Abstract

The effect of superconducting Y-deficient YBa2Cu3Oy nano-particles prepared by the planetary ball milling technique and silver inclusion on electrical fluctuation conductivity of polycrystalline YBa2Cu3Oy has been reported. Samples, synthesized by the conventional solid-state reaction technique, have been investigated using X-ray diffraction, scanning electron microscope and electrical resistivity. Scanning electron microscope analyses show that nano-particles of Y-deficient YBa2Cu3Oy are embedded in the superconducting matrix. The density of these nano-particles strongly depends on milling parameters. The fluctuation conductivity has been analyzed as a function of reduced temperature using the Aslamazov–Larkin model. Three different fluctuation regions namely critical, mean-field and short-wave are observed. The zero-temperature coherence length, the effective layer thickness of the two-dimensional system, critical magnetic fields and critical current density are estimated. Superconducting parameters are affected by Y-deficient YBa2Cu3Oy nano-particles. It has been found that attainment of an optimum concentration and well-dispersed of nano-sized inclusions by ball milling process improves the physical properties. On the other hand, the sample with Y-deficient YBa2Cu3Oy nano-particles and Ag exhibits better superconducting properties in comparison with free added one.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Since the discovery of high temperature superconductor (HTS) materials, numerous studies have been carried out in order to understand the mechanism of high-T c superconductivity. These materials have salient features such as granular character, short superconducting coherence length and low charge carrier density. These distinctive characteristics enhance thermodynamic fluctuation effects, produce a significant rounding of the transition curve and thus greatly enlarge the temperature region in which fluctuations of the order parameter are important. Cooper pairs have a finite existence probability above the normal-superconductor transition originating from thermal fluctuation and leading to an excess conductivity Δσ. There are different models for interpretation of thermal fluctuation effects in HTS materials such as Aslamazov–Larkin (AL), Maki–Thompson (MT), Lawrence–Doniach (LD) and Hikami–Larkin (HL) methods [1–4]. Most of the investigations are based on the Aslamazov–Larkin theory [1]. Superconducting properties such as conduction dimensionality and coherence length depend both on the intrinsic properties (i.e. removal of oxygen) and also on the extrinsic properties such as the grain morphology of samples. Despite numerous investigations of thermal fluctuation in HTS, the conclusions about the inhomogeneities which occur at varying length scales are contradictory [5–11]. Some studies have shown that inhomogeneities occur at widely varying length scales crucially influencing the critical and the mean-field regions of superconducting order parameter and the dimensionality of the fluctuation conductivity. However, other studies have shown that chemical imperfections and inhomogeneities inside the grains and large length scale compared to the superconducting coherence length have negligible effect on the superconducting order parameter fluctuation region but broaden the superconducting transition [6, 11].

It is well known that the preparation method and the nature of the chemical doping and additives can introduce additional defects in the form of single atom, grain boundaries or impurity phases in the superconductor material, which lead to increase the number of inhomogeneities in the compound. Much attention has been paid to the impact of nano-sized inclusions in fluctuation induced conductivity in superconducting materials. It is reported that a suitable amount of metal, semiconductor or magnetic nano-particles can produce mesoscopic and microscopic defects and help to improve the performance of practical superconductors [6, 11, 12]. Among metallic materials, silver inclusion has a large impact on the evolution of microstructure and electronic structure of YBCO compound. Ag induces mesoscopic modification and microscopic inhomogeneity in the composites [6]. Recently, we have reported the effect of planetary ball milling process in YBCO compounds [13] and we have shown that the ball milling process can generate Y-deficient YBa2Cu3Oy (Y-123) nano-particles dispersed on the Y-123 matrix. The use of an optimal energy ball milling by controlling some processing parameters such as ball-to-powder weight ratio, speed rotation and number of balls allows us to obtain a desired microstructure for raising the flux pinning properties in YBCO. As the fluctuation induced conductivity provides useful information on some of the fundamental aspects, such as understanding the intrinsic superconducting characteristics and the dimensionality of high-T c systems, it is interesting to study the excess conductivity in the polycrystalline Y-123 embedded with superconducting nano-particles of Y-deficient Y-123.

The aim of this work is to study the correlations between microstructure and fluctuation induced conductivity in Y-123 compound embedded with various concentrations of superconducting nano-particles of Y-deficient Y-123 generated by the planetary ball milling technique. We evaluate the superconducting parameters such as conduction dimensionality, zero temperature coherence length of systems, critical magnetic fields and critical current density. Also a comparative investigation on the thermal fluctuations conductivity above the superconducting transition temperature of silver added milled and unmilled samples has been carried out.

2 Experimental process

Details of the preparation of YBa2Cu3Oy polycrystalline samples have been described previously [13] and herein we give a brief description. A mixture Y2O3 (99.9 %), BaCO3 (99.9 %) and CuO (99.9 %) powders according to the chemical formula of Y:Ba:Cu = 1:2:3 (Y-123) was pelletized and then calcined at 950 °C for 12 h in air in order to produce an oxide precursor without remainder of any carbonates. The resulting oxide precursor was divided into two parts, one part was milled via the planetary milling technique by varying various ball milling parameters (experimental data for ball milling are summarized in Table 1) and another was grounded by hand in an agate mortar. For Ag-added samples, silver was added to the oxide precursors during the final processing stage. In order to mix uniformly the fine Ag particles with the oxide precursor, AgNO3 solution was added to the oxide precursor powder. Appropriate amounts of AgNO3 solution was mixed with the milled and hand grinding oxide precursor powders and then dried. Both Ag-added and non-added milled and hand grinded oxide precursors were pressed uniaxially into pellets, sintered in air at 950 °C for 8 h and then furnace cooled to room temperature. The samples were labeled as “milled”, “Ag-milled” (for planetary milled precursor) and “unmilled”, “Ag-unmilled” (for hand grinded precursor).

The structure and phase purity of the powder sample ground from sintered pellets were examined by powder X-ray diffraction (XRD) using a Philips 1710 diffractometer with \( CuK_{\alpha } \) radiation in 2θ range from 20° to 60° with step size of 0.015° and step time of 10 s. Refinement of the X-ray diffraction data was carried out by the Rietveld method using the FULLPROF program with multi-phase capability and pseudo-Voight peaks shape functions. The R p and R wp factors and the Goodness of fit χ 2 were used as the numerical criteria of fitting. The microstructure of samples was characterized using a scanning electron microscope (SEM) (JEOL-JEM 5510). The transport properties of the samples were studied by measuring the electrical resistivity-temperature ρ(T). The pellets were carefully cut into bars shaped samples with almost similar dimensions. Electrical contacts were made using silver paint and the contact resistance value was approximately 0.5 Ω. Special care was taken in the temperature interval close to the transition in order to determine accurately the fluctuation contribution to the conductivity. The acquisition of the data close to the transition was obtained with the temperature varying in rates of 3 K/h.

3 Results and discussion

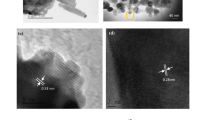

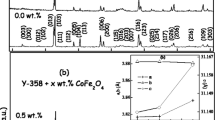

XRD patterns of both milled and unmilled samples are shown in Fig. 1. The XRD analysis shows that all samples are mainly composed of perovskite based Y-123 with orthorhombic Pmmm symmetry. From the SEM micrographs (Fig. 2) and coupled energy dispersive X-ray (EDX) analyses, it is observed that the milled sample exhibits nanoscale entities of Y-deficient Y-123 submerged within the Y-123 crystallites [13]. The Rietveld method has been successfully applied to determine quantitatively phase abundances of the different crystallographic phases in the compound. Therefore, a fitting of the XRD data has been carried out considering stoichiometric Y-123, Y-deficient Y-123 and secondary phases. The estimated concentrations of the different phases are given in Table 1. The Y-deficient Y-123 phase concentration is increased from 4.5 to 30 wt% with increasing the ball to powder weight ratio and the speed of rotation.

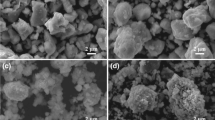

Figure 2(a)–2(e) show the SEM micrographs of the transverse cross-section morphology of sintered samples derived from YBCO precursor oxide with and without ball milling. The milled samples exhibit nano-entities embedded inside the Y-123 matrix [13]. Such entities have not been observed in unmilled samples (Fig. 2(a)). To estimate the elemental compositions, comparative analyses have been performed in the regions where entities are present and absent. Figure 2(f) shows an example of a typical EDX spectrum analysis taken from the regions containing the observed nano-entities. The chemical compositions are illustrated in the inset of Fig. 2(f). Our large set of EDX analyses from several crystallites either from the matrix (R01, R02) or from the embedded nano-particles (R1, R2, R3) can be classified into two phases: stoichiometric Y-123 and Y-deficient Y-123. Nano-particles inside the matrix are consistently yttrium deficient with a small deviation of the yttrium compared to the nominal composition of YBa2Cu3Oy. It should be mention that the density of Y-deficient Y-123 entities increases on increasing the weight ball proportion and rotation speed. A closer examination reveals that fine particles with a spherical shape stick together to form such irregular agglomerates (inset of Fig. 2(c)). The D-milled sample shows a totally different morphology compared to other milled samples. For higher Y-deficient Y-123 wt% content, i.e. for 30 wt% most of the Y-deficient Y-123 nano-particles agglomerate and cover the surfaces of Y-123 crystallites. The use of a suitable energy ball milling variables facilitates the formation of a desired microstructure with an optimal fine Y-deficient Y-123 particles dispersed on the Y-123 matrix.

In order to analyse the intrinsic electrical resistivity of samples, ρ(T) values can instead be normalized to the resistivity of the normal state at temperature 220 K. Figure 3 shows the temperature dependence of the normalized electrical resistivity ρ(T)/ρ(220 K) for samples. All samples show metallic-like behavior in the normal state and a superconducting transition to zero resistance at the temperature T co . T co characterizes the global superconductivity in the samples where the long-range superconducting order is achieved. It shows a progressive decrease with the increase of Y-deficient Y-123 concentration from 0 to 18 wt% and a sharp decrease for higher concentration 30 wt%. The observed decrease in T co (Inset of Fig. 3) with Y-deficient Y-123 content can be explained by the modification of grain boundary characteristics and the decoupling of the superconducting grains. The resistivity curves in the metallic behavior can be expressed by the linear equation such as: ρ n (T) = ρ o + αT, (In our samples, the linear resistivity behavior holds above 150 K approximately) where α is the resistivity temperature coefficient, considered as a parameter that depends on the intrinsic electronic interaction and ρ o is the residual resistivity which is an indicator of the sample homogeneity and defects density. The estimated values of α and ρ o , T co and the broadening transition width ΔT for all samples are included in Table 2. ρ o increases on increasing the Y-deficient Y-123 concentration embedded in Y-123 matrix. It is well established that the ball milling process produces significant perturbation of microstructure in the samples caused by either interfaces, heterogeneities or induced defects. The larger the number of defects, heterogeneities etc., the higher their scattering offered to the mobile carriers and as consequence higher values of ρ o are expected.

Generally, the excess of conductivity due to thermal fluctuation of the order parameter for HTS materials depends both on the internal defects in the structure and on the extrinsic properties of samples such as the grain morphology etc. The excess conductivity Δσ is defined as \( \varDelta \sigma = \frac{1}{\rho (T)} - \frac{1}{{\rho_{n} (T)}} \) where ρ(T) is the measured resistivity and ρ n (T) is the normal resistivity. According to Aslamazov and Larkin theory [1], the excess conductivity Δσ above T c (T c is the mean-field temperature determined as the temperature corresponding to the maximum in \( d\rho /dT \) curves) in the mean-field region, is given by Δσ = Aɛ −λ, where ɛ = (T − T c )/T c is the reduced temperature and λ is the Gaussian critical exponent related with the conduction dimensionality D as λ = 2 − D/2. Values of these exponents are λ 3D = 0.5, λ 2D = 1 and λ 1D = 1.5 for three dimensions (3D), two dimensions (2D), one dimensions (1D) fluctuations respectively. A is a temperature independent constant which is given by \( \frac{{e^{2} }}{{32\hbar \xi_{c} (0)}} \); \( \frac{{e^{2} }}{16\hbar d} \) and \( \frac{{e^{2} \xi_{c} (0)}}{32\hbar s} \) for (3D), (2D) and (1D) cases respectively. e is the electronic charge, ξ c (0) is the zero-temperature coherence length along the c-axis, d is the effective layer thickness of the 2D system and s is the wire cross-sectional area of the 1D system.

In order to compare experimental data with the theoretical expression for the fluctuation conductivity, ln (Δσ) versus ln (ɛ) is plotted in Fig. 4(a)–4(e). The different regions of the plots are linearly fitted and the exponent values are determined from the slopes. It can be seen from Fig. 4 that each plot can be divided into three regions namely critical, mean-field and short wave fluctuation regions. At higher temperature, very far away from the mean-field temperature T c , one can observe a dominance of a short wave fluctuation with power low region whose conductivity exponent λ(SW) ≈ 3. Short-wavelength fluctuations (SWF) effects appear when the characteristic wavelength of the order parameter becomes of the order of coherence length [14, 15]. The first part which is closer to short wave fluctuation region possesses exponent value λ(1D) indicating 1D behavior. Similar behaviors have also been observed in Zn0.95Mn0.05O and ZnO added YBa2Cu3O7–y superconductors [11], in Hg0.8Tl0.2Ba2Ca2Cu3O9−δ substituted by Sm and Yb [16], Dy2BaCuO5 added DyBa2Cu3Oy [17] and in Ag added YBa2Cu3O7−y superconductors [18]. The appearance of 1D excess conductivity suggests the existence of 1D conducting channels in the superconductor. The 1D regime fluctuation has been interpreted by the existence of conducting charge stripes in the superconducting cuprate [19]. This model incorporates electronic and magnetic structural features. Notably the width of the 1D region decreases on increasing the Y-deficient Y-123 concentration (Fig. 4(f)). These results suggest that both microscopic, mesoscopic and inhomogenities destabilize conducting charge stripes. Upon further decrease of the temperature, we identify 2D exponent values λ(2D) ≈ 1 indicating the existence of 2D fluctuations. The width of the 2D region increases on increasing the Y-deficient Y-123 concentration (Fig. 4f). This behavior may be due to the higher density of grain boundaries which contribute to the weak links between the superconducting grains. Larger numbers of grain boundaries each with a different T c can give rise to 2D fluctuation induced conductivity over a wide temperature region [20].

(a)–(e) Variations of excess conductivity Δσ as a function of the reduced temperature ε in ln–ln plot, respectively for unmilled and milled samples. CR critical region, MFR mean-field region, SWR short-wave region. (f) Variations of widths of the 3D, 2D and 1D regions as a function of various concentration of deficient Y-123 nano-particles

Lawrence and Doniach [3] have extended the AL theory for layer superconductor, where conduction occurs mainly in 2D CuO2 planes and these planes are coupled by Josephson tunneling. These authors have predicted a crossover from 2D to 3D behavior of the order parameter fluctuations in the mean-field region at characteristic temperature \( T_{LD} = T_{c} [1 + \,(2\xi_{c} (0)/d)^{2} ] \). The temperature T LD is a measure of intra-granular characteristics [21]. From all plots of Fig. 4, it is clearly seen that T LD slightly shifts towards the lower temperature on increasing the concentration of Y-deficient Y-123. The observed gradual decrease of T LD suggests that Y-deficient Y-123 nano-particles induces microscopic inhomogeneity in the grains. The incorporation of Y-deficient Y-123 nano-particles into the YBCO results in the large number of defects such as inhomogeneities, strain etc. which are suitable centers for oxygen diffusion [22, 23]. Y-deficient Y-123 nano-particles incorporation influences the charge fluctuation in the grains, thus modifying the over all electronic structure of YBCO. Below the 3D fluctuation regime a crossover from mean-field to critical fluctuations region takes place at T G , where the dimensional exponent varies from about 0.34 in the unmilled sample to 0.28, 0.18, 0.17 and 0.13 in the milled ones. These values are expected from the prediction of the 3D-XY universality class, with dynamics given by representative E-model [24]. The existence of such regimes of fluctuation conductivity characterized by a small exponent is reported in thin films of YBCO/Au composites [7], in the YBCO under magnetic field [25], in the Y0.95Pr0.05Ba2Cu3O7–d compound [26] and the Er1−xCexBa2Cu3O7–d sample [27]. This small exponent affects the system dynamics and associated with a crossover to an ultimate weakly first-order character of the normal-superconducting transition of high temperature cuprates [25].

Using the slopes determined through the analysis of experimentally observed data for fluctuation induced conductivity, we can achieve the reliable values of the zero temperature coherence length along the c-axis ξ c (0) and the effective layer thickness d (Table 3). ξ c (0) shows a slight decrease with increase in Y-deficient Y-123 concentration from 0 to 8 wt% and then a sharp increase for higher concentration (18 and 30 wt%). The obtained values are higher than that for highly aligned grains sample (ξ c (0) = 2.3 Å) [28], the single crystal (ξ c (0) = 2 Å) [29] and for thin films (ξ c (0) = 1.4 Å) [30]. This behavior may be attributed to the complex transport properties, the nature of present defects and greater number of inhomogeneities in polycrystalline compounds. The zero coherence length is described by the relation: ξ c (0) = ℏ2 k F /2 mΔ, where the Fermi vector depends on the density of charge carriers (k F = (3π 2 N/V)1/3) [31]. The highest values of the coherence length and interlayer coupling J = (2ξ c (0)/d)2 (Table 3) obtained in the D-milled sample can be understood by the increase of the density of carriers in the conducting planes. Also the estimated values of the effective layer thickness d are much larger than the interlayer spacing 1.17 nm in single crystal of YBCO, so d can be regarded as an effective length in the direction perpendicular to the current over which superconducting correlation extend. The enhancement of core density due to the decrease of grain size of YBCO crystallites as shown in Fig. 2 is a possible source of the decrease of d for samples with lower Y-deficient Y-123 content.

According to the Ginzburg–Landau theory [32], the important physical parameters such as: lower critical magnetic field B c1(0), upper critical magnetic field B c2(0) and critical current density J c (0) can be calculated. In order to estimate the thermodynamic critical magnetic field B c (0), we have used the Ginzburg number N G which is expressed as: \( N_{G} = \left| {(T_{G} - T_{c} } \right.)/\left. {T_{c} } \right| = \frac{1}{2}[k_{B} /B_{C}^{2} (0)\gamma^{2} \xi_{c}^{3} (0)]^{2} \). Where k B is Boltzmann constant and γ is the anisotropy factor [33]. Once it is determined thermodynamic critical magnetic field \( B_{c} (0) = \varphi_{0} /2\sqrt 2 \pi \lambda (0)\xi_{c} (0) \), (\( \varphi_{0} = \frac{h}{2e} \) is the flux-quantum number), we can deduce the lower critical magnetic field \( B_{c1 \, } (0) = \frac{{B_{c} (0)}}{\kappa \sqrt 2 }ln\,\kappa \), the upper critical magnetic field \( B_{c2} \, (0) = \sqrt 2 \kappa B_{c} \) and critical current density \( J_{c} \, (0) = \frac{{4\kappa B_{c1} (0)}}{3\sqrt 3 \lambda (0)ln\,\kappa } \) where κ is the Ginzburg–Landau parameter and is defined as the ratio of the penetration depth to the coherence length. All estimated values for samples are listed in Table 3. It is clear that the B-milled sample incorporated by 8 wt% of Y-deficient Y-123 nano-particles exhibits the best critical magnetic fields (B c1(0) and B c2(0)) and the critical current density J c (0) (Fig. 5). These can be due to the reduction of magnetic vortex motion strengthening of pinning capability within the milled sample. A suitable concentration of Y-deficient Y-123 nano-particles acts as efficient pinning sources and it is the cause of the improvement of flux pinning properties and transport capabilities of material. These results are consistent with those obtained in Gd-123 added with nano-sized ferrite CoFe2O4 [34] and in Y-123 added with nano-sized Zn0.95Mn0.05O and ZnO [11]. The D-milled sample integrated by high concentration of Y-deficient Y-123 nano-particles (30 wt%) exhibits the lower values of the critical superconducting parameters (B c1(0), B c2(0) and J c (0)). This result can be due to the surplus fine particles brought into the prepared milled sample which generate an excess of disorder in the superconducting matrix and weakly coupled grains. So the attainment of optimum concentration and well-dispersed of nano-sized inclusions by ball milling process increases the number of grain boundaries and this would bring about more disorder and fine scale lattice defects and consequently led to an enhancement of the flux pinning properties.

It is advisable to look into the fluctuation induced conductivity analysis and correlate the impact of both silver addition and the incorporation of Y-deficient Y-123 nano-particles in superconducting properties in YBCO compound. In order to compare the relevant silver effect, we have considered the unmilled sample and B-milled sample which is embedded by 8 wt% of Y-deficient Y-123 nano-particles and exhibits the best superconducting characteristics. XRD patterns of both B-milled and unmilled samples sintered with AgNO3 during the final processing stage are shown in Fig. 6. Silver does not change the width and the position of the diffraction peaks of Y-123. Only characteristic peaks corresponding to silver have been identified. We present in Fig. 7 the ρ(T)/ρ(220 K) for Ag-unmilled and Ag-B-milled samples. Compared to non added samples, we have observed a slight increase in the zero resistance temperature \( {\text{T}}_{\text{co}} \) and a decrease in the residual resistivity ρ o with AgNO3 addition (Table 2). This result may be attributed to the improvement of the intergrain connectivity characteristics. Indeed silver does not react chemically with the YBCO but resides in the grain boundaries [35].

Figure 8(a) and 8(b) show SEM micrographs of unmilled and milled samples sintered with AgNO3 respectively. The milled sample sintered with AgNO3 (Fig. 8(b)) have exhibited entities bright in contrast with sizes ranging from 60 to 30 nm. These nano-sized entities take place into the grains with relatively uniform distribution along with some segregation in the grain boundaries compared to free added one (Fig. 2(c)). In order to obtain more detailed information about Ag distribution in the sample, we have performed quantitative EDX analysis on several areas of Ag added milled sample. Our large set of EDX analyses show approximately the presence of the same quantity of silver in addition to Y, Ba, Cu, O elements. Figure 8(c) shows an example of a typical EDX spectrum analysis. Since the milled sample reveals a uniform distribution of nano-sized inclusions, a more homogeneous distribution of grain boundaries is expected. Hence the added Ag will be more finely and uniformly dispersed at the grain boundaries after sintering for the milled sample. However, for the unmilled sample, Ag may be agglomerated with each other to some extent at grain boundaries and led to the formation of silver inhomogeneously distributed in the sample.

SEM micrographs of (a) unmilled, (b) B-milled samples sintered with AgNO3 addition and (c) EDX spectrum taken from the nanoscale entities shown in Fig. 5b

In Fig. 9, we have plotted ln (Δσ) versus ln (ɛ) for Ag-unmilled (a) and Ag-B-milled (b) samples. The calculated superconducting parameters, B c1(0), B c2(0) and J c 0)) for Ag added samples are listed in Table 3. Compared to non added ones, we have revealed that both zero temperature coherence length along the c-axis ξ c (0) and the effective layer thickness of the 2D system d decrease with AgNO3 addition. This behavior may result from the enhancement of the core density and connectivity/interlink between the grains as observed in SEM micrographs. It is believed that Ag diffuses into the grain boundary as a metal during thermal processing and it is responsible for the increasing of the interconnections between the grains. Similar trend has been observed in Pb-doped (Cu0.5–xPbxTl0.5)-1223 superconductors [36]. On the other hand, we have observed a widening of 3D regime compared to non added samples suggesting that the number of mobile carriers scattering source is decreased. The lower and upper critical magnetic fields and the critical current density are enhanced by AgNO3 addition and its values are higher in the Ag added sample embedded with 8 wt% of Y-deficient Y-123 nano-particles (Fig. 10). The better pinning properties of the silver added samples embedded by 8 wt% of Y-deficient Y-123 nano-particles may be attributed to the relatively uniform distribution of nano-sized Y-deficient Y-123 and well dispersed of finer Ag. So, it can be expected that a suitable density of efficient flux pinning sites enhances the critical current density at the applied magnetic field.

4 Conclusions

We have studied the fluctuation induced conductivity of YBCO superconductors in the paraconductivity region. The focus is given to the role of Y-deficient Y-123 superconducting nano-particles embedded in superconducting matrix and generated by a planetary ball milling process. The experimental data of the resistivity are fitted with Aslamazov and Larkin model. Three different regimes corresponding to critical, mean-field and short wave fluctuation regions are observed. We have observed a change of the intrinsic superconducting characteristics and the dimensionality of investigated samples. These results may be attributed to the Y-deficient Y-123 nano-particles. The lower and upper critical magnetic fields and the critical current density are enhanced for sample embedded with 8 wt% of Y-deficient Y-123 nano-particles and then suppressed with further increase of the concentration of Y-deficient Y-123 nano-particles. These results suggest that the attainment of an optimum concentration and well-dispersed of nano-sized inclusions improves the electrical transport capability of samples. On the other hand, we have shown that the best flux pinning is observed in sample with 8 wt% of Y-deficient Y-123 nano-particles and contains silver. This is due to the finely and uniformly distribution of silver and Y-deficient nano-sized particles.

References

L G Aslamazov and A I Larkin Phys. Lett. A 26 238 (1968)

K Maki and R S Thompson Phys. Rev. B 39 2767 (1989)

W E Lawrence and S Doniach, in Proceedings of the Twelfth International Conference on Low Temperature Physics (Kyoto, 1970) (ed.) E. Kanda (Keigaku, Tokyo) p. 361 (1971)

S Hikami and A I Larkin Mod. Phys. Lett. B 2 693 (1998)

E M M Ibrahim and S A Saleh Supercond. Sci. Technol. 20 672 (2007)

U K Mohapatra, R Biswal, D Behera, N C’Mishra Supercond. Sci. Technol. 19 635 (2006)

E J Cukaukas and L H Allen J. Appl. Phys. 84 6187 (1988)

F Ben Azzouz, M Annabi, M Zouaoui and M Ben Salem Phys. Stat. Sol. (c) 9 2978 (2006)

M Sahoo and D Behera J. Phys. Chem. Solids 74 950 (2013)

A Esmaeili and H Sedghi J. Alloys Compd. 537 29 (2012)

I Bouchoucha, F Ben Azzouz and M Ben Salem J. Supercond. Nov. Magn. 24 345 (2011)

A Kujur and D Behera Physica C 483 45 (2012)

A Hamrita, Y Slimani, M K Ben Salem, E Hannachi, L Bessais, F Ben Azzouz, M Ben Salem Ceramics International 40 1461 (2014)

A Mohanta and D Behera Physica C 470 295 (2010)

A Harabor, N A Harabor and M Deletter J. Optoelectron. Adv. M. 8 1072 (2006)

A I Abou-Aly, R Awad, I H Ibrahim and W Abdeen Solid State Commun. 149 281 (2009)

T Sato, H Nakane, S Yamazaki, N Mori, S Hirano, S Yoshizawa and T Yamaguchi Physica C 392 643 (2003)

T Sato, H Nakane, S Yamazaki and N Mori Physica C 372 1208 (2002)

A Bianconi, A Valletta, A Perali and N L Saini, Physica C 296 269 (1998)

A A Khurram, M Mumtaz, N A Khan, M M Ahadian and A Iraji-zad Supercond. Sci. Technol. 20 742 (2007)

J Maza and F Vidal Phys. Rev. B 43 10560 (1991)

J Plain, T Puig, F Sandiumenge, X Obradors and J Rabier Phys. Rev. B 65 104526 (2002)

S K Chen, L Zhou, K G Wang, X Z Wu, P X Zhang and Y Feng Physica C 377 571 (2002)

P C Hohenberg and B I Halperin Rev. Mod. Phys. 49 435 (1977)

R Menegotto Costa, P Pureur, M Gusmão, S Senoussi, K Behnia Solid State Commun. 113 23 (2000)

F M Barros et al Phys. Rev. B 73 094515 (2006)

Y A Opata et al Mod. Phy. Lett. B 25 1671 (2011)

S I Lee Synth. Met. 71 1547 (1995)

B Oh et al Phys. Rev. B 37 7861 (1988)

W Göb, W Lang, W Kula and R Sobolewski Superlattice Microst. 21 345 (1997)

S Ismail, A K Yahya and N A Khan Ceramics International 39 S257 (2013)

M P Rojas Sarmiento, M A Uribe Laverde, E Vera López, D A Landinez, J Roa-Rojas Physica. B 398 360 (2007)

B Lundqvist, Ö Rapp and M Andersson Phys. Rev. B 62 3542 (2000)

A I Abou Aly, N H Mohammed, R Awad, H A Motaweh and D El-Said Bakeer J. Supercond. Nov. Magn. 25 2281 (2012)

Y Zhao and C H Cheng Physica C 386 286 (2003)

N A Khan, A A Khurram, U Firdous, S Ullah and S Khan Physica C 474 29 (2012)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hannachi, E., Slimani, Y., Ben Salem, M.K. et al. Fluctuation induced conductivity studies in YBa2Cu3Oy compound embedded by superconducting nano-particles Y-deficient YBa2Cu3Oy: effect of silver inclusion. Indian J Phys 90, 1009–1018 (2016). https://doi.org/10.1007/s12648-016-0839-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12648-016-0839-4

Keywords

- Y-123 superconductor

- Y-deficient Y-123 nano-particles

- Excess conductivity

- Critical superconducting parameters