Abstract

Earthworms have been successfully used in the vermicomposting of different organic residues to produce vermicompost. Therefore, three different earthworm species Eisenia fetida, Eudrilus eugeniae, Perionyx excavates were utilized for the conversion of dewatered sludge (DS) of pulp and paper mill into stable compost. DS was mixed with saw dust (SD) in four different proportions such as (50:50, 60:40, 70:30 and 80:20). Stability analysis of compost was study by stability parameters i.e. C/N ratio, oxygen uptake rate, CO2 evolution and biodegradable organic matter. Compost stability studies revealed that the final compost became stable in all proportions with every earthworm species. However the substrate combination of DS and SD (70:30) proved to be the best mixture on an overall basis with earthworm species E. fetida.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

India has a large network of pulp and paper mills of varying capacity. On an industrial scale the waste from paper and pulp mills are managed through destructive methods: landfilling practices and incineration. Both methods lead to the loss of a profitable resource and have obvious environmental and economic disadvantage. The solid wastes produced from pulp and paper mills are interesting sources of organic matter and their proper disposal and management is burden to the industries. But composting/vermicomposting could be an adequate technology for its transformation. The practice of vermiculture is at least a century old but it is now being revived worldwide with diverse ecological objectives such as waste management, soil detoxification and regeneration and sustainable agriculture. Vermicomposting is a decomposition process involving interactions between earthworms and microorganisms and it is an economical, viable and sustainable option for waste management. It is easy to operate and can be conducted in contained space to produce a good quality product (compost). Earthworms have been successfully used in the vermicomposting of urban, industrial and agricultural wastes in order to produce organic fertilizers and obtain protein for animal feed. Several epigeics (Eisenia fetida, Eisenia andrei, Eudrilus eugeniae, Perionyx excavatus and Perionyx sansibaricus) have been identified as potential candidates to decompose organic waste materials [1, 2]. Research into the potential use of earthworms to break down and manage solid waste began in the late 1970’s and the use of earthworms in sludge management has been termed vermicomposting or vermistabilization [3]. In its basic form, this is a low-cost technology system that primarily uses earthworms in the processing or treatment of organic wastes [4]. Biological conditioning of wastes through vermitechnology has multiple advantages however; India has yet to appreciate the full importance of vermitechnology despite the potential for the production of 400 tonne of vermicompost annually from waste degradation [5]. Vermicomposting, the microbial composting of organic wastes through earthworm activity, has proved to be successful in processing sewage sludge and solids from wastewater [3], paper wastes [6], urban food and garden residues, animal wastes [7]. In 1998, the Government of India announced exemption from the tax liability to all those institutions, organizations and individuals in India practicing vermiculture on a commercial scale. Earthworms have been successfully utilized by several researchers for stabilization of wastes generated from different industries [2, 8–15].There are also a few studies dealing with vermicomposting process of dewatered sludge coming from effluent treatment plant of pulp and paper mill. Compost quality is an important issue since compost is thought to be beneficial for both agriculture and the environment. Stability is an important aspect of composting in relation to its field application, potential of odor generation and pathogen regrowth [16, 17]. Stability prevents nutrients from becoming tied up in rapid microbial growth, allowing them to be available for plant needs. Unstable compost can show phytotoxic behavior and therefore affect crops. This is due to the occurrence of toxic substances produced due to an insufficient biodegradation of organic compounds [18]. Therefore, it is essential to prove the stability of compost to ensure about the technology and operational performance. Information on stability of compost in vermicomposting, for the mixed organic wastes is rather limited. Hence, it is essential to check the stability to asses the composting process within vermicomposting process.

Compost requires to be matured and stable at the end of the composting period so that it can be applied directly in the fields. Biological stability indicates the extent to which readily biodegradable organic matter has decomposed [19]. Hence, in this paper efforts were made to feasibility of the dewatered sludge spiked with saw dust for producing a matured and stable end product through vermicomposting.

This study examines the efficiency of three earthworm species E. fetida, E. eugeniae, P. excavates in bioconverting dewatered sludge of pulp and paper mill mixed with saw dust. The earthworm growth and reproductivity were evaluated and compared with the changes in stability parameters of this mixture in the presence and absence of earthworms.

Materials and Methods

Compost Material

Dewatered sludge (DS) and saw dust (SD) were used for preparation of different waste mixtures. DS was collected form effluent treatment plants of Nagaon Paper Mill, Kagajnagar, India. SD was used as a bulking agent (it is accepted world wise as a bulking agent) with DS for increasing nitrogen content in vermicompost. The physico-chemical properties of DS were 6.82 ± 0.01 of pH, 71.2 ± 1.2 % of moisture content, 31.6 ± 1.7 % of total organic carbon, 6.4 ± 0.8 g/kg of total nitrogen, 18.9 ± 0.5 (mg/g (volatile solid) VS/day) of oxygen uptake rate and 8.72 ± 0.84 (mg/g VS/day) of CO2 evolution.

Culturing of Earthworms

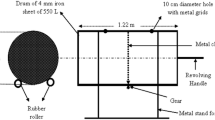

For developing the cultures, Perspex bin sizes 450 × 300 × 450 mm were fabricated in the laboratory. For aeration and drainage purpose 16 holes of 10 mm diameter were drilled along the longer sides and 16 at the bottom respectively. Hopper with steel frame was used to collect the leachate (if any) (Fig. 1). Before the addition of the culturing media and the earthworms, bedding was prepared from chopped hay (about 50 mm), cow dung, banana pulp (chopped about 50 mm), tree leaves all are partially degraded. The bedding was then watered to keep it moist to enable the worms to breathe. The earthworm species were then added and partially degraded cow dung was added for culturing the earthworms.

Experimental Setup

The experiments were conducted in triplicate, in locally made bamboo containers (reactor) of volume 90.47 × 104 mm3 (radius-120 mm and depth-90 mm) (Fig. 1). The containers were kept in the laboratory at room temperature. 10 cm bedding was kept in all the containers using a mixture of hay (155 g), CD (375 g), banana leaves and tree leaves (280 g) respectively which were partially degraded for 2 weeks. Approximately 50 g (~100–120 in numbers) of earthworms (E. fetida, E. eugeniae, P. excavates) having both clitellated and juvenile, were inoculated in the bedding for acclimatization of the earthworms to the new environment then the substrate was added the next day on the top.

1.5 kg of four different mixtures of DS, SD (Table 1) was added to each of the containers. Reactors for each mixture were kept without earthworms which were referred to as Control. The reactors with E. fetida were referred to as Rf1, Rf2, Rf3 and Rf4 respectively while the controls were referred to as CRf1, CRf2, CRf3 and CRf4. The reactors with E. eugeniae were referred to as Re1, Re2, Re3 and Re4 and its respective controls as CRe1, CRe2, CRe3 and CRe4. The reactors with P. excavatus were referred to as Rp1, Rp2, Rp3 and Rp4 respectively, while the controls were referred to as CRp1, CRp2, CRp3 and CRp4 respectively. The mixing proportion DS, SD are reported in Table 1. The quantity of the substrate was decided based on the findings that the earthworms can consume the material half their body weight per day under favorable conditions [20]. The moisture level was maintained about 50–60 % throughout the study period by periodic sprinkling of adequate quantity of tap (potable) water. To prevent moisture loss, the reactors were covered with gunny bags.

Parameters Analysis

About 110 g of homogenized wet samples (free from earthworms, hatchlings and cocoons) were taken out at 0, 15th, 30th and 45th day of composting period. The 0 days refers to the sample taken out before earthworm inoculation. Wet samples were used for the analysis of stability parameters i.e. oxygen uptake rate (OUR), CO2 evolution as described in [21], biochemical oxygen demand (BOD) and chemical oxygen demand (COD) [22]. Dry samples were analyzed for total organic carbon content according to [23] and percentage of nitrogen content was calculated using Kjeldahl method. Finally, carbon-to-nitrogen (C/N) ratio was determined by dividing the total organic carbon content to the total nitrogen content. In addition earthworm growth related parameters like earthworm biomass; and total mortality were measured at the end of every 15th day of the experiment.

Statistical Analysis

All results reported are the means of three replicate. The results were statistically analyzed at 0.05 levels using one way analysis of variance (ANOVA) and Tukey’s HSD test was used as a post hoc analysis to compare the means using Statistica software.

Results and Discussion

C/N Ratio

The parameter traditionally considered to determine the degree of maturity of compost and to decline its agronomic quality is the C/N ratio. The trend in the change in C/N ratio was observed to be similar in all the earthworm reactors. From the results it was observed that all the three earthworm species worked equally well with similar results. The maximum change in C/N ratio was observed in Rf 3 (3.24 folds) followed by Rf 4 (3.19 folds) and Rf 2 (2.78 folds) at the end of composting period (Fig. 2). The decrease in C/N ratio was in the range of 1.5 folds in all the composting reactors. For the reactors with E. eugeniae species of earthworm the change in C/N ratio was as follows Re3 (3.13 folds) followed by Re4 (2.94 folds) and Re2 (2.62 folds) respectively. For the reactors with P. excavatus species of earthworm the change in C/N ratio was as follows Rp3 (2.85 folds) followed by Rp4 (2.55 folds) and Rp2 (2.52 folds) respectively. Reduction of C/N ratio was observed more in every vermicompost as compared to control reactors composts. The change in the ratio of different substrates did not seem to affect the C/N ratio. Ratio of C/N decreased, which indicated the changes in total carbon and higher levels of nitrogen in the vermicompost [24]. The decrease in C/N ratio over time might also be attributed to the increase in the earthworm population [25]. All the reactors with earthworms showed a C/N ratio less than 20. It is believed that a C/N ratio below 20 is indicative of acceptable maturity, while a ratio of 15 or lower being preferable [26]. C/N ratio varied significantly for all vermicompost and compost (P < 0.05) on all sampling days.

CO2 Evolution Rate

The highest decrease in rate of respiration activity observed during initial phases of composting periods. The reduction trend for all the reactors seemed to be similar however the different substrate combinations seem to affect the earthworm species as seen from the results. Comparisons among the reactors with different earthworm species showed that the reactors with the earthworm species E. fetida had the least value of CO2 evolution rate at the end of the composting period with a value of 0.56 for Rf1, 0.84 for Rf2, 0.72 for Rf3 and 0.36 for Rf4 respectively. The highest CO2 reduction was observed in Rf4 (27.72 folds) followed by Rf1 (24.35 folds) and Rf3 (14.83 folds) at the end of composting period. The highest CO2 reduction in reactors with E. eugeniae earthworm was observed in Re4 (17.2 folds) followed by Re1 (14.2 folds) and Re3 (12.41 folds) at the end of composting period. In P. excavatus earthworm reactors highest CO2 reduction was observed in Rp4 (14.67 folds) followed by Rp1 (12.99 folds) and Rp3 (11.86 folds) at the end of composting period (Fig. 3). Similar observation was made by earlier researchers also [21, 27]. Reduction of CO2 evolution was observed more in every vermicompost as compared to control reactors composts. CO2 evolution correlates directly with aerobic respiration and hence aerobic biological activity [28]. Insufficient mature compost has a strong demand of O2 and high CO2 production rates, due to intense development of microorganisms as a consequence of the abundance of easily biodegradable compounds in the raw material. For this reason, O2 consumption and CO2 production are indicative of compost stability and maturity [28]. Oxygen uptake and CO2 evolution are more direct and have been described as being opposite sides of the same equation under aerobic conditions [29]. All are significant (P < 0.05) at the end of composting period.

Oxygen Uptake Rate (OUR)

Oxygen uptake rate is commonly used as stability index and most accepted method for the determination of biological activity of a material. It measures stability by evaluating the amount of readily biodegradable organic matter still present in the sample through its carbonaceous oxygen demand [14]. Kalamdhad and Kazmi [30] found OURs to be high in active stage of composting, as microbes grow rapidly from digesting readily biodegradable substrate. As composting begins, large organic molecules are broken down to smaller, soluble ones and temporarily more substrate may become available. The highest OUR reduction in E. fetida reactors was observed in Rf1 (5.34 folds) followed by Rf 2 (5.06 folds) and Rf 3 (3.69 folds) at the end of composting period (Fig. 4). The highest OUR reduction in E. eugeniae reactors was observed in Re3 (5.8 folds) followed by Re4 (4.59 folds) and Re2 (4.29 folds) at the end of composting period. In P. excavatus reactors highest OUR reduction was observed in Rp3 (7.11 folds) followed by Rp4 (4.18 folds) and Rp2 (4.01 folds) at the end of composting period. Khwairakpam and Bhargava [14] have also reported similar results. Comparisons among the reactors with different earthworms showed that the OURs were least in Rp3 with a value of 2.0 mg/g VS/day; followed by Rf1 with a value of 2.1 mg/g VS/day; followed by Rf2 with a value of 2.9 mg/g VS/day; followed by Re4 with a value of 3.1 mg/g VS/day, respectively. Reduction of OURs was observed more in every vermicompost as compared to control reactors composts. OURs for all vermicompost and compost was statistically significant (P < 0.05) at the end of composting period.

Soluble BOD and COD

It is generally recognized that the percentage of readily biodegradable organic matter is an important aspect of compost quality. According to Wang et al. [31] while compost is applying to the soil for crop use, care should be taken because the biological processes will continue and can strip the nutrients of soil even though after stabilization of compost. Hence BOD is an important parameter to monitor. Reduction of soluble BOD and COD were observed more in every vermicompost as compared to control reactors composts. The highest BOD reduction was observed in Rf2 (4.54 folds) followed by Rf4 (4.35 folds) and Rf3 (4.3 folds) at the end of composting rectors with E. fetida earthworm. The highest BOD reduction during E. eugeniae reactors was observed in Re3 (3.22 folds) followed by Re4 (2.7 folds) and Re2 (2.42 folds) at the end of composting period (Fig. 5). In P. excavatus reactors highest BOD reduction was observed in Rp3 (3.01 folds) followed by Rp2 (2.94 folds) and Rp1 (2.91 folds) at the end of composting period. Kalamdhad and Kazmi [30] have reported 46–64 % reduction in BOD in case of rotary drum composting which was slightly less than the vermicomposting. Comparisons among the different reactors with different earthworm species showed that minimum reduction in BOD was in the following manner Rf2, Rf1, Rf3, Rf4 with values 5.7, 6.3, 6.5, 6.7 mg/kg at the end of the composting period. Decrease in COD was observed by other workers also [14]. The highest COD reduction was observed in Rf 3 (5.77 folds) followed by Rf1 (5.37 folds) and Rf2 (5.27 folds) at the end of composting period (Fig. 6). The highest COD reduction (in E. eugeniae reactors) was observed in Re3 (5.47 folds) followed by Re1 (5.25 folds) and Re4 (4.92 folds) at the end of composting period. The highest COD reduction (in P. excavatus reactors) was observed in Rp1 (5.43 folds) followed by Rp3 (5.26 folds) and Rp4 (4.69 folds) at the end of composting period. Comparisons among the different reactors with different earthworm species showed that minimum reduction in COD was in the following manner Rf3, Re4, Rf 2, Rp1 with values of 119, 124, 133, 145 mg/kg at the end of the composting period. The difference in BOD and COD in the end product obtained was significant (P < 0.05) for the entire samples.

Growth and Reproduction of Earthworms

According to Chaudhari and Bhattacharjee [32] the size of earthworm population and their rate of growth as well as fecundity depend upon the amount of food present. The vermicompost was dark brown in color and homogenous after 45 days of earthworm activity. The earthworm biomass had increased in all vermicompost as days increased. Maximum percentage live biomass change was in the order viz., Rf3 (58.33), Rf2 (52.38), Rf1 (48.97), Re3 (48.45) respectively (Table 2). For the reactors with E. fetida maximum percentage change in earthworm biomass was observed in Rf3 (58.33), Rf2 (52.38), Rf1 (48.97), Rf4 (45.05) respectively. For the reactors with E. eugeniae maximum percentage change in earthworm biomass was observed in Re3 (48.45), Re2 (37.39), Re1 (34.78), Re4 (31.00) respectively. For the reactors with P. excavatus maximum percentage change in earthworm biomass was observed in Rp3 (46.23), Rp2 (41.17), Rp1 (18.03), Rp4 (1.96) respectively. Comparison among all the reactors, the cocoon production in the vermicompost was observed maximum in the reactors with E. fetida. Hatching of juveniles were more, it indicated that cocoon productions were higher before 45 days. On an overall the earthworm species E. fetida proved to be the best on account of biomass increment as well as juveniles hatched when compared with the other earthworm species.

Conclusion

The efficiency of vermicomposting process was found maximum in the reactors with earthworm species E. fetida while the reactors with earthworm species E. eugeniae and P. excavatus worked almost similarly. The substrate combination of DS and SD (70:30) proved to be the best mixture on an overall basis. The vermicompost obtained from all the reactors were matured and stable as confirmed by the CO2 evolution rate and OUR results. The value added matured end product can be directly used in the fields. All earthworm species worked equally well, the best results could be obtained from the reactors with earthworm species E. fetida in terms of earthworm biomass and juveniles.

References

Wong, S.H., Griffiths, D.A.: Vermicomposting in the management of pig-waste in Hong Kong, world. J. Microbiol. Biotechnol. 7, 593–595 (1991)

Suthar, S.: Vermicomposting potential of Perionyx sansibaricus (perrier) in different waste materials. Bioresour. Technol. 98(6), 1231–1237 (2007)

Neuhauser, E.F., Loehr, R.C., Malecki, M.R.: The potential of earthworms for managing sewage sludge. In: Edward, C.A & Neuhauser E.F. (eds.) Earthworms in Waste and Environmental Management. SPB Academic Publishing, The Hague, the Netherlands; ISBN. 90-5103-017-7 (1988)

Hand, P.: Earthworm biotechnology. In: Greenshields, R. (ed.) Resources and application of biotechnology. The New Wave Mac-Millan Press Ltd., US (1988)

Sinha, R.K.: Vermiculture biotechnology for waste management and sustainable agriculture. In: Sinha, R.K. (ed.) Environmental crisis and human’s at risk, pp. 233–240. INA Shree Publication, India (1996)

Elvira, C., Sampedro, L., Benítez, E., Nogales, R.: Vermicomposting of sludges from paper mill and dairy industries with eisenia andrei: a pilot-scale study. Bioresour. Technol. 63(3), 205–211 (1998)

Domínguez, J., Edwards, C.A.: Effects of stocking rate and moisture content on the growth and maturation of eisenia andrei (oligochaeta) in pig manure. Soil Biol. Biochem. 29, 743–746 (1997)

Elvira, C., Goicoechea, M., Sampedro, L., Mato, S., Nogales, R.: Bioconversion of solid paper-pulp mill sludge by earthworms. Bioresour. Technol. 57(2), 173–177 (1996)

Taylor, M., Clarke, W.P., Greenfield, P.F.: The treatment of domestic wastewater using small-scale vermicompost filter beds. Ecol. Eng. 21, 197–203 (2003)

Suthar, S.: Potential utilization of guar gum industrial waste in vermicompost production. Bioresour. Technol. 97(18), 2474–2477 (2006)

Suthar, S.: Bioconversion of post-harvest crop residues and cattle shed manure into value-added products using earthworm Eudrilus eugeniae kinberg. Ecol. Eng. 32(3), 206–214 (2008)

Suthar, S., Singh, S.: Comparison of some novel polyculture and traditional monoculture vermicomposting reactors to decompose organic wastes. Ecol. Eng. 33, 210–219 (2008)

Khwairakpam, M., Bhargava, R.: Bioconversion of filter mud using vermicomposting employing two exotic and one local earthworm species. Bioresour. Technol. 100, 5846–5852 (2009)

Khwairakpam, M., Bhargava, R.: Vermitechnology for sewage sludge recycling. J. Hazard. Mater. 161, 948–954 (2009)

Kaur, A., Singh, J., Vig, A.P., Dhaliwal, S.S., Pushpinder, J.R.: Cocomposting with and without eisenia fetida for conversion of toxic paper mill sludge to a soil conditioner. Bioresour. Technol. 101(21), 8192–8198 (2010)

Miller, F.C.: Minimizing odor generation. In: Hoitink, H.A.J., Keener, H.M. (eds.) Science and engineering of composting, pp. 219–241. Ohio University, Stentiford, OH (1993)

Zucconi, F., Monaco, A., Forte, M., De Bertoldi, M.: Phytotoxins during the stabilization of organic matter. In: Grasser, J.K.R. (ed.) Composting of agricultural and other wastes, pp. 73–86. Elsevier, Amsterdam (1985)

Brodie, H.L., Francis, R.G., Lewis, E.C.: What makes good compost? BioCycle 35, 66–68 (1994)

Lasaridi, K.E., Stentiford, E.I.: A simple respirometric technique for assessing compost stability. Water Res. 32, 3717–3723 (1998)

Haimi, J., Huhta, V.: Capacity of various organic residues to support adequate earthworm biomass for vermicomposting. Biol. Fertil. Soils 2, 23–27 (1986)

Kalamdhad, A.S., Pasha, M., Kazmi, A.A.: Stability evalutation of compost by respiration techniques in a rotary drum composter. Resour. Conserv. Recycl. 52, 829–834 (2008)

APHA: Standard methods for the examination of water and wastewater. 17th (eds.), American Public Health Association, Washington DC (1995)

Mohee, R., Driver, M.F.B., Sobratee, N.: Transformation of spent broiler litter from exogenous matter to compost in as sub-tropical context. Bioresour. Techol. 99(1), 128–136 (2008)

Vinceslas-Akpa, M., Loquet, M.: Organic matter transformations in lignocellulosic waste products composted or vermicomposted (Eisenia fetida anderei): chemical analysis and 13C CPMAS NMR spectroscopy. Soil Biol. Biochem. 29(3/4), 751–758 (1997)

Ndegwa, P.M., Thompson, S.A.: Effects of C-to-N ratio on vermicomposting of biosolids. Bioresour. Technol. 75(1), 7–12 (2000)

Morais, F.M.C., Queda, C.A.C.: Study of storage in xuence on evolution of stability and maturity properties of MSW composts. In: Proceedings of the fourth international conference of ORBIT association on biological processing of organics: advances for a sustainable society part II. Perth. Australia (2003)

Kalamdhad, A.S., Kazmi, A.A.: Effects of turning frequency on compost stability and some chemical characteristics during rotary drum composting. Chemosphere 74, 1327–1334 (2009)

Hue, N.V., Liu, J.: Predicting compost stability. Compost Sci. Util. 3, 8–15 (1995)

Iannotti, D.A., Pang, T., Toth, B.L., Elwell, D.L., Keener, H.M., Hoitink, H.A.J.: A quantitative respirometric method for monitoring compost stability. Compost Sci. Util. 1, 52–65 (1993)

Kalamdhad, A.S., Kazmi, A.A.: Mixed organic waste composting using rotary drum composter. Int. J. Environ. Waste Manage. 2(1/2), 24–36 (2008)

Wang, P., Changa, C.M., Watson, M.E., Dick, W.A., Chen, Y., Hoitink, H.A.J.: Maturity indices for composted dairy and pig manures. Soil Biol. Biochem. 36, 767–776 (2004)

Chaudhari, P.S., Bhattacharjee, G.: Capacity of various experimental diets to support biomass and reproduction of Perionyx excavates. Bioreour. Technol. 82, 147–150 (2002)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sonowal, P., Khwairakpam, M. & Kalamdhad, A.S. Stability Analysis of Dewatered Sludge of Pulp and Paper Mill During Vermicomposting. Waste Biomass Valor 5, 19–26 (2014). https://doi.org/10.1007/s12649-013-9225-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-013-9225-z