Abstract

Interest in the cultivation of plants specifically for energetic use has grown tremendously in recent years. Among the numerous tested energetic plants, Miscanthus seems to be an especially, promising ‘energy crop’. The presented data may have a contribution in developing Miscanthus pellets as a feedstock for energy recovery systems. Combustion and pyrolysis are efficient methods for controlling energy efficiency from Miscanthus. Thermogravimetric analyses were performed at heating rates of 5, 10, 15, and 20°C min−1 under nitrogen and air atmospheres with analysis of gaseous (CO, CO2 and VOC) pollutants and aerosols. Reactivity and kinetics measurements of Miscanthus pellets were also performed. Thermal degradation of Miscanthus pellets under inert atmosphere is similar to those found for other lignocellulosic materials. Under nitrogen, the main study was the determination of kinetic constants. These constants for main devolatilization step are not affected by variation of the heating rate with activation energy of 90 kJ mol−1 and a first reaction order. Thermal degradation of Miscanthus pellets under air occurs in main two steps: rapid decomposition and residual degradation. The amounts of CO2, CO and VOC emitted were 17.4, 3.7 and 1.0 mmol g−1, respectively. Pellets degradation produces 1.0 × 1012 particles (PM10) per gram of sample. 99% are particles with a diameter below 1 μm (57% are nanoparticles inferior to 0.1 μm). Nucleation mode dominates during the first step (190–253°C) centred at 0.04 μm whereas during the second step (253–310°C) a coagulation mode is observed centred at 0.5 μm.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The thermal utilization of biomass can contribute to the reduction of CO2 release since the same amount of CO2 is extracted from the air during the growth period of the plants. Biomass can be provided by both residual material from forestry and agriculture, such as wood, or straw, and cultivated energy crops such as whole cereal plants, willows, and fodder grasses.

Among the numerous tested energetic plants, Miscanthus seems to be especially, promising ‘energy crop’ [1, 2]. Therefore, Miscanthus crop growing were well developed in Europe in the last 10 years [3, 4].

Nevertheless, if the literature on the growing of Miscanthus is well documented, few studies dealt with its energetic uses. Collura et al. have examined Miscanthus combustion in standard conditions by using 25 and 60 kW boilers. They have observed that emission factors meet the European standards (EN 303-5) except for dust emission [5]. They observed very high values for dust emissions factors for samples as straw and pellets Miscanthus, values close to 100 g G J−1. This problem is related to the powdery nature of this energetic crop. De Jong et al. studied the pyrolysis of Miscanthus pellets using thermogravimetric analysis (TGA) at different heating rates with measurement of products by means of Fourier Transform Infrared Spectroscopy (TG-FTIR) [6]. They have showed that tar release increases with increasing heating rate while light gaseous species (mostly CO, CO2 and CH3CHO) showed an adverse dependence on the heating rate.

If gaseous emissions are well controlled, particles monitoring needs more improvement. Fine particles are likely to pose a risk to environment and health because they can travel deeply into the respiratory tract. Particularly, very small particles (diameter below 1 μm) which largely dominate in number may be responsible for some adverse health effects associated to air-pollutant exposure. These ultra fine particles get deposited in the alveolar regions of the lung where the absorption efficiency for trace elements is up to 60–80% [7, 8]. Therefore, in a context of environmental policy, it is useful to identify and characterize the sources of ultra fine particles. Cascade impactors are widely used for this purpose since they allow collecting particles and measuring the number size distribution. They can be used in many fields, e.g. particles emitted from diesel engines, ambient aerosols or other aerosols from combustion sources [9–11]. Investigations about particle formation by wood oxidation are essentially performed in commercial furnaces and residential fireplaces with a continuously feed in wood. These previous studies in domestic or commercial wood stoves, show large discrepancies in number concentration of particle emitted ranging from 107 to 1010 cm−3, dependent of various combustion parameters in stoves [12].

In this work, thermal degradation characteristics of Miscanthus pellets have been examined under inert and air atmospheres. Kinetics parameters such as activation energy, preexponentiel factor and reaction order were determined and compared with other biomasses. Carbon oxides and volatile organic compounds were also measured during thermal degradation of Miscanthus under air atmosphere. A particular attention was devoted to the analysis of fine and ultrafine particles emitted in the exhaust. The presented data may have a contribution in developing Miscanthus pellets as a feedstock in energy recovery systems.

Experimental Study

Raw Materials

Miscanthus pellets were supplied by Novabiom France harvested in Champhol (France) in 2006 and produced by extrusion without any additive. The pellets used were individual cylinders of 6 mm wide by 10–30 mm in length.

Equipment and Procedure

Thermogravimetric analyses (TGA) were carried out using a CAHN 121 thermobalance. Nitrogen gas and air were used as purge gases. All TGA experiments were conducted at a constant purge flow rate of 12 NL h−1 and at different heating rates ranging from 5 to 20°C min−1. Three thermogravimetric experiments were carried out for each biomass sample from room temperature up to slightly above 900°C. A blank experiment was conducted to exclude a buoyancy effect. The initial mass of the samples used was 20 mg. The use of small masses was necessary to reduce the effects of side reactions and mass and heat transfer limitation.

The high heating value (HHV) was measured with a Prolabo type calorimeter LECO 300.

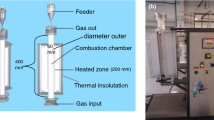

Gas Emissions and Particle Matter Analysis

During thermal decomposition tests under air atmosphere (at a heating rate of 10°C min−1) the molar fractions of carbon oxides (CO2 and CO) at the TG outflow were continuously measured by an infrared analyzer (BINOS 100, Rosemount). Volatile Organic Compounds (VOC) were analyzed by a Flame Ionized Detector (NGA 2000, Rosemount).

An Electrical Low Pressure Impactor (ELPI) manufactured by Dekati Ltd. (Tampere, Finland) was also used to collect particles from 29 nm to 10 μm into 12 size fractions. This cascade impactor system separates the particles on the basis of their aerodynamic equivalent cut-off diameter (Dae) at 50% efficiency, allowing the collection of twelve size fractions ranging from 29 nm to 10 μm. Properties of the impaction stages and particle matter terminology are detailed in Table 1. Within the ELPI, the particles are first electrically charged according to their Stokes diameter, and then impacted on different stages according to their inertia related to their aerodynamic diameter. Before entering the impactor stages, the particles are charged in a positive unipolar particle charger (corona charger). After being charged, the particles are introduced in the cascade impactor in order to be separated on the basis of their inertia and their aerodynamic diameter. A multistage electrometer counts the charged aerosol particles. The current induced is then simultaneously measured for the twelve impactor stages and it is directly converted by the electrometer in particles number and concentrations using mathematical algorithms [13]. The number of particles depends both on the induced current measured at each stage, and on the density of the particles in the exhaust gas, which has to be provided by the user. Particle number and concentrations calculated accounts for this particularity using 1 g cm−3 of density value [13]. In a dense medium in drops, it was shown by multidimensional numerical calculations that the collection of the aerosols of the inertial field could be modified. The presence of several drops modifies the flow inducing a reduction in the effectiveness of collection and the presence of a layer of incondensable gases around a drop, because of the condensation of the vapor, generates an increase in the deposit of the aerosols on these drops on the higher plates of the impactor ranged from 3 to 10 μm [14, 15]. For these reasons, if particle matter was collected on the twelve plates of the ELPI from 29 nm to 10 μm, mass emission factors and distributions were only calculated for PM2.5 in this study. Calculations of mass emission factors and their distributions do not take into account stages 10 to 12 (Table 1). Only stages 1 to 9 were considered and represent PM2.5.

Results and Discussion

Properties of the Raw Material

Proximate and ultimate analyses were carried out to characterize Miscanthus pellets. Results are summarized in Table 2. They are in the same order of magnitude than results obtained in previous investigations [5, 6]. The high heating value (HHV) measured with a Prolabo type calorimeter is 17,600 kJ kg−1. Recently, some papers described the estimation of HHV of different biomass on the basis of their elemental composition. The authors report the following equation: HHV (MJ kg−1) = −1.3675 + 0.3137C + 0.7009H + 0.0318O, where C, H and O are, respectively the carbon, hydrogen and oxygen contents in wt% [16]. In our case the calculated HHV is equal to 18,130 kJ kg−1 for Miscanthus pellets compared with the measured value of 17,600 kJ kg−1, is within the 3% range of error.

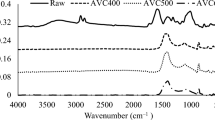

Miscanthus Pellets Pyrolysis

Figure 1 shows TGA and DTG curves for pyrolysis of Miscanthus pellets under inert atmosphere at a heating rate of 10°C min−1. 3.7% weight losses occurred between temperatures of 25 and 105°C corresponding to moisture evaporation. Volatiles were evolved in the temperature range 180–355°C. The total percentage of weight loss at the end temperature of 900°C was 77%. Maximum rate of weight loss occurs at a temperature of 318°C with a value of 0.20% s−1 corresponding to a weight loss of 66.8%. As suggested in literature, it may correspond to the major loss of cellulose and hemicellulose components and partial loss of the lignin component of the Miscanthus pellets [17, 18]. At the end of main devolatilization step, the continuous weight loss represents constant decomposition of pyrolysis residue and lignin [17–20].

Reactivity of Miscanthus pellets is close to other biomasses tested in the same experimental conditions. According to Munir et al., maximum rate losses for cotton stalk, sugarcane bagasse, shea meal were 0.18, 0.16 and 0.1% s−1, respectively [21]. Maximum rate loss of Arundo donax was also in the same order of magnitude with a value of 0.16% s−1 in the same experimental conditions [22]. Moreover, Tpeak values obtained for Miscanthus straw and pellets are lower than values obtained for cotton stalk (334°C) and sugarcane bagasse (355°C). The results of thermal degradation in an inert atmosphere at different heating rates are presented in Table 3. Thermal degradation rates increase with the heating rate. This behavior was previously described for various biofuels [20–25]. These results were used to calculate kinetic parameters.

Pyrolysis Kinetic Parameters

According to the pyrolysis kinetic model used by several authors [22, 23], the results of the kinetic parameters (preexponential factor, activation energy and reaction order and the coefficients of determination, R2, at different heating rate during main devolatilization are reported in Table 4.

During the main devolatilization, variation of the heating rate does not influence the kinetic parameters. Activation energy is close to 90 kJ mol−1 and the preexponential factor of ln (A) is approximately 13 (ln (s−1)). In addition, a first reaction order is obtained for the main devolatilization step whatever the heating rate. Activation energy values are in agreement with values obtained in literature for different biomass materials. Zhang et al. have obtained values of 85.4 and 84.5 kJ mol−1 for the devolatilization of wood chips and peanut shell, respectively [26]. Nassar et al. have obtained activation energy of 88 kJ mol−1 during Bagasse pyrolysis [27]. Chouchene et al. have obtained 84 kJ mol−1 during the thermal degradation of olive solid waste particle under nitrogen atmosphere [28].

Miscanthus Pellets Thermal Degradation Under Air Atmosphere

Thermogravimetric Profiles

Figure 2 shows TGA and DTG curves for Miscanthus pellets combustion under air atmosphere at different heating rates.

Under oxidative atmosphere, the decomposition behaviour of the Miscanthus pellets suggested that there are mainly two stages of weight loss. The first stage is attributed to the volatilization of light molecules as obtained under inert atmosphere, occurring in the temperature range of 200–260°C at 10°C min−1 heating rate. In this region, there was a very large weight loss (~74%) at a very high rate (1.5% s−1) as compared with the amount (~60%) and rate of weight loss (0.2% s−1) in the inert atmosphere. Above 260°C, a small amount of weight loss (~16%) at a slower rate of weight loss (0.13% s−1) is observed. This second stage is attributed to the residual decomposition and the formation of ash. The shape of degradation curves were very similar to the ones obtained by Mansaray and Ghaly during thermal degradation of rice husk in an oxygen atmosphere and Kumar et al. during corn stover combustion [29, 30].

Figure 2 shows that the heating rate has not a significant effect on the initial temperature of Miscanthus pellets degradation. However, an increase of the heating rate tended to slightly increase thermal degradation processes towards higher temperatures. In fact, the higher the heating rate, the wider the temperature range for Miscanthus pellets is obtained. However, it was observed that the decomposition rate decreases with the increase of heating rate. Similar behaviour was obtained during the direct oxidation of wood pellets and Silopi Asphaltite combustion [31, 32]. This behaviour may be explained that, with increasing heating rates, the thermal devolatilization is enhanced, as obtained under inert atmosphere, leading to formation of a volatiles cloud which prevents oxygen to diffuse toward the solid material. However, oxygen-solid reactions are heterogeneous and require diffusion to the reactive surface, which can be compromised by the conditions used. Hence, as the heating rate increased, the contact of oxygen with the combustion residue becomes more difficult and less reaction takes place, resulting in a decrease in reactivity.

CO, CO2 and VOC Analysis

The analyses of carbon oxides (CO and CO2) as well as volatile organic compound (VOC) were carried out in order to better evaluate the thermal degradation behaviour of the Miscanthus pellets under air atmosphere. The emissions of carbon oxides and volatile organic compounds show one single peak during thermal degradation of Miscanthus pellets under air (Fig. 3). The shape of the curves of CO, CO2 and VOC was in agreement with the one obtained for the DTG curve. The temperature of the CO, CO2 and VOC peaks is similar to the corresponding temperature of the maximum of the mass loss rate obtained at 10°C min−1. The amount of CO2, CO and VOC emitted was 17.4, 3.7 and 1.0 mmol per g of wet sample, respectively. These values correspond to a carbon balance of 47, 10 and 3% of initial carbon as CO2, CO and VOC respectively. The amount of emitted CO2 is lower for Miscanthus pellets than for Miscanthus straw (62% of initial carbon as emitted CO2 for straw [33] and for pine wood (chips and sawdust) and Arundo Donax which was previously studied during TGA analysis under air atmosphere [33, 34]. Previous studies on chips and sawdust pine wood [34] indicated a carbon balance of 65 and 52% of initial carbon as CO2, respectively. Results obtained on other biomass Arundo Donax indicated a carbon balance of 70% as CO2 [33]. These results may be attributed to the slower decomposition rate during devolatilization of Miscanthus straw, Arundo Donax and natural pine wood samples which leads to a higher amount of remaining char. Thus, the oxidation of these samples would lead to a higher emission of CO2 comparing to Miscanthus pellets which leads to a higher amount of tar.

Particle Matter Analysis

As shown in Fig. 2, the thermal degradation of Miscanthus pellets is achieved in the temperature range of 300–350°C. Particle matter (PM0.1 to PM10) records show that emissions of PM10 were later achieved at 310°C at a heating rate of 10°C min−1. Thermal degradation of Miscanthus pellets under air atmosphere generates 1.0 1012 particles per g of sample in the temperature range of 20–310°C. This value represents 6.2 × 1013 p MJ−1. Miscanthus pellets generates more particles than natural chips and sawdust pine wood samples (2 × 1013 p MJ−1) in the same conditions. Among energetic crops, Arundo Donax is the biomass that emits the most number of particles per MJ of sample (1.6 × 1014 p MJ−1). One order of magnitude is observed between these two energetic crops [33, 34].

99% in number of aerosols produced have a diameter less than 1 μm but only 57% are nanoparticles with a diameter lower than 0.1 μm between 20 and 310°C. The percentage of PM0.1 for Miscanthus pellets is lower than for Miscanthus straw, Arundo Donax and pine wood samples which generate larger amount of nanoparticles (PM0.1 > 63%). 56% of the PM10 is emitted during the first step (190–253°C) of the decomposition whereas 41% is produced during the second step (253–310°C). The number of particles distribution of PM10 is given in Fig. 4 for both temperature ranges. The aerosols emitted during the oxidative pyrolysis of Miscanthus pellets consisted primarily of fine submicron particles as shown in Fig. 4 whatever the temperature range. Nevertheless, a slightly difference appears between the two main phases of the thermal oxidative process. Nucleation mode dominated during the first step (190–253°C) of the decomposition of Miscanthus pellets at 0.04 μm. During the second step (253–310°C: oxidation of remaining char), a coagulation mode is observed and centred at 0.5 μm. 62% of the total emitted PM0.1 is generated during the first step of the decomposition of Miscanthus pellets (190–253°C).

Mass emission factor of the Miscanthus pellets for PM2.5 was also calculated and it is equal to 55 mg per g of sample. This result is similar to the value obtained on Miscanthus straw and is lower than for Arundo Donax [33]. These values were also obtained for chips of pine wood [34].

Mass emission factors are dependent of the different proportions of polymers as cellulose, xylan and lignin in the sample. As it was shown by Dorge et al., cellulose polymer was characterized by the highest mass emission factor compared to lignin and xylan with values close to 100, 50 and 25 mg g−1, respectively [35].

The mean mass concentration of particles downstream to reactor from oxidative pyrolysis of Miscanthus pellets is equal to 53 mg m−3 for PM2.5. It is consistent with results of the literature obtained during the oxidative pyrolysis of Arundo Donax, Miscanthus straw and wood chips [33, 34].

Conclusions

Thermal decomposition of Miscanthus pellets was performed by TGA under inert and oxidative atmosphere. The thermal behaviour under inert atmosphere of this energetic crop does not differ from other lignocellulosic materials by TGA. Main components are devolatilized in the temperature range 180–400°C depending of the heating rate. A high amount of char (23 w%) still remained at 900°C. The parameters of the reaction kinetics were obtained and compared with other biomasses under inert atmosphere. An activation energy of 90 kJ mol−1 and a first reaction order were found for all the tested heating rates. Kinetic parameters are well defined by a first order global model.

The oxidation takes places in a temperature range of 220–340°C depending of the heating rate. Compared to the behaviour of similar biomasses (Arundo Donax, wood chips and sawdust) in the same conditions, the oxidative reaction of Miscanthus is achieved at lower temperatures. Increasing the heating rate strongly impacts the reactivity of Miscanthus under oxidative atmosphere. The process is shifted towards high temperature and maximal mass rates are decreased. It is due to the formation of a volatiles cloud which prevents oxygen to diffuse toward the solid material and decreases the carbon balance sheet.

An important point developed in this paper is the detailed analysis of aerosols emitted in the exhaust. Aerosols are mainly formed during devolatilization and oxidation of volatiles steps. Particle matter analysis during Miscanthus pellets degradation under air atmosphere shows that aerosols are mainly constituted of particles with a diameter below 1 μm representing more than 99% of the total amount of particles (57% are nanoparticles with a diameter lower than 0.1 μm). Emission factors and concentrations in the exhaust are very close to those found for lignocellulosic materials in the same experimental conditions.

The presented data may have a contribution in developing Miscanthus pellets as a feedstock for energy recovery systems and particularly to cope with the future stringent standards on CO, VOC and particle emissions imposed by some European governments such as Belgium, Germany or Switzerland. Manufacturers of domestic appliances will need to develop post-treatment processes of fumes that must be efficient for the abatement of submicroparticles.

References

Styles, D., Jones, M.B.: Energy crops in Ireland: Quantifying the potential life-cycle greenhouse gas reductions of energy-crop electricity. Biomass Bioenergy 31, 759–772 (2007)

Lewandowski, I., Kicherer, A., Vonier, P.: CO2-balance for the cultivation and combustion of Miscanthus. Biomass Bioenergy 8, 81–90 (1995)

Acaroğlu, M., Aksoy, A.S.: The cultivation and energy balance of Miscanthus × giganteus production in Turkey. Biomass Bioenergy 29, 42–48 (2005)

Styles, D., Thorne, F., Jones, M.B.: Energy crops in Ireland: An economic comparison of willow and Miscanthus production with conventional farming systems. Biomass Bioenergy 32, 407–421 (2008)

Collura, S., Azambre, B., Finqueneisel, G., Zimny, T., Weber, J.V.: Miscanthus × Giganteus straw and pellets as sustainable fuels, Combustion and emission tests. Environ. Chem. Lett. 4, 75–78 (2006)

De Jong, W., Pirone, A., Wójtowicz, M.A.: Pyrolysis of Miscanthus Giganteus and wood pellets: TG-FTIR analysis and reaction kinetics. Fuel 82, 1139–1147 (2003)

Linlay, W.H., Stapleton, K.W., Zuberbulher, P.: Fine particle fraction as measure of mass depositing in the lung during inhalation of nearly isotonic nebulized aerosols. J. Aerosol Sci. 28, 1301–1309 (1997)

Renwick, L.C., Donaldson, K., Clouter, A.: Impairment of alveolar macrophage phagocytosis by ultrafine particles. Toxicol. Appl. Pharmacol. 172, 119–127 (2001)

Shi, J.P., Khan, A.A., Harrison, R.: M.: Measurements of ultrafine particle concentration and size distribution in the urban atmosphere. Sci. Total Environ. 235, 51–64 (1999)

Tsukamoto, Y., Goto, Y., Odaka, M.: Continuous measurement of diesel particulate emissions by a Electrical Low-Pressure Impactor. SAE Technical paper series 2000-01-1138 (2000)

Wierzbicka, A., Lillieblad, L., Pagels, J., Strand, M., Gudmundsson, A., Gharibi, A., Swietlicki, E., Sanati, M., Bohgard, M.: Particle emissions from district heating units operating on three commonly used biofuels. Atmos. Environ. 39, 139–150 (2005)

Johansson, L.S., Tullin, C., Leckner, B., Sjövall, P.: Particle emissions from biomass combustion in small combustors. Biomass Bioenergy 25, 435–446 (2003)

Marjamäki, M., Keskinen, J., Chen, D., Pui, D.: Performance evaluation of the electrical low pressure impactor (ELPI). J. Aerosol Sci. 31, 249–261 (2000)

Gauchet, N., Vendel, J.: Modelling of the aerosol collection efficiency by drops-influence of the distance between the drops. J. Aerosol Sci. 31, 41–42 (2000)

Tsai, R., Liang, L.J.: Correlation for thermophoretic deposition of aerosol particles onto cold plates. J. Aerosol Sci. 32, 473–487 (2001)

Friedl, A., Padouvas, E., Rotter, H., Varmuza, K.: Prediction of heating values of biomass fuel from elemental composition. Anal. Chim. Acta 544, 191–198 (2005)

Varhegi, G., Antal, M.J., Jakab, E., Piroska, S.: Kinetic modelling of biomass pyrolysis. J. Anal. Appl. Pyrol. 42, 73–87 (1997)

Manasray, G.K., Ghaly, A.E.: Thermal degradation of rice husks in nitrogen atmosphere. Bioresour. Technol. 65, 13–20 (1998)

Vamvuka, D., Kakaras, E., Kastanaki, E., Grammelis, P.: Pyrolysis characteristics and kinetics of biomass residuals mixtures with lignite. Fuel 82, 1949–1960 (2003)

Grønli, M.G., Várhegyi, G., Di Blasi, C.: Thermogravimetric analysis and devolatilization kinetics of wood. Ind. Eng. Chem. Res. 41, 4201–4208 (2002)

Munir, S., Daood, S.S., Nimmo, W., Cunliffe, A.M., Gibbs, B.M.: Thermal analysis and devolatilization kinetics of cotton stalk, sugar cane bagasse and shea meal under nitrogen and air atmospheres. Bioresour. Technol. 100, 1413–1418 (2009)

Jeguirim, M., Trouvé, G.: Pyrolysis characteristics and kinetics of Arundo Donax using thermogravimetric analysis. Bioresour. Technol. 100, 4026–4031 (2009)

Jeguirim, M., Dorge, S., Loth, A., Trouvé, G.: Devolatilization kinetics of Miscanthus straw from thermogravimetric analysis. Int. J. Green Energy 7, 164–173 (2010)

Órfão, J.J.M., Antunes, F.J.A., Figueiredo, J.L.: Pyrolysis kinetics of lignocellulosic materials—three independent reactions model. Fuel 78, 349–358 (1999)

Mészáros, E., Várhegyi, G., Jakab, E., Marosvölgyi, B.: Thermogravimetric and reaction kinetic analysis of biomass samples from an energy plantation. Energy Fuels 18, 497–507 (2004)

Zhang, X., Xu, M., Sun, R., Sun, L.: Study on biomass pyrolysis kinetics. J. Eng. Gas Turbines Power 128, 493–496 (2006)

Nassar, M.M., Ashour, E.A., Wahid, S.S.: Thermal characteristics of bagasse. J. Appl. Polym. Sci. 61, 885–890 (1996)

Chouchene, A., Jeguirim, M., Khiari, B., Trouvé, G., Zagrouba, F.: Thermal degradation behavior of olive solid waste: Influence of the particle size and oxygen atmosphere. Resour. Conserv. Recy. 54, 271–277 (2010)

Mansaray, K.G., Ghaly, A.E.: Thermal degradation of rice husks in nitrogen atmosphere. Bioresour. Technol. 65, 13–20 (1998)

Kumar, A., Wang, L., Dzenis, Y.A., Jones, D.D., Hanna, M.A.: Thermogravimetric characterization of corn stover as gasification and pyrolysis feedstock. Biomass Bioenergy 32, 460–467 (2008)

Biagini, E., Tognotti, L.: Comparison of devolatilization/char oxidation and direct oxidation of solid fuels at low heating rate. Energy Fuels 20, 986–992 (2006)

Altun, N.E., Kok, M.V., Hicyilmaz, C.: Effect of particle size and heating rate on the combustion of Silopi asphaltite. Energy Fuels 16, 785–790 (2002)

Jeguirim, M., Dorge, S., Trouvé, G.: Thermogravimetric analysis and emission characteristics of two energy crops in air atmosphere: Arundo donax and Miscanthus giganthus. Biores. Tech. 101, 788–793 (2010)

Dorge, S., Kehrli, D., Trouvé, G.: Caractérisation des fractions fines (PM2.5) et ultrafines (PM0.1) d’aérosols issus de la combustion de bois de pin par thermogravimétrie. Revue Internationale sur l’Ingénierie des Risques Industriels 1, 169–183 (2008)

Dorge, S., Kehrli, D., Jeguirim, M., Trouvé, G.: Study of aerosol formation during the oxidation of wood samples and lignocellulosic polymers by thermogravimetry. 11th Conference Process Integration Modelling and Optimization for energy Saving and Pollution Reduction, pp.1397–1398. Prague, Tchéquie, 24–28th Aug 2008

Acknowledgments

Authors acknowledge the Alsace Regional Council for supporting research in the GRE and Novabiom France for supplying Miscanthus pellets.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dorge, S., Jeguirim, M. & Trouvé, G. Thermal degradation of Miscanthus pellets: kinetics and aerosols characterization. Waste Biomass Valor 2, 149–155 (2011). https://doi.org/10.1007/s12649-010-9060-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-010-9060-4