Abstract

This paper focuses on the comparison of waste-to-energy processes in terms of life cycle analysis. The processes compared are the municipal solid waste (MSW) direct combustion (known as mass burning) and the combustion of refused derived fuel (RDF) produced after separation of recyclable materials in a mechanical–biological treatment (MBT) facility. The basis of comparison for the two processes in this paper is their global warming potential (GWP). In specific, three European countries (Greece, Germany and France) were chosen as case studies. Their selection was based on their electricity mix characteristics and the general population culture toward waste management practices, as depicted in the waste composition. The waste composition applied for each country is the average estimated by local statistics and Eurostat data. The comparison between the two methods of incineration leads to the conclusion that the incineration of RDF has less impact on the greenhouse effect than the incineration of MSW. A sensitivity analysis based on different setup configurations for paper and plastic separation in the MBT plant was carried out. The results validate the priorities of waste management hierarchy, since the scenarios with high separation of valuable materials, such as paper and plastics, were environmentally friendlier in terms of GWP impact. The sensitivity analysis based on the change of the recovering rate shows an approximately linear relation of inverse proportion between recovering rate and total environmental impact. Furthermore, the increase in electricity efficiency plays a significant role in the greenhouse effect for the Greek scenario, while its respective effectiveness for the French scenario is lower. Since the final choice between the two processes relies solely upon the needs that should be met on specific occasions, the modeling has been carried out through life cycle analysis principles, in order to provide a decision-making tool for the selection of the most appropriate waste-to-energy technology according to the criteria that be set.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In most developed and developing countries, where population, prosperity and urbanization figures present continuous and radical rise, one of the major challenges for municipalities is to handle and dispose of increasing quantities of solid waste. Furthermore, the continuous depletion of natural resources puts high pressure on every country to follow specific waste management strategies, in order to recover materials and/or energy. Directive 2008/98/EC [1] sets the basic concepts and definitions related to waste management, such as the definitions of waste, recycling and recovery. It explains when waste ceases to be waste and becomes a secondary raw material (so-called end-of-waste criteria), as well as how to distinguish between waste and by-products. According to waste legislation, the EU Member States set a hierarchy of priorities for waste management:

-

(a)

Waste prevention

-

(b)

Preparing for reuse

-

(c)

Recycling

-

(d)

Recovery

-

(e)

Disposal

However, even considering the most optimistic estimation on waste prevention, minimization, reuse and recycling, European countries will have a significant amount of residual municipal waste that will either have to be disposed or could be treated for recovering energy and/or materials from it.

The consumers’ behavior can have a large influence on the composition of the separately collected fractions and on that of the residual waste. Rigamonti et al. [2] considered changes in its composition through three different scenarios by including separate collection of materials and food waste with different collection rates.

The thermal treatment for the residual waste is a common method applied in Europe. The attractiveness toward thermal treatments is given by the possibility of making significant energy recovery thanks to the technological developments achieved in this field [3].

More specifically, combustion of municipal solid waste (MSW) or refused derived fuels (RDF) is applied in many European countries as an energy recovery technology, often combined with recycling of useful materials, mainly metals prior to incineration. In many European countries, the label for fuel recovered from MSW is the solid recovered fuel (SRF). SRF can be regarded as a waste-derived fuel the quality of which is monitored and controlled by processing. It falls into specified quality categories based on heating value and chlorine and mercury content [4]. A list of SRF production plants in Europe is given in ERFO [5], along with the productivities of each country. Germany is the dominant country in the production of SRF by producing 6150 kt SRF per annum (reference year 2010). However, in this study, it is considered that RDF is produced in Germany for comparative reasons with the other examined countries.

In what concerns the combustion of municipal waste, it is widely applied in Europe, especially in northern countries. For EU-27, it is noticed that thermal treatment (mainly combustion) accounts for 22 % of municipal waste management applications, while the respective percentage is 25 % for the recycling process, 38 % for disposal to landfills and 15 % for composting [6]. A number of relative studies about the investigation of MSW combustion with energy recovery in environmental terms have been carried out. For example, Assamoi and Lawryshyn [7] compared the landfilling method with the MSW incineration, while Yang et al. [8] investigated the impact of MSW incineration with energy recovery on the global warming potential (GWP), based on the parameters of waste characteristics and the type of substitute fuel. According to the study by Consonni et al. [9], the best energy balance corresponds to the direct W-t-E case compared to the light mechanical pretreatment and feeding to grate combustor, RDF production and incineration in a fluidized bed combustor.

Life cycle analysis (LCA) is a particularly useful tool, which can be applied to sustainable municipal solid waste management, with the aim of reaching a conclusion as to which would be the most sustainable waste management method in environmental terms [10, 11]. Hence, LCA methodology forms a support tool for selecting the best MSW management strategy [12]. The waste management strategies taking place in LCA should aim at maximizing energy and material recovery, while minimizing the final amount of waste delivered to landfill and the pollution related to all treatment and collection steps [13]. A plethora of studies have been carried out, comparing several MSW management treatment methods, such as landfilling, composting, anaerobic digestion and incineration. The studies usually refer to scenarios taking place in a specific area in order to compare the current waste management method with the proposed ones [14–18]. In some cases, studies focus on energy recovery methods from waste, mentioning the environmental benefits that arise from the utilization of biogenic fraction of waste [19, 20]. Hence, the LCA tool can be used as a decision tool, which would significantly support the local authorities in selecting the best waste management treatment methods.

In their study, Cimpan and Wenzel [21] compare waste-to-energy (W-t-E) technologies in terms of LCA principles. Specifically, primary energy savings potential is used to compare residual municipal solid waste treatment systems, including configurations with mechanical and mechanical–biological pretreatment, which produce waste-derived fuels, biogas and/or recover additional materials for recycling, alongside a system based on conventional mass burn W-t-E and ash treatment.

The contribution of the present LCA paper is the comparison of the W-t-E scenarios regarding their GWP. The first one focuses on recovery of metals prior to combustion and the achievement of the demands of the EU landfill directive in order to avoid the disposal of the MSW in landfills through the treatment of MSW in an upstream mechanical–biological treatment (MBT) plant, while the second one considers the combustion of MSW directly after its collection. Previous studies on LCA of W-t-E processes, such as the study by Cimpan and Wenzel [21], have taken into consideration only the waste composition parameter as valid for their evaluation. The present paper introduces the energy mix profile as additional crucial parameter on the study of such processes. Hence, three European countries (Greece, Germany and France) were chosen as case studies, since these countries perform different energy mix characteristics. In specific, the Greek electricity mix is mainly characterized by lignite power plants; the French electricity mix is characterized by nuclear plants, while the German electricity mix is considered more balanced than that of the former two countries. Hence, the greenhouse effect contributions are correlated with waste characteristics and the local energy mix used for electricity generation through a complicated relationship. For instance, plastics in the waste fraction give rise to fossil CO2 emissions through the combustion, but on the other hand lead to a considerably increase in the lower heating value (LHV) of MSW, leading to a reduction in GHG emissions. Hence, the impact of the electricity mix in combination with the average waste composition of the each country to the greenhouse effect is depicted in this paper, by presenting scenarios with respect to the change in the capacity of the optical separators for paper and plastic, as well as, the technological improvement, by indicating the electrical efficiency.

Materials and Methods

Life Cycle Analysis

Generally, LCA can be defined as a method that studies the environmental aspects and potential impacts of a product or system from raw material extraction through production, use and disposal. The general categories of environmental impacts to be considered include resource use, human health and ecological consequences [22]. The typical stages of LCA are firstly presented in the standards ISO 14041–14043. These standards have been replaced by the ISO 14044:2006 [23]. ISO 14044:2006 specifies requirements and provides guidelines for life cycle assessment (LCA) including: definition of the goal and scope of the LCA, the life cycle inventory analysis (LCI) phase, the life cycle impact assessment (LCIA) phase, the life cycle interpretation phase, reporting and critical review of the LCA, limitations of the LCA, relationship between the LCA phases, and conditions for use of value choices and optional elements.

Methodology

The impact assessment methods used in LCA can be divided into two categories: those that focus on the amount of resources used per unit of product (upstream methods) and those which estimate the emissions of the system (downstream methods) [16]. This LCA paper uses the latter method, calculating the GWP through the equivalent carbon dioxide emissions (CO2eq). The distinction of CO2eq emissions is made according to the ETC/RWM working paper [24]. Hence, CO2eq emissions have been divided into two distinct categories: CO2eq emitted and CO2eq avoided emissions. A positive number indicates impact to the environment, while a negative number indicates avoidance of the respective GWP impact, simultaneously contributing to remarkable environmental benefit. The CO2eq emissions include emissions that are diffused directly or indirectly in the environment from the processes involved in each of the two aforementioned W-t-E treatment methods. In order to identify the potential of avoiding CO2eq emissions, two categories of emissions are considered. The first one refers to the resource savings by reusing recyclable materials, while the second one refers to the emissions avoided by using renewable energy. Therefore, the avoided material emissions refer to the avoidance of energy, transportation, processes and other primary resources used in their production. As far as the avoided energy emissions are concerned, they refer to those emissions that would be emitted, if energy was not recovered by thermal combustion of the waste and fossil fuels were used instead [25]. Due to the organic content of MSW (biogenic fraction), the biogenic carbon dioxide is considered neutral [26], since the amount of CO2eq absorbed during the plant growth is the same as that released at the end of its life. Hence, the energy production from waste is associated with lower greenhouse gas (GHG) emissions than those diffused when fossil fuels are used.

The most significant GHG emissions are carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), sulfur hexafluoride (SF6) perfluorocarbons and hydrofluorocarbons (HFCs). However, only CO2, CH4 and N2O emissions have been included in this study for the calculation of CO2eq emissions. The calculated CO2eq emissions represent the total impact of the above emissions to the greenhouse effect, in 100-year horizon. The emission factors for the rest of GHGs are not common and have low impact to the greenhouse effect.

Furthermore, the calculation of biogenic and fossil emissions of the carbon life cycle is based on the principles provided in IPCC 2007 GWP 100a [27]. The emission factors regarding this method are summarized in Table 1. It is mentioned that the carbon monoxide emissions are not taken into account, since IPCC 2007 GWP 100a does not consider the impact of this source.

Goal and Scope Definition

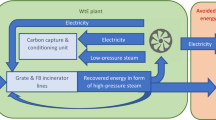

The objective of this study is to evaluate the environmental performance of two different W-t-E cases. The first one focuses on recovering as many useful materials—mainly metals—as possible and producing high-quality RDF in an upstream MBT plant in combination with RDF incineration. The second one considers the combustion of MSW directly after its collection, in combination with the recovery of ferrous (FE) and nonferrous (NFE) metals from the combustion ash residues. The comparison will be accomplished in terms of GWP impact using LCA methodology and is illustrated in Fig. 1. The results are calculated for three countries, examined as separate case studies, introducing the energy profile of each country and the waste composition of the residual waste as main parameters.

Boundaries Definition and Functional Unit

The LCA, as performed in this paper, includes all activities of waste management except for collection and transportation of MSW to the MBT plant or MSW incineration plant. Moreover, landfills for disposal of residues are considered to be located in the vicinity of the respective treatment plants. Hence, the impact of residues transportation is considered negligible. The transportation of RDF from MBT plant to W-t-E plant and the transportation of residues are not taken into account in the basic scenario, since the facilities are colocated. Furthermore, the stabilization process for fly ash and the disposal for bottom ash are not taken into account, since the fly ash and the bottom ash are not characterized as dangerous. Specifically, the first scenario refers to the RDF incineration in combination with recovery of materials. The overall flowchart of the MBT process is illustrated in Fig. 2. It is assumed that there are two landfills, each one next to the respective plant. This eliminates any dependence on the distance between the MBT plant and W-t-E plant when modeling the examined waste management scenario. The flowchart of the W-t-E plant is shown in Fig. 3. The waste incinerator plants consist of three basic sections: the combustion system (typically a variation of the water-cooled moving grate technology), the boiler and the flue gas treatment system. In specific, hot flue gases from the combustion system first pass through a steam boiler and are subsequently treated in a system typically consisting of quench spray dryer, electrostatic precipitators, acid scrubbers, desulfurization with lime, DeNOx with ammonia and finally a bag filter [28]. The boundaries of the system examined include the production of chemical agents, especially lime, ammonia and activated carbon, needed for the flue gas treatment. The boiler ash and the fly ash are stabilized before their disposal, while the bottom ash is disposed to landfill directly.

The only difference mentioned for MSW incineration is the additional process of recovering ferrous and nonferrous metals from the bottom ash, before its disposal to landfill (Fig. 3).

The various activities which have been considered in each of the two previously described scenarios and are examined in order to determine the GWP emissions are summarized in Table 2.

The functional unit applied in comparison with the results of the two scenarios refers to 1 tonne of MSW input.

Selected Study Countries

The present LCA study is applied in three countries: Greece, France and Germany. The countries have been selected due to their different electricity mix profile in combination with their different waste composition. Specifically, the Greek electricity mix is mainly characterized by lignite power plants; the French electricity mix is characterized by nuclear plants, while the German electricity mix is considered more balanced than that of the former two countries. The distribution of electricity mix resources [2] for the three examined countries, as well as their respective emission factor, is summarized in Table 3. The “other” category refers to electricity produced from diesel, hydro-pumping and other sources (waste). The emission factor for each technology may vary for each country as a result of variations in the specific technology or the age of the power plants; however, for the scope of this analysis, this is not considered a variable and average values are used instead. Furthermore, an average waste fraction composition of the examined countries is summarized in Table 4, based on data given by Eurostat and other data sources.

The category “combustibles” refer mainly to other nonbiodegradable wastes, while the “noncombustibles” refer to batteries, accumulators, etc. The category “other” mainly refers to fines (inert materials and very small pieces of paper and plastics, whose recovery is not economical).

The examined MSW quantity is 350,000 tons annually, while the facilities of the respective MBT and W-t-E plant are deemed as similar, since the technology does not change for each examined country.

Life Cycle Inventory

The Life cycle inventory was developed using a combination of publicly available LCA model technical reports, including suitable indicators, greenhouse gas inventory guidelines and respective LCA papers published in scientific journals. The aim of the inventory is the determination of the CO2eq factors for each process taken into account in this LCA study, regarding the defined system boundaries.

Waste-to-Energy Plants

W-t-E plants in this study comprise of (a) conventional mass grate thermal treatment plants in the first case and (b) dedicated, so-called RDF mono-combustion plants in the second case. Reimann [34] and Grosso et al. [35] have studied a plethora of W-t-E plants, part of their work including the investigation of the energy efficiency of those plants. Furthermore, according to the BREF document of the European Commission [36], the grate combustors are the waste incineration equipment offering the largest treatment capacity in terms of thermal power input per line.

In order to reflect the wide variation observed in energy efficiency of W-t-E plants across Europe, and to allow the comparison of alternatives on an equal basis, the energy recovery efficiency in this study is equal to the average efficiency of new W-t-E plants constructed in Europe. The mono-combustion RDF case includes only electrical power generation, without the possibility of heat utilization. Specifically, typical new waste incineration plants in Europe have net electrical efficiency between 18 and 24 %, mainly depending on their size and boiler steam parameters. The electrical efficiency can be increased up to 30–32 % by using, for example, external superheating in fossil-fired boilers. Consonni and Vigano [37] have examined the correlation between thermal input and electrical efficiency. The electrical efficiency considered in this study is equal to 20 % (an average value typically used in related scientific literature). Furthermore, the self-consumption of electricity is estimated at 20 % of the produced electricity, while the remainder is sold to the electrical grid.

Almost all carbon in the waste can be considered completely oxidized to CO2 and emitted to the atmosphere. Carbon in the waste (g C) should be converted into CO2 using the factor 44/12 based on their molar masses.

The CO2 emissions were calculated based on the composition of waste, the carbon content and the proportion of fossil carbon of each waste stream, according to the formula proposed by IPCC methodology [38]:

CO2 emissions = CO2 emissions in inventory year; MSW = total amount of municipal solid waste as wet weight incinerated (t/year); WF j = fraction of waste type/material of component j of the MSW incinerated (fraction); CF j = fraction of carbon in the dry matter (i.e., carbon content) of component j; FCF j = fraction of fossil carbon in the total carbon of component j; OF j = oxidation factor (fraction) that was assumed to be 1; 44/12 = conversion factor from C to CO2; j = component of the MSW incinerated such as food waste, paper/cardboard and plastic.

In what concerns the nitrous oxide (N2O) that formed in the flue gas from nitrogen present in the air and in the waste input, their amount is very small compared with CO2 emissions. Since N2O is more effective greenhouse gas than CO2, these emissions should be assessed. The most common values are around 8–18 g/tonne waste [39]. These values are lower than those be suggested by the UK Greenhouse Inventory (38 g/tonne waste) [40].

Mechanical–Biological Treatment plant

The MBT processes manipulate and convert raw waste into different streams, which are directed to material recycling, energy recovery or disposal. A typical flowchart of the MBT plant used in this study is illustrated in Fig. 2.

The streams undergo mechanical separation and biological treatment in order to recover materials and to reduce the humidity of the resulting fuel. The mechanical separation is achieved by using several components, such as near-infrared (NIR) separators, ballistic separators and magnets, and also by hand picking for the removal of heavy and large objects. In order to facilitate separation, waste is shredded to the average size of a few hundred millimeters. The shredder is usually followed by a drum screen, creating two waste streams of different size. Materials recovered at this stage are plastic materials, such as the polyethylene (PE), the polypropylene (PP), the polyethylene terephthalate (PET) and the plastic film, paper, metals (ferrous and nonferrous) and glass. It is noted that glass mainly refers to glass bottles in the recyclables stream, separated by hand sorting, as shown in Fig. 2. The biological treatment is the second stage of the MBT plant. Moisture of the waste is reduced to less than 15 % by continuous aerobic drying for a few days. During that time, air is forced through the waste. The biological drying takes place in closed reactors and is optimized to preserve most of the calorific value of degradable organic matter by controlling the biodegradation process (duration of 7 days). Regarding the mass balance of the process examined in this study, the incoming waste to the biological box is reduced by approximately 30 %, because of moisture and easily degradable matter. After the biological treatment, a second-stage mechanical process takes place, in order to recover metal concentrates and remove inert material (e.g., stones or broken glass fragments). Inert material refers to the stream of residues, which consists of noncombustible substances and is directed to the landfill. The remaining waste is considered RDF.

In what concerns the technical characteristics of the MBT process, the availability amounts to 45 %—a low rate, due to maintenance and heavy cleaning—and the load factor is 90 %. Further consumption of fuel (natural gas) is required for the operation of the air cleaning system.

According to Cipman and Wenzel [21], the estimated pretreatment energy use amounts to 100 kWhe and 25 kWhNG per ton of MSW. The natural gas consumptions refer to the operation of the air cleaning system used for the reduction of odors from the biological boxes, such as the regenerative thermal oxidation (RTO) systems [41].

The composition of RDF depends on the applied technology, namely the capability of optical separators to separate valuable materials. In this study, the composition of RDF for each case study is summarized in Table 5, considering the total fraction of RDF resulting by the merge of all the produced RDF fractions in the described process (Fig. 2) and also taking into account the separated fractions given in Table 6. As shown, the efficiency for plastic material is distinguished in four different fractions: PE, PP, PET and plastic film.

Recovering Materials

The recovered materials separated in the MBT plant are sold to the recycling industries in order to be reused. Hence, environmental benefit is achieved, due to the use of these secondary materials instead of the respective primary resources. The benefits for each category of recovered materials are summarized in Table 7. The database has been created through extensive literature review [42–46]. The system boundaries applied in these additional LCA studies are limited mainly to the respective process of primary material production. The present study uses the average value of avoided emissions in order to model the LCA of the examined scenarios.

Landfill Facility

In this study, landfill facilities are used for the disposal of MBT residues and ash resulting from the combustion of waste in the W-t-E plants. The landfill facilities are considered sanitary landfills. According to Heyer et al. [47], at the time of landfill disposal a certain remaining portion of readily and medium-degradable organic compounds is still present in the MBT waste and is even well available. Hence, the MBT waste contributes to the biodegradation processes at the time of landfill disposal by strongly mitigating the rate of methane emissions, which would have been emitted without the pretreatment process. In addition, according to a study of Harborth et al. [48], the N removal during pretreatment is remarkably low. Specifically, the reduction of nitrogen content is not considerable and even enrichment of nitrogen is possible. Hence, MBT landfills have been regarded as an N sink.

The released landfill gas is a complex mix of CO2 and CH4 created by the action of microorganisms within the landfill. Hence, the CH4 generation is considered the significant factor for the impact to GWP. It is determined using the amount of organic carbon that is accessible to biochemical decomposition based on the composition of waste [49]. The produced landfill gas is taken into account without considering any energy recovery method, since the landfill gas generation is low and it is not commercially viable to extract and beneficially utilize the landfill gas [50]. Due to the lack of data for disposal of MBT residues and to the fact that the contribution of GWP to the overall impact is considered negligible, its calculation was carried out according to the conventional methods used in the databases provided by studies of Manfredi et al. [51] and Kong et al. [52].

Specifically, the GWP is calculated regarding the biogenic carbon content of the waste material landfilled and the type of the waste. It has to be mentioned that organic kitchen waste has a high degree of degradability, whereas paper has a lower degree of degradability. The dissimilation factors used for the estimation have been taken from the study of Malfredi et al. [51]. The factors are presented in the Table 8. To summarize, by taking consideration the content of biogenic carbon (C, in kg tonne−1 ww) and assuming that on a mass base 55 % of the carbon becomes CH4 and 45 % becomes CO2, the following equations give the overall amount of methane and carbon dioxide generated within 100 years of degradation (\( G_{{{\text{CH}}_{ 4} }} \) in m3 CH4 tonne−1 wet waste; \( G_{{{\text{CO}}_{ 2} }} \) in m3 CO2 tonne −1 ww):

It is mentioned that the factor of 1.40 corresponds to the volume (m3) occupied by 1 kg methane at standard temperature and pressure (STP: T = 0 °C, P = 101.3 kPa).

The construction and the operation of the landfill are not taken into account in this LCA study, due to the fact that landfill refers to disposal of residues, so their impact has not been given first priority.

Production of Chemical Agents

The chemical agents which are mainly used in the flue gas treatment system are the lime and the ammonia. The GWP impact is based on the processes through which these chemical agents are produced. The quantities are estimated according to the limits set by German Directive [53]), including an excess ratio amount to 1.5 for each chemical agent. The results approach the values presented in the study of Integrated Pollution Prevention and Control edited by the European Commission [36]. It is mentioned that hard coal is used as fossil fuel for the required energy consumption.

More specifically, the lime production is based on the following chemical equation, through the disintegration of calcium carbonate:

Lime is the chemical agent used to reduce emissions such as sulfur dioxide (SO2), hydrogen chloride (HCl) and hydrogen fluoride (HF). The factors used are in line with the respective methodology of the European Commission [21].

The production of ammonia is carried out through the set of the following equations.

Ammonia is the agent applied to reduce the created NOx emissions, both mono-nitrogen oxide (NO) and nitrogen dioxide (NO2), while the activated carbon is used for the reduction of mercury (Hg) and other heavy metals.

Results and Discussion

Basic Characteristics

Τhe lower heating value (LHV) of MSW and RDF for each case is calculated according to the databases provided in the study of Cherubini et al. [16]. German MSW composition presents the highest value in LHV, compared with Greek and French composition, which is due to high percentages of paper and plastic. As mentioned above, using the same technology in the MBT plant, the energy content of German RDF has higher value than the others, following the trend of MSW. In addition, the estimated biogenic fraction of MSW and RDF stream is given according to the directive of CEN/TS 15440 [54]. The results are summarized in Table 9. The percentage of the biogenic fraction of the Greek waste proves higher than that of the French and German waste, because of the high percentages of organic fraction found in mixed waste; the latter are due to the fact that the source separated methods of organic fraction for its utilization in compost or energy recovery (e.g., anaerobic digestion) are limited in Greece.

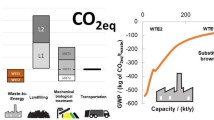

Life Cycle Assessment of basic scenario

The basic method of comparison between the two cases is described through LCA principles. The results are presented in Table 10 and are illustrated in the respective single score Fig. 4, which give the overall impact to greenhouse effect, per category of process. As shown, the process of waste combustion has the main contribution to the overall carbon life cycle assessment regarding the direct and avoided emissions for all case studies. The material avoided emissions (savings) were introduced in the scenario of RDF combustion, apart from the avoided emissions of metals, which have been taken into account for both scenarios. The saving emissions of the production process of nonferrous metals, mainly aluminum, have the highest contribution to greenhouse effect impact, compared with the other recovering materials. Regarding the scenario of direct MSW combustion, the losses of the recovered metals from the resulting ash are estimated at 5 % of the materials. Furthermore, the landfill emissions of residues from the MBT plant and the energy consumption in its facilities have obviously been considered only for the RDF combustion to energy scenario. The energy consumptions of the W-t-E plant have not been considered in the calculations, since they are covered by the produced electricity. The GWP impact of the MBT plant construction process for each country case study is the same, since the applied technology does not change. On the other hand, the GWP impact of the W-t-E plant construction process is differentiated, due to the different energy content of input waste in each case. Hence, the installed capacity of W-t-E plants changes, with direct results to construction according to the aforementioned methodology. The respective avoided emissions are presented only for the case of France, since the presence of nuclear plants instead of lignite and hard coal plants is more prevalent than in Greece and Germany.

As mentioned above, the process of waste combustion has more significant impact to greenhouse effect than the other considered processes.

In both combustion methods (RDF combustion and mass burning), the Greek case presents the lowest GWP impact regarding the process of waste combustion, as a result of the higher content of biogenic carbon in comparison with the other cases. Furthermore, the Greek case presents avoided GWP impact for both waste combustion scenarios due to the combination of high biogenic carbon content with high fossil carbon technologies currently used for energy production.

The French case does not present avoided emissions in the process of waste combustion, since the energy production in the country is based on nuclear plants. Similarly, the waste combustion to energy process in the German mass burning case is estimated to contribute at a higher rate than an average energy plant of present time. Regarding the case of RDF combustion, the German scenario slightly presents avoided emissions for the referred process.

The methodology of the overall GWP is based on the calculation of direct emissions except for those which correspond to avoided energy emissions (e.g., emissions from waste combustion process), the avoided energy emissions and the saving emissions (avoided material).

Based on this calculation method, in the mass burning scenario the Greek case presents the lowest GWP impact. Furthermore, mass burning in the French case does not present any avoided emissions, because of the low average emission factor of the country’s energy mix.

On the other hand, as far as the RDF combustion scenario is concerned, the Greek case study presents the lowest GWP impact, since the energy mix characteristics are introduced.

Sensitivity Analysis

The main assumption made in the basic scenario is the configuration of optical separators for recovering materials. The most valuable materials separated through the operation of optical separators are paper and plastic. Hence, case studies based on the different setup of optical separators are carried out in this section. The results are presented in Figs. 5 and 6, including direct and avoided emissions to GWP impact. The scenarios are based on different configuration of the optical separators in separating paper and plastic materials. For each examined scenario, the remaining not separated or additionally separated fraction is added or removed from the fraction of RDF, respectively. Hence, the potential of the optical separators and the resulting produced RDF are summarized in Table 11.

Overall global warming potential impact (t CO2eq/t MSW) for MSW direct combustion and RDF combustion (case A: setup configuration of optical separator for low rate of paper separation, case B: setup configuration of optical separator for normal rate of paper separation, case C: setup configuration of optical separator for high rate of paper separation); the paper separation potential is the examined variable parameter

Overall global warming potential impact (t CO2eq/t MSW) for MSW direct combustion and RDF combustion (case A: setup configuration of optical separator for low rate of plastic separation, case B: setup configuration of optical separator for normal rate of plastic separation, case C: setup configuration of optical separator for high rate of plastic separation); the plastic separation potential is the examined variable parameter

As shown in the following figures, the process of production of paper or plastic has higher contribution to GWP than the process of combustion to energy of the material. Hence, the higher separation of material is achieved, the less environmental impact to greenhouse effect is carried out.

Furthermore in order to include the change of technology in the sensitivity analysis, the electrical efficiency is considered a parameter for further investigation. The results for all case studies are illustrated in Fig. 7. Specifically, by increasing electrical efficiency, more avoided emissions are achieved, as a result of higher potential energy substitution. In the case study of Greece, whereby the energy mix of the country is included in the analysis, the achieved avoided emissions are more than those in the case studies of the other two countries. The change of investment cost has been considered negligible in the calculations of the present study. In a case of techno-economic assessment, this parameter should be included, due to its importance to the final results.

Conclusions

In this work, the LCA methodology was applied to assess the comparison between two different W-t-E options from an environmental perspective; the first one focuses on recovering as many useful materials as possible and producing high-quality RDF in an upstream MBT plant, while the second one considers the combustion of MSW directly after its collection. The results of this study show that the scenario of RDF combustion in combination with recovering materials in a MBT plant has less impact to greenhouse effect than the mass burning scenario, for the same primary flow of waste and same electrical efficiency for the two W-t-E plants, regardless of the energy mix and waste composition of each country. However, in Greece the MSW incineration scenarios perform lower impacts than the respective scenario of RDF combustion in combination with recovering materials for electricity efficiencies at 25–30 %. This occurs due to the overcome of the benefits from the energy produced in comparison with the respective environmental advantages from the recovery of materials. In Greece, the mass burning option presents lower impact than that of the respective analysis in France and Germany. This is due to rich in organic fraction composition of waste, which is a result of limited source separation practices of organic MSW fraction in Greece. In Greece, the avoided emissions appear more significant than those in the case studies of the other two countries, due to the fact that the Greek energy mix is mainly characterized by lignite power plants, something that eventually results in the substitution of electricity produced along with considerable greenhouse gas emissions. On the other hand, France presents the lowest avoided impact to greenhouse effect, due to the operation of nuclear power plants. Sensitivity analysis was performed on the basic parameters of the scenarios, namely the separating rate of valuable materials, such as paper and plastic, and the technology modeling in the electrical efficiency. The sorting of materials appears to be a more environmentally sustainable practice than their combustion, following the principles of waste management hierarchy. The option of higher separating fraction leads to less impact in terms of GWP, while the optimization of technology, through the increase in electrical efficiency of a W-t-E plant, results in higher avoided emissions. This becomes even more evident in the case of Greece due to the high average emission factor resulting from the mix of power plants. The final conclusion from the comparison between the RDF combustion scenario and mass burning scenarios is that the former has less impact to greenhouse effect and is easier to be accepted by the local society, since it is combined with an associated recycling process. On the other hand, the MSW combustion is more attractive than RDF combustion when power plant capacity is considered. To summarize, based on the evaluation done in this paper, GHG emissions from waste combustion could be minimized primarily by lowering the needs for energy and on the other hand by increasing the energy recovery from the waste as much as possible. The local energy mix determines both the GHG emissions as a result of the provision of electricity used in a MSWI plant and the GHG savings owing to the production of electricity by MSWI. The environmental friendly incentives can lead to the promotion of the construction of waste-to-energy plants in areas, where the use of fossil fuels as energy resources is dominant. This target can be achieved through the establishment of competitive feed-in-tariff values on the national legislative framework of each country.

The choice between the two processes relies solely upon the needs that should be met on specific occasions (e.g., use of the heat in nearby processes or district heating). Further refinement of the processes described may be achieved by incorporating specific changes, one of them being the location of the RDF combustion plant in the same site with the MBT plant, and using the air from the biological treatment as primary combustion air, instead of using additional energy in the form of natural gas for the elimination of volatile organic compounds, which cause odors.

Abbreviations

- eq:

-

Equivalent

- e:

-

Electrical

- NG:

-

Natural gas

References

European Commission: Directive EC 2008/98 http://ec.europa.eu/environment/waste/framework/ (2008). Accessed on 30 Aug 2013

Rigamonti, L., Grosso, M., Giugliano, M.: Life Cycle assessment for optimizing the level of separated collection in integrated MSW management systems. Waste Manag. 29(2), 934–944 (2009)

Stehlík, P.: Up-to-date technologies in waste to energy field. Rev. Chem. Eng. 28, 223–242 (2012)

CEN/TC 343 2006, CEN/TS 15359:2006 Solid recovered fuels—specifications and classes, European Committee for Standardisation, Technical Committee CEN/TC 343

European Recovered Fuel Organization (ERFO). http://erfo.info/ (2010). Accessed 7 Mar 2015

European Commission: Energy and Environmental Statistics. Published by Eurostat. http://epp.eurostat.ec.europa.eu/portal/page/portal/eurostat/home/. Accessed on 5 Sept 2013

Assamoi, B., Lawryshyn, Y.: The environmental comparison of landfilling vs. incineration of MSW accounting for waste diversion. Waste Manag. 32(5), 1019–1030 (2012)

Yang, N., Zhang, H., Chen, M., Shao, L.-M., He, P.-J.: Greenhouse gas emissions from MSW incineration in China: impacts of waste characteristics and energy recovery. Waste Manag. 32, 2552–2560 (2012)

Consonni, S., Giugliano, M., Grosso, M.: Alternative strategies for energy recovery from municipal solid waste. Part A: mass and energy balances. Waste Manag. 25, 123–135 (2005)

Ekvall, T., Assefa, G., Bjorklund, A., Ericksson, O., Finnveden, G.: What life cycle does and does not do in assessments of waste management. Waste Manag. 27, 986–996 (2007)

Liamsanguan, Ch., Gheewala, HSh: LCA: a decision support tool for environmental assessment of MSW management systems. J. Environ. Manag. 87(1), 132–138 (2008)

De Feo, G., Malvano, C.: The use of LCA in selecting the best MSW management system. Waste Manag. 29(6), 1901–1915 (2009)

Cherubini, F., Bargigli, S., Ulgiati, S.: Life cycle assessment (LCA) of waste management strategies: landfilling, sorting plant and incineration. Energy 34, 2116–2123 (2009)

Blengini, G.A., Fantoni, M., Busto, M., Genon, G., Zanetti, M.C.: Participatory approach, acceptability and transparency of waste management LCAs: case studies of Torino and Cuneo. Waste Manag. 32, 1712–1721 (2012)

Buttol, P., Masoni, P., Bonoli, A., Goldoni, S., Belladonna, V., Cavazzutti, C.: LCA of integrated MSW management systems: case study of the Bologna District. Waste Manag. 27, 1059–1070 (2007)

Cherubini, F., Bargigli, S., Ulgiati, S.: Life cycle assessment of urban waste management: energy performances and environmental impacts. The case of Rome, Italy. Waste Manag. 28, 2552–2564 (2008)

Miliūtė, J.: Application of life cycle assessment in optimization of municipal waste management systems: the case of Lithuania. Waste Manag. Res. 28, 298–308 (2010)

Song, Q., Wang, Z., Li, J.: Environmental performance of municipal solid waste strategies based on LCA method: a case study of Macau. J. Clean. Prod. 57, 92–100 (2013)

Wittmaier, M., Langer, S., Sawilla, B.: Possibilities and limitations of life cycle assessment (LCA) in the development of waste utilization systems—applied examples for a region in Northern Germany. Waste Manag. 29(5), 1732–1738 (2009)

Woon, K.S., Lo, M.C.: Greenhouse gas accounting of the proposed landfill extension and advanced incineration facility for municipal solid waste management in Hong Kong. Sci. Total Environ. 458–460, 499–507 (2013)

Cimpan, C., Wenzel, H.: Energy implications of mechanical-biological treatment compared to direct waste-to-energy. Waste Manag. 33, 1648–1658 (2013)

Bjarnadóttir, H., Friðriksson, G., Johnsen, T., Sletsen, H.: Guidelines for the use of LCA in the waste management sector. Published by Nordtest. http://infohouse.p2ric.org/ref/37/36469.pdf. Accessed 20 Jan 2014

ISO 14041-14044. Environmental Management. Life Cycle Assessment. Requirements and Guidelines (2006)

Skovgaard, M., Hedal, N., Villanueva, A, Andersen, F.M., Larsen, H.: Municipal waste management and greenhouse gases. Publishing in ETC/RWM working paper. http://www.risoe.dk/rispubl/art/2008_27.pdf (2008). Accessed 10 Jan 2014

Consonni, S., Giugliano, M., Grosso, M.: Alternative strategies for energy recovery from municipal solid waste: part B: emission and cost estimates. Waste Manag. 25(2), 137–148 (2005)

European Commission, 2007. Commission Decision of 18 July 2007 establishing guidelines for the monitoring and reporting of greenhouse gas emissions pursuant to Directive 2003/87/EC of the European Parliament and of the Council (notified under document number C(2007) 3416)

Intergovernmental Panel on Climate Change (IPCC). http://www.ipcc.ch (2007)

Scipioni, A., Mazzi, A., Niero, M., Boatto, T.: LCA to choose among alternative design solutions: the case study of a new Italian incineration line. Waste Manag. 29(9), 2462–2474 (2009)

Hellenic Ministerial Decision (HMD). 50910/2727/2003 (Government Gazette1909/22.12.2003), Rules and Terms for the Solid Waste Management, National and Regional Management Plan; 2003 [in Greek]

Koufodimos, G., Samaras, Z.: Waste management options in southern Europe using field and experimental data. Waste Manag. 22, 47–59 (2002)

Minoglou, M., Komilis, D.: Optimizing the treatment and disposal of municipal solid wastes using mathematical programming—a case study in a Greek region. Resour. Conserv. Recycl. 80, 46–57 (2013)

Beylot, A., Villeneuve, J.: Environmental impacts of residual Municipal Solid Waste Incineration: a comparison of 110 French incinerators using a life cycle approach. Waste Manag. 33(12), 2781–2788 (2013)

Muhle, S., Balsam, I., Cheeseman, C.R.: Comparison of carbon emissions associated with municipal solid waste management in Germany and the UK. Resour. Conserv. Recycl. 54, 793–801 (2010)

Reimann, D.O.: CEWEP Energy Reports III (status 2007–2010): results of Specific Data for Energy, R1 Plant Efficiency Factors and NCV of 314 European W-t-E Plants. CEWEP, Bamberg (2012)

Grosso, M., Motta, A., Rigamonti, L.: Efficiency of energy recovery from waste incineration in the light of the new Waste Framework Directive. Waste Manag. 30, 1238–1243 (2010)

European Commission, 2006. Reference Document on the Best Available Techniques for Waste Incineration. http://eippcb.jrc.ec.europa.eu/reference Accessed Feb 2014

Consonni, S., Vigano, F.: Waste gasification vs. conventional Waste-To-Energy: a comparative evaluation of two commercial technologies. Waste Manag. 32, 663–666 (2012)

IPCC 2006: IPCC Guidelines for National Greenhouse Gas Inventories. In: Waste, vol. 5 Available from World Wide Web: http://www.ipcc-nggip.iges.or.jp/public/gp/english. Accessed Feb 2014

Astrup, T., Moller, J., Fruergaard, J.: Incineration and co-combustion of waste: accounting of greenhouse gases and global warming contributions. Waste Manag. Res. 27(8), 789–799 (2009)

AEA: UK Greenhouse Gas Inventory, 1990–2004: Annual Report for Submission Under the Framework Convention on Climate Change. DEFRA, UK (2006)

Velis, C.A., Longhurst, P.J., Drew, G.H., Smith, R., Pollard, S.J.T.: Biodrying for mechanical-biological treatment of wastes: A review of process science and engineering. Bioresour. Technol. 100(11), 2747–2761 (2009)

Merrild, H., Damgaard, A., Christensen, T.H.: Recycling of paper: accounting of greenhouse gases and global warming contributions. Waste Manag. Res. 27, 746–753 (2009)

Astrup, T., Fruergaard, T., Christensen, T.H.: Recycling of plastic: accounting of greenhouse gases and global warming contributions. Waste Manag. Res. 27, 763–772 (2009)

Prognos in Co-operation with institute of Environmental research university of Dortmund: Resource savings and CO2 reduction potential in waste management in Europe and the possible contribution to the CO2 reduction target in 2020, Final report. http://www.prognos.com/fileadmin/pdf/publikationsdatenbank/SUMMARY_Resource_savingsand_CO2_reduction_potentials_200810.pdf (2008). Accessed on 30 Aug 2013

Damgaard, A., Larsen, A.W., Christensen, T.H.: Recycling of metals: accounting of greenhouse gases and global warming contributions. Waste Manag. Res. 27, 773–780 (2009)

Larsen, A.W., Merrild, H., Christensen, T.H.: Recycling of glass: accounting of greenhouse gases and global warming contributions. Waste Manag. Res. 27, 754–762 (2009)

Heyer, K.-U., Hupe, K., Stegmann, R.: Methane emissions from MBT landfills. Waste Manag. 33, 1853–1860 (2013)

Harborth, P., Fuss, R., Munnich, K., Flessa, H., Fricke, K.: Spatial variability of nitrous oxide and methane emissions from an MBT landfill in operation: strong N2O hotspots at the working face. Waste Manag. 33, 2099–2107 (2013)

Obersteiner, G., Binner, E., Mostbauer, P., Salhofer, S.: Landfill modeling in LCA—a contribution based on empirical data. Waste Manag. 27(8), 58–74 (2007)

Devera, S.A., Swarbricka, G.E., Stuetza, R.M.: Passive drainage and biofiltration of landfill gas: Australian field trial. Waste Manag. 27, 277–286 (2006)

Manfredi, S., Tonini, D., Christensen, T.H., Scharff, H.: Landfilling of waste: accounting of greenhouse gases and global warming contributions. Waste Manag. Res. 27, 825–836 (2009)

Kong, D., Shan, J., Iacoboni, M., Maguin, S.R.: Evaluating greenhouse gas impacts of organic waste management options using life cycle assessment. Waste Manag. Res. 30(8), 800–812 (2012)

Seventeenth Ordinance on the Implementation of the Federal Immission Control Act (Ordinance on Waste Incineration and Co-Incineration-17. BlmSchV), of November 1990 (Federal Law Gazette I p. 2545, 2832) corrected on 14 August 2003 (Federal Law Gazette I p. 1633)

CEN/TS 15440 Technical Specification. Solid recovered fuels-Method for the determination of biomass content (2006)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kourkoumpas, DS., Karellas, S., Kouloumoundras, S. et al. Comparison of Waste-to-Energy Processes by Means of Life Cycle Analysis Principles regarding the Global Warming Potential Impact: Applied Case Studies in Greece, France and Germany. Waste Biomass Valor 6, 605–621 (2015). https://doi.org/10.1007/s12649-015-9367-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-015-9367-2