Abstract

This study concerns the production of hydrogen and methane from a Food Residue Biomass (FORBI) product (Papanikola et al. in 5th international conference on sustainable waste management systems, Athens, 2017), generated from pre-sorted HFW in a CSTR and in a PABR respectively. FORBI is generated by drying and shredding the fermentable fraction of household food waste collected door-to-door in the Municipality of Halandri, Greece. Hydrogen production from FORBI through anaerobic fermentation under acidogenic mesophilic conditions was carried out using a 4 L CSTR, operated at 12 h HRT under an organic loading of 15 g TS L−1. The H2-CSTR was operated for 40 days. During the operation of H2-CSTR the production of biogas reached up to 0.1026 Lbiogas gFORBI−1 and the percentage of hydrogen in the gas up to 48.2%. The conversion of FORBI into methane was carried out through the operation of a 77 L PABR operated under mesophilic methanogenic conditions at various operating parameters (OLR, HRT, T). Two different approaches were adopted for the pre-treatment of the feedstock. For the two first phases of the experimental procedure, a liquid extraction step was carried out before feeding the bioreactor with the separated liquid fraction, while in the subsequent three phases, a whole suspension of FORBI was used as feed. The mean biogas production rate was 0.158 ± 0.02 Lbiogas gFORBI−1 and the mean methane percentage in the biogas was 67.5 ± 2.1%, in the first two phases. The mean biogas production rate was 0.519 ± 0.03 Lbiogas gFORBI−1 and the mean methane percentage in the biogas was 66 ± 2.8%, when a whole suspension of FORBI was fed to the PABR.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

The present work, pursued under the framework of the Horizon2020 project WASTE4think, focuses on investigating the anaerobic digestion and dark fermentation potential of a biomass product (named FORBI: Food Residue Biomass) for the production of biofuels (biomethane and biohydrogen respectively). The FORBI production process includes drying and shredding of household fermentable waste (HFW) and it is a promising idea since it significantly reduces the mass and volume of the HFW, it can be stored for prolonged periods of time without deteriorating, odors are eliminated and the product is homogenized.

Introduction

The generation and disposal of MSW is dramatically increasing in the recent years due to the rapid population growth (over 9 billion by 2050) [2] and modernization throughout the world. According to a recent report, published by the World Bank, currently more than 1.3 billion tons of municipal solid waste are generated annually worldwide, while waste generation is expected to exceed 2.2 billion tons in the next decade [3]. Breaking down the solid waste generation data, it has been proved that 30–50% of the MSW is food waste, out of which 95% is ultimately landfilled. These quantities of landfilled food waste reflect a great wastage of nutrient content and energy recovery potential, while at the same time landfilled food waste is a major contributor to landfill methane and other GHG emissions. Moreover, the Urban Development Series of World Bank suggests that “poorly managed waste has an enormous impact on health, local and global environment and the economy. In addition, improperly managed waste usually results in down-stream costs higher than what it would have cost to manage the waste properly in the first place” [3]. Hence, policies have been developed recently, aiming at minimizing the amounts of fermentable waste ending up in landfills.

In Europe alone, 88 million tons of food is wasted, with an overall cost estimated at 143 billion Euros according to the literature [4,5,6,7]. Scientific and technological developments offer a variety of valorization options and technologies for the production of valuable chemicals, products and biofuels [8,9,10]. The exploitation of these -or some of these-options could drastically minimize the amount of food waste ending up in the landfills.

The current research work, pursued within the framework of WASTE4think, a Horizon2020 project, is based on work previously done extensively studying anaerobic digestion and fermentation of food waste [8,9,10,11,12,13,14,15]. More specifically, this paper focuses on the effectiveness and benefits of using pretreated food waste (dried and shredded) as a feedstock for methane (CH4) production via anaerobic digestion and hydrogen (H2) production via dark fermentation.

WASTE4think proposes an innovative management approach of the HFW that includes source separation and separate collection of this fraction in the Municipality of Halandri, followed by drying and shredding of the collected waste at the Municipality level. The scope of the project is to evaluate the generated product, named FORBI (Food Residue Biomass) as a potential feedstock for the production of biofuels, among various valorization alternatives. FORBI is a high quality homogenized and dry biomass product weighing approximately 25% of the original food waste collected [1], which may be stored for prolonged periods of time without deterioration.

The idea of implementing a pre-treatment step to improve the characteristics of the organic waste before using it as an anaerobic digestion feedstock to enhance methane production is not new. There are a lot of research papers covering the specific subject both for organic waste generally and food waste more specifically for methane [16,17,18] and hydrogen [19] production. Moreover, the combination of thermal and mechanical pre-treatment has been evaluated in the past [18], however not systematically and not in a homogenized food waste product like FORBI.

The scope of the current research paper is to investigate the effect of drying/shredding pre-treatment and pursue an initial evaluation of FORBI as feedstock for the production of biomethane and biohydrogen, respectively.

Methane production was carried out using a Periodic Anaerobic Baffled Reactor, a novel high-rate bioreactor designed to operate at high organic loading rates. The PABR resembles a simple ABR with the compartments configured circularly. Variation of the switching frequency (or equivalently the switching period (T), i.e. the time for switching the feed to all compartments) allows flexibility in the operation of the PABR. The PABR can be operated as a simple ABR, if the switching frequency is set to zero, and, at relatively high switching frequency, as a single-compartment upflow bioreactor [20,21,22,23].

Materials and Methods

The measurements of tCOD and sCOD, TSS and VSS, total alkalinity and temperature were carried out according to Standard Methods [24]. The pH and conductivity were measured using a digital pH-meter (WTW INOLAB PH720) and conductivity meter (WTW INOLAB), respectively. For the quantification of VFAs, 1 mL of sample acidified with 30 μL of 20% H2SO4 was analyzed on a gas chromatograph (SHIMADZU GC-2010 plus) equipped with a flame ionization detector and a capillary column (Agilent technologies, 30 m × 0.53 mm ID × 1 μm film, HP-FFAP) and an autosampler (SHIMADZU AOC-20s). The oven was programmed from 105 to 160 °C at a rate of 15 °C min−1 and subsequently to 225 °C (held for 3 min) at a rate of 20 °C min−1. Helium was used as the carrier gas at 30 mL min−1, the injector temperature was set at 230 °C and the detector at 230 °C. For the quantification of the methane content of the biogas, a GC-TCD was used (Shimadzy GC-2014). The separation column’s (Carboxen 1000) length was 5 m and the interior diameter 2.1 mm. The initial temperature of the GC-TCD was 40 °C. For the estimation of the methane content a temperature programme was used (duration: 25 min) during which the temperature was increasing 10 °C min−1 until reaching 185 °C and staying stable at this temperature for 5 min. The methane content then was calculated using a standard calibration curve. The biogas production rate was measured using an oil displacement technique [20, 21].

FORBI Generation and Characteristics

FORBI is a biomass product generated by an alternative food waste management scheme. A GAIA GC-200 Food Waste Drying Machine developed by GAIA Corp. is fed with the raw food waste collected daily and after a 9-h drying/shredding process FORBI is collected from the dryer tank.

The proposed HFW management scheme offers a variety of benefits, since FORBI exhibits numerous advantages:

-

1.

The volume and weight of the processed solid feedstock is reduced by as high as 75–80% compared to the initial raw food waste.

-

2.

A homogenized product is generated, with highly repeatable physicochemical characteristics (they don’t vary appreciably)

-

3.

No odors are emitted.

-

4.

FORBI may be stored for prolonged periods without deteriorating.

A series of analyses had been conducted, in a previous study, to develop an in-depth characterization of FORBI [1]. The results show,that FORBI exhibits high homogeneity. Moreover, the bulk density of FORBI was found to be as high as 690 kg m−3. The basic results of the characterization of FORBI are shown in Table 1.

Moreover, an elemental analysis as well as an experimental determination of the NCV and GCV of FORBI are given in Table 2.

Hydrogen Production Experimental Procedure

In order to investigate the use of FORBI as feedstock for the production of biohydrogen through dark fermentation, a pilot-scale CSTR was used. The CSTR had a working volume of 4 L and was operated under anaerobic and mesophilic conditions (35 °C). For the operation of the pilot-scale bioreactor, FORBI with particles < 5 mm was used (FORBI 5 mm).

Gas and liquid samples were taken routinely and analyzed for hydrogen and methane content using the same method as explained before. Total Suspended Solids (TSS), Volatile Suspended Solids (VSS), and Volatile Fatty Acids (VFAs) were also estimated on a regular basis. The production of biogas was also measured.

During start-up, the CSTR was inoculated with 1 L of thermally treated (95 °C for 15 min) activated sludge and was fed with an aquatic suspension of FORBI (15 g FORBI L−1). The bioreactor was started up in batch mode for 48 h (data not shown). It was then operated in a continuous mode under an HRT (hydraulic retention time) of 12 h using the same aquatic suspension of FORBI. The CSTR operated without pH regulation.

Methane Production Experimental Procedure

The scope of the experimental procedure was to evaluate FORBI as an anaerobic digestion feedstock for methane production using a pilot-scale PABR, of operating volume of 77 L. Therefore, the bioreactor was operated at various OLR and HRT outlined in Table 1. The PABR was equipped with sampling valves in every compartment, placed in the middle-height of the compartment. The PABR consists of two concentric cylinders, the interior of which is filled with water maintained at 35 °C through temperature control.

The PABR was initially operated with a HRT of 12.2 days and a T of 2 days, with an influent tCOD of 7250 mg L−1 for 86 days (phase #1). After a steady periodic state was reached, the HRT was decreased to 10 days and the mean influent tCOD was increased to 11,690 mg L−1 for an operation period of 43 days (phase #2). A liquid extraction step was used as pretreatment during phases #1 and #2, feeding the bioreactor only with FORBI extract so as to keep the solids content of the feed low, a general requirement for high-rate bioreactors. Initially, FORBI was suspended in water, in a proportion of 18 gFORBI L−1water and was vigorously stirred for 30 min. Then the slurry was filtered under pressure using a cloth filter. The liquid phase (filtrate) retained 36.4% of the organic content of the waste during phase #1 and 29.3% during phase #2. The solid phase collected was valorized for the production of compost.

After a steady periodic state was reached, the HRT was decreased to 8.7 days and the PABR was fed with a mean influent tCOD of 10,760 mg L−1 (phase #3). During phase #3, a whole suspension of FORBI was used instead of the liquid fraction, in order to see if FORBI hydrolysis is fast enough to sustain a high-rate anaerobic digestion without solids separation. As the PABR proved to handle satisfactorily a whole FORBI suspension as a feed, for the next experimental phase (phase #4) the HRT was decreased to 5 days without changing the influent tCOD (tCOD = 10,830 mg L−1). In phase #5, the HRT was maintained at 5 days, while the tCOD in the feed was approximately doubled (22,630 mg L−1). The fifth phase (phase #5) was split into two sub-phases, investigating the response of the PABR when alternating the switching frequency (T). More specifically, during phase #5.1 a sharp increase of the tCOD was implemented leading to an influent tCOD of 22,630 mg L−1, while the HRT was not changed. Then, after 18 days of operation the switching period was decreased from 2 to 1 days without changing any other parameters (phase #5.2). (Table 3)

Results and Discussion

Hydrogen Production

The CSTR was operated for 30 days. During the operation the production of biogas reached up to 0.1026 Lbiogas gFORBI−1 and the maximum percentage of hydrogen was 48.2%.

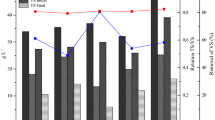

During the operation of the bioreactor, the biogas production rate was not constant Fig. 1b, despite the fact that the pH of the bioreactor remained 4.2–4.6 throughout the experiment Fig. 1a. During the first 7 days, the production rate of biogas increased from 0.65 to 3.07 L Lbioreactor−1 d−1. Afterwards, it decreased significantly and was 1.37 L Lbioreactor−1 d−1 on the average for the rest of the period. The concentrations of the main metabolic products measured during the operation of the hydrogen producing reactor are presented in Fig. 2. The dominant metabolic products, measured, were acetic and butyric acids, which are common for biohydrogen producing bioreactors [25]. The low concentrations of propionic acid indicate an efficient hydrogen production process, since during the formation of propionate hydrogen is consumed [14, 26].

The decrease of the biogas production rate after the seventh day of operation could be attributed to the consumption of hydrogen by hydrogen consuming microorganisms which consume H2 and CO2 to produce acetate [25]. In order to eliminate these hydrogen consuming microorganisms, the bioreactor was purged with air for 1 h using an air pump (arrows in Fig. 1a, b). After each purging, the biogas production rate increased significantly but not to the level observed in the beginning of the operation.

A concise literature review was carried out to compare the obtained hydrogen production with others based on food waste (Table 4).

Methane Production

The PABR exhibited great stability during all five phases of the process. During the stable periodic state of phase #1, the mean tCOD removal rate was 89% (Fig. 3b) with a mean effluent tCOD concentration of 872 mg L−1. The VSS remained below 0.5 g L−1 (Fig. 3a) in all four compartments of the PABR during the whole phase #1. The mean biogas production rate was 0.158 Lbiogas gFORBI−1 and the mean methane composition of the biogas was 65–70%.

During phase #2, the OLR almost doubled from 0.59 to 1.17 gCOD Lbioreactor−1 d−1, by decreasing the HRT from 12.2 to 10 days and by increasing the mean influent tCOD from 7320 to 11,690 mg L−1. The mean tCOD removal rate was 93.5% (Fig. 3b) and the mean biogas production rate was 0.11 Lbiogas gFORBI−1. The pH remained at optimum levels for methane production in all four compartments of the reactor during phases #1 and #2. The mean methane composition of the biogas was 65–70% (Fig. 4).

Subsequently, the reactor was fed with a whole suspension of FORBI and operated at an HRT of 8.7 days (phase #3). The feed TSS concentration was 10 g L−1. The PABR responded efficiently to the change, while no problems were observed by the high solids content, that is contained in FORBI’s suspension (approximately 15 g L−1). The mean tCOD removal rate was 86.4%. Feeding with a whole suspension of FORBI, with all its solids content, resulted in a substantial increase of the mean biogas production rate to 0.56 Lbiogas gFORBI−1. The mean methane composition of the biogas remained in the range 65–70%.

In the next experimental phase (phase #4) the HRT was further decreased to 5 days, while the average tCOD of the influent remained the same, leading to an organic loading rate of 2.14 gCOD Lbioreactor−1 d−1. The PABR handled very well the decrease of the HRT. The average tCOD removal rate observed was 80.5% while the biogas productivity was 0.5 Lbiogas gFORBI−1, once a stable periodic operation was established. The average methane composition of the biogas was 69.6%.

Finally, in the fifth phase of the experimental procedure (phase #5), the average feed tCOD was increased to 22,630 mg L−1 leading to an organic loading rate of 4.53 gCOD Lbioreactor−1 d−1. Again, the bioreactor’s stability was very good, achieving an average tCOD removal of 85.6%, while slightly increasing the biogas productivity to 0.531 Lbiogas gFORBI−1. The methane content was stable, giving an average value of 62.7%. In this phase, the VSS (Fig. 3a) and the VFAs (Fig. 5) of the bioreactor were slightly increased showing kinetic limitation at this loading rate. Hence, the switching period was decreased from 2 to 1 days to investigate the system’s response to this change to the operational parameters. The result of this change was that both the VSS and the VFAs showed a slight decrease, without, however, reaching the very low levels of the previous phases.

Table 5 presents the aggregated results of the five experimental phases of the methane production are presented.

A literature review on the anaerobic digestion of food waste, shown that drying and shredding food waste as a pretreatment method is really promising (Table 6).

Conclusion

The present work concerns the production of Hydrogen and Methane from a Food Residue Biomass (FORBI) product, generated from pre-sorted fermentable household waste in a CSTR and in a Periodic Anaerobic Baffled Reactor (PABR) respectively. FORBI is generated by drying and shredding the fermentable fraction of household food waste collected door-to-door in the Municipality of Halandri.

Operating at an HRT of 12 h, the maximum production of hydrogen from FORBI was 0.1026 Lbiogas gFORBI−1 with a hydrogen concentration of 48.2%. Homoacetogenesis seems to have reduced the amount of hydrogen produced. Short aeration of the reactor has allowed temporary increase in the biogas production rate, but it is clear that further work is necessary to secure a stable and optimal hydrogen production.

The PABR proved an excellent high rate reactor for methane production from FORBI. The reactor was capable of handling successfully a suspension of FORBI, without the need for solids removal, yielding on the average 0.519 Lbiogas gFORBI−1 and 66% methane content. Some kinetic limitation has appeared at an organic loading of 4.53 gCOD Lbioreactor−1 d−1.

Compared to other published works, drying and shredding food waste has proved to be a promising method in terms of maximizing biogas productivity and especially when it comes to biomethane production, through anaerobic digestion. Hence, FORBI apart from its benefits regarding mass and volume reduction, homogeneity and stability, is an excellent feedstock for either a dark fermentation or an anaerobic digestion process.

Abbreviations

- ABR:

-

Anaerobic baffled reactor

- CSTR:

-

Continuous stirred tank reactor

- FORBI:

-

Food residue biomass

- GCV:

-

Gross calorific value

- GHG:

-

Green house gases

- HFW:

-

Household fermentable waste

- HRT:

-

Hydraulic retention time

- MSW:

-

Municipal solid waste

- NCV:

-

Net calorific value

- OLR:

-

Organic loading rate

- PABR:

-

Periodic anaerobic baffled reactor

- sCOD:

-

Soluble chemical oxygen demand

- T:

-

Switching period

- tCOD:

-

Total chemical oxygen demand

- TSS:

-

Total suspended solids

- VFAs:

-

Volatile fatty acids

- VSS:

-

Volatile suspended solids

References

Papanikola, K., Papadopoulou, K., Tsiligiannis, C., Fotinopoulou, I., Katsiampoulas, A., Chalarakis, E., Georgiopoulou, M., Rontogianni, V., Michalopoulos, I., Lyberatos, G.: Food residue biomass product as an alternative energy source for the cement industry. In: 5th International Conference on Sustainable Waste Management Systems, pp. 1–6. Athens (2017)

FAO: How to Feed the World in 2050. Insights from an Expert Meet, vol. 2050, pp. 1–35. FAO, Rome (2009). https://doi.org/10.1111/j.1728-4457.2009.00312.x

Hoornweg, D., Bhada-Tata, P.: What a waste: a global review of solid waste management. Urban Dev. Ser. Knowl. Pap. no.15, World Bank. 116 (2012). https://doi.org/10.1111/febs.13058

FUSIONS: Estimates of European food waste levels. FUSIONS, Stockholm (2016)

Charles, J.G.H., Beddington, J.R., Crute, I.R., Haddad, L., Lawrence, D., Muir, J.F., Pretty, J., Robinson, S., Thomas, S.M., Toulmin, C.: Food security: the challenge of feeding 9 billion people. Science 327, 812–819 (2010).

Food and Agriculture Organization (FAO): Food Wastage Footprint: Impacts on Natural Resources. FAO, Paris (2013)

Ellen MacArthur Foundation: Urban Biocycles (2017)

Luque, R., Clark, J.H.: Valorisation of food residues: waste to wealth using green chemical technologies. Sustain. Chem. Process. 1, 10 (2013). https://doi.org/10.1186/2043-7129-1-10

Zhang, R., El-Mashad, H.M., Hartman, K., Wang, F., Liu, G., Choate, C., Gamble, P.: Characterization of food waste as feedstock for anaerobic digestion. Bioresour. Technol. 98, 929–935 (2007). https://doi.org/10.1016/j.biortech.2006.02.039

Lin, C.S.K., Pfaltzgraff, L.A., Herrero-Davila, L., Mubofu, E.B., Abderrahim, S., Clark, J.H., Koutinas, A.A., Kopsahelis, N., Stamatelatou, K., Dickson, F., Thankappan, S., Mohamed, Z., Brocklesby, R., Luque, R.: Food waste as a valuable resource for the production of chemicals, materials and fuels. Current situation and global perspective. Energy Environ. Sci. 6, 426 (2013). https://doi.org/10.1039/c2ee23440h

Zhang, Z., O’Hara, I.M., Mundree, S., Gao, B., Ball, A.S., Zhu, N., Bai, Z., Jin, B.: Biofuels from food processing wastes. Curr. Opin. Biotechnol. 38, 97–105 (2016). https://doi.org/10.1016/j.copbio.2016.01.010

Pan, J., Zhang, R., El-Mashad, H.M., Sun, H., Ying, Y.: Effect of food to microorganism ratio on biohydrogen production from food waste via anaerobic fermentation. Int. J. Hydrogen Energy. 33, 6968–6975 (2008). https://doi.org/10.1016/j.ijhydene.2008.07.130

Ismail, F., Abd-Aziz, S., MeiLing, C., Hassan, M.A.: Statistical optimization of biohydrogen production using food waste under thermophilic conditions. Open Renew. Energy J. 2, 124–131 (2009)

Li, M., Zhao, Y., Guo, Q., Qian, X., Niu, D.: Bio-hydrogen production from food waste and sewage sludge in the presence of aged refuse excavated from refuse landfill. Renew. Energy. 33, 2573–2579 (2008). https://doi.org/10.1016/j.renene.2008.02.018

Zhang, C., Su, H., Baeyens, J., Tan, T.: Reviewing the anaerobic digestion of food waste for biogas production. Renew. Sustain. Energy Rev. 38, 383–392 (2014). https://doi.org/10.1016/j.rser.2014.05.038

Kondusamy, D., Kalamdhad, A.S.: Pre-treatment and anaerobic digestion of food waste for high rate methane production: a review. J. Environ. Chem. Eng. 2, 1821–1830 (2014). https://doi.org/10.1016/j.jece.2014.07.024

Mata-Alvarez, J., Macé, S., Llabrés, P.: Anaerobic digestion of organic solid wastes. An overview of research achievements and perspectives. Bioresour. Technol. 74, 3–16 (2000). https://doi.org/10.1016/S0960-8524(00)00023-7

Ariunbaatar, J., Panico, A., Esposito, G., Pirozzi, F., Lens, P.N.L.: Pretreatment methods to enhance anaerobic digestion of organic solid waste. Appl. Energy. 123, 143–156 (2014). https://doi.org/10.1016/j.apenergy.2014.02.035

Elbeshbishy, E., Hafez, H., Dhar, B.R., Nakhla, G.: Single and combined effect of various pretreatment methods for biohydrogen production from food waste. Int. J. Hydrogen Energy. 36, 11379–11387 (2011). https://doi.org/10.1016/j.ijhydene.2011.02.067

Skiadas, I.V., Gavala, H.N., Lyberatos, G.: Modelling of the periodic anaerobic baffled reactor (PABR) based on the retaining factor concept. Water Res. 34, 3725–3736 (2000). https://doi.org/10.1016/S0043-1354(00)00137-8

Skiadas, I.V., Lyberatos, G.: The periodic anaerobic baffled reactor. Water Sci. Technol. 38, 401–408 (1998)

Michalopoulos, I., Chatzikonstantinou, D., Mathioudakis, D., Vaiopoulos, I., Tremouli, A., Georgiopoulou, M., Papadopoulou, K., Lyberatos, G.: Valorization of the liquid fraction of a mixture of livestock waste and cheese whey for biogas production through high-rate anaerobic co-digestion and for electricity production in a microbial fuel cell (MFC). Waste Biomass Valoriz. (2017). https://doi.org/10.1007/s12649-017-9974-1

Michalopoulos, I., Mathioudakis, D., Premetis, I., Michalakidi, S., Papadopoulou, K., Lyberatos, G.: Anaerobic co-digestion in a pilot-scale periodic anaerobic baffled reactor (PABR) and composting of animal by-products and whey. Waste Biomass Valoriz. (2017). https://doi.org/10.1007/s12649-017-0155-z

WEF: Standard Methods for the Examination of Water and Wastewater. American Public Health Association, Washington, DC (1995)

Alexandropoulou, M., Antonopoulou, G., Lyberatos, G.: Food industry waste’s exploitation via anaerobic digestion and fermentative hydrogen productions in an up-flow column reactor. Waste Biomass Valoris 7, 711–723 (2016)

Sivagurunathan, P., Sen, B., Lin, C.-Y.: High-rate fermentative hydrogen production from beverage wastewater. Appl. Energy 147, 1–9 (2015)

Nathao, C., Sirisukpoka, U., Pisutpaisal, N.: Production of hydrogen and methane by one and two stage fermentation of food waste. Int. J. Hydrogen Energy. 38, 15764–15769 (2013). https://doi.org/10.1016/j.ijhydene.2013.05.047

Reungsang, A., Sreela-Or, C., Plangklang, P.: Non-sterile bio-hydrogen fermentation from food waste in a continuous stirred tank reactor (CSTR): performance and population analysis. Int. J. Hydrogen Energy. 38, 15630–15637 (2013). https://doi.org/10.1016/j.ijhydene.2013.03.138

Pisutpaisal, N., Nathao, C., Sirisukpoka, U.: Biological hydrogen and methane production in from food waste in two-stage CSTR. Energy Procedia. 50, 719–722 (2014). https://doi.org/10.1016/j.egypro.2014.06.088

Cavinato, C., Giuliano, A., Bolzonella, D., Pavan, P., Cecchi, F.: Bio-hythane production from food waste by dark fermentation coupled with anaerobic digestion process: a long-term pilot scale experience. Int. J. Hydrogen Energy. 37, 11549–11555 (2012). https://doi.org/10.1016/j.ijhydene.2012.03.065

Banks, C.J., Chesshire, M., Heaven, S., Arnold, R.: Bioresource technology anaerobic digestion of source-segregated domestic food waste: performance assessment by mass and energy balance. Bioresour. Technol. 102, 612–620 (2011). https://doi.org/10.1016/j.biortech.2010.08.005

Zhang, L., Jahng, D.: Long-term anaerobic digestion of food waste stabilized by trace elements. Waste Manag. 32, 1509–1515 (2012). https://doi.org/10.1016/j.wasman.2012.03.015

Yong, Z., Dong, Y., Zhang, X., Tan, T.: Anaerobic co-digestion of food waste and straw for biogas production. Renew. Energy. 78, 527–530 (2015). https://doi.org/10.1016/j.renene.2015.01.033

Acknowledgements

This work is produced under research project Horizon 2020, Grant Agreement No 688995. «Moving towards Life Cycle Thinking by integrating Advanced Waste Management Systems-[WASTE4THINK].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Michalopoulos, I., Lytras, G.M., Mathioudakis, D. et al. Hydrogen and Methane Production from Food Residue Biomass Product (FORBI). Waste Biomass Valor 11, 1647–1655 (2020). https://doi.org/10.1007/s12649-018-00550-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-018-00550-4