Abstract

Production of biofuels from farm animal waste represents a promising approach to diversifying green energy production and reducing competition for cultivable lands between fuel and food-oriented crops. This work was aimed to define the technical feasibility and the specific suitability of cattle, swine and poultry manure to integrating bioethanol and biomethane production, using the biorefinery concept. Saccharification obtained by dilute acid pretreatment (3.5% H2SO4, 121 °C, 30 min) followed by enzymatic hydrolysis resulted in total sugar recovery of 230.16, 160.40, and 98.40 mg g−1 (of dry matter) for cattle, pig, and poultry manure respectively. The sugar was then fermented using free yeast co-cultures. The ethanol obtained was 56.32 mg g−1 of dry matter for cattle (about 52.59% of the theoretical ethanol yield); 27.98 mg g−1 for swine (about 88.66% of the theoretical ethanol yield); 12.69 mg g−1 for poultry (about 31.32% of the theoretical ethanol yield). Methane production from distillation waste was 72.95 mg g−1 from dry raw faeces for cattle, 126.48 mg g−1 for swine and 119.03 mg g−1 for poultry. Cattle manure showed the best energy balance in terms of ethanol production with about 824.16 kJ kg−1 of dry faeces, but the two integrated processes generated a net energy balance of 1.28 MJ kg−1 for cattle, 4.57 MJ kg−1 for swine and 4.79 MJ kg−1 for poultry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The production of bioethanol and biomethane from lignocellulosic waste materials represents a promising alternative technology for replacing fossil fuels with biofuels [1], overcoming existing concerns over competition for cultivable lands between energetic and food-oriented crops [2]. Animal husbandry is one of the main agro-economic sectors in Europe, with about 6 million cattle, 9.3 million swine and 24,000 poultry farms in Italy alone. Production of slurry/manure is about 50 L head−1 day−1 for cattle (on the basis of 600 kg per head), 4.7 m3 head−1 year−1 for a 90 kg pig and from 18.5 to 39.5 t live weight−1 year−1 for poultry, depending on the bird species. Animal waste, widely used today for biogas generation, can therefore also become an input biomass for bioethanol production due to its good fibre content [3]. The energy potential of manure would be enhanced by the combining the ethanol approach with the biogas chain. Integration of the two processes permits better exploitation of organic compounds.

Of the different types of manure, cattle manure is the most suitable for energy exploitation because the diet of these animals has a high fibre content and a low protein content [3, 4]. Considering the chemical process (acid and high temperature treatment) the nitrogen content must be taken into account, because it causes the Millard side reaction [3]. In livestock, farming different straw or wood chips can be used as litter for animals, which can also increase the amount of fibre. Some studies have demonstrated that manure digestate is a good candidate for alcoholic fermentation [5, 6]. Nevertheless, digestate is penalised by sugar loss (particularly C5) due to anaerobic digestion and its use in bioethanol production could be hindered due to low exploitation of all the sugars (C6 and C5) produced [5]. Many studies have focused on the use of manure as a renewable energy source for biogas production, but very few deal with bioethanol production [7, 8]. Other studies have concerned the saccharification of cellulose and hemicellulose in manure [3, 4, 9]. The lignocellulosic materials present in manure are only partially altered by the gut microbiota of the animal and are thus potentially excellent candidates for the production of 2nd generation ethanol [10]. Methods to obtain fermentable sugar from lignocellulosics have been studied since the 1970s. The main solutions for converting lignocellulosic material into sugars are dilute acid pretreatment followed by enzymatic hydrolysis [11, 12]. Liao et al. (2004) [13] demonstrated that dilute acid treatment combined with high temperature (120 °C and 2% sulphuric acid) was able to remove manure hemicellulose and lignin and partially break down the crystal structure of cellulose, thus allowing the cellulose to be more easily attacked by enzymes [10, 13]. Liao et al. [14] demonstrated that the removal of hemicellulose facilitates the adsorption of the functional enzyme as compared to the removal of lignin alone. Lignin, which is chemically very complex, limits the rate of enzymatic hydrolysis by acting as a physical barrier and has a great impact on this step, but it is one of the main components in certain lignocellulosic materials [7, 15]. Hemicelluloses are polymers of pentoses (xylose, arabinose) and hexoses (mannose, glucose and galactose); the composition depends on the xylan plant source [16]. Hemicellulases could replace the use of chemicals and avoid related issues (inhibiting compound formation, costs and environmental management), but can also act as a ”helper” enzyme, due to a cleaning effect which facilitates access to cellulose [17, 18].

Glucose and xylose are the two dominant sugars in lignocellulosic hydrolysates. The utilisation of co-cultures of naturally occurring microorganisms for ethanol production appears to have advantages, since there is the potential for synergistic action between metabolic pathways from diverse microorganisms [19, 20]. We preferred the co-culture with Saccharomyces cerevisiae and Pichia stipitis because their optimal operating ranges for process parameters are similar (30 °C, pH 4.5–5.0). S. cerevisiae has a high ethanol tolerance and high yield, but is unable to ferment xylose [21]. P. stipitis exhibits great potential for industrial applications, because this species has a high ethanol yield and no requirement for added vitamins during fermentation [22]. Rapid and efficient fermentation of hydrolysates is limited, because in addition to monomeric sugars a range of toxic compounds are generated during the pretreatment and hydrolysis of lignocellulosics: weak acid, furan derivatives and phenolic compounds [23]. S. cerevisiae has been considered to be the best yeast for lignocellulosic hydrolysate fermentation, due to its ethanol producing capacity and high inhibitor tolerance [24], but Delgenes et al. (1996) [25] showed that S. cerevisiae is significantly inhibited mainly by the presence of furfural and hydroxymethyl furfuraldehyde. At the same time, P. stipitis and Candida shehatae are also inhibited by acetic acid and furan derivatives, in relation to their concentration [22, 25]. Kluyveromyces marxianus is one of the most promising yeasts in terms of biotechnological applications; some of its strains can ferment xylose and cellobiose, while others have a high yield in terms of hexose fermentation [26].

The study is a part of the ZOOTANOLO project “The production of bioethanol as innovative energy valorisation of manure”. Different animal farms located in two rural regions in northern Italy were considered; alpine dairy cattle farms with an average of 50 animals, one poultry farm rearing intensive breeding broilers and one small organic pig farm.

The use of cattle manure as a carbon source to obtain biofuels is more challenging than the use of other biomass feedstock, and the complex chemical/physical composition of manure requires research into specific solutions to improve the efficiency of its use in energy transformation processes [4]. Efficient saccharification is currently an important limiting step in cost effective biofuel generation from farm slurry waste [27]. The lack of industrially robust microbial consortia for co-fermentation of glucose and xylose in the “manure environment” is also a technical barrier [19].

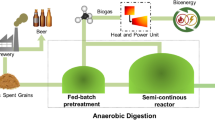

To verify the technical feasibility of integration processes, we worked using a biorefinery concept. Previous approaches have considered only cattle or poultry manure [5,6,7,8]. This work considers all the main kinds of farm animals (cattle, pigs and poultry) in order to compare their suitability for integrated energy processes.

Thus, the specific aims of this work were: (a) to verify the technical feasibility of bioethanol production from cattle, swine and poultry manure; (b) to integrate the bioethanol process with anaerobic digestion of distillation waste (DW) and (c) to define the behaviour of each kind of animal manure in integrated processes by comparing mass and energy balances.

Materials and Methods

Sampling and Analysis Methods

Manure samples included dairy manure with straw as litter (dairyM), dairy slurry (dairyS), solid fraction of dairy slurry (SFdairyS), beef slurry (beefS), pig manure (pigM) and poultry manure with straw as litter (poultryM). The samples are described as “slurry” or “manure” based on their dry matter content, which depends both on the specific kind of animal husbandry and the different collection and storage systems adopted. The average DM values of slurry ranged from 5 to 10%, whilst the average DM values of manure ranged from 10 to 20%.

The cattle samples came from alpine mountain farms. The daily diet of the cows consisted of forage (grassland hay and alfalfa hay) and concentrated feed (soybeans, beet pulp, maize, barley and sugarcane molasses). Analysis of the cows’ diet highlighted about 15–20% starch content; non-structural carbohydrate (NSC) content was about 37%, the NDF% was about 35–40%, crude protein was about 10%, lipid content was 5–8% and ash was 5% (our internal data for forage analysis in alpine farms). The straw used as litter was about 1 kg day−1 for dairy cow manure. The daily diet of beef consisted mainly in concentrated feed and had a more content of digestible fibre and a lower content of NDF (about 19–22%).

The swine diet was either liquid (mash) or dry (grain or flour) and consisted of different mixture of cereals (i.e. maize, barley, oats and sorghum), oilseeds (sunflower and rapeseed), legumes (pea and soybean), forage (grassland hay and alfalfa hay) and animal feed (fishmeal enrichment with specific supplements) [28]. The daily diet depended on the growth stage; in the initial stage it consisted mainly of barley, protein, fibre and oilseed, the second consisted of raw grains and soybean, while the amount of fibre decreased, and in the last stage, concentrated feed prevailed (60–70%), while protein and fibre were limited.

The daily broiler chicken diet depended on the growth stage and was based on easily digestible concentrated feed with a high content of protein (22–23% of protein) and cereals (maize, wheat, barley, oats, and sorghum). In the first growth stage, the animals eat only concentrated feed, from 5 to 10 weeks the animals were fed 23.1% cereals and 76.9% concentrated feed, and in the last growth stage (after 10 weeks) the diet was 50% feed and 50% cereals [29].

After sampling (2 kg/sample), the manure was stored at −20 °C. Characterisation of all the manure samples included: dry matter (DM), volatile solids (VS), cellulose, hemicellulose and lignin, using the Van Soest procedure [30]. The total sugar content was determined with the anthrone method [31]. An enzymatic kit (K-EtOH, Megazyme) was used to detect the ethanol concentration. Ammonium, nitrogen, starch and β-glucan content were quantified. COD, P, pH and alkalinity were determined in DW in order to perform the BMP tests.

Process Testing

The work consisted of two phases: an initial phase studying bioethanol production and a second defining biogas production. We performed different pretreatment, hydrolysis and fermentation tests to determine bioethanol production from each sample. BMP tests were used to evaluate the methane potential of DW.

Pretreatment

The manure was diluted with distilled water up to 30–50 g L−1 of dry matter and then mechanically homogenised.

Hydrolysis

We performed four different treatments on each type of manure: control, acid hydrolysis, enzymatic hydrolysis and combined acid and enzymatic hydrolysis. Manure acid hydrolysis was performed in a 500 mL glass bottle by adding 3.5% (w/w) of 96% sulphuric acid (Sigma Aldrich, D) and incubating at 121 °C for 20 min in a DLVS7/E 50.80 (Delama, Italy) autoclave. After treatment, manure pH was brought to 4.5 with sodium hydroxide (Sigma Aldrich, D). Acid treatment was performed starting from the results of other previous studies to recover all the C5-sugars from xylan [4, 14]. Enzymatic hydrolysis was performed using 1 L of sample in a laboratory-scale bioreactor (BIOSTAT® A plus 2MO, Sartorius Stedim Systems GmbH). The commercial enzymes used were (100 FPU g−1 DM): (i) Amylyve TC (α-amylase) from Aspergillus niger (Lyven); (ii) Cellulyve (1-4-β-endo-d-glucanase, cellobiohydrolase and cellobiase) from Trichoderma reesei (Lyven); (iii) Lyvanol Devisco, a hemicellulase preparation from Trichoderma longibrachiatum (Lyven), and; (iv) Cellulyve (endo-1,4-β-d-glucanase, eso-1,4-β-d-glucanase and β-glucosidase) (Lyven). The process was carried out in two steps: (i) the first with α-amylase for 2 h at 55 °C, the second with cellulase and hemicellulase for 72 h at 50 °C. Tween 80 was added as surfactant to improve enzymatic degradation. Sugar yield and saccharification degree were determined for each treatment.

Fermentation

In the fermentation trials we employed two yeast strains for all the samples studied: S. cerevisiae NRRL Y-12632 and P. stipitis NRRL Y- Y-11545. On the SFdairyS sample we tested more yeasts. P. stipitis, Candida shehatae (NRRL Y-17029) and K. marxianus (NRRL Y-7571) were employed to verify the improvement of fermentation yields obtained with S. cerevisiae and P. stipitis. We chose not to consider genetically modified microorganisms (GMOs). All the yeasts were purchased from the Agricultural Research Service Culture Collection - Washington DC USA and then were cultivated in YPD Broth (Sigma-Aldrich, D) at pH 6.2 and stored at −80 °C until use. As the starter culture, yeasts were grown in 250 mL YPD medium for 48 h at 30 °C. Yeast cultures were enriched by centrifugation (4000 rpm for 15 min); yeast cells were collected in 10 mL of peptone water (1 g L−1 of Mycological Peptone, Oxoid, UK), then added to the sample. Fermentation was performed in a 1 L glass bottle at 30 °C; after 72 h the fermentation was stopped and ethanol and fermentation yield were calculated.

BMP

The biomethane potential test (BMP) was carried out on distillation waste (DW) obtained after the process described above (pretreatment, acid hydrolysis, enzymatic hydrolysis and fermentation). DW was obtained by distilling the material recovered after fermentation. As an inoculum, we used the digestate from an anaerobic digestion plant fuelled with cattle manure. The DW samples were added to the inoculum without any dilution and without the addition of supplemental nutrient. Tests were performed in 1 L bottles and these were then stored at 38 ± 1 °C for 30 days; methane production was quantified by adapting the protocol described by Angelidaki et al. [32].

Data Expression and Statistics

The efficiency of saccharification was expressed as the percentage of sugar released after hydrolysis treatment. The sugar yield was expressed as mg of sugar for each gram of DM of the samples (mg g−1 DM). The ethanol yield was defined as mg g−1 of DM manure. The ratio between the ethanol content and sugar content in each sample expressed the alcoholic fermentation yield. The yields obtained were compared with theoretical ethanol yield (0.51 g g−1) [19, 33]. When not specifically indicated, all data are expressed on DM basis and each test was performed in triplicate.

Data were analysed using ANOVA and multiple pairwise comparison, performed with Tukey’s (HSD) test with a level of significance of α = 0.05, using STATISTICA software, release 9 (Statsoft Inc., Tulsa, OK, USA). The aim of ANOVA was to establish: (a) the contribution of acid pretreatment and enzymatic hydrolysis to the sugar and ethanol yield of manure fibre; (b) the difference in sugar and ethanol yield for each kind of sample considered after different treatments. The aim of data analysis was to compare the yield obtained in order to determine the different suitability of cattle, pig and poultry manure for bioethanol and biomethane production in the integration process.

Mass and Energy Balance

Mass balance was expressed in g of ethanol kg−1 dry raw faeces and g of methane kg−1 dry raw faeces; the energy balance was calculated based on the same approach adopted by MacMellan et al. [6] and was expressed in MJ kg−1 dry raw manure. The bioethanol energy input due to the energy required for ethanol production (kJ g−1) was calculated by Piccolo and Bezzo (2009) [34] and was 15.88 kJ g−1. These Authors estimated the bioethanol energy value for bioethanol production from wet hardwood chips. The energy requirements is due to pre-treatments, distillation, dehydration and evaporation processes. We adapted this value for our test evaluations on different feedstock, also according to McLellan et al. (2013) [6]. The bioethanol energy output was 28 kJ g−1, which is positive due to the high heating value of ethanol. The energy input for anaerobic digestion is due to the heat necessary to maintain mesophilic conditions in the reactor (37 °C) and to the specific heat of wet raw feed, which was assumed to be equal to 4.2 kJ kg−1 K− 1 [5]. Output energy was calculated from the specific heating value of methane (50 kJ g−1).

Results and Discussion

Composition of Raw Material

Table 1 shows the fibre composition of animal manure and slurry. The fibre content was over 40% of DM in all the samples studied (Table 1). The lignocellulose content changes considerably in relation to the rearing technique, diet and kind of animal, ranging from 39.74% in poultry manure to 62.85% in the solid fraction of dairy slurry. The cellulose content was higher in dairyM (29.27% DM, which corresponds to 292.69 mg g−1) and SFdairyS (26.85% DM, which corresponds to 268.47 mg g−1). Two factors contribute to the greater content of lignocellulose in cattle manure than in that of other animals, despite the cattle’s digestive system: the cellulose/hemicellulose content in cattle diet and the use of straw as litter. Cattle manure was the most promising type of manure, due to its high fibre content, considering that total fibre ranged between 43 and 62% of total DM (Table 1). The values from the cattle samples considered were very high when compared to estimates reported in previous works [3, 7]. Feedlot manure and manure from alpine farms (as in our work) is very different, as a result of the diet (alpine farms do not use ensilaged feed), storage/handling of manure, geography, rearing method and as regards the use of straw/sawdust as litter.

The swine samples had a very high DM content (19.6%) due to the use of straw as litter and it was therefore considered as manure. PigM had a lower cellulose content (13.35% DM or 133.47 mg g−1) but a higher content of hemicellulose (24.75% DM or 247.5 mg g−1). Pigs have a higher hemicellulose content than cattle because they are not able to use the sugar from lignocellulose in their digestive tract. Hemicellulose belongs to structural and available polysaccharides and is therefore mainly degraded in the digestive tract of cattle [4]. Pigs and poultry may provide promising sugar and ethanol results because their hemicellulose and cellulose content is not degraded, but cattle samples have higher lignocellulose values.

The lignin content was greater in cattle samples (between 102.10 and 140.46 mg g−1) than in pig and poultry samples. Some of the cellulose and lignin fraction remaining in manure after rumination comes from the unavailable fraction of fibre from forage, which is not degraded in the digestive’s tract by cows.

Low starch (2.5–3.2 g L−1) and β-glucan (1.5–2.1 g L−1) content was only detected in pig samples. The nitrogen content for the different samples ranged between 1.80 and 2.50% DM for cattle, 4.25% DM for pigs and 5.00% DM for poultry. The ammonia content in the different samples ranged between 1971 mg kg−1 for dairyS and 744 mg kg−1 for dairyM, 2379 mg kg−1 for pigM and 5398 mg kg−1 for poultryM. A very high nitrogen content may compromise sugar production by introducing the potential for debilitating secondary reactions such as Browning reactions [13, 35, 36]. Therefore, different nitrogen content in the different kinds of animals considered must be taken into account in the acid and enzymatic hydrolysis of fibre.

Ash content was very high and variable: 17.94% of DM or (dairyM); 19.67% of DM (dairyS); 9.97% of DM (SFdairyS); 12.90% of DM (beefS); 26.5% of DM (poultryM). The ash content arises from dietary mineral supplements and at the same time from the way of collecting manure [5]. The highest values were from poultryM living on the ground, as a result of soil and stones easily trapped in the faeces.

Sugar and Ethanol Yield

Figures 1, 2 and Table 2 summarise the results obtained for all the samples considered. Estimated sugar production was 148.86 mg g−1 (dairyM), 126.25 mg g−1 (dairyS), 211.16 mg g−1 (SFdairyS), 144.66 mg g−1 (beefS), 63.04 mg g−1 (pigM) and 90.12 mg g−1 (poultryM) respectively, after combined acid and enzymatic hydrolysis (Table 2). SFdairyS had the best performance: 211.26 mg g−1 sugar content and 56.32 mg g−1 ethanol content. The saccharification percentages improved after the combination of acid and enzymatic hydrolysis and were always better for all the samples (Table 2). The effect of combined acid and enzymatic hydrolysis is reported in Fig. 1: enzymatic hydrolysis resulted in a lower sugar content than acid hydrolysis (Fig. 1). ANOVA highlighted a significant (p < 0.005) difference between the control and acid hydrolysis and between the control, acid hydrolysis and combined acid and enzymatic hydrolysis. From comparison of animal waste (cattle, pig and poultry), it is possible to note that combined acid and enzymatic hydrolysis lead to a better exploitation of their lignocellulosic content, but there are some difference due to the specific properties of the samples. For cattle samples, the alfalfa fibre remaining in the manure after stomach digestion was too recalcitrant [3, 4, 9, 13] and acid pre-hydrolysis was necessary. This is in agreement with the results obtained from other previous studies on manure saccharification [3, 4, 9]. Acid hydrolysis was better than enzymatic treatment for dairyM, SFdairyS and beefS. The beef samples obtained the best saccharification value (41.22%) after combined acid and enzymatic hydrolysis, but also after acid hydrolysis: 81.54 mg g−1 which corresponds to 26.78% of saccharification. It is possible to explain this result considering that the beef’ diet consisted mainly in concentrated feed with a larger amount of more easily digestible fibre and probably the content of not degraded hemicellulose may be greater.

In pigM and dairyS, enzymatic hydrolysis was better than acid hydrolysis (74.24 and 74.38 mg g−1). This is for two different reasons. For pigM, this result highlights better performance of hemicellulase than other samples, because the hemicellulose chain is not degraded in the digestive tract and therefore the more digestible fraction has still not been used. Another reason is the high nitrogen content of pigM (2739 mg kg−1) and dairyS (1971 mg kg−1), considering that ammonia and free amino acids can influence the final sugar yield [36]. Liao et al. (2006) [35] demonstrated that longer acid and high temperature treatment led to greater consumption of xylose through Browning reactions. Therefore, the nitrogen content could have a much greater impact on hemicellulose-sugars yield than cellulose-sugars yield after acid treatment at high temperature. For the same reason, poultry manure had a lower saccharification percentage than other samples after combined acid and enzymatic hdyrolysis (22.33%). The worst enzymatic saccharification results were from SFdairyS (0.73%) and poultryM (3.87%). This may be due to higher lignin content (SFdairyS, 140.46 mg g−1) or higher ash content (poultryM, 26.5% of DM), which may lead to a loss of cellulolytic enzyme activity through non-productive adsorption that reduces or removes the enzymes prior to hydrolysis [7, 37]. The presence of hemicellulose hinders cellulose activity and better removal of hemicelluloses guarantees better saccharification of glucan. The use of hemicellulase as a helper-enzyme [17] permits pentose recovery, but is not sufficient to degrade hemicellulose and make cellulose chains more accessible to cellulase, mostly in cattle samples.

Sugar recovery from cattle manure was lower than the values obtained in previous studies (264 mg g−1) [7], perhaps due to the composition and origin of the manure. Our samples came from alpine farms, whilst the manure used in other works came from the feedlots of intensive farms that had a different diet and production scope. Another reason may concern the experimental conditions for our acid pre-hydrolysis tests. Acid concentration (<2.5%) and high temperature treatment increase the presence of enzymes’ inhibitory compounds, such as acid insoluble lignin and polyphenolics, which diminish cellulose activity within the solid residue [15, 37]. Consequently, we assume that enzymatic glucan saccharification probably did not take place completely. Inhibition of enzyme activity and the ammonia–sugar reaction (as previously explained) could explain our results as regards sugar recovery and saccharification.

Figure 2 shows the effect of the treatment on ethanol content after alcoholic fermentation. The results are in agreement with sugar results (Fig. 1): the combined acid and enzymatic hydrolysis gave the best results for both sugar and ethanol yields. ANOVA highlighted a significant (p < 0.005) difference between the ethanol content and yield only for combined acid and enzymatic treatment compared to others (control, acid hydrolysis, enzymatic hydrolysis) (Table 2). The fermentation yield of the theoretical ethanol yield after combined acid and enzymatic hydrolysis was very similar for most samples and was greater than 50%, except for beefS (38.39%) and poultryM (31.32%) samples (Table 2). PigM gave the best value: 88.66%. When considering ethanol content (as mg g−1), the best performance came from samples with the highest sugar recovery content (dairyM, dairyS, SFdairyS). The relatively low fermentation yield compared to the theoretical ethanol yield may be due to the inhibition effect of the toxic compound content of hydrolysates [23]. Although S. cerevisiae has a high tolerance to toxic compounds [24], fermentation in a manure environment and the lack of withdrawal treatments probably did not permit S. cerevisiae to perform well. Xylose fermentation by P. stipitis may also be repressed, but probably less so than S. cerevisiae, given the better fermentation yield obtained after acid hydrolysis than after enzymatic hydrolysis (Table 2; Fig. 2). The aeration condition was performed to ensure xylose-fermentation, considering that low levels of oxygen are necessary for efficient ethanol formation from xylose by the xylose fermenting yeasts [19], but this condition lowered the S. cerevisiae fermentation yield [38]. Respiratory-deficient mutant strains of S. cerevisiae could be used in co-culture system to solve this problem of oxygen supply [19]. Although operating process conditions agreed (30 °C and pH 4–5), this co-culture in our test was not performing well and maybe both yeasts are inhibited. It is also probable that P. stipitis and S. cerevisiae had adverse effect on each other [19, 38].

In order to improve ethanol recovery, we tested different co-fermentation with K. marxianus, P. stipitis and C. shehatae. We chose to employ only SFdairyS sample, because of the best saccharification performance and the best sugar content in the tests described above. A significant (p < 0.005) improvement was observed (Fig. 3): the results showed a better theoretical ethanol yield (84.21%) than co-fermentation with S. cerevisiae and P. stipitis. The promising results for co-culture obtained with K. marxianus, C. shehatae and P. stipitis (84.21% of the theoretical ethanol yield, which corresponds to 75.44 mg g−1) were due to better conversion into ethanol in the presence of several sugar types. Co-culture with K. marxianus and P. stipitis had not shown the adverse effect on each other [38]. The activity of non–Saccharomyces yeasts probably, improved the substrate utilisation rate, thus increasing the ethanol yield. Our test was a preliminary approach to employ non-Saccharomyces yeast in manure fermentation. Future tests will focus on verify the yields and the kinetics of these co-cultures.

Our experiments showed that it is possible to obtain bioethanol from all the types of manure considered, in agreement with the results of Vancov et al. [7] and Wolsendbet et al. [8], highlighting the suitability of different animal waste for bioethanol production and addressing some problems related to the sustainability of the process. Pig and poultry manure had good fermentation yield results, but ethanol recovery was higher in dairy manure and dairy slurry. Acid-based pretreatment at 3.5% was able to inhibit downstream processes (enzyme hydrolysis, fermentation and DW management) but complete substitution with hemicellulase enzyme was not effective and a dilute acid hydrolysis step was necessary for breakdown of the hemicellulose-lignin complex. The sustainability of 2nd generation biofuels is based on correctly exploiting of all kinds of sugars, C5 and C6, produced by fibre degradation.

Biomethane Production from DW

The main properties detected in DW are reported in Table 3. It should be noted that dry matter content was <12% in all samples. For cattle samples, we considered only SFdairyS, the most promising samples. Cattle DW had 0.12 mg kg−1 of fresh matter in terms of total nitrogen content and 650 mg kg−1 ammonia concentration; total nitrogen in pig DW was 0.33 mg kg−1 of fresh matter and ammonia was 720 mg kg−1; poultry manure total nitrogen was 0.58 mg kg−1 of fresh matter and ammonia was 1050 mg kg−1. COD values were higher in pig and poultry samples, as well as VS (42.71% SFdairyS DW; 63.06% pigM DW; 70.76% poultryM DW) content and DM content (5.13% SFdairyS DW; 8.37% pigM DW; 11.28% poultryM DW) (Table 3). The inoculum digestate came from an anaerobic digestion plant fuelled with cattle manure, and the DM content was 6.48% and VS 70.5% of DM. The ratio between the VS of the inoculum and the VS of the DW tested was 0.2. Biomethane production from each type of DW and from the inoculum (residual production) are reported in Fig. 4. All the samples exhausted their biogas potential within 11 days (Fig. 4). The anaerobic digestion tests provided production of biogas equal to 134.14 Nml g−1 of cattle DW (SFdariyS), 272.11 Nml g−1 of pig DW (pigM) and 269.41 Nml g−1 of poultry DW (poultryM). The methane concentration in biogas was about 65% and this level was already reached by the 4th day. The methane concentration and production was similar for each sample considered. Specific biomethane production, expressed in relation to DM content, was 102.11 Nml g−1 DM of cattle DW, 172.83 Nml g−1 DM of pig DW and 166.62 Nml g−1 DM of poultry DW. These results are due to the different composition of the manure: the significant fraction of non-fibre VS in pigs and poultry, not used in the bioethanol process, permits a much better biogas/biomethane yield.

Mass and Energy Balance

The mass and energy balance made it possible to compare ethanol production with methane production and to highlight the behaviour and suitability of different kinds of animal manure. Mass and energy balance (Table 4) were calculated for each of the tested manures (cattle, pig and poultry) using the best values obtained from the bioethanol process experiments (Table 2) and anaerobic digestion tests. The value considered of ethanol produced was 68 g kg−1 for cattle, 29 g kg−1 for pigs and 24 g kg−1 for poultry. Methane recovery after anaerobic digestion of distillation waste was 72.94 g kg−1 for cattle, 123.47 g kg−1 for pigs and 119.03 g kg−1 for poultry. The two integrated processes generated a net energy balance of 1.28 MJ kg−1 for cattle, 4.57 MJ kg−1 for swine and 4.79 MJ kg−1 for poultry (Table 4). The pig and poultry net energy balance was better than for cattle, because of the higher methane energy value and lower production costs. After saccharification and fermentation, we obtained 86.18 L ethanol t−1 dry faeces for cattle, 36.75 L ethanol t−1 dry faeces for pigs and 30.42 L ethanol t−1 dry faeces for poultry. The value increased to 95.61 L ethanol t−1 when using co-fermentation with K. marxianus, P. stipitis and C. shehate. The value for cattle was higher than the values reported in previous works [5] due to sugar loss during the anaerobic digestion stage [7]. There are many differences between the specific animals considered: cattle, pigs and poultry. The energy balance of ethanol production from cattle was about 824.16 kJ kg−1 dry faeces. This value is higher than the value reached following the digestion of dairy manure fibre, 278–361 kJ kg−1 dry faeces [5] and confirms that the use of raw manure for ethanol production is better than digestate, given that all the sugar was employed in the fermentation process [5, 7]. The energy balance of anaerobic digestion was very positive for pig and poultry manure, due to the higher DM content as compared to cattle. The net energy balance was therefore better for pigs and poultry, but the greater impact is due to methane production. Following the process studied in this work, analysis of the mass and energy balance suggests that cattle manure is more suitable for bioethanol production than pig and poultry faeces, which are instead more suitable for methane production. It is important to note that bioethanol can be sold at a price equal to 1000 € ton−1 [39], which could be greater than the price of methane, 0.85–1.05 € kg−1. This has to be considered as a preliminary approach to bioethanol and biomethane production in a biorefinery concept.

Conclusion

The study increases knowledge about the use of manure in biofuel production, in relation to proper exploitation of organic content, particularly lignocellulosic content, in a biorefinery concept. Study of the technical feasibility of bioethanol production highlighted that it is possible to obtain bioethanol from all the types of manure considered. Pig and poultry manure had good fermentation yield results, but ethanol recovery was higher in dairy manure and dairy slurry. The current issues to be addressed mainly regarding control of toxic and inhibitory compound concentrations and introduction a specific detoxification system to perform enzyme activity and avoid the inhibition of yeasts. Specific pre-treatments to remove lignin, such as the decrystallization method, could be tested in order to increase the amount of cellulose hydrolysed to produce glucose, especially for cattle samples and to find technical solutions to appropriately exploit the lignin content of manure. Selection of specific pairs of microorganisms, suitable for the particular composition of different types of manure would appear to be very important in order to improve the fermentation of a wide range of sugar types.

All the DW produced biogas with biomethane concentration about 65%. The BMP values were higher in pig and poultry: the significant fraction not used in the bioethanol production permits a much better biogas yield. Integration of the different processes highlighted the suitability of different animal manure in relation to the yield of both bioethanol and biomethane. The mass and energy balance values showed the contribution of each sample considered: the cattle manure are more suitable to bioethanol production, whilst anaerobic digestion is the best exploitation way for pigM and poultryM.

Abbreviations

- DM:

-

Dry matter

- FM:

-

Fresh matter

- VS:

-

Volatile solids

- dairyM:

-

Dairy manure

- dairyS:

-

Dairy slurry

- SDdairyS:

-

Solid fraction of dairy slurry (after solid–liquid separation)

- beefS:

-

Beef slurry

- pigM:

-

Pig manure

- poultryM:

-

Poultry manure

- FEM:

-

Fondazione Edmund Mach

- NSC:

-

Non–structural carbohydrates

- NDF:

-

Neutral detergent fibre

- ADF:

-

Acid detergent fibre

- ADL:

-

Acid detergent lignin

- BMP:

-

Biomethane potential

- DW:

-

Distillation waste

References

Hahn-Hägerdal, B., Galbe, M., Gorwa-Grauslund, M. F., Lidén, G., Zacchi, G.: Bio-ethanol—the fuel of tomorrow from the residues of today. Trends Biotechnol. 24(12), 549–556 (2006)

Budsberg, E., Rastogi, M., Puettmann, M. E., Caputo, J., Balogh, S., Volk, T. A., Gustafson, R., Johnson, L.: Life-cycle assessment for the production of bioethanol from willow biomass crops via biochemical conversion. Forest. Prod. J. 64(4), 305–313 (2012)

Chen, S., Wen, Z., Liao, W., Liu, C., Kincaid, R. L., Harrison, J. H., Elliott, D.C., Stevens, D.J.: Studies into using manure in a biorefinery concept. Appl. Biochem. Biotechnol. 121–124, 999–1015 (2005)

Wen, Z., Liao, W., Chen, S.: Hydrolysis of animal manure lignocellulosics for reducing sugar production. Bioresour. Technol. 91, 31–39 (2004)

Yue, Z., Teater, C., MacLellan, J., Liu, Y., Liao, W.: Development of a new bioethanol feedstock—anaerobically digested fiber from confined dairy operations using different digestion configurations. Biomass Bioenergy 35(5), 1946–1953 (2011)

MacLellan, J., Chen, R., Kraemer, R., Zhong, Y., Liu, Y., Liao, W.: Anaerobic treatment of lignocellulosic material to co-produce methane and digested fiber for ethanol biorefining. Bioresour. Technol. 130, 418–423 (2013)

Vancov, T., Schneider, R. C. S., Palmer, J., Mcintosh, S., Stuetz, R.: Potential use of feedlot cattle manure for bioethanol production. Bioresour. Technol. 183, 120–128 (2015)

Woldesenbet, A.G., Shiferaw, G., Chandravanshi, B.S.: Bio-ethanol production from poultry manure at Bonga Poultry Farm in Ethiopia. Afr. J. Environ. Sci. Technol. 7(6), 435–440 (2013)

Chen, S., Liao, W., Liu, C., Wen, Z., Kincaid, R.L., Harrison, J.H., Elliott, D.C., Brown, M.D., Solana, A.E., Stevens, D.J.: Value-added chemicals from animal manure. Pacific Northwest National Laboratory, Final Technical Report (2003)

Alvira, P., Tomas-Pejo, E., Ballesteros, M., Negro, M. J.: Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour. Tecnol. 101, 4851–4861 (2010)

Galbe, M., Zacchi, G.: Pretreatment of lignocellulosic material for efficient bioethanol production. Adv. Biochem. Eng. Biotechnol. 108, 41–65 (2007)

Liao, W., Liu, Y., Wen, Z., Frear, C., Chen, S.: Studying the effects of reaction conditions on components of dairy manure and cellulose accumulation using dilute acid treatment. Bioresour. Technol. 98, 1992–1999 (2007)

Liao, W., Liu, Y., Liu, C., Chen, S.: Optimizing dilute acid hydrolysis of hemicellulose in a nitrogen-rich cellulosic material—dairy manure. Bioresour. Technol. 94, 33–41 (2004)

Liao, W., Wen, Z., Hurley, S., Liu, Y., Liu, C., Chen, S.: Effects of hemicellulose and lignin on enzymatic hydrolysis of cellulose from dairy manure. Appl. Biochem. Biotechnol. 121–124, 1017–1030 (2005)

Kim, Y., Ximenes, E., Mosier, N.S., Ladisch, M.R.: Soluble inhibitors/deactivators of cellulase enzymes from lignocellulosic biomass. Enzyme Microb. Technol. 48(4–5), 408–415 (2011)

Saha, B.C.: Hemicellulose bioconversion. J. Ind. Microbiol. Biotechnol. 30, 279–291 (2003)

Berlin, A., Gilkes, N., Kilburn, D., Bura, R., Markov, A., Skomarovsky, A., Saddler, J.: Evaluation of novel fungal cellulase preparations for ability to hydrolyze softwood substrates—evidence for the role of accessory enzymes. Enzyme Microb. Technol. 37, 175–184 (2005)

Gao, D., Uppugundla, N., Chundawat, S. P., Yu, X., Hermanson, S., Gowda, K., Dale, B.E.: Hemicellulases and auxiliary enzymes for improved conversion of lignocellulosic biomass to monosaccharides. Biotechnol. Biofuels 4, 5 (2011)

Chen, Y.: Development and application of co-culture for ethanol production by co-fermentation of glucose and xylose: a systematic review. J. Ind. Microbiol. Biotechnol. 38, 581–597 (2011)

Bader, J., Mast-Gerlach, E., Popović, M.K., Bajpai, R., Stahl, U.: Relevance of microbial coculture fermentations in biotechnology. J. Appl. Microbiol. 109, 371–387 (2010)

Jeffries, T.W., Jin, Y.S.: Metabolic engineering for improved fermentation of pentoses by yeasts. Appl. Microbiol. Biotechnol. 63, 495–509 (2004)

Nigam, J.N.: Ethanol production from wheat straw hemicellulose hydrolysate by Pichia stipitis. J. Biotechnol. 87, 17–27 (2001)

Palmqvist, E., Hahn-Hägerdal, B.: Fermentation of lignocellulosic hydrolysates. I: inhibition and detoxification. Bioresour. Technol. 74(1), 17–24 (2000)

Olsson, L., Hahn-Haegerdal, B.: Fermentative performance of bacteria and yeasts in lignocellulose hydrolysates. Process Biochem. 28(4), 249–257 (1993)

Delgenes, J.P., Moletta, R., Navarro, J.M.: Effects of lignocellulose degradation products on ethanol fermentations of glucose and xylose by Saccharomyces cerevisiae, Zymomonas mobilis, Pichia stipitis, and Candida shehatae. Enzyme Microb. Technol. 19, 220–225 (1996)

Moreno, A. D., Ibarra, D., Ballesteros, I., González, A., Ballesteros, M.: Comparing cell viability and ethanol fermentation of the thermotolerant yeast Kluyveromyces marxianus and Saccharomyces cerevisiae on steam-exploded biomass treated with laccase. Bioresour. Technol. 135, 239–245 (2013)

Chen, H., Qiu, W.: Key technologies for bioethanol production from lignocellulose. Biotechnol. Adv. 28(5), 556–562 (2010)

http://sito.entecra.it/portale/public/documenti/alimenti_per_il_suino_biologico.pdf. Accessed 23 March 2017

http://www.venetoagricoltura.org/upload/File/progetti_speciali/4_alimentazione_pollo.pdf. Accessed 23 March 2017

Goering, H.K., Soest, P.J.: Forage fibers analyses (Apparatus, reagent, procedures and some application) In: Agriculture Handbook No. 379. ARS-USDA, Washington, DC, pp 1–12 (1970)

Bailey, R.W.: The reaction of pentoses with anthrone. Biochem. J. 68(4), 669–672 (1958)

Angelidaki, I., Alves, M., Bolzonella, D., Borzacconi, L., Campos, J.L., Guwy, A.J., Van Lier, J.B.: Defining the biomethane potential (BMP) of solid organic wastes and energy crops: a proposed protocol for batch assays. Water Sci. Technol. 59(5), 927–934 (2009)

Krishnan, M.S., Ho, N.W.Y., Tsao, G.T.: Fermentation kinetics of ethanol production from glucose and xylose by recombinant Saccaharomyces 1400 (pLNH33). Appl. Biochem. Biotechnol. 77–79, 373–388 (1999)

Piccolo, C., Bezzo, F.: A techno-economic comparison between two technologies for bioethanol production from lignocellulose. Biomass Bioenergy 33, 478–491 (2009)

Liao, W., Liu, Y., Chuanbin, L., Zhiyou, W., Shulin, C.: Acid hydrolysis of fibers from dairy manure. Bioresour. Technol. 97, 1687–1695 (2006)

Fennema, O.R.: Food Chemistry, 3rd ed. Marcel Dekker, Inc., New York (1996)

Horn, S.J., Eijsink, V.G.H: Enzymatic hydrolysis of steam-exploded hardwood using short processing times. Biosci. Biotechnol. Biochem. 74(6), 1157–1163 (2010)

Rouhollah, H., Iraj, N., Giti, E., Sorah, A.: Mixed sugar fermentation by Pichia stipitis, Saccharomyces cerevisiae and an isolate xylose-fermenting Kluyveromyces marxianus and their cocultures. Afr. J. Biotechnol. 6(9), 1110–1114 (2007)

http://www.eubia.org/index.php/about-biomass/biofuels-for-transport/bioethanol. Accessed 20 Sept 2016

Acknowledgements

The work is a part of the ZOOTANOLO project; a project funded by the Italian Ministry of Agriculture, according to Decree No. 26290/7303/09 of 12/11/2009.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bona, D., Vecchiet, A., Pin, M. et al. The Biorefinery Concept Applied to Bioethanol and Biomethane Production from Manure. Waste Biomass Valor 9, 2133–2143 (2018). https://doi.org/10.1007/s12649-017-9981-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-017-9981-2