Abstract

The objective of this study was to evaluate changes in physical, chemical and biological parameters to assess the maturity and stability of composts prepared from mixture of different organic wastes over a time period of 150 days. Six different composts were prepared using a mixture of different organic wastes with or without enrichment of rock phosphate (RP), microorganism inoculation (MO) and agro-industrial wastes (sewage sludge, pressmud, poultry waste). All the composts attained a constant temperature with no measurable changes (ambient level) at 120 days of composting. Compost maturity should be assessed by measuring two or more compost parameters, and that parameters of compost maturity need to satisfy the following threshold values: organic matter loss >42 %, C:N ratio <15, water soluble organic C (Cw):organic N (Norg) ratio <0.55, humic acid:fulvic acid ratio >1.9, humification index >30 %, cation exchange capacity:total organic carbon ratio >1.7 and germination index >70 %. Ambient temperature, decrease in bacterial and fungal counts along with increase in actinomycetes count and stable at the end of composting could also be used as stability parameters. Composts enriched with RP, MO and agro-industrial wastes matured earlier compared to un-enriched composts. Application of agro-industrial waste composts significantly increased wheat yield compared with addition of their raw materials. Agro-industrial waste composts applied with recommended dose of NK fertilizers produced wheat yield comparable to that obtained with recommended dose of NPK fertilizers, indicating a net saving of 100 % P fertilizer.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Composting of organic wastes is a bio-oxidative process involving the mineralization and partial humification of the organic matter, leading to a stabilized final product, free from phytotoxicity and pathogens [4, 43]. The variability of the organic matter undergoing composting makes compost research challenging. According to an estimate, about 1,688.3 Mt of organic resources are generated yearly in India and that can be recycled through composting [6]. Composting is one of the most effective means of recycling of organic wastes that can be used as a source of soil amendment and organic matter in agricultural land. Composts are considered a valuable product that can be used as a source of soil amendment and organic matter in agricultural land. The application of composted manure has increased over the years. This practice improves the quality of the crops and preserves the environment [15, 23]. However, non-composted manure may have adverse effects on plant growth and/or seed germination [14] because of their wide C:N ratio and production of phytotoxic substances such as phenolic and volatile fatty acids during organic matter decomposition [21]. The need to treat and dispose of organic wastes to reduce potential damage has made compost production and its agricultural application an attractive solution. The composting industry is poised for a new era of growth where the product must be evaluated both for safety and quality purposes. Composts prepared from different organic wastes differ in their quality, which further depends upon the composition of raw material and composting technology used for compost production [30]. Compost quality is closely related to its stability and maturity. Maturity is associated with plant-growth potential or phytotoxicity [17], whereas stability is often related with the compost’s microbial activity. However, both stability and maturity usually go hand in hand, since phytotoxic compounds are produces by the microorganisms in unstable composts [44]. Several parameters have been proposed for evaluating compost maturity and stability [4, 5, 11, 19, 42]. However, there is no single method that can be universally applied to all types of compost due to variation of materials and composting technology [3, 9, 13]. The aims of this study were two fold. The first was to evaluate changes in physical, chemical and biological parameters to determine the maturity and stability of composts prepared from organic wastes; and the second was to study their response to wheat in comparison to their raw materials and chemical fertilizers.

Materials and Methods

The farm wastes [mustard straw, paddy straw, pearl millet boobla (flower glumes and rachilla)] and cattle dung were collected from University research farm; agro-industrial wastes viz. poultry waste (PW), from the University farm; pressmud (PM), a waste by-product, from Co-operative Sugar Mill (Meham, Haryana, India); sewage sludge (SS) from Okhala Sewage Treatment Plant (New Delhi, India); biofertilizer cultures N2 fixing (Azotobacter chroococcum) and phosphate solubilizing (Bacillus polymixa) microorganisms (MO) from Department of Microbiology, CCS Haryana Agricultural University, Hisar, India; and rock phosphate from M/s Pyrites, Phosphates and Chemicals Ltd. (Dehradun, India). The RP contained total P, 9.2 %; water-soluble P, 56 mg kg−1; 0.5 M NaHCO3-soluble P, 180 mg kg−1; 2 % citric-acid soluble P, 3.2 g kg−1; free CaCO3, 11.2 %; and had a pH (H2O) of 7.9. Paddy and mustard straw were chopped into lengths of about 4–6 cm before mixing. Mustard straw, pearl millet boobla (flower glumes and rachilla), paddy straw and cattle dung were mixed in the ratio of 4:1:1:2 (dry weight basis), respectively, to prepare a mixed farm waste (MFW). The MFW was mixed with agro-industrial wastes in a ratio of 2:1 (dry weight basis). The mass of different composting materials and chemical composition of non-composted (raw materials) and composted materials are presented in Tables 1 and 2. To prepare the different composts, composting materials of each treatment in triplicates were weighed separately in polyethylene bags after thorough mixing. After moistening the material, 1 kg each powdered RP (100 mesh) was mixed in all the composting mixtures except composting mixture C1 (MFW + N). The initial C:N ratio of all the composting mixtures was adjusted to 30:1 by adding a solution of urea. Each composting mixture (5 kg) was then inoculated with 150 mL molasses and 250 mL slurry containing 5 % each of fertile soil, well-decomposed compost and fresh cattle dung. Finally, the moisture of all the composting mixtures was maintained at 70 % (by weight). After thorough mixing, composting mixture was put into polyethylene bags and allowed to decompose in the cemented pits (6 m length × 2 m width × 1 m height) for 150 days. A plastic pipe with upper cap was installed in the middle of each bag and temperature was measured daily by placing the thermometer through the plastic pipe. At 70 days of composting when the temperature came down below 45 °C, composting mixtures C3 (Microbial inoculants compost) was inoculated with N2 fixing (Azotobacter chrococcum) and phosphate solubilizing (Bacillus polymixa) microorganism containing 1 × 108 counts per g on dry weight basis. During composting, materials were turned after 8, 15, 30, 60, 90 and 120 days to provide oxygen and promote homogeneity of the materials. Representative compost samples were drawn at 15, 30, 60, 90, 120 and 150 days. Both non-composted (raw materials) and composted materials were analyzed for organic C using dry combustion method [28], total N using the Kjeldahl method [7], total P by developing blue color with ascorbic acid [20]. The rate of organic matter mineralization was measured by determining the loss of organic matter at each time interval. The loss of organic matter was calculated according to the following equation:

where X1 and X2 are the % organic matter at zero (initial) and sampling day, respectively.

The Cw was estimated in a 1:20 ratio of compost–water suspension by chromic acid wet digestion method [40]. The Norg was calculated as the difference between total N and inorganic-N (sum of NH4 +–N and NO3 −–N). The CEC was determined with BaCl2-Triethanolamine method of Lax et al. [24]. HA and FA were determined by extracting compost with 0.1 N NaOH by using the method described by Schlichting and Blume [33]. The HI [5] was defined as humic acid C (CHA) as a percentage of TOC (CHA/TOC × 100). The effect of compost maturity on seed GI was determined with tomato (Lycopersicon esculentum L) seeds, using the method described by Zucconi et al. [45]. Twenty seeds were seeded in triplicate in a petri dish containing filter paper wetted with 3 ml of 1:10 compost:water extract from different composts. A petri dish containing a filter paper wetted with deionized water was kept as a control. After incubation at 25 °C for 5 days, the seed germination percentage and root length of the germinated seeds were recorded. The GI was calculated using the following expression [45]:

Microbial counts were determined by the serial dilution plate technique. Bacteria and actinomycetes were allowed to grow in soil extract agar [1] and fungi on Martin’s rose Bengal agar [25].

Greenhouse Experiment

A greenhouse experiment was conducted to compare the effects of different composts, their raw materials and chemical fertilizer by growing wheat (Triticum aestivum L.) crop in pots. Soil was collected from a field of CCS Haryana Agricultural University, Hisar; air-dried, ground, sieved (2-mm) and analyzed for physico-chemical properties. The soil was loamy sand with: pH (1:2), 8.3; EC (1:2), 0.14 dS−1; organic C, 0.12 %; CEC, 3.10 (cmol (P+) kg−1); available N, 30.3 mg kg−1; available P, 5.12 mg kg−1 and available K, 62.0 mg kg−1. Details of treatments are given in Table 4. Each pot was filled with 4 kg sieved soil, mixed with half of recommended dose of N and full dose of K (at the rate of 60 and 60 kg ha−1, respectively) as basal dose except in treatment T1 (unfertilized control). The remaining half-dose of N (60 kg ha−1) was applied 21 days after sowing. Urea and muriate of potash were used as a source of N and K. All the 150-day-old composts were applied equivalent to 26 kg P ha−1. Farm waste compost (T2) and raw materials of different agro-industrial wastes (T5, T7 and T9) considered as control, were applied on carbon equivalent to their composts. Recommended dose of NPK (T11) applied at a rate of 120-26-50 kg ha−1 was used for comparison. After imposing all the treatments, the soil of each pot was mixed thoroughly and irrigated with deionized water. Ten seeds of wheat (T. aestivum L.) of cultivar cv Sonak were sown in each pot. After germination, five plants were maintained in each pot. The pots were arranged in the greenhouse in a completely randomized design with three replications. The pots were irrigated with measured quantity of deionized water as and when required. The plants were harvested at maturity and data of grain and straw (dry matter) yield was recorded.

Statistical analyses were accomplished using the program STATISTCA 6.0. StatSoft, Inc. (2001). All determinations were carried out in triplicate and LSD values at P = 0.05 were used to determine the significant differences between treatment means. Linear correlations between compost maturity parameters were determined.

Results and Discussion

Temperature

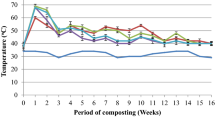

Temperature evolution is an indicator of microbial activity during the composting process. Changes in temperature at various stages of decomposition of different composts are shown in Fig. 1. Temperature of all the composts reached maximum (52–63 °C) within 4–6 days of composting, and reflected rapid initiation of composting process. After 6 days, it decreased gradually but remained in thermophilic range (>45 °C) up to 61–68 days. Later, it further decreased and reached ambient level on 101st day of composting except farm waste (C1) and phospho (C2) composts. The composts enriched with agro-industrial wastes showed more rapid increase in temperature than non-enriched composts. In general, temperature decreased after each turning indicating decrease in easily decomposable organic matter. Therefore, the turning of pile, maintenance of moisture at optimum level and addition of easily available carbon sources are necessary to enhance the microbial activity [35, 38]. The compost indicates a good degree of stability when temperature during composting approaches the ambient level [32]. All the composts attained ambient temperature at 120 days indicating compost stability. As per the criteria established for maturity of compost, the rise in temperature is confirmed by high rate of organic matter decomposition, whereas gradual decrease in temperature indicates the slowdown in microbial activity due to decrease in oxygen, moisture and easily decomposable organic matter.

Organic Matter Loss

The cumulative loss of organic matter increased with composting time in all the composts due to greater availability of easily biodegradable substances to microbes (Fig. 2) [3]. Highest losses of organic matter were observed during first 30 days of composting in all the composts, and slowed thereafter. Maximum losses of organic matter were observed in microbial inoculants (C3) compost followed by pressmud (C5), sewage sludge (C4), phospho (C2), poultry (C6) and farm waste (C1) composts. It indicates that the addition of RP, agro-industrial wastes and inoculation of microorganisms enhanced the rate of organic matter decomposition. The organic matter loss >42 % may be accepted as an index value for mature compost. As per this limit, the microbial inoculants (C3), sewage sludge (C4) and pressmud (C5) composts matured at 120 days and poultry waste (C6) and phosho (C2) composts at 150 days. The farm waste (C1) compost did not mature even at 150 days.

C:N Ratio

The C:N ratio is traditionally used to establish the compost maturity [5]. The relevance of C:N ratio relies on the fact that a decrease in the ratio implies in the degree of humification of organic matter. The C:N ratio of all the compost mixtures decreased substantially up to 120 days, and stabilized thereafter (Fig. 3). The decrease in C:N ratio of all the composts coincides with the increase in loss of organic matter. As the decomposition progressed due to losses of carbon mainly as carbon dioxide, the carbon content of the compostable material decreased with time and N content per unit material increased which resulted in the decrease of C:N ratio. The phospho (C2), microbial inoculants (C3) and agro-industrial waste (C4, C5, C6) composts showed more rapid decrease in C:N ratio than the farm waste (C1) compost. Previous researchers reported that a C:N ratio below 20 was assumed to be indicative of compost maturity [12], and a ratio of 15 or less is preferable [4, 26]. By considering this criterion, microbial inoculants (C3), sewage sludge (C4) and pressmud (C5) composts showed their maturity at 120 days; poultry waste (C6) and phospho (C2) composts at 150 days and farm waste (C1) compost did not mature even at 150 days. At 150 days of composting, highest C:N ratio was recorded in farm waste compost (C1) followed by phospho (C2), microbial inoculants (C3), poultry waste (C6), pressmud (C5) and sewage sludge (C4) compost. The agro-industrial waste composts showed more rapid decrease in C:N ratio as compared to other composts. Addition of agro-industrial wastes as organic additives might have helped in increasing biological activity. On the other hand, some researchers reported that C:N ratio was not a good indicative of mature compost due to large variability in raw materials and often gives a misleading indication of maturity; also, it may not reflect a material which is sufficiently decomposed [34].

Cw:Norg Ratio

The Cw:Norg ratio of all the composts decreased significantly during composting (Fig. 4). The initial ratio varied from 2.67 to 3.48 and decreased to 0.32–0.62 at 150 days of composting. The Cw:Norg ratio <0.70 was considered indicative of mature compost [16]. However, Bernal et al. [5] proposed the Cw:Norg ratio <0.55 to describe well matured and stabilized compost. As per this criterion, microbial inoculants (C3), sewage sludge (C4) and pressmud (C5) composts were matured at 120 days, poultry waste (C6) and phospho (C2) composts at 150 days and farm waste (C1) compost did not mature even at 150 days.

HA:FA Ratio

The HA:FA ratio of all the composts increased significantly with composting time mainly due to decrease in FA production (Fig. 5). The values of HA:FA ratio in the composts at 150 days ranged from 1.78 to 2.95. Generally, fresh and raw composts contain low levels of HA and higher levels of FA compared to mature compost [10], and a similar trend occurred in this study. Iglesias- Jimenez and Perez-Garcia [19] proposed a value of HA:FA ratio >1.9 as a maturity index of city-refuse and sewage-sludge composts. In our study, microbial inoculants (C3), sewage sludge (C4) and pressmud (C5) composts attained values >1.9 at 120 days, poultry waste (C6) and phospho (C2) composts at 150 days, and farm waste (C1) compost did not attain this value even at 150 days. However, Bernal et al. [5] and Veeken et al. [39] reported that HA:FA ratio was not a good indicative of mature compost because of wide variation in composition of raw materials used for composting. The use of composts having a HA:FA ratio more than 1.9 may be more effective and sustainable for the environment and agriculture.

HI

The HI increased during composting showing the humification of organic matter (Fig. 6). Initial HI values of different composts ranged from 4.3 to 6.0 and increased from 13.2 to 36.6 at 150 days. Increase in HI with maturation of compost was also observed by Bernal et al. [5]. In the present study, HI > 30 % may be proposed to assess the maturity of composts prepared using a mixture of different organic wastes. As per this limit, microbial inoculants (C3), sewage sludge (C4), pressmud (C5) and poultry waste (C6) composts matured at 120 days; farm waste (C1) and phospho (C2) composts did not mature even at 150 days.

CEC:TOC Ratio

The CEC:TOC ratio of all the composts increased with composting time (Fig. 7). Initial CEC:TOC ratio varied from 0.38 to 0.71 which increased to 1.25–2.20 at 150 days of composting. Highest ratio (2.20) was observed in sewage sludge (C4) compost and lowest (1.25) in farm waste (C1) compost, indicating their highest and lowest degree of humification. Roig et al. [31] proposed CEC:TOC ratio of 1.7 as the lowest limit for describing compost well humified composts prepared from cattle, sheep, chicken and rabbit manure and this value can be considered as lowest acceptable value prior to their application to the soil. As per this limit microbial inoculants (C3), sewage sludge (C4), pressmud (C5) and poultry waste (C6) composts matured at 120 days, phospho (C2) compost at 150 days, and farm waste (C1) compost did not mature even at 150 days.

GI

GI is a sensitive parameter to evaluate phytotoxicity of composts because phytotoxicity ia s problem associated with immature composts [37, 45]. Such composts may contain various heavy metals; ammonia and/or low molecular weight organic compounds that may reduce seed germination and also inhibit root development [8]. Up to 60 days of composting, the GI of all the composts fluctuated and increased significantly thereafter (Fig. 8). The decrease in GI indicates the presence of phytotoxins in wastes mixtures during composting while an increase reflects the disappearance of phytotoxic substances [44]. The lowest GI values (34.2 %) at 60 days of composting in sewage sludge (C4) compost might be due to release of heavy metals from sewage sludge, which affects root elongation in particular. The lower value (38.9 %) of GI in farm waste (C1) compost at 150 days of composting indicated the presence of phytotoxic substances released during organic matter decomposition. Zucconi et al. [45] reported that the compost with GI values >80 % was phytotoxin-free and considered as having completed maturity [34, 37]. Ko et al. [23] reported that the compost having GI value >110 % was considered mature compost because the GI values reported by previous researchers were not a suitable threshold value for determining the maturity of composted animal manure. However, results obtained using GI should be interpreted with caution, because the GI was affected by the type of seed used and applied extraction rates [5, 36]. In the present study, a GI value >80 % was not seen in any of the compost, but a value >70 % was observed in microbial inoculants (C3), pressmud (C5) and poultry waste (C6) composts at 120 days. Hence, a GI value >70 % may be accepted as an indication for maturity of composts.

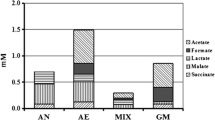

Bacterial Counts

Total bacterial counts decreased significantly with composting time in all the composts except microbial inoculants compost (C3) where an increase was observed after 90 days due to inoculation with N2 fixing (A. chrococcum) and phosphate solubilizing (B. polymixa) microorganisms at 70 days of composting (Fig. 9a). The decrease in bacterial count with time might be due to decrease in water soluble carbon. Highest bacterial counts were observed in microbial inoculants (C3) compost as compared to other composts. Among agro-industrial waste composts, highest counts were observed in pressmud (C5) compost followed by poultry waste (C6) compost and sewage sludge (C4) compost at 150 days of composting. The inhibition at initial days of composting might be due to presence of toxic compounds (caramels and melanoidins) which on later stage became inactive [22, 41]. Bacterial counts were decreased significantly up to 120 days and become stable at 150 days in sewage sludge (C4), pressmud (C5) and poultry waste (C6) composts indicating their maturity at 120 days.

Changes in a bacterial, b fungal and c actinomycetes counts during composting of different composting mixtures. C1-Farm waste compost; C2-Phospho compost; C3-Microbial inoculants compost; C4- Sewage sludge compost; C5-Pressmud compost; C6-Poultry waste compost. Error bars represent the standard deviation

Fungal Counts

Total fungal counts increased significantly up to 60 days in sewage sludge (C4), pressmud (C5) and poultry waste (C6) composts, up to 90 days in farm waste (C1) and phospho (C2) composts and up to 120 days in microbial inoculants (C3) compost and decreased thereafter with composting time (Fig. 9b). At 150 days of composting, highest numbers of fungal counts were recorded in microbial inoculants (C3) compost and lowest in poultry waste (C6) compost. At the initial stages of composting, higher fungal counts were noticed especially in sewage sludge (C4) and pressmud (C5) composts as compared to other composts but at latter stages of composting counts were decreased.

Actinomycetes Count

The initial actinomycetes count of different composts ranged between 5 × 105 and 10 × 105 g−1 and increased to 30 × 105 to 45 × 105 g−1 at 150 days of composting (Fig. 9c). At 150 days of composting, highest counts were found in phospho (C2) compost and lowest in microbial inoculants (C3) compost. At 150 days, gummy whitish appearance was observed in almost all the composts indicating the presence of actinomycetes.

Correlation Between Maturity and Stability Parameters

The correlation coefficients were determined between maturity and stability parameters by using values of different characteristics at different days of composting. It is noted that organic matter loss, C:N ratio, HA:FA ratio, HI, CEC:TOC ratio were highly correlated with 6–7 parameters, therefore these parameters can be used to assess the maturity of the composts prepared by mixing of different types of organic wastes (Table 3). The Cw:Norg ratio was best correlated with 5 parameters, GI with 3 parameters and can also be considered as maturity assessment parameter.

Yield of Wheat

Application of agro-industrial waste composts, their raw materials and chemical fertilizer significantly increased the grain and straw yield of wheat over unfertilized control (Table 4). The maximum increase (118 % over unfertilized control) in grain yield was recorded by the application of poultry waste compost (T10) followed by pressmud compost (T8) microbial inoculants compost (T4) and recommended dose of NPK fertilizer (T11). Application of phospho compost (T3), microbial inoculants compost (T4), sewage sludge compost (T6) and pressmud compost (T8) showed non-significant differences in yield with recommended dose of NPK fertilizer (T11). The yields were significantly higher with agro-industrial waste composts (T6, T8 and T10) as compared to their raw materials (T5, T7 and T9). Agro-industrial waste composts applied with NK (recommended dose) fertilizers produced wheat grain yield comparable to that obtained with NPK (recommended dose) fertilizers, indicating a net saving of 100 % of P fertilizer. The higher yield in poultry waste compost (T10) was mainly due to the presence of high amount of water soluble P (900 mg P kg−1) as compared to other composts (155–378 mg P kg−1). These findings support previous findings of Bajpai et. al. [2] and Ibrahim et al. [18] who concluded that application of compost prepared from fruit and vegetable wastes improved the yield of maize and wheat crops. Increase in wheat yield in our study could be attributed to enhanced nutrient use efficiency in the presence of composts. Previous studies have also shown that composted organic materials enhance fertilizer use efficiency by releasing nutrients slowly and thus reducing the losses, particularly that of N [27, 29].

Conclusions

Compost maturity is a complex characteristic and cannot be determined by a single parameter. Our findings suggest that compost maturity should be assessed by measuring two or more parameters. Correlation analysis showed that the optimal values of the selected parameters for our experimental conditions, are as follows: organic matter loss >42 %, C:N ratio <15, Cw:Norg ratio <0.55, HA:FA ratio >1.9, HI > 30 %, CEC:TOC ratio >1.7 and GI > 70 %. Ambient temperature, decrease in bacterial and fungal counts, and increase in actinomycetes counts and stable at the end of composting are the best indicators for establishing compost stability. As per the above maturity and stability parameters, composts enriched either with RP or inoculation of microorganisms or agro-industrial wastes matured earlier as compared to compost prepared without any enrichment. Application of agro-industrial waste composts could be more effective to increase the yield compared to their raw materials. Combined use of composts and NK fertilizer (recommended dose) produced wheat grain yield comparable to that obtained with NPK (recommended dose) fertilizer, indicating a saving of P fertilizer. Hence, instead of using NPK fertilizer alone, the integrated use of compost and NK fertilizer could be more effective and sustainable for environment and agriculture.

References

Allen, O.N.: Experiments in Soil Biology, 3rd edn. Burgers Publishing Co, Minneapolis (1957)

Bajpai, R.K., Upadhyay, K., Joshi, B.S.: Productivity and economics of rice-wheat cropping system under integrated nutrient supply systems. Indian J. Agron. 47, 20–25 (2002)

Benito, M., Masaguer, A., Moliner, A., Arrigo, N., Palma, R.M.: Chemical and microbiological parameters for the characterization of the stability and maturity of pruning waste compost. Biol. Fertil. Soils 37, 184–189 (2003)

Bernal, M.P., Alburquerque, J.A., Moral, R.: Composting of animal manures and chemical criteria of compost maturity assessment. A review. Bioresour. Technol. 100, 5444–5453 (2009)

Bernal, M.P., Paredes, C., Sanchew-Monedero, M.A., Cegarra, J.: Maturity and stability parameters of composts prepared with a wide range of organic wastes. Bioresour. Technol. 63, 91–99 (1998)

Bhattacharyya, P.: Prospect of organic nutrient resources utilization in India. Indian J. Fert. 3, 93–107 (2007)

Bremner, J.M., Mulvaney, C.S.: Total N. In: Page, A.L., Miller, R.H., Keeney, D.R. (eds.) Methods of Soil Analysis, Part II, pp. 371–378. American Society of Agronomy, Madison (1982)

Brinton, W.F.: Compost Quality Standards and Guidelines, pp. 32–35. Woods End Research Laboratory, USA (2000)

Chang, J.I., Chen, Y.J.: Effects of bulking agents on food waste composting. Bioresour. Technol. 101, 5917–5924 (2010)

Chefetz, B., Hatcher, P.G., Hadar, Y., Chen, Y.: Chemical and biological characterization of organic matter during composting of municipal solid wastes. J. Environ. Qual. 25, 776–785 (1996)

Raj, D., Antil, R.S.: Evaluation of maturity and stability parameters of composts prepared from agro-industrial wastes. Bioresour. Technol. 102, 2868–2873 (2011)

Golueke, C.G.: Principles of biological resources recovery. BioCycle 22, 36–40 (1981)

He, X.T., Logan, T.J., Traine, S.J.: Physical and chemical characteristics of selected U.S. municipal solid waste composts. J. Environ. Qual. 24, 543–552 (1995)

Hoekstra, N.J., Bosker, T., Lantinga, E.A.: Effects of cattle dung from farms with different feeding strategies on germination and initial root growth of cress (Lepidium sativum L). Agric. Ecosyst. Environ. 93, 189–196 (2002)

Hoitink, H.A.J.: Trends in treatment and utilization of solid wastes through composting in the United States. In: Warman, P.R., Taylor, B.R. (eds.) Proceedings International Composting Symposium, vol. 1, pp. 1–13. CBA Press Inc., Nova Scotia (2000)

Hue, N.V., Liu, J.: Predicting compost stability. Compost Sci. Util. 3, 8–15 (1995)

Iannotti, D.A., Grebus, M.E., Toth, B.L., Madden, L.V., Hoitink, H.A.J.: Oxygen respirometry to assess stability and maturity of composted municipal solid waste. J. Environ. Qual. 23, 1177–1183 (1994)

Ibrahim, M., Hassan, A., Iqbal, M., Valeem, E.E.: Response of wheat growth and yield of various levels of compost and organic manure. Pak. J. Bot. 40, 2135–2141 (2008)

Iglesias-Jimenez, E., Perez-Garcia, V.: Determination of maturity indices for city refuse composts. Agr. Ecosyst. Environ. 38, 331–343 (1992)

John, M.K.: Colorimetric determination of phosphorus in soil and plant material with ascorbic acid. Soil Sci. 109, 214–220 (1970)

Kirchmann, H., Widen, P.: Separately collected organic household wastes. Swedish J. Agric. Res. 24, 3–12 (1994)

Kitts, D.D., Wu, C.H., Stich, H.F., Powrite, W.D.: Effect of glucose-lysine Maillard reaction products on bacterial and mammalian cell mutagenesis. J. Agric. Food Chem. 41, 2253–2258 (1993)

Ko, H.J., Kim, K.Y., Kim, H.T., Kim, C.N., Umeda, M.: Evaluation of maturity parameters and heavy metal contents in composts made from animal manure. Waste Manage. 28, 813–820 (2008)

Lax, A., Roig, A., Costa, F.: A method for determining the cation exchange capacity of organic materials. Pl. Soil 94, 349–355 (1986)

Martin, J.P.: Use of acid base Bengal and streptomycin in the plate method of estimating soil fungi. Soil Sci. 69, 215–233 (1950)

Morel, J.L., Colin, F., Germon, J.C., Godin, P., Juste, C.: Methods for the evaluation of the maturity of municipal refuse compost. In: Gasser, J.K.R. (ed.) Composting of Agricultural and Other Wastes, pp. 56–72. Elsevier Applied science Publications, Barking, Essex (1985)

Muneshwar, S., Singh, V.P., Reddy, K.S., Singh, M.: Effect of integrated use of fertilizer nitrogen and farmyard manure or green manure on transformation of N, K and S and productivity of rice-wheat cropping system on a Vertisol. J. Indian Soc. Soil Sci. 49, 430–435 (2001)

Nelson, D.W., Sommers, L.E.: Total carbon, organic carbon and organic matter. In: Page, A.L. (ed.) Methods of Soil Analysis, Part II, pp. 539–579. American Society of Agronomy, Madison (1982)

Nevens, F., Reheul, D.: The application of vegetable, fruit and garden waste compost in addition to cattle slurry in a silage maize monoculture: nitrogen availability and use. Eur. J. Agron. 19, 189–203 (2003)

Ranalli, G., Botturea, G., Taddei, P., Garavni, M., Marchetti, R., Sorlini, G.: Composting of solid and sludge residues from agricultural and food industries. Bioindicators of monitoring and compost maturity. J. Environ. Sci. Health 36, 415–436 (2001)

Roig, A., Lax, A., Gegarra, J., Costa, T., Harnandez, M.T.: Cation exchange capacity as a parameter for measuring the humification degree of manures. Soil Sci. 146, 311–316 (1988)

Satisha, G.C., Devaranjan, L.: Effect of amendments on windrow composting of sugar industry pressmud. Waste Manage. 27, 1083–1091 (2007)

Schlichting, E., Blume, H.P.: BodenKundlxhes Praktikum, pp. 136–138. Paul Parey, Hamburg, Berlin (1966)

Sellami, F., Hachicha, S., Chtourou, M., Medhioub, K., Ammar, E.: Maturity assessment of composted olive mill wastes using UV spectra and humification parameters. Bioresour. Technol. 99, 6900–6907 (2008)

Singh, C.P., Ruhal, D.S., Singh, M.: Solubilization of low grade rock phosphate by composting with a farm waste, pearl millet boobla. Agric. Wastes 8, 17–25 (1983)

Tang, J.C., Maie, N., Tada, Y., Katayama, A.: Characteristics of the maturing process of cattle manure compost. Process Biochem. 41, 380–389 (2006)

Tiquia, S.M., Tam, N.F.Y., Hodgkiss, I.J.: Effect of composting on phyto-toxicity of spent pig manure saw dust litter. Environ. Pollut. 93, 249–256 (1996)

Tiquia, S.M., Tam, N.F.Y., Hodgkiss, I.J.: Effect of turning frequency on composting of spent pig-manure sawdust litter. Bioresour. Technol. 62, 37–42 (1997)

Veeken, A., Nierop, K., deWilde, V., Hamelers, B., deWilde, V.: Characterization of NaOH extracted humic acid during composting of a biowaste. Bioresour. Technol. 72, 33–41 (2009)

Walkley, A.J., Black, C.A.: Estimation of soil organic carbon by the chromic acid titration method. Soil Sci. 37, 29–38 (1934)

Wedzicha, B.L., Kaputo, M.Y.: Melanoidins from glucose and glycine: composition, characteristics and reactivity towards sulphit ion. Food Chem. 43, 359–367 (1992)

Wu, L., Ma, L.Q., Martinez, G.A.: Comparison of methods for evaluating stability and maturity of biosolid composts. J. Environ. Qual. 29, 424–429 (2000)

Zucconi, F., de Bertoldi, M.: Compost specification for the production and characterization of compost from municipal solid waste. In: de Bertoldi, M., et al. (eds.) Compost: Production, Quality and Use, pp. 30–50. Elsevier, Barking (1987)

Zucconi, F., Mona, C.A., Forte, M., de Bertoldi, M.: Phytotoxins during the stabilization of organic matter. In: Gasser, J.K.R. (ed.) Composting of Agricultural and Other Wastes, pp. 73–85. Elsevier Applied Science Publishers, Barking (1985)

Zucconi, F., Pera, A., Forte, M., de Bertoldi, M.: Evaluating toxicity of immature compost. Biocycle 22, 54–57 (1981)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Antil, R.S., Raj, D., Narwal, R.P. et al. Evaluation of Maturity and Stability Parameters of Composts Prepared from Organic Wastes and Their Response to Wheat. Waste Biomass Valor 4, 95–104 (2013). https://doi.org/10.1007/s12649-012-9141-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-012-9141-7