrimental effects of high molecular-mass polyphenols on olive mill wastewater biotreatment. Bioprocess Biochem. 35, 725–735 (2000)

Ergul, F.E., Sargin, S., Ongen, G., Sukan, F.V.: Dephenolisation of olive mill wastewater using adapted Trametes versicolor. Int. Biodeter. Biodegr. 63, 1–6 (2009)

Gonçalves, C., Lopes, M., Ferreira, J.P., Belo, I.: Biological treatment of olive mill wastewater by non-conventional yeasts. Bioresour. Technol. 100, 3759–3763 (2009)

Gonçalves, C., Lopes, M., Alves, M., Belo, I.: Use of olive mill wastewater by lipolytic yeasts. J. Biotechnol. 131, S179 (2007)

Abdelmoez, W., Mostafa, N.A., Mustafa, A.: Utilization of oleochemical industry residues as substrates for lipase production for enzymatic sunflower oil hydrolysis. J. Clean. Prod. 59, 290–297 (2013)

Thabet, H.M., Pasha, C., Ahmed, M.M., Linga, V.R.: Isolation of novel lipase producing Sporobolomyces salmonicolor OVS8 from oil mill spillage and enhancement of lipase production. Jordan J. Biol. Sci. 5(4), 301–306 (2012)

Dimitrijević, A., Veličković, D., Bezbradica, D., et al.: Production of lipase from Pseudozyma aphidis and determination of the activity and stability of the crude lipase preparation in polar organic solvents. J. Serb. Chem. Soc. 76(8), 1081–1092 (2011)

Fadil, K., Chahlaoui, A., Ouahbi, A., et al.: Aerobic biodegradation and detoxification of wastewaters from the olive oil industry. Int. Biodeter. Biodegr. 51, 37–41 (2003)

Deming, S.N., Morgan, S.L.: Experimental design: a chemometric approach, in data handling in science and technology, vol. 11, 2nd edn. Elsevier, New York (1993)

Alonso, F.O.M., Oliveira, E.B.L., Dellamora-Ortiz, G.M., Pereira-Meirelles, F.V.: Improvement of lipase production at different stirring speeds and oxygen levels. Braz. J. Chem. Eng. 22, 9–18 (2005)

Acknowledgements

This work was prepared in the framework of the project “Mediterranean Cooperation in the Treatment and Valorisation of Olive Mill Wastewater (MEDOLICO)” which is funded by the European Union under the “ENPI Cross-Border Cooperation Mediterranean Sea Basin Programme”. MEDOLICO total budget is 1.9 million Euro and it is co-financed through the European Neighbourhood and Partnership Instrument (90%) and national funds of the countries participating in the project (10%). The authors wish to thank Margarida Monteiro for important support with yeast cultures and maintenance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Salgado, V., Fonseca, C., Lopes da Silva, T. et al. Isolation and Identification of Magnusiomyces capitatus as a Lipase-Producing Yeast from Olive Mill Wastewater. Waste Biomass Valor 11, 3207–3221 (2020). https://doi.org/10.1007/s12649-019-00725-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-019-00725-7