Abstract

Various bioactive agrowastes derived phenolic compounds (APCs) obtained from agrowastes lignin hydrolyzed methods and evaluated for their potential antioxidant, antimicrobial and anti-quorum activities with special reference to food borne pathogens. Half-maximal inhibitory concentrations (IC50) of isolated phenolic compounds against 2,2-diphenyl-1-picrylhydrazyl (DPPH) radicals have been found in the range of 53–84 µg/mL, whereas samples obtained by hydrolysis in absence of acid have shown the (IC50) values of ~ 120 µg/mL. The APCs have shown significant antimicrobial activity against Gram positive (Bacillus subtilis) as compared to Gram negative (Pseudomonas aeruginosa) bacteria. The bacterial killing as well as anti-quorum sensing activity (inhibiting the violacein production) has been observed against Chromobacterium violaceum. Flow cytometric analysis has been also confirmed the cell death occurs in Gram positive and Gram negative bacteria. The present study suggests that APCs derived from agro-wastes can serve as an important source of natural antioxidant and antimicrobial agents. The natural ingredients will be considered as emerging materials for food packaging.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Statement of Novelty

-

Benign conditions have used for the generation of agrowastes derived bioactive phenolic compounds (APCs).

-

Bioactive compounds generated like estragole, anethole, phorbol, ferulic acid, cinnamic acid etc.

-

The APCs have shown significant antioxidant, antimicrobial and anti-quorum sensing activity.

-

The APCs will be useful for food packaging applications

Introduction

Agro-wastes (AW) are the lignocellulosic materials obtained from various agricultural related activities, which also include sometime manures, stalks, husk, leaves, and vegetable matters [1]. Agro-waste materials are mostly composed of three types of polymeric units i.e., cellulose, hemicelluloses and lignin. While cellulose and hemicelluloses are utilized as raw material chiefly in paper industry and lignocellulosic based ethanol bio-refineries, lignin remains largely unused waste material [2]. Lignin is composed of three types of phenypropane alcohol units (p-cournaryl, coniferyl and sinapyl alcohol) linked together as a result of polymerization process. Lignin makes up to 10–25% of lignocellulosic biomass and is a rich source of various types of phenolic and bioactive compounds [3]. In agrowastes, most of the phenolic compounds could be generated by the lignin or lignans transformations using various chemical methods [3, 4]. Generally these chemical methods are based on subjecting the biomass to acid hydrolysis, alkali oxidation, extraction in ionic liquids, organosolv pulping and wet oxidation [5,6,7,8]. Of above methods, acid hydrolysis has effectively been used in converting lignin into value added phenolic compounds such as coniferyl aldehyde, ferulic acid, 4-hydroxy-benzoic acid, benzoic acid, vanillin, guaicol, etc. [6, 9]. These lignin degradation products are considered as potential waste and toxic ingredients during bio-ethanol production as they inhibit the growth of microbes which help in the ethanol production [6, 7]. This inherent bio-cidal property of lignocellulosic waste derived compounds can be exploited elsewhere.

Sugarcane baggasse (SCB), rice husk (RH) and bamboo (BB) are one of the most abundant by-products of agro-industry with a production of more than 250 million tons per year in India [1]. Phenolic compounds derived from lignocellulosic waste have been shown to possess useful properties such as antioxidant and antimicrobial activity against food borne pathogens [10]. A number of studies appearing in recent literature have also highlighted their effectiveness as anti-cancerous and cardiovascular diseases, immunomodulating, anti-inflammatory, anti-arthritic, anti-angiogenic, antiviral, anti-obesity, anti-diabetes and neuroprotective agents [11, 12]. Another important application of phenolic compounds lies in their potential application as additives or preservative agents in food industry in enhancing the nutrient value and shelf life of the food [10]. It is commonly assumed that bacterial contamination in food items is chiefly governed by cell-to-cell communication called quorum sensing (QS) [13]. QS leads to bacterial infection mediated by hormone-like compounds called auto-inducers which regulate various cellular functions in bacteria such as sporulation, biofilm formation, virulence factors and pigment production [14]. Thus inhibition of QS activity may be considered as potent target of antimicrobial path of phenolic compounds. At the same time bacterial tolerance against phenolic compounds depends on the nature of phenolic structures and constitution [15]. Therefore, chemical transformation of lignin derived from AW into commercially useful and high economic value chemicals remains a current challenge for researchers.

Earlier, some studies have been reported on isolation of phenolic compounds from various AW in polar and non-polar solvents [8, 16]. Acid catalysis at high temperature and pressure has been proved to be most effective in generating various types of phenolic compounds from lignin degradation along with sugars [6, 17]. Hydrophobic resins have also been employed to selectively adsorb phenolic compounds from aqueous extractions of the AW [16,17,18,19]. It is imperative from above discussion that a more selective and effective method is required to isolate economically useful chemical compounds from the AW.

The present work is directed towards isolation and characterization of AW namely SCB, RH and BB derived phenolic compounds (APCs) and evaluation of their antioxidant and antimicrobial activities for food packaging applications.

Materials and Methods

Materials

2,2′-Azino-bis(3-ethylbenzothiazoline-6-sulphonic acid) ABTS, 1,1-diphenyl 2-picrylhydrazyl (DPPH), Folin–Ciocalteu reagent and dinitrosalicylic acid were purchased from SRL, India. Organic solvents (acetone, ethanol, methanol, isopropanol, chloroform, DMSO and toluene), sulfuric acid, sodium carbonate, sodium hydroxide and l-ascorbic acid (vitamin C) were purchased from Merck, India. Glucose, β-carotene, linoleic acid, α-tocopherol, acyl (homoserine) lactones, kanamycin, propidium iodide (PI) and hydrophobic resin (XAD16) were purchased from Sigma Aldrich, India. The test strains Bacillus subtilis (MTCC 121, Gram positive), Pseudomonas aeruginosa (MTCC 1688, Gram negative) and quorum-sensing bacteria (Chromobacterium violaceum, MTCC 2656) were obtained from IMTECH, Chandigarh, India. Milli-Q grade water was used throughout the experiment.

Agrowaste Collection

AW (SCB, RH and BB) were collected from local areas of Allahabad, India. Collected biomass were dried in oven (42 °C) for 3 days and cut into small pieces. Dried agrowaste was fractioned in gridding machine, broken into a particle dimension between average lengths of ~ 3–2 mm (with sieve) and again dried at 42 °C overnight. Powdered biomasses were kept in plastic seal pack bag until further utilization.

Extraction of Phenolic Compounds

Before the acid or water hydrolysis, AW were first dewaxed (to remove extractives) with toluene–ethanol in ratio of (2:1) by soxhlet apparatus. After extraction AW were dried and the solvents removed. AW residues (1 gm) were dissolved in 10 mL of H2SO4 solution with different concentrations (0.1–0.5%, v/v). Then the mixture was transferred into a 20 mL Teflon-lined autoclave reactor and heated at 200 °C for a period of 3 h. After cooling the reactor to room temperature, solid and liquid fractions were separated by muslin cloth, centrifuged and pH was adjusted to 4.0 by 1 N NaOH. The liquid fraction was stored in deep freezer for 1 week until further use and analysis.

Isolation of Phenolic Compounds

Phenolic compounds from acid or water catalyzed liquid samples were isolated by a hydrophobic resin (XAD 16), because of this resin has more specificity with phenolics. The adsorption of phenolic compounds was carried out with some modification to standard method as described elsewhere Lopes et al. [4].

Acid hydrolyzed slurries were collected after hydrolysis and passed through a filter candle with pore size of 2.5 µm to remove large suspended particles, which act as filtration unit. Filtered liquid slurry was passed through filtration unit in which hydrophobic resin was impregnated. Before the utilization resin was activated and washed with isopropanol and water (milli-Q) for 6 h. After that activated resin was mixed (5%, w/v) with liquid samples (100 mL at 30 °C and pH 3.0) (acidic pH favored adsorption) then after treatment, phenolic adsorbed resin was separated and filtered from liquid fraction. Resin was then washed with milli Q water twice and treated with acetone and water (50:50) for the desorption of phenolic compounds. Obtained phenolic compounds were filtered through 0.45 µm syringe membrane filter, solvent was evaporated through rotavapor and the remaining solid dried in vacuum (lyophilizer). APCs were stored in freezer (8 °C) until further utilization and analysis. The resulting APC samples were denoted as SCB, RH and BB, respectively.

Characterization Techniques

Gas chromatographic–mass spectrometry (GC–MS) analysis was carried out using a Thermo Trace 1300 GC series Thermo TSQ 8000 (Thermo Scientific, India) gas chromatograph coupled with a MS TSQ 8000 mass detector. The column TG 5MS with (30 m × 0.25 mm i.d. × 0.25 µm film thickness) and 5% diphenyl + 95% dimethyl poly siloxane was used. The column temperature was at first held at 60 °C for 2.0 min then raised to 280 °C at a rate of 10 °C/min. Helium gas (purity 99.99%) was used as the carrier gas with flow rate of 1 mL/min. Injector temperature was maintained at 250 °C, and the injection volume was 1.0 µL in the splitless mode. The MS transfer line temperature was held at 280 °C. Mass spectra were scanned from m/z 50 to 700 with electron energy 70 eV and total GC operation time was 29.1 min. Compounds were identified by assessment of retention time and mass spectral library data (NIST library version-year 2005).

Fourier transform infrared spectroscopy (FT-IR) spectra were recorded in KBr pellets with Nicolet 170 SXFT-IR spectrophotometer in 4000–500 cm−1 region.

The ultraviolet–visible (UV–Vis) absorbance spectra of diluted samples in 10% methanol were recorded by using a double-beam UV–Vis spectrophotometer (Shimadzu UV-2450 spectrophotometer, USA) over a wavelength range of 250–700 nm.

Estimation of Total Phenolic Compounds

The content of total phenolic compounds in isolated samples was spectrophotometrically estimated by modified Folin–Ciocalteu method [20]. The reagent used in this study was 1 N Folin–Ciocalteu. The catechol (0.1 mg/mL) solution was used as standard. A mixture of 100 µL of test samples, 1.9 mL distilled water and 0.5 mL Folin–Ciocalteu reagent (1 N), was shaked for 3 min, then 2 mL of 10% Na2CO3 solution in water was added in it with thorough mixing. This reaction mixture was placed in a boiling water bath for 5 min, cooled to room temperature, and kept in a dark place. The absorbance of the samples was measured at 650 nm using UV–Vis spectrophotometer.

Total Reducing Sugars Analysis

Total reducing sugars analysis of samples was done by Miller’s method based on a colorimetric reaction between the sugars and dinitrosalicylic acid by Miller [21].

Antioxidant Assay

1,1-Diphenyl-2-picrylhydrazyl (DPPH) Radical Scavenging Assay

The purple colored free radical solution of 1,1-diphenyl-2-picrylhydrazyl (DPPH) was measured by reference procedure described by Brand-Williams [22] with slight modification. In this assay, aliquot of 1 mL of extracted APCs (10–1000 µg/mL) were mixed with 1 mL of 0.25 mM DPPH (in methanol) solution. After keeping the reaction mixture in a dark place for 30 min, absorbance was measured against a blank at 517 nm using UV/Vis spectrophotometer. The extracted solvent was used as blank. An equal amount of solvent and DPPH without sample was used as a control. l-Ascorbic acid (10–1000 µg/mL) was used as standard. The percentage free radical scavenging activity was calculated according to the following equation:

where Ac is the absorbance of the control, As is the absorbance of the sample.

The IC50 value which is defined as the concentration of APCs or samples required to scavenge the DPPH radical by 50% was obtained by linear regression analysis of dose–response curve plotting between different concentration of samples (10–100 µg/mL) and % of inhibition (IC50, expressed in µg/mL).

ABTS·+ Radical Scavenging Activity

The ABTS free radical cation scavenging assay was carried out according to the procedure of Munro et al. [11] with some modifications. In brief, ABTS·+ radicals cation was produced by the reaction of 7.4 mM ABTS (in 25 mL) on addition of 2.6 mM potassium persulfate (25 mL). The resulting solution was kept for 16 h till a dark greenish color was produced. After completion of incubation, ABTS·+ solution was further diluted with water (1 mL of ABTS·+ reagent + 19 mL DW) until initial absorbance value of 0.7 ± 0.005 at 734 nm was reached. Scavenging activity of ABTS·+ with samples was measured in a reaction mixture (3 mL), 2 mL diluted ABTS·+ solution + 1 mL samples or standard kept for 1 h in a dark place. The absorbance was taken at 734 nm. The radical scavenging capacity (%) was calculated from the difference in absorbance at (A734 nm) between the control and the sample. Vitamin C (10–50 µg/mL) was used as a standard. The percentage of scavenging inhibition capacity of ABTS·+ was calculated using the following equation.

whereas A0 is absorbance of control and Ai is absorbance of samples.

Phosphomolybdate Assay (PMA)

The total antioxidant capacity of APCs was estimated by reported method Prieto [23]. The reaction mixture contained 50 µL APCs samples solution (1 mg/mL) and mixed with 950 µL of the reagent solution (0.6 M sulfuric acid, 28 mM sodium phosphate and 4 mM ammonium molybdate) against a blank (water). The reaction mixture was heated in a boiling water bath for 90 min. After cooling the samples at room temperature, absorbance of the test sample was measured at 695 nm. The antioxidant activity (AA) was calculated as vitamin C equivalent (mg 100 g−1 dry matter).

Reducing Power Assay (RPA)

The reducing power assay of the APCs was determined by the method of Oyaizu [24]. In brief, different concentration of (0.01–0.1 mg/mL) of test sample (APCs) was mixed with 0.5 mL of the 0.2 M phosphate buffer (pH 6.6) and 0.5 mL of 1% potassium ferricyanide solution and vortex. The mixture was incubated at 50 °C for 20 min in a water bath, cooled to room temperature and was centrifuged at 5000 rpm for 15 min after addition of 0.3 mL of 15% trichloroacetic acid solution. After the centrifugation the upper layer of the solution (0.5 mL) was collected and mixed with 1 mL distilled water and freshly prepared ferric chloride (FeCl3) solution (0.5 mL 0.1%). After 10 min the absorbance was recorded at A700 nm. Ascorbic acid and gallic acid at various concentrations (0.01–0.1 mg/mL) were used as positive standard. A blank was prepared without adding standard or test compound. Increased absorbance of the reaction mixture has been indicative of the reducing power of the APCs.

β-Carotene–Linoleic Acid Bleaching Test

The antioxidant potential of agro-waste derived APCs was evaluated through β-carotene–linoleic acid bleaching test method developed by Ceylan et al. [13]. In brief, 1 mL of β-carotene solution (0.5 mg/mL in chloroform) was mixed with 20 µL of linoleic acid and 200 µL of Tween 40 (100%), to make 10 mL of this emulsion on the basis of above ratio. 5 mL of this emulsion were mixed with 200 µL of test samples in 50% methanol to make samples with different concentrations (0–500 µg/mL). The samples were heated at 50 °C for 2 h, before the absorbance was measured at 490 nm against a blank containing the emulsion without β-carotene. α-Tocopherol was used as the positive control [absorbance was recorded at initial (t = 0 and after t = 2 h)]. The AA percentage (%) was calculated and expressed as the percentage of inhibition of β-carotene oxidation using the following equation:

where ASt0 and ASt120 are absorbance of the tested samples and ACt0, and ACt120 are the controls at 0 and 120 min, respectively.

Antibacterial Assessment

The study of antimicrobial activity of isolated APCs were tested against two bacterial strains of B. subtilis Gram positive and P. aeruginosa Gram negative. Antimicrobial test was performed by using agar disc diffusion method [25]. In brief, nutrient agar media (28 g/L in water) and nutrient broth (13 g/L in water) were prepared. The nutrient agar media was then poured into autoclaved petri dishes. In inoculated agar plates 200 µL APCs (1 mg/mL) were placed in wells (10 mm) with control. The incubation was continued for 14 h at 37 °C, when finally the zone of inhibition around disc was measured in (mm) to determine the antibacterial efficacy.

Anti-quorum Sensing Activity

Bacterial Strain and Growth Condition

The anti-quorum sensing activity of the APCs was tested against bacterial strain C. violaceum, which is the standard used to detect the QS inhibitory activity (QSI). It is based on production of purple colored violacein in response to auto-inducer molecules called acyl (hexanoyl) homoserine lactones (AHLs). The bacteria strain was revived in 100 mL Luria–Bertani (LB) medium (pH 7.0), 100 µL of kanamycin was added with concentration of 20 mg/mL, followed by filtration using 0.2 µm syringe filter growth of bacteria has been maintained at 30 °C overnight.

Quorum Sensing Inhibition in C. violaceum

The agar disk diffusion method was used to detect QSI effect of phenolic compounds by the reported method [13]. 20 mL of Luria Bertani agar media (1.0 g yeast extract, 3.0 g agar, 2.0 g tryptone, 2.0 g sodium chloride, 200 mL deionized water) was poured in petri plate and seeded with 100 µL of an active culture of C. violaceum (105 CFU/mL) with 20 µL kanamycin, and 30 µL AHLs (stock solution 0.5 mg/mL in DMSO). The petri plate was kept in laminar for 1 h to allow it to solidify. Wells of 10 mm were creates in each solidified agar plate and 100 µL of isolated phenolic compounds in different concentrations (100–400 µg) in 10% methanol were added with 10% methanol as control. The treated plates were incubated in an incubator (Remi, India) for overnight at 30 °C. The appearance of purple color of violacein pigment was observed. The QS inhibitory activity was manifested by the formation of a colorless, opaque or no pigment production around the well on a purple background of plate.

Cell Death Study

The flow cytometric analysis was used for cell death study of two microbial strains of B. subtilis (Gram positive) and P. aeruginosa (Gram negative). In brief, active bacterial culture were grown in nutrient broth, harvested the bacterial cell through centrifugation (3000 rpm, 5 min) and isolated bacterial cells washed with PBS (10 mM, pH 6.5) three times. Finally bacterial cells were dissolved in PBS, vertex and recorded the absorbance (O.D) 0.5 with spectrophotometer. Now, cells were treated with isolated APCs (100 µg/mL), after the treatment APCs in PBS followed by filtration with 0.2 µm membrane syringe filter. The bacterial cells were incubated for 4 h and then 10 µL PI dye (1 mg/mL) was added in 200 µL bacterial cell suspension for 20 min incubation before subjecting it to flow cytometry (FACS BD, Becton Dick-inson, USA) analysis. A parallel control experiment (without treatment) was also carried out.

Statistical Analysis

All the experimental results are presented as mean values and data are represented as mean ± standard deviation (SD) of three independent experiments. The half-maximal inhibitory concentrations (IC50) values have been calculated by linear regression analysis (y = mx + c). The graph analysis has been carried out using Graph Pad Prism Software version (5.0).

Results and Discussion

Extraction and Isolation of Phenolic Compounds

The isolated phenolic compounds from various types of AW have been quantified. Sulfuric acid in different concentrations was used for the extraction of phenolic compounds from AW residues. The highest concentration of APCs have been found with 0.3% acid concentration, in SCB (55.05 ± 1.6), RH (41.57 ± 0.5) and BB (58.33 ± 0.32) mg per gram of biomass in comparison to water treated residues. The major difference between the hydrolysis in presence of acid and in aqueous conditions lies not only in lignin degradation or transformation but also in the release of reducing sugar. It has been reported earlier that at high temperature (< 150 °C) water basically helped in degradation of lignin and hemicellulose to reducing sugars [6]. It is known that at high acid concentration reducing sugars are converted to furfural and hydroxymethylfurfural via dehydration of sugars [17]. The isolated APCs were dried and dissolved in methanol (50%) for further analysis [26]. The optimization procedure has been employed for maximum recovery of phenolic compounds and with 0.3% acid treatment, chiefly SCB has been found to release high content of phenolic compounds.

GC–MS Analysis

The compounds identified through this technique are basically derivatives of lignin or lignin degraded products such as simple phenolic acids, ketone and aldehydes. A representative gas chromatogram (GC) of APCs is shown in (Fig. 1). The chemical constituents with peak area percent (%) and molecular weight were analyzed by reference (NIIST library). SCB-acid derived APCs have been found to contain benzoic acid (2.18%), estragole (3.40%), anethole (3.18%), syringaldehyde (4.52%), vanillin (1.13%), cinnamic acid (2.76%), phorbol (1.99%), conferyl aldehyde (4.12%) and ferulic acid. In RH-acid and BB-acid samples also the above compounds have been found with different peak area %. Anethole is a derivative of phenylpropene unit (lignin monomer), that occurs in plants as a secondary metabolite, it was found in all APCs samples and its concentration or peak area was found more prominent as compared to other phenolic compounds. A previous study has also reported similar phenolic contents in lignocellulosic biomass treated with dilute acid [30]. In the previous study it has been reported that vanillin, estragole, anethole, ferulic acid, cinnamic acid, coniferyl aldehyde, guaicol and syringic acid are mainly generated from lignin degradation via acid hydrolysis [27]. Acid-catalyzed degradation of lignin causes hydrolytic cleavages of α- and β-aryl ether linkages presents between lignin monomers (strongest bond), in lignin C–O bond and C–C bonds between monomers units are more fixed [27], the reaction scheme denoting the depolymerization of lignin (β-O-4) structure (Route 1) and repolymerisation involving a lignin structure with an immediate aromatic carbon (Route 2) is shown in Scheme 1. Some of the GC–MS peaks remained unidentified due to lack of any valid library data for matching compounds.

FTIR Spectra

FTIR spectra of all the agrowaste derived phenolic compounds isolated in this study have been recorded in the range of (4000–500 cm−1). All the APCs characteristic frequencies of the functional groups present in them are shown in (Fig. 2a–c). The APCs samples derived from acid hydrolysis show broad peaks corresponding to the stretching vibrations appear at 3347 cm−1, 3283 cm−1 and 3280 cm−1 respectively due to phenolic O–H, aliphatic O–H and C–H bonds. The vibrations due to carbonyl group have appeared at 1710 cm−1 and at 1608 and 1513 cm−1 due to aromatic ring [27]. A sharp peak ascribed to aromatic C–H bending appear at (649–576 cm−1) in all the APCs samples. Another sharp peak appearing between 1023 and 1034 cm−1 has been assigned to coupled C–O and C–C stretching phenolic compounds. Another frequency detected at 1154 cm−1 common in all the samples is due to phenolic O–H + ether C–O stretching.

UV–Vis Absorption Spectra

The UV–Vis spectra of the isolated phenolic compounds have been recorded in the wavelengths range of (250–700 nm). While phenolic compounds derived from acid treatment exhibit absorbance peaks at 324 nm, 315 nm and 318 nm for SCB, RH and BB respectively, water hydrolyzed phenolic compounds also showed absorption between 300 and 320 nm (Fig. 2d). Lambda max (maximum) for all samples lies in range of 300–330 nm which can be safely attributed to polyphenolic compounds [4]. In case of acid catalyzed products the intensity of the absorption peaks has been found to increase which is due to the high content of the phenolic compounds. In general, UV–Vis spectral data conform to typical UV absorbance (270–320 nm) characteristic of aromatic phenols [4, 5].

A typical FT-IR spectra of the agro-waste derived phenolic compounds and symbol represents a (SCB-acid), b (RH-acid) and c (BB-acid) and UV–Vis spectra of APCs, d (in 10% methanol) and inset images of acid catalyzed liquid sample (left) after XAD-16 adsorption (middle) after purification or regeneration of resin (right) brown colour. (Color figure online)

Antioxidant Activity

DPPH Radical Scavenging Capacity

It has been reported that free radical scavenging activity of phenolic compounds is due to their capacity to release hydrogen atoms or electrons to free radicals [11]. The DPPH (1,1-diphenyl-2-picrylhydrazyl) radical scavenging activity in percentage (%) of APCs is shown in (Fig. 3a). DPPH· scavenging was found to be higher in the acid catalyzed SCB and BB derived APCs showing consistently higher activity in comparison to aqueous extract of these residues. The results of the AA are summarized in. APCs exhibited dose dependent radical scavenging ability with respect to standard ascorbic acid (IC50 = 3.17 µg/mL) with the maximum scavenging activity occurring in the range of 50–100 µg/mL concentration. Among all acid treated APC samples SCB showed the highest scavenging activity (IC50 = 53.26 µg/mL) followed by RH (IC50 = 84.15 µg/mL) and BB (IC50 = 70.32 µg/mL) on the other hand water treated samples have shown the maximum radical scavenging activity at (IC50 = 120 µg/mL) given in Table 1. These results suggest that phenolic compounds derived from SCB have an efficient radical scavenging activity.

ABTS Scavenging Assay

AA was also measured using the ABTS assay and expressed as percentage (%) of free radicals (ABTS·+) scavenging activity or percent of inhibition (Fig. 3b). Phenolic compounds derived by acid catalysis fraction of agrowaste residues indicate approximately three times high radical scavenging activity than those of aqueous catalyzed APCs. AA of all APCs samples has been found to get enhanced with concentration boost, representing a quantity dependent association due to aromatic moieties that easily scavenge free radicals [26].

Phosphomolybdate Assay (PMA)

In this study (PMA), aromatic compounds or substances which can readily lose electrons and reduce the molybdenum ions are considered to have high AA [26]. The results of the AA (reduction of MoVI to MoV) of acid or water catalyzed APCs fractions derived from agrowaste residues SCB, BB and RH are tabulated in (Table 1). The order of AA of APCs has been found in acid treated samples derived from the agrowaste SCB > BB > RH while this order is BB > SCB > RH in water catalyzed products. Ascorbic acid as a known positive control has shown higher AA compared to isolated APCs fractions.

Reducing Power Assay (RPA)

In RPA, any chemical compound having reduction property reacts with potassium ferricyanide (Fe3+) to convert it to potassium ferrocyanide (Fe2+) which may further react with ferric chloride to form ferric–ferro complex. This complex can be monitored by measuring its absorbance at 700 nm, increasing absorbance exhibits high reducing power of the compounds. The results of this assay (Fig. 3c) indicate that the absorbance (at 700 nm) of isolated APCs fraction increases in a dose dependent manner from 0.299 (29.9%) at 0.1 mg/mL to 0.986 (98.6%) at 1 mg/mL, in samples catalyzed in presence of acid. The absorbance for the standards ranged from 0.137 to 0.602 (0.1–1 mg/mL) and 0.172–0.658 (0.1–1 mg/mL) for ascorbic acid and gallic acid respectively (Fig. 3c).

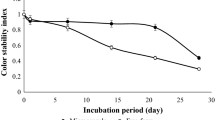

β-Carotene–Linoleic Acid Bleaching (BCB) Test

The BCB test is based on the loss of original or natural yellow colour of β-carotene by free radicals generated during linoleic acid oxidation in emulsion formation [28]. The time of β-carotene bleaching can be decreased in presence of antioxidants. So β-carotene has been used in the AA assessment of AW derived phenolic compounds. The AA (%) of APCs as compared to α-tocopherol are shown in (Fig. 3d). The AA (%) has been found to decrease in the order α-tocopherol > SCB-acid > BB-acid > RH-acid > BB-water > SCB-water > RH-water. In general, AA (%) depends upon the concentration and the nature of phenolic compounds in each sample. α-tocopherol and acid catalyzed APCs have shown high (AA %) antioxidants due to presence of more phenolics. In contrast, water extracted APCs have shown low AA. About 50% AA% was found with APCs (SCB and BB-acid) at the concentration of 500 µg/mL.

Antimicrobial Results

The antibacterial properties of all the isolated and purified APCs have been tested against two microbial strains B. subtilis (Gram positive) and P. aeruginosa (Gram negative) and their inhibitory zone data are tabulated in (Table 2). All extracted APCs have shown significant growth inhibitory effects on Gram positive but less significant on Gram negative bacteria. It is clear from the data that APCs (derived from acid or water treatments) do show potential antimicrobial activity. APCs derived from AW by acid or water in concentration of 200 µg, have shown appreciable antibacterial activity against B. subtilis such as SCB (38, 17 mm), RH (31, 23 mm) and BB (34, 25 mm) but against P. aeruginosa, their activity is less prominent [SCB (11, 4 mm), RH (8, 0 mm) and BB (10, 0 mm)] as shown in (Table 2). It has been reported that Gram-positive bacteria are generally more sensitive to phenolic compounds or antibiotics as compared to Gram-negative bacteria [22, 26]. A possible explanation of this observation lies in the difference in composition of outer membrane of Gram positive and Gram negative bacteria. Gram positive bacterial cell walls are rich in lipoproteins and phospholipids than Gram negative bacteria which might enhance the permeability of hydrophobic compounds [13]. Another argument in favour of above observation relates to the inherent defense mechanism adopted by the Gram negative bacteria owing to the presence of unique periplasmic space which is not present in Gram positive bacteria. The opposition of gram negative bacteria towards antibacterial agents lies in the presence of hydrophilic surface of their outer membrane which is rich in lipoproteins and lipopolysaccharide causing a barrier to the diffusion of antimicrobial agent [16].

We conclude that the enhanced antimicrobial properties, shown by the APCs are largely due to hydrophobicity, lipophilicity and capability of these compounds to bind with proteins at acidic pH [6].

Quorum Sensing Inhibition in C. violaceum (Agar Diffusion Assay)

Isolated APCs in this study have also been tested for quorum sensing inhibition (QSI) activity against C. violaceum by using their different concentrations (100–400 µg) as shown in (Table 3). The QSI can be seen by the formation of a turbid halo around the sample loaded wells, while only few samples of APCs have shown colorless or opaque zones. The APCs inhibited both growth (killing) and production of violacein in C. violaceum, but in some samples bacterial growth can be observed around the well. In comparison to APCs samples, control samples there were no QSI found. APCs (400 µg) derived from SCB-acid showed highest inhibitory activity with C. violaceum with 18 mm halo inhibitory zone was formed. Other plant extracts have also shown similar results in this assay [13, 18]. A bacteria–bacteria communication or QS regulates the pathogenesis of many infectious organisms. The phenolic compounds isolated from AW used in this study were found to be effectively inhibiting the bacterial growth of QS strains.

Flow Cytometric Cell Death Study

Cell membrane integrity is considered to be a chief and important factor between cell viability and death. Viable cells have healthy and tight cell membranes that cannot be permit to enter some DNA staining dye, while dead cells are assumed to have disrupted or broken cell membranes. PI is DNA staining dye and normally barred from viable cells [29]. When cell membrane was disrupted by any antimicrobial agents then red-fluorescent PI intercalates with DNA. Thus, the flow cytometry is good approach for bacterial death or viability assays against antimicrobial agents. Flow cytometric analysis results have shown high cell death in range of (9.2–35.3%) for Gram positive bacteria whereas very low cell death (0.9–7%) for Gram negative in 4th channel (Q1-LR) as depicted in. Phenolic compounds penetrate in cell via membrane and interact with cellular proteins and block proton motive force and deplete intracellular ATP concentration which creates an osmotic pressure resulting in the cellular death [30]. The natural ingredients may be considered as emerging materials to food packaging applications for better shell life and food values [31].

Conclusions

Benign hydrolytic conditions have been employed for the generation and isolation of agrowaste derived phenolic compounds (APCs). The AW exploited in this study are SCB, RH and BB lignin. APCs isolated by a hydrophobic resin XAD-16 in this study have been evaluated for their potential bioactivity in area of antioxidant and antimicrobial agents. The results have shown high AA of APCs in terms of both scavenging of free radicals and significant antimicrobial activity against Gram positive in compared to Gram negative bacteria. The study has demonstrated the usefulness of AW derived chemicals as a alternatives of synthetic preservatives which can be used as natural antioxidants and antimicrobials which may find applications as medicinal supplements and food additives, particularly may serve modern food packaging technologies.

References

Madurwar, M.V., Ralegaonkar, R.V., Mandavgane, S.A.: Application of agro-waste for sustainable construction materials: a review. Constr. Build. Mater. 38, 872–878 (2013)

Hoareau, W., Trindade, W.G., Siegmund, B., Castellan, A., Frollini, E.: Sugarcane bagasse and curaua lignins oxidized by chlorine dioxide and reacted with furfuryl alcohol: characterization and stability. Polym. Degrad. Stab. 86, 567–576 (2004)

Zeng, J., Tong, Z., Wang, L., Zhu, J.Y., Ingram, L.: Isolation and structural characterization of sugarcane bagasse lignin after dilute phosphoric acid plus steam explosion pretreatment and its effect on cellulose hydrolysis. Bioresour. Technol. 154, 274–281 (2014)

Lopes, A.M.C., Brenner, M., Fale, P., Roseiro, L.B., Lukasik, R.B.: Extraction and purification of phenolic compounds from lignocellulosic biomass assisted by ionic liquid, polymeric resins and supercritical CO2. Sustain. Chem. Eng. 6, 3357–3367 (2016)

Da Silva, C.G., Grelier, S., Pichavant, F., Frollini, E., Castellan, A.: Adding value to lignins isolated from sugarcane baggasse and Miscanthus. Ind. Crops. Product. 42, 87–95 (2013)

Jonsson, L.J., Martin, C.: Pretreatment of lignocellulose: formation of inhibitory by-products and strategies for minimizing their effects. Bioresour. Technol. 199, 103–112 (2016)

Isikgor, F.H., Becer, C.R.: Lignocellulosic biomass: a sustainable platform for the production of bio-based chemicals and polymers. Polym. Chem. 6, 4497–4559 (2015)

Wang, H.M., Tucker, Y.J.: Recent development in chemical depolymerization of lignin: a review. J. Appl. Chem. 12, 1–9 (2013)

Rahimi, A., Ulbrich, A., Coon, J.J., Stahl, S.S.: Formic-acid-induced depolymerization of oxidized lignin to aromatics. Nature 13, 249–452 (2014)

Rai, S., Dutta, P.K., Mehrotra, G.K.: Agrowaste derived phenolic compounds as additives to chitosan film for food packaging applications: antibacterial and antioxidant study. J. Indian Chem. Soc. 93, 1–8 (2016)

Munro, B., Vuong, Q.V., Chalmers, A.C., Goldsmith, C.D., Bowyer, M.C., Scarlett, C.J.: Phytochemical antioxidant and anti-cancer properties of Euphorbia tirucalli methanolic and aqueous extracts. Antioxidants 4, 647–661 (2015)

Tsuda, T.: Recent progress in anti-obesity and anti-diabetes effect of berries. Antioxidants 5, 1–13 (2016)

Ceylan, O., Sahin, M.D., Akdamar, G.: Antioxidant and anti-quorum sensing potential of Acer monspessulanum subsp. monspessulanum extracts. Planta Med. 82, 1–6 (2016)

Kumar, N.V., Murthy, P.S., Manjunatha, J.R., Bettadaiah, B.K.: Synthesis and quorum sensing inhibitory activity of key phenolic compounds of ginger and their derivatives. Food Chem. 159, 451–457 (2014)

Zheng, R., Su, S., Zhou, H., Yan, H., Ye, J., Zhao, Z., You, L., Fu, X.: Antioxidant/antihyperglycemic activity of phenolics from sugarcane (Saccharum officinarum L.) bagasse and identification by UHPLC-HR-TOFMS. Ind. Crops. Prod. 101, 104–114 (2017)

Soto, M.L., Conde, E., Gonzalez-Lopez, N., Conde, M.J., Moure, A., Sineiro, J., Falque, E.H., Domínguez Nunez, M.J., Parajo, J.C.: Recovery and concentration of antioxidants from winery wastes. Molecules 17, 3008–3024 (2012)

Jonsson, L.J., Alriksson, B., Nilvebrant, N.O.C.: Bioconversion of lignocellulose: inhibitory and detoxification. Biotechnol. Biofuels 6, 1–10 (2013)

Chen, Y., Zhang, W., Zhao, T., Li, F., Zhang, M., Li, J., Zou, Y., Wang, W., Cobbina, S.J., Wu, X., Yang, L.: Adsorption properties of macroporous adsorbent resins for separation of anthocyanins from mulberry. Food Chem. 194, 712–722 (2016)

Li, A., Zhang, Q., Chen, J., Fei, Z., Long, C., Li, W.: Adsorption of phenolic compounds on Amberlite XAD-4 and its acetylated derivative MX-4. React. Funct. Polym. 49, 225–233 (2001)

Singleton, V.L., Orhofer, R., Lamuela-Raventos, R.M.: Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin–Ciocalteu reagent. Methods Enzymol. 299, 152–178 (1999)

Miller, G.M.: Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31, 426–428 (1959)

Brand-williams, W., Cuvelier, M.E., Berset, C.: Use of free radical method to evaluate antioxidant activity. LWT Food Sci. Technol. 28, 25–30 (1995)

Prieto, P., Pineda, M., Aguilar, M.: Spectrophotometric quantification of antioxidant capacity through the formation of a phosphomolybdenum complex: specific application of vitamin E. Anal. Biochem. 269, 337–341 (1999)

Oyaizu, M.: Studies on products of browning reactions: antioxidative activities of products of browning reaction prepared from glucosamine. Japn. J. Nutr. 44, 307–315 (1986)

Archana, D., Singh, B.K., Dutta, J., Dutta, P.K.: Chitosan-PVP-nano silver oxide wound dressing: in vitro and in vivo evaluation. Int. J. Biol. Macromol. 73, 49–57 (2015)

Tian, F., Li, B., Ji, B., Yang, J., Zhang, G., Che, Y., Luo, Y.: Antioxidant and antimicrobial activities of consecutive extracts from Galla chinensis: the polarity affects the bioactivities. Food Chem. 113, 173–179 (2009)

Li, C., Zhao, X., Wang, A., Huber, G.W., Zhang, T.: Catalytic transformation of lignin for the production of chemicals and fuels. Chem. Rev. 115, 11559–11624 (2015)

Liu, F., Liu, Q., Wang, A., Zhang, T.: Direct catalytic hydrogenolysis of kraft lignin to phenols in choline-derived ionic liquids. Sustain. Chem. 4, 3850–3856 (2016)

Manna, D.K., Mandal, A.K., Sena, I.K., Maji, P.K., Chakraborti, S., Chakraborty, R., Islam, S.S.: Antibacterial and DNA degradation potential of silver nanoparticles synthesized via green route. Int. J. Biol. Macromol. 80, 455–459 (2015)

Andary, J., Maalouly, J., Ouaini, R., Chebib, H., Beyrouthy, M., Rutledge, D.N., Ouaini, N.: Phenolic compounds from diluted acid hydrolysates of olive stones: effect of overliming. Adv. Crops Sci. Technol. 1, 1–5 (2013)

Dulf, F.V., Vodnar, D.C., Dulf, E.H., Diaconeasa, Z., Socaciu, C.: Liberation and recovery of phenolic antioxidants and lipids in chokeberry (Aronia melanocarpa) pomace by solid-state bioprocessing using Aspergillus niger and Rhizopus oligosporus strains. LWT Food Sci. Technol. 87, 241–249 (2018)

Acknowledgements

Authors are thankful to the Director, Motilal Nehru National Institute of Technology, Allahabad, India for providing institutional facilities at the Center for Interdisciplinary Research (CIR).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rai, S., Dutta, P.K. & Mehrotra, G.K. Natural Antioxidant and Antimicrobial Agents from Agrowastes: An Emergent Need to Food Packaging. Waste Biomass Valor 11, 1905–1916 (2020). https://doi.org/10.1007/s12649-018-0498-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-018-0498-0