Abstract

Biochars were slowly pyrolyzed from dried swine manure waste by slow pyrolysis at different temperatures (300–750 °C) and heating times (0–120 min). The influence of pyrolysis temperature and heating time on the physicochemical properties of the biochars were studied. It was found that the ash content, pH, mineral nutrients, total heavy metals (except Zn), and pore properties of all swine-manure-derived biochars increased with increasing temperature and time. The yield and N, O, and H contents decreased with increasing temperature and time. The manure-derived biochar was rich in soil macronutrients and micronutrients, such as N, P, K, Ca, Mg, Na, Fe, Mn, Cu, and Zn. Excessive pyrolysis temperature (i.e., 750 °C) significantly increased the electrical conductivities of the biochars, i.e., the amount of soluble salts, and was also associated with the risk of volatilization of heavy metals (e.g., Zn) with low melting point. Linear correlation analyses showed that there were significant correlations between physical and chemical characteristics of the biochars, and the P values of correlation coefficients were often < 0.001. The principal component analysis implied that the properties of the swine-manure-derived biochars were mainly affected by ash content. Furthermore, the chemical and pore properties were also consistent with the observations of the XRD and FTIR. The swine-manure-derived biochar at 450 °C after 60 min could be used as an excellent medium to soil environment because of relatively low soluble salts and heavy metals, abundant mesoporous pores, surface functional groups, and nutrients.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

Environmental application of manure-derived biochar has received much attention. A detailed analysis of the effect of pyrolysis conditions on the physicochemical properties of swine-manure-derived biochar was provided. Meanwhile, mathematical analysis methods (linear correlation analysis and principal component analysis) were used to study the correlation between physicochemical properties of the biochars. Temperature affected the properties of swine-manure-derived biochar more clearly than time. Ash content was the most important factor that affected the properties of the biochars. The suitable pyrolysis conditions for swine-manure-derived biochar as a soil amendment were suggested in this study.

Introduction

Biochar is the solid, C-rich product of slow heating of biomass at low temperature, with the absence or near-absence of O [1,2,3]; it can be used for C sequestration, reducing greenhouse gas emissions, waste management, renewable energy, soil improvement, crop productivity enhancement, and environmental remediation [4,5,6,7,8]. Although almost all carbonaceous biomass can be converted into biochar through thermal pyrolysis, a life cycle assessment of pyrolysis biochar systems suggests that it is more environmentally and financially viable to produce biochar from waste biomass [9]. Thus, the conversion of industrial and agricultural waste organic matter into biochar through pyrolysis has attracted wide interest and research in recent years [10,11,12,13,14]. In this case, agricultural residues have been proposed as favorable feedstock materials for creating biochar [15]. Plant residues (e.g., straw and woody biomass) are disadvantageous when compared to traditional fertilizers for supplying crop nutrients due to their low nutrient contents (e.g. N, P and K). Conversely, manures are nutrient-rich materials; it correspondingly follows that pyrolysis of manures would produce a nutrient-rich biochar for use as a soil amendment [16].

For the last decade, China and the world have seen a significant increase in the number of intensive animal feeding operations, which produce a large quantity of manure and exceed the capacity of nearby land to assimilate the organic C and nutrients in manure [17]. Recently, biochar made from animal manure has shown the potential for improving soil fertility, C sequestration and water quality [18,19,20,21,22]. These roles of biochar are closely related to its physical and chemical characteristics, which mainly depend on the biochar feedstock and pyrolysis conditions such as temperature and holding time [23, 24]. Pyrolysis temperature is the most important factor because thermochemical changes (e.g., the release of volatiles and condensable compounds from the unorganized phase of biomass) are temperature dependent [25]. Meanwhile, the product of pyrolysis also depends on the holding time in the reaction zone. In general, a longer holding time results in secondary char produced from a reaction between the primary char and volatiles [23, 24]. However, there are limited studies on biochar characteristics at specific temperatures with different holding times. The temperature affects biochar properties more significantly than heating time for straw and lignosulfonate [26]. The effect of holding time is greater at low temperatures and less at high temperatures for eight types of plant feedstocks [23, 27, 28]. Suitable pyrolysis conditions (i.e., pyrolysis temperature and holding time) for biochar derived from different feedstocks are different for soil amendments [27,28,29]. Due to the large differences in composition and properties of various agricultural residues, the suitable conditions for biochar preparation may be different for different needs. At present, suitable pyrolysis conditions for potential environmental application of swine-manure-derived biochar are not clear, and need to be further studied.

In recent years, a large number of characteristic indexes of biochar have been studied extensively, such as porosity, ash, volatile matter, pH, electrical conductivity (EC), organic and inorganic elements (e.g., C, H, O, P, K, Ca and Mg) and heavy metals (e.g., Cu, Zn, Pb and Cd) [16, 24, 27, 30, 31]. Multivariate analysis technology can determine the inherent link between these indexes and their influence on each other. For example, many related indexes could be recombined into a new group of mutually independent synthetic indexes to replace the original indexes through principal component analysis (PCA). PCA has been widely used in the assessment of environmental pollutants in air, water, soil and sediment [32,33,34,35]. However, literature on the relationships among biochar indexes is very limited. Some indexes may be more important than others because they are more relevant to biochar characteristics.

Therefore, the aim of this study was to investigate the effects of pyrolysis temperature and holding time on the physicochemical properties of swine-manure-derived biochar and its potential environmental applications. Thus, a series of biochar products were prepared at prescribed temperature (300–750 °C) for different times (0–120 min). Furthermore, the relationships among the indexes of biochar properties were analyzed using linear correlation analysis and PCA.

Materials and Methods

Swine Manure

Separated swine manure solid was obtained from a solid–liquid separation system treating flushed manure at an intensive swine production area, located in Meizhou, Guangdong Province, China. The manure sample was then dried using solar heating in an open space. Prior to proximate analysis, the dried sample was stored in a desiccator. The biomass sample was further dried in an oven at approximately 105 °C and ground to pass through a 2 mm sieve for the ultimate (organic) and inorganic element analyses and the pyrolysis experiment.

Biochar Preparation

The ground manure sample was placed into a net corundum holder, and then housed at the center of a tube furnace. The sweep gas from a N2 cylinder with a constant flow rate of 500 cm3 min−1 was precisely metered to the experimental system using a mass flow controller. The experimental conditions in the pyrolysis system were performed at a fixed heating rate of about 10 °C min−1 up to the prescribed temperature ranging from 300 to 750 °C, and then held for 0–120 min before cooling to approximately 25 °C. The resulting biochar product was taken from the holder in order to determine its mass, and then stored in the desiccator for chemical and physical characterization without any further treatment. Yields of the swine-manure-derived biochars were calculated by the difference between the masses before and after pyrolysis. Biochar samples were sieved to < 0.145 mm and stored in amber glass bottles for further analysis.

Swine Manure and Biochar Characterization

The pH and EC of the swine manure and biochars were measured with a Mettler-Toledo SevenMulti dual pH/conductivity meter using a ratio of solid sample to distilled water of 1:10 (w/v). Moisture was determined by the weight loss after heating to 105 °C in an open crucible and holding at this temperature until the solid sample weight stabilized. Volatile matter was determined by the weight loss after heating to 950 °C in a covered crucible and holding for 7 min. The ash content of the sample was measured using the residual weight after heating at 750 °C for 6 h in a muffle furnace. After the determination of moisture, volatile matter, and ash, fixed C was calculated by difference, according to the procedures of Meng et al. [31].

Elements (C, H, N, and S) were analyzed on an Elementar Vario EL Cube Elemental Analyzer, and O was calculated by subtracting C, N, H, S, and the moisture and ash contents from the total mass of the sample. An inductively coupled plasma–optical emission spectrometer (PerkinElmer Optima 5300DV, USA) was used to determine the relevant nutrient elements and heavy metals, including P, K, Na, Ca, Mg, Fe, Mn, Cu, Zn, Pb, Cd, Cr and Ni. Prior to analysis, the solid sample (about 0.1 g) was digested using the concentrated HNO3/H2O2 solutions in a pressure bomb to form homogeneous solution samples. The digested solution was diluted with de-ionized water, in which a small amount of the diluted solution was removed to measure the contents of elements.

The BET surface area, pore properties, XRD and FTIR analyses were performed using a surface area and porosity analyzer (Micromeritics, ASAP 2020 V3.0, USA), a computer-controlled Siemens D5000 instrument (Bruker D8 ADVANCE, Germany), and a spectrometer instrument (Thermo Scientific Nicolet iS10, USA) respectively, according to the procedures of Tsai et al. [30].

Statistical Analysis

All results were expressed as an average of three replicates and standard deviations. Statistical analysis was performed with SPSS software (Version 23, SPSS Inc., Chicago).

Results and Discussion

Physicochemical Properties of Swine Manure

Table S1 indicates the results of pH and EC, and proximate, ultimate, and inorganic element analyses for dried swine manure. In this study, the pH (7.8) and EC (2.4 mS cm−1) values of manure biomass were similar to those of manure in related literature [15, 28, 31], and were higher than those of the documented plant biomass [12, 14, 22, 27]. The weak alkalinity of pig manure biomass is beneficial to acidic soil improvement, but excessive EC (the content of soluble salts) can adversely influence the water uptake and lower the nutrient consumption of plants [37]. The manure biomass contained a large percentage of volatile matter (58.6 wt%), which was comparable to crop residues, such as rice and wheat straws [26, 29], thereby indicating that the dried biomass was abundant in organic elements. The ultimate analysis confirmed that there were high contents of C and O in the manure biomass (i.e., 34.1 and 20.5 wt% respectively), which supported undigested feeds (e.g., forage, lipids, and proteins) for this swine manure waste [30]. In addition, the manure biomass contained 1.8% N, which was higher than the N contents reported in rice, corn and wheat straws (below 1%) [26, 29, 38], and may have been due to high protein content.

The ash content (maximum of 21.4 wt%) of this biomass was much higher than that of the reported crop straws; for example, those of rice, corn and wheat straws were only 10.3%, 5.2%, and 10.8%, respectively [26, 29, 38]. This may be advantageous for agricultural utilization because inorganic nutrients are generally present in ash. As also shown in Table S1, the manure contained relatively higher levels of P, K, Ca, Mg, Fe, Mn, Cu, and Zn compared with crop straws (e.g., rice, corn and wheat straws) [39]. This suggested that the swine manure could be more suitable as a soil fertilizer. Meanwhile, the content of several heavy metals (such as Pb, Cd, Cr and Ni) was far below the standard limit for microbial organic fertilizers of European Union countries. However, the high Cu and Zn contents in the manure waste were of concern because of their chronic toxicity in liver and kidneys [30].

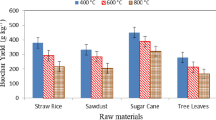

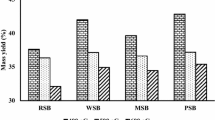

Biochar Yield and Proximate Analysis

The yield and proximate analysis (moisture, ash, volatile matter, and fixed C) of swine-manure-derived biochars at different pyrolysis conditions are shown in Fig. 1a and Table 1. The biochar yield and volatile matter contents of the biochars decreased gradually with increasing pyrolysis temperatures. This decrease in yield and volatile matter was mainly due to the increased pyrolysis of lignocellulosic components and devolatilization of organic materials with increased pyrolysis temperatures [40]. Meanwhile, the yield at lower temperature (300 °C) was higher than that at higher temperatures (450 °C, 600 °C, and 750 °C) (Fig. 1a). It was also found that the yield of biochar produced by swine manure was higher than that produced by crop straws (e.g., rice, corn and wheat straws) [26, 27, 29, 38]. This may have been attributed to higher ash content in the manure. The proximate analysis confirmed that the ash content in manure biochars could reach above 50% at high pyrolysis temperatures (600 °C and 750 °C), which is much higher than that in crop-straw-derived biochars [26, 27, 29, 38].

In contrast, ash contents in the manure biochars increased gradually with increasing temperature, which was due to the concentrations of minerals and increased organic matter losses from the residues [15, 16]. Compared with the feedstock (Table S1), fixed C contents in the biochars clearly increased during pyrolysis and reached over 10%, but they were still lower than that in the crop-straw-derived biochars (greater than 50% at high pyrolysis temperature) [26, 27, 29]. This may have been due to relatively higher C content in the crop straws and its stability during pyrolysis.

The effect of holding time on yield and proximate components was smaller than that of the pyrolysis temperature (Fig. 1a; Table 1). Generally, the yield and volatile matter content decreased gradually with increasing time and were stable after 60 min, but ash content increased with increasing time and was also stable after 60 min. Increased holding times at low (300 °C) or high (750 °C) temperatures compared with those at medium (450 °C or 600 °C) temperatures more significantly affected the yield of biochars and their proximate components (e.g., ash, volatile matter, and fixed C contents) (Table 1). This may have been attributed to the more rapid decomposition and volatilization of organic materials at lower pyrolysis temperature [40], but the CO2 gas release caused by the thermal decomposition of mineral (e.g., CaCO3) at higher pyrolysis temperature [30].

According to a study on biochars derived from plant feedstocks, it was found that holding time had a significant influence on the biochar properties at low pyrolysis temperature (300 °C), but had little effect at high pyrolysis temperature (600 °C) [27]. Similarly, studies have found that holding time has less of an effect on the characteristics of biochars prepared from manure (cow and goat manure) at 500 °C [24, 28]. According to the studies by Zhang et al. [26] and Wu et al. [29], when the holding time was longer than one hour, it had only a small effect on the characterization of the biochars derived from straws, even at lower pyrolysis temperatures of 200 °C or 300 °C. Based on the aforementioned studies and the present study, it can be confirmed that the effect of holding time on biochar characteristics usually occurs at low temperatures and within one hour. This may be because at low temperatures more organic matter can be pyrolyzed in the feedstock biomass, while the content of this organic matter decreases sharply before reaching the higher pyrolysis temperatures.

pH, EC, and Ultimate Analysis

The data on pH and EC of swine-manure-derived biochars are listed in Fig. 1b, c. The pH increased rapidly with the increase in temperatures from 300 to 750 °C, the maximum pH values were 9.9, 11.4, 12.1, and 12.9 at 300 °C, 450 °C, 600 °C and 750 °C, respectively. These pH values were clearly higher than those of the straw-derived biochars under the same pyrolysis conditions [26, 27, 29, 36]. The manure biochars exhibited a more alkaline nature because the minerals began to separate from the organic matrix as a result of becoming ashed beyond 200 °C [15]. The presence of inorganic alkaline compounds (CaCO3) has previously been reported in dairy-manure-derived biochar [15, 41]. Another study also showed that inorganic carbonates were the major alkaline components of crop-straw-derived biochars at high temperatures, and organic anions also contributed to the alkalinity of the biochars, especially for those generated at low temperatures [42]. Similar to the yield, increased holding times at a pyrolysis temperature of 300 °C compared with those at 450 °C, 600 °C or 750 °C pyrolysis temperature would more significantly affect the pH of biochars.

The EC value reflected the degree of salinity in the biochar. The EC value of the biochar decreased with increasing pyrolysis temperatures and was less than 1 mS cm−1, especially with an increased holding time at 300 °C (Fig. 1c). This decrease in EC with an increased temperature was also observed in another study on manure-derived biochar [15], and may have been attributed to the decrease in soluble salts in the biochar prepared at a lower temperature. Cao and Harris [15] reported that the content of water soluble P, Ca, and Mg decreased in dairy-manure-derived biochar as production temperature increased from 200 to 500 °C because amorphous P–Ca–Mg crystallized to form less soluble phases at 500 °C.

It is important to note that the EC values of the biochars at 750 °C were one order of magnitude higher than that at several other temperatures, and reached a maximum of 11.0 mS cm−1. This was probably due to the thermal decomposition of the minerals formed during lower temperature pyrolysis such as the formation of whitlockite (Ca, Mg)3(PO4)2 at higher pyrolysis temperatures [30], which increased the solubility of Ca and Mg and increased the EC values for biochar. The EC values of the biochars should be appropriate to avoid creating unwanted salt effects in soils, especially at high biochar application rates (3–30 tons ha−1) [16]. From this point of view, the manure biochar was not suitable for preparation at high temperatures (750 °C).

The ultimate analysis of biochars derived from swine manure is listed in Table 2. Compared with the raw feedstock, the C and N contents slightly increased, but the H and O contents significantly decreased in the biochars generated at 300 °C (Tables 1, 3). This was probably because the decomposition of organic matter was dominated by loss of surface –OH functional groups to dehydration at the lower temperature [40], and recalcitrant N occurring in heterocyclic compounds was present in the biochars [43]. Then, the C, H, O, and N contents showed a downward trend. Similar phenomena have also been observed in biochars prepared from various manure feedstocks [16]. This property is a typical feedstock response during the pyrolysis process, where the feedstock at higher temperatures loses C-bound O and H atoms due to structural core degradation [40]. However, it should be noted that the C content showed a clear upward trend with increasing holding times at 750 °C, and was accompanied by a rapid decrease in O content and a slight decrease in N content. The mechanism for this observation is not well understood. This could have been due to the formation of a more stable, less readily decomposable C in the organic C element of the raw material, while other organic elements, such as O and N, reacted to produce gas, thereby increasing the relative C content.

In addition, the content of organic S was very low (< 1%). The content decreased and then increased with increasing pyrolysis temperatures and holding times, which was higher in biochars generated at 750 °C than in those generated at other pyrolysis temperatures (Table 2). Ro et al. [19] reported organic S losses to the vapor phase, primarily as carbonyl sulfide, during pyrolysis. Previous research observed the thermal decomposition of organic S during pyrolysis at temperatures up to 400 °C; at higher temperatures approaching 700 °C, the S as insoluble sulfides in the biochar matrix was altered by the addition of native S to unsaturated sites on the biochar surface [44].

As shown in Table 2, biochar O/C, H/C and (O + N)/C atomic ratios mainly decreased with increasing pyrolysis temperature and holding time; the rate of decline was greater at 300 °C than at 450 °C, 600 °C, and 750 °C after 60 min. This trend was mainly due to removal of polar surface functional groups and instances of higher degrees of carbonization resulting in the formation of more aromatic structures, which are more recalcitrant OC structures [45,46,47,48,49]. Moreover, lower H/C ratios indicate that biochar produced with higher temperature and longer holding time becomes more aromatic [50]. Generally, lower ratios of H/C or O/C are associated with a higher degree of biochar aromaticity [51]. Recent research reported that biochar with ratios of H/C or O/C of less than 1.19 or 0.60 had a mean residence time of longer than 100 years in the soil and could be a measure for C sequestration while amended to soil [52]. The swine manure biochar prepared at 450 °C, 600 °C, and 750 °C had relatively low and stable ratios of H/C and O/C, and might also be suitable for soil amendment as a measure of C sequestration.

Mineral Nutrients and Heavy Metals

Statistics of mineral nutrient concentrations in swine-manure-derived biochars are presented in Table 3. The macromineral and micromineral nutrient (P, K, Ca, Mg, Na, Fe, and Mn) contents in the biochars were higher than those in the raw feedstock (Table S1) and increased with increasing pyrolysis temperatures and holding times. These increases were probably due to the loss of C, H, O, and N during the pyrolysis process, thereby resulting in a relative increase in concentrations of these nutrients. In this study, biochars produced from swine manures had higher mineral nutrient contents than biochars produced from agricultural straws, forest litter, and natural plant wood [27, 53, 54]. Because they are rich in minerals important for plant growth, such as P, manure-based biochars may be better suited as an alternative fertilizer for plant growth in soil [16, 31].

The concentrations of heavy metals present in the biochars are also shown in Table 3. The increases in heavy metals (Cu, Pb, Cd, Cr, and Ni) contents in the biochars were similar to those of the nutrient elements. They were also higher than those in the raw feedstock due to the condensation effect during pyrolysis, but were lower than the permitted legal limits for elements (e.g., Cu, Zn, Pb, Cd, Cr and Ni) as specified by US Environmental Protection Agency [55]. Almost all metals were retained in the biochars in the present study, which was similar to the results reported by Cantrell et al. [16] and Meng et al. [31].

However, Chen and Yan [56] found that heavy metals emissions during the incineration of sewage sludge were in the following order: Cd > Pb > Zn > Cr > Cu > Mn > Ni. Therefore, heavy metal concentrations need to be monitored during feedstock production. It is worth noting that Zn concentration showed a rapid decrease (from 1.3 to 0.5 g kg−1) in the swine-manure-derived biochars at 750 °C, which was probably because the melting point of Zn is lower (420 °C) and its compounds were reduced to Zn metal under anaerobic conditions and then lost. Cantrell et al. [16] and Meng et al. [31] reported that Cd and Pb in manure-derived biochars exhibited losses during pyrolysis at 700 °C. It was also reported that 18% of Cd could be lost in gas and oil phases at 400 °C, with up to 89% lost at 600 °C during pyrolysis of heavy-metal-contaminated plants used in phytoremediation [57]. Pb vaporization was detected during incineration of municipal waste at temperatures as low as 650 °C [58]. At present, the mechanism of volatilization of metals in biochars derived from different sources and types of manure is not clear and needs further study. Regardless, annual loading rates should be monitored if there are intentions of long term repeated soil applications of manure biochars [16].

Linear Correlation Analysis

There were many significant correlations among biochar yield, moisture, ash, volatile matter and fixed C of swine-manure-derived biochar (Table S2). For example, the yield was significantly and positively correlated with volatile matter content (p < 0.001), and was significantly and negatively correlated with ash content (p < 0.001). That is to say, the change in the yield of swine-manure-derived biochar was almost the same as that of volatile matter contents, but was opposite to that of ash content. This was in line with the results in Fig. 1a and Table 1, and was consistent with some findings concerning biochars prepared from plant and animal feedstocks [27, 29,30,31]. A recent study showed that there were also significant correlations between biochar yield with volatile matter and fixed C in the biochars derived from eight plant-based biomasses, which included four agricultural wastes (wheat straw, corn straw, peanut shells, and sweet potato vine), two forest litters, and two natural plant woods, but the yield of the plant-derived biochars was not significantly related to ash content [27]. This implied that ash had more important roles or effects on the biochars prepared from animal feedstocks than those from plant feedstocks.

Table 4 shows that a large number of significant correlations existed between physicochemical properties and elemental contents of biochars and the yield of biochar and its proximate components. For example, pH was significantly and positively correlated with ash content (p < 0.001), and was significantly and negatively correlated with yield (p < 0.001). This suggested that pyrolysis temperature and residence time of biochar could be improved if high alkalinity biochar is desired, which means that the yield is reduced and the ash content is increased at the same time. Similar results were also found in studies on biochars produced from plant and animal feedstocks [27, 29,30,31]. There was a similar correlation between EC values and yield and ash content (Table 4). This implied that biochars obtained at high temperatures have high pH values as well as high EC values; the EC value was greater than 10 mS cm−1 at 750 °C (Fig. 1c), which is undesirable. High EC means excessive salinity, which may be harmful to crop growth.

C content was only significantly correlated with fixed C content in the swine-manure-derived biochars (p < 0.01; Table 4). This suggested that the C content in the biochars was only affected by fixed C content. The contents of other organic elements (H, O, N, and S) in the biochars were significantly correlated with their proximate components (Table 4). There was a similar correlation between the H, O, and N contents and the yield and the proximate components. As shown in Table 2, the changes in H, O, and N contents were almost the same during pyrolysis. This was also consistent with several studies on biochars prepared from plant and animal feedstocks [29,30,31]. There was also a similar correlation between the concentrations of mineral nutrients and heavy metals (except Zn) in the biochars and the yield and the proximate components (Table 4). This suggested that these elements had similar physicochemical behavior during pyrolysis, which has also been observed in studies on manure-derived biochars [16, 30, 31].

Principal Component Analysis

PCA is a commonly used multivariate analysis method. Relevant original indexes can be re-grouped into a new group of independent comprehensive indexes to replace the original indexes. That is to say, a few principal components are derived from the original variables so that they retain the information of the original variables as much as possible and are not related to each other. As shown in Table S2 and Table 4, there were significant correlations among the 25 index variables in the 20 biochar samples at 300 °C to 750 °C with holding times of 0 to 120 min. These indexes include the biochar yield, proximate components, pH, EC, organic elements, mineral nutrients and heavy metals in the biochars.

Through the PCA of these indicators, two principal components were obtained. The first principal component represented 75% of the variation, while the second principal component represented 17% of the variation; the sum of the two principal components was greater than 90% (Fig. 2). This showed that through the analysis of the two principal components, more than 90% of the variation information of all biochar samples and their indicators could be obtained. Through the variables loadings plot (Fig. 2a), it can be seen that the first principal component was positively correlated with ash, fixed C, pH, EC, S, P, K, Na, Ca, Mg, Fe, Mn, Cu, Zn, Pb, Cd, Cr, and Ni contents, and was negatively correlated with biochar yield, moisture, volatile matter, H, O, and N contents. According to the graph (Fig. 2a), each index could be divided into two groups. The first group was comprised of the components and elements retained in the biochars (including ash, fixed C, S, P, K, Na, Ca, Mg, Fe, Mn, Cu, Zn, Pb, Cd, Cr and Ni), and the second group was comprised of the volatile components and elements (including moisture, volatile matter, H, O, and N), as shown in Fig. 2a. In addition, it was found that the components and elements retained in the biochars were closely related to ash content, while the volatile components and elements were closely related to volatile matter content. According to the samples scores plot (Fig. 2b), each biochar sample could be divided into three groups. The first group was comprised of the biochar sample at a pyrolysis temperature of 750 °C with a holding time of 0 to 120 min (sample Nos. 16–20 in Fig. 2b). The second group was comprised of the biochar samples at pyrolysis temperatures of 450 °C and 600 °C with holding times of 0 to 120 min (sample Nos. 6–15 in Fig. 2b). The third group was comprised of the biochar sample at a pyrolysis temperature of 300 °C with a holding time of 0–120 min (sample Nos. 1–5 in Fig. 2b). This further demonstrated that there was a large difference among the physicochemical properties and element contents of the biochars at different pyrolysis temperatures.

Principal component analysis of the 25 indicator variables on the 20 biochar samples at 300 °C to 750 °C with holding times of 0 to 120 min. a Variables loadings plot: The indicator variables include biochar yield (BY), moisture (M), ash (A), volatile matter (VM), fixed C (FC), pH, EC, C, H, O, N, S, P, K, Na, Ca, Mg, Fe, Mn, Cu, Zn, Pb, Cd, Cr and Ni contents. b Samples scores plot: the biochar sample “1, 2, 3, 4 or 5” means the biochar at 300 °C with a holding time of 0, 15, 30, 60 or 120 min, “6, 7, 8, 9 or 10” means the biochar at 450 °C with a holding time of 0, 15, 30, 60 or 120 min, “11, 12, 13, 14 or 15” means the biochar at 600 °C with a holding time of 0, 15, 30, 60 or 120 min, and “16, 17, 18, 19 or 20” means the biochar at 750 °C with a holding time of 0, 15, 30, 60 or 120 min respectively

Moreover, the distance between the 450 °C and 600 °C samples was smaller than the distance between the 300 °C and the 750 °C samples (Fig. 2b). This showed that the 450 °C and 600 °C samples were less affected by holding time, while the 300 °C and the 750 °C samples were significantly affected by holding time. If Fig. 2a, b were merged, both the 750 °C samples and the components and elements retained in the biochars would be on the right side of the first principal component, i.e., the positive value. This illustrated that these properties of 750 °C samples were mainly affected by ash content. However, both the 300 °C samples and the volatile components and elements in the biochars were on the left side of the first principal component, i.e., the negative value. This illustrated that these properties of the 300 °C samples were mainly affected by volatile matter content. The 450 °C and 600 °C biochar samples were between the 300 and the 750 °C samples, and their nature was also between the 300 °C and the 750 °C samples.

BET Surface Area and Pore Properties

Pyrolysis temperature and holding time effects on BET surface area and pore properties are presented in Table 5. In the pyrolysis temperature range studied (300–750 °C), the swine-manure-derived biochar BET surface area, microporous surface area, total pore volume, and microporous pore volume mainly increased with increasing temperature. It was also found that surface area and pore volume of the biochar at lower temperature (300 °C) were very small with larger average pore width (25.94–51.20 nm), but were larger with smaller average pore width (4.42–6.48 nm) at higher temperature (450–750 °C). The mesoporous pores were created in the biochars at 450 °C and above, which was similar to the results reported by Tsai et al. [30] and Meng et al. [31]. Greater surface area is desirable because it aids in improving soil properties and increases water retention capacity to a greater extent [59].

XRD and FTIR Analyses

As shown in Fig. 3a, the results of XRD patterns for all resulting biochars were similar. There were the most strong peaks at 2θ 26.8° and 29.5°, which probably indicated the presence of quartz (SiO2) and calcite (CaCO3) respectively. In addition to calcite and quartz, the resulting biochars contained high levels of P, Ca, Mg and K based on the mineral elements analyses (Table 3), suggesting that some associated mineral crystals, such as sylvite (KCl), periclase (MgO) and whitlockite ((Ca,Mg)3(PO4)2), can be found in the biochar sample [15, 30]. Swine manure showed elevated background between 2θ = 14° and 26°, likely attributable mainly to organic matter, remained distinct at 300 °C, but was absent at other pyrolysis temperatures. Similar phenomena were also observed in dairy-manure-derived biochar [15].

Changes in FTIR spectral properties of the biochars over the range of pyrolysis temperatures and holding time are presented in Fig. 3b. The swine manure was characterized by the organic function groups [15], showing a band from O–H stretching (3200–3600 cm−1), CH2 (2852 and 2923 cm−1) in biopolymers, C=O stretching of carboxylic bonds (1652 cm−1), C=C stretching of aromatic rings (1543 cm−1) and C=C stretching (1421 cm−1), and C–O stretching (1042 cm−1) (Fig. 3b). These bands increased at lower pyrolysis temperatures (300–450 °C), but disappeared at higher temperatures (600–750 °C). These bands were absent in biochar samples pyrolyzed at 600 °C and above because the cleavage of these organic groups was due to higher mass loss during thermal decomposition and gas (e.g., CO2) product evolution [30]. These FTIR results were also in agreement with the findings of ultimate analyse (Table 2).

Conclusions

In the present study, a series of biochars were prepared from dried swine manure waste using slow pyrolysis at different temperature with different holding times. The ash content, pH, mineral nutrients, and total heavy metals (except Zn) of all swine-manure-derived biochars mainly increased as temperature and time increased, whereas the yield and N, O, and H contents decreased with increasing temperature and time as a result of pyrolytic volatilization during pyrolysis. The manure-derived biochar was rich in soil macronutrients and micronutrients such as N, P, K, Ca, Mg, Na, Fe, Mn, Cu and Zn. The physicochemical properties and elemental contents of the biochars were closely related to the proximate components, which were mainly affected and controlled by ash or volatile matter content. They were particularly affected by ash content, which was the most important factor in proximate components. Excessive pyrolysis temperature (e.g., 750 °C) significantly increased the EC of the biochars, i.e., the amount of soluble salts and was also associated with the risk of volatilization of heavy metals (e.g., Zn) with low melting point. The biochars prepared at 450 °C after 60 min could be used as a soil amendment because of their relatively low soluble salts and heavy metals, abundant mesoporous pores, surface functional groups, and nutrients.

References

Sohi, S.P.: Carbon storage with benefits. Science 338, 1034–1035 (2012)

Mahdi, Z., Hanandeh, A.E., Yu, Q.M.: Influence of pyrolysis conditions on surface characteristics and methylene blue adsorption of biochar derived from date seed biomass. Waste Biomass Valoriz 8, 2061–2073 (2017)

Ferreira, S.D., Manera, C., Silvestre, W.P., Pauletti, G.F., Altafini, C.R., Godinho, M.: Use of biochar produced from elephant grass by pyrolysis in a screw reactor as a soil amendment. Waste Biomass Valoriz. (2018). https://doi.org/10.1007/s12649-018-0347-1

Nanda, S., Dalai, A.K., Berruti, F., Kozinski, J.A.: Biochar as an exceptional bioresource for energy, agronomy, carbon sequestration, activated carbon and specialty materials. Waste Biomass Valoriz. 7, 201–235 (2016)

Lehmann, J., Rillig, M.C., Thies, J., Masiello, C.A., Hockaday, W.C., Crowley, D.: Biochar effects on soil biota—a review. Soil Biol. Biochem. 43, 1812–1836 (2011)

Wang, D., Zhang, W., Hao, X., Zhou, D.: Transport of biochar particles in saturated granular media: effects of pyrolysis temperature and particle size. Environ. Sci. Technol. 47, 821–828 (2013)

Li, F., Cao, X., Zhao, L., Wang, J., Ding, Z.: Effects of mineral additives on biochar formation: carbon retention, stability, and properties. Environ. Sci. Technol. 48, 11211–11217 (2014)

Vandecasteele, B., Reubens, B., Willekens, K., De Neve, S.: Composting for increasing the fertilizer value of chicken manure: effects of feedstock on P availability. Waste Biomass Valoriz. 5, 491–503 (2014)

Roberts, K.G., Gloy, B.A., Stephen, J., Scott, N.R., Johannes, L.: Life cycle assessment of biochar systems, estimating the energetic, economic, and climate change potential. Environ. Sci. Technol. 44, 827–833 (2010)

Kwapinski, W., Byrne, C.M.P., Kryachko, E., Wolfram, P., Adley, C., Leahy, J.J., Novotny, E.H., Hayes, M.H.B.: Biochar from biomass and waste. Waste Biomass Valoriz 1, 177–189 (2010)

Chen, H., Zhai, Y., Xu, B., Xiang, B., Zhu, L., Qiu, L., Liu, X., Li, C., Zeng, G.: Characterization of bio-oil and biochar from high-temperature pyrolysis of sewage sludge. Environ. Technol. 36, 470–478 (2014)

Chowdhury, Z.Z., Karim, M.Z., Ashraf, M.A., Khalid, K.: Influence of carbonization temperature on physicochemical properties of biochar derived from slow pyrolysis of durian wood (Durio zibethinus) sawdust. BioResources 11, 3356–3372 (2016)

Adebisi, G.A., Chowdhury, Z.Z., Alaba, P.A.: Equilibrium, kinetic, and thermodynamic studies of lead ion and zinc ion adsorption from aqueous solution onto activated carbon prepared from palm oil mill effluent. J. Clean. Prod. 148, 958–968 (2017)

Chowdhury, Z.Z., Pal, K., Johan, R.B., Dabdawb, W.A.Y., Ali, M.E., Rafique, R.: Comparative evaluation of physiochemical properties of a solid fuel derived from Adansonia digitata trunk using torrefaction. BioResources 12, 3816–3833 (2017)

Cao, X.D., Harris, W.: Properties of dairy-manure-derived biochar pertinent to its potential use in remediation. Bioresour. Technol. 101, 5222–5228 (2010)

Cantrell, K.B., Hunt, P.G., Uchimiya, M., Novak, J.M., Ro, K.S.: Impact of pyrolysis temperature and manure source on physicochemical characteristics of biochar. Bioresour. Technol. 107, 419–428 (2012)

Tsai, W.T., Liu, S.C., Chen, H.R., Chang, Y.M., Tsai, Y.L.: Co-pyrolysis of swine manure with agricultural plastic waste: laboratory-scale study. Waste Manag. 34, 1520–1528 (2014)

Novak, J.M., Busscher, W.J., Laird, D.A., Ahmedna, M., Watts, D.W., Niandou, M.A.S.: Impact of biochar amendment on fertility of a Southeastern coastal plain soil. Soil Sci. 174, 105–112 (2009)

Ro, K.S., Cantrell, K.B., Hunt, P.G.: High-temperature pyrolysis of blended animal manures for producing renewable energy and value-added biochar. Ind. Eng. Chem. Res. 49, 10125–10131 (2010)

Sun, K., Ro, K.S., Guo, M., Novak, J.M., Mashayekhi, H., Xing, B.: Sorption of bisphenol A, 17a-ethinyl estradiol and phenanthrene on thermally and hydrothermally produced biochars. Bioresour Technol. 102, 5757–5763 (2011)

Sun, K., Gao, B., Ro, K.S., Novak, J.M., Wang, Z., Herbert, S., Xing, B.: Assessment of herbicide sorption by biochars and organic matter associated with soil and sediment. Environ. Pollut. 163, 167–173 (2012)

Gondek, K., Mierzwa-Hersztek, M.: Effect of low-temperature biochar derived from pig manure and poultry litter on mobile and organic matter-bound forms of Cu, Cd, Pb and Zn in sandy soil. Soil Use Manag. 32, 357–367 (2016)

Yuan, H., Lu, T., Wang, Y.Z., Huang, H.Y., Chen, Y.: Influence of pyrolysis temperature and holding time on properties of biochar derived from medicinal herb (Radix isatidis) residue and its effect on soil CO2 emission. J. Anal. Appl. Pyrol. 110, 277–284 (2014)

Touray, N., Tsai, W.T., Li, M.H.: Effect of holding time during pyrolysis on thermochemical and physical properties of biochars derived from goat manure. Waste Biomass Valori. 5, 1029–1033 (2014)

Downie, A., Crosky, A., Munroe, P.: Physical properties of biochar. In: Lehmann, J., Joseph, S. (eds.) Biochar for Environmental Management: Science and Technology, pp. 13–32. Earthscan, London (2009)

Zhang, J., Liu, J., Liu, R.: Effects of pyrolysis temperature and heating time on biochar obtained from the pyrolysis of straw and lignosulfonate. Bioresour. Technol. 176, 288–291 (2015)

Sun, J.N., He, F.H., Pan, Y.H., Zhang, Z.H.: Effects of pyrolysis temperature and residence time on physicochemical properties of different biochar types. Acta Agric. Scand. Sect. B 67, 12–22 (2016)

Yue, Y., Li, G.T., Lin, Q.M., Zhao, X.R.: Slow pyrolysis as a measure for rapidly treating cow manure and the biochar characteristics. J. Anal. Appl. Pyrol. 124, 355–361 (2017)

Wu, W.X., Yang, M., Feng, Q.B., McGrouther, K., Wang, H.L., Lu, H.H., Chen, Y.X.: Chemical characterization of rice straw-derived biochar for soil amendment. Biomass Bioenergy 47, 268–276 (2012)

Tsai, W.T., Liu, S.C., Chen, H.R., Chang, Y.M., Tsai, Y.L.: Textural and chemical properties of swine-manure-derived biochar pertinent to its potential use as a soil amendment. Chemosphere 89, 198–203 (2012)

Meng, J., Wang, L.L., Liu, X.M., Wu, J.J., Brookes, P.C., Xu, J.M.: Physicochemical properties of biochar produced from aerobically composted swine manure and its potential use as an environmental amendment. Bioresour. Technol. 142, 641–646 (2013)

Wang, Y., Wang, P., Bai, Y.J., Tian, Z.X., Li, J.W., Shao, X., Mustavich, L.F., Li, B.L.: Assessment of surface water quality via multivariate statistical techniques, a case study of the Songhua River Harbin region, China. J. Hydro-Environ. Res. 7, 30–40 (2013)

Pandey, B., Agrawal, M., Singh, S.: Assessment of air pollution around coal mining area, emphasizing on spatial distributions, seasonal variations and heavy metals, using cluster and principal component analysis. Atmos. Pollut. Res. 5, 79–86 (2014)

Ma, X.L., Zuo, H., Tian, M.J., Zhang, L.Y., Meng, J., Zhou, X.N., Min, N., Chang, X.Y., Liu, Y.: Assessment of heavy metals contamination in sediments from three adjacent regions of the Yellow River using metal chemical fractions and multivariate analysis techniques. Chemosphere 144, 264–272 (2016)

Luo, J., Qi, S.H., Xie, X.M., Sophie Gu, X.W., Wang, J.J.: The assessment of source attribution of soil pollution in a typical e-waste recycling town and its surrounding regions using the combined organic and inorganic dataset. Environ. Sci. Pollut. R 24, 3131–3141 (2017)

Junna, S., Wang, B.C., Xu, G., Shao, H.B.: Effects of wheat straw biochar on carbon mineralization and guidance for large-scale soil quality improvement in the coastal wetland. Ecol. Eng. 62, 43–47 (2014)

Chan, K.Y., van Zwieten, L., Meszaros, I., Downie, A., Joseph, S.: Agronomic values of green waste biochar as a soil amendment. Soil Res. 45, 629–634 (2008)

Zhao, X., Ouyang, W., Hao, F.H., Lin, C.Y., Wang, F.L., Sheng, H., Geng, X.J.: Properties comparison of biochars from corn straw with different pretreatment and sorption behaviour of atrazine. Bioresour. Technol. 147, 338–344 (2013)

Amonette, J.E., Joseph, S.: Characteristics of biochar, microchemical properties. In: Lehmann, J., Joseph, S. (eds.) Biochar for Environmental Management: Science and Technology, pp. 33–52. Earthscan, London (2009)

Novak, J.M., Lima, I., Xing, B.S., Gaskin, J.W., Steiner, C., Das, K.C., Ahmedna, M., Rehrah, D., Watts, D.W., Busscher, W.J., Schomberg, H.: Characterization of designer biochar produced at different temperatures and their effects on a loamy sand. Ann. Environ. Sci. 3, 195–206 (2009)

Cao, X.D., Ma, L.N., Gao, B., Harris, W.: Dairy–manure derived biochar effectively sorbs lead and atrazine. Environ. Sci. Technol. 43, 3285–3291 (2009)

Yuan, J.H., Xu, R.K., Zhang, H.: The forms of alkalis in the biochar produced from crop residues at different temperatures. Bioresour. Technol. 102, 3488–3497 (2011)

Kazi, Z.H., Schnitzer, M.I., Monreal, C., Mayer, P.: Separation and identification of heterocyclic nitrogen compounds in bio-oil derived by fast pyrolysis of chicken manure. J. Environ. Sci. Health B 46, 51–61 (2011)

Knudsen, J.N., Jensen, P.A., Lin, W., Frandsen, F.J., Dam-Johnson, K.: Sulfur transformations during thermal conversion of herbacous biomass. Energy Fuels 18, 810–819 (2004)

Chen, B.L., Zhou, D.D., Zhu, L.Z.: Transitional adsorption and partition of nonpolar and polar aromatic contaminants by biochars of pine needles with different pyrolytic temperatures. Environ. Sci. Technol. 42, 5137–5143 (2008)

Keiluweit, M., Nico, P.S., Johnson, M.G., Kleber, M.: Dynamic molecular structure of plant biomass-derived black carbon (biochar). Environ. Sci. Technol. 44, 1247–1253 (2010)

Uchimiya, M., Lima, I.M., Thomas Klasson, K., Chang, S., Wartelle, L.H., Rodgers, J.E.: Immobilization of heavy metal ions (CuII, CdII, NiII, and PbII) by broiler litter–derived biochars in water and soil. J. Agric. Food Chem. 58, 5538–5544 (2010)

Spokas, K.A.: Review of the stability of biochar in soils, predictability of O:C molar ratios. Carbon Manag. 1 289–303 (2010)

Enders, A., Hanley, K., Whitman, T., Joseph, S., Lehmann, J.: Characterization of biochars to evaluate recalcitrance and agronomic performance. Bioresour. Technol. 114, 644–653 (2012)

Fu, P., Yi, W.M., Bai, X.Y., Li, Z.H., Hu, S., Xiang, J.: Effect of temperature on gas composition and char structural features of pyrolyzed agricultural residues. Bioresour. Technol. 102, 8211–8219 (2011)

Conti, R., Rombolà, A.G., Modelli, A., Torri, C., Fabbri, D.: Evaluation of the thermal and environmental stability of switchgrass biochars by Py-GC-MS. J. Anal. Appl. Pyrol. 110, 239–247 (2014)

Klasson, K.T.: Biochar characterization and a method for estimating biochar quality from proximate analysis results. Biomass Bioenerg 96, 50–58 (2017)

Uras, ü, Carrier, M., Hardie, A.G., Knoetze, J.H.: Physico-chemical characterization of biochars from vacuum pyrolysis of South African agricultural wastes for application as soil amendments. J. Anal. Appl. Pyrol. 98, 207–213 (2012)

Al-Wabel, M.I., Al-Omran, A., El-Naggar, A.H., Nadeem, M., Usman, A.R.A.: Pyrolysis temperature induced changes in characteristics and chemical composition of biochar produced from conocarpus wastes. Bioresour. Technol. 131, 374–379 (2013)

EPA.: Protection of Environment. Standards for the use or disposal of sewage sludge. Code of Federal Regulations. Title 40, Pt. 503. US Environmental Protection Agency, Washington, DC. (2005)

Chen, T., Yan, B.: Fixation and partitioning of heavy metals in slag after incineration of sewage sludge. Waste Manage. 32, 957–964 (2012)

Lievens, C., Yperman, J., Vangronsveld, J., Carleer, R.: Study of the potential valorisation of heavy metal contaminated biomass via phytoremediation by fast pyrolysis, Part I. Influence of temperature, biomass species and solid heat carrier on the behaviour of heavy metals. Fuel 87, 1894–1905 (2008)

Asthana, A., Falcoz, Q., Sessiecq, P., Patisson, F.: Modeling kinetics of Cd, Pb, and Zn vaporization during municipal solid waste bed incineration. Ind. Eng. Chem. Res. 49, 7605–7609 (2010)

Shaaban, A., Sian-Meng, S., Nona Merry, M., Mitan, M.F.D.: Characterization of biochar derived from rubber wood sawdust through slow pyrolysis on surface porosities and functional groups. Proc. Eng. 68, 365–371 (2013)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 21507042), and the Guangdong Provincial Natural Science Foundation (Nos. 2016A030307010 and 2018A030307014).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, K., Peng, N., Lu, G. et al. Effects of Pyrolysis Temperature and Holding Time on Physicochemical Properties of Swine-Manure-Derived Biochar. Waste Biomass Valor 11, 613–624 (2020). https://doi.org/10.1007/s12649-018-0435-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-018-0435-2