Abstract

Freeze-dried banana powder represents an ideal source of nutrients and has not yet been used for probiotic incorporation. In this study, microencapsulation by freeze drying of probiotics Lactobacillus acidophilus and Lactobacillus casei was made using whey protein isolate (WPI), fructooligosaccharides (FOS), and their combination (WPI + FOS) at ratio (1:1). Higher encapsulation yield was found for (WPI + FOS) microspheres (98%). Further, microcapsules of (WPI + FOS) were used to produce a freeze-dried banana powder which was analyzed for bacterial viability under simulated gastrointestinal fluid (SGIF), stability during storage at 4 °C and 25 °C, and chemical and sensory properties. Results revealed that (WPI + FOS) microcapsules significantly increased bacteria stability in the product over 30 days of storage at 4 °C averaging (≥ 8.57 log CFU/g) for L. acidophilus and (≥ 7.61 log CFU/g) for L. Casei as compared to free cells. Bacteria encapsulated in microspheres (WPI + FOS) were not significantly affected by the SGIF, remaining stable up to 7.05 ± 0.1 log CFU/g for L.acidophilus and 5.48 ± 0.1 log CFU/g for L.casei after 90 min of incubation at pH 2 compared to free cells which showed minimal survival. Overall, encapsulated probiotics enriched freeze-dried banana powders received good sensory scores; they can therefore serve as safe probiotics food carriers.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Probiotics are living microorganisms which when consumed in adequate quantities confer beneficial effect on health [1]. More studies revealed that the number of probiotics inside the colon can be improved by prebiotics, which are non-digestible food ingredients found to promote the growth of helpful bacteria in the gut [2]. However, the use of probiotics in food carrier is limited by their sensitivity to various factors such as pH, production temperatures, post acidification, hydrogen peroxide, and storage temperature, as reported by many studies [3, 4].

Microencapsulation is one of the latest technologies used to preserve probiotic bacteria from detrimental environment, allowing the release of a large amount of viable bacteria in the gut [5]. Among the various encapsulating agents, whey protein isolate (WPI) has been successfully used as wall material for the microencapsulation of bacteria [6,7,8] and fructooligosaccharides exerted efficient prebiotics properties when used for the encapsulation of Lactobacillus plantarum and its incorporation into noodles formulation [9].

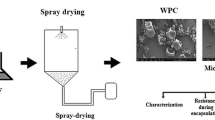

Although spray drying is widely used due to its low-cost production, freeze drying provides products of better quality mainly because the temperature used stay low during the whole process. At low temperature, the aroma, the majority of the taste, the texture, and the nutrients could be kept intact. The color does not change much in comparison to spray drying and can therefore get more consumer acceptance of the product [10].

Commonly used probiotics products are dairy products, but more attention is given to non-dairy products in response to the growing demand of vegetarian and lactose intolerant consumers. Banana powder represents an excellent alternative due to its nutritious properties, low cost of raw material, and availability round the year.

More banana powder has been found to be useful as a general treatment for dyspepsia [11]. However, the development of such products requires to not only maintain the probiotics viability to a minimum of 106 CFU/g for their effective functionality, but also to meet consumers’ acceptability [1].

In this context, the present study addresses two major research objectives. Firstly, to investigate the effects of microencapsulation by freeze drying using a combination of whey protein isolate and fructooligosaccharides on the survival of a mixture of probiotic bacteria. Secondly, to develop a novel functional food and to report the microcapsules effect on bacteria stability into the product, the chemical properties over 30 days of storage, the sensory qualities, and the in vitro viability.

Materials and Methods

Cells and Reagents

Commercial probiotic strains of Lactobacillus acidophilus and Lactobacillus casei were obtained from Jiangsu Beneficial Bacteria and Biological Technology Co., Ltd. (Jiangsu, China), whey protein isolate (92%) used in this study was purchased from Beijing Milky Way Trade Corp., Ltd. (Beijing, China), and fructooligosaccharides was provided by Baolingbao Biology Co., Ltd. (Shandong, China).

Cells Preparation

After a detailed literature review on health benefits of probiotics, two species widely used for their proven beneficial healthy properties were chosen. Commercial freeze-dried cultures of L.acidophilus and L.casei were stored at − 4 °C and revived at room temperature prior to use. The strains were reactivated for three times before use. The strains were inoculated into MRS broth (Huankai Microbial Sci & Tech Co., Ltd., Guangzhou, China) and incubated at 37 °C for 24 h. The cells were harvested by centrifugation (Allegra™64R, Beckman, Germany) at 3000 g, 4 °C for 10 min, and washed twice with saline solution. Afterwards, cells were dispersed into saline solution and used for encapsulation. Prior to encapsulation, the viable cell count was performed after tenfold serial dilutions followed by pour plate on a modified Man–Rogosa Sharpe mMRS–BPB medium (by adding 0.05% w/v cysteine and 0.002% w/v bromophenol blue, pH 6.5). The use of the medium mMRS–BPB enabled a differential enumeration of both species L.acidophilus and L. casei following a method described by Lee and Lee [12]. Cells were incubated for 72 h at 37 °C. Final identification of each strain was done using classic microbiology tests including Gram staining for morphological detection, mobility, catalase and oxidase tests, indole producing, and carbohydrates fermentation (arabinose, fructose, galactose, lactose, mannitol, salicin, sucrose, and trehalose) tests. The viable cell counts of both strains before encapsulation were 3 × 109 ± 0.1 CFU/g for L.acidophilus and 2 × 109 ± 0.1 CFU/g for L.casei.

Microencapsulation

All glasswares used in this experiment were sterilized at 121 °C for 15 min. Probiotic bacteria L.acidophilus and L.casei were encapsulated by three different wall material preparations: whey protein isolate(WPI), fructooligosaccharides (FOS), and their combination at 1:1 ratio (WPI + FOS). Encapsulation was made according to the method described by Rajam et al. [13] with some modifications. Briefly 25 g of FOS powder was dissolved in 200-mL sterile milli-Q water using a magnetic stirrer. From samples of 10 mL of the culture volume, freshly harvested cell concentrate of L.acidophilus (15 g), and L.casei (15 g) were mixed thoroughly with FOS solution to obtain 1:1 core to wall ratio. WPI powder (12.5 g) was mixed with sterile milli-Q water (112.5 mL), and the solution (10% w/v) was stirred gently using a magnetic stirrer to dissolve the WPI. To denature the whey protein, the whey protein isolate solution (10% w/v) was kept at 90 °C for 30 min in a water bath and then cooled to room temperature [14]. FOS powder (12.5 g) dissolved in 87.5-mL sterile milli-Q water was blended with WPI solution and homogenized at 100 rpm for 5 min. The freshly harvested cell concentrate of L.acidophilus and L.casei (30 g) was mixed together with WPI + FOS in order to obtain a desired core to wall ratio of 1:1. All sample solutions were homogenized for 60 s at 7000 rpm and stored at − 4 °C for 48 h prior to freeze drying. The samples were freeze dried in a pilot scale freeze drier (− 40 °C) for 24 h. The freeze-dried microcapsules were collected, packed in polythene bags, sealed in aluminum foil, and stored at 4 °C until further characterization.

Encapsulation Yield

The encapsulation yield (EY) is a criterion to measure the influence of the encapsulation procedure on the number of living cells. The EY was calculated according to the method described by Heidebach et al. [15] as follows:

Where (Cpcm) represents the ratio between the protein concentration of the protein–cell mixture and Cslurry the resulting capsule–slurry.

Morphological Characterization of the Microcapsules

The morphology of freeze-dried microcapsules was examined prior to storage using a Hitachi S4300/N field emission, variable pressure, and scanning electron microscope (SEM). The working distance was 11.3 mm and beam energy was 1.2 kV. Prior to SEM examination, the microcapsule powders were mounted on a double sided carbon tape on a stud and coated with gold.

Manufacture of Probiotics Enriched Banana Powder

Raw Material

The raw materials used in this work were ripened banana fruits variety Cavendish purchased from a local market, showing 75% of ripening (yellow color with green tips). Banana showed an average moisture content of 77.5% (w/v), which is suitable for obtaining banana flour [16]. This stage corresponds to stage 5 of the banana ripening color index [17].

Preparation of Free and Encapsulated Probiotics Enriched Banana Powder

We used 500 g of bananas to obtain one batch of paste. The paste was prepared as follows: bananas were washed in chlorinated water (4 ppm); then blanched for 30 min in boiling water to reduce the number of microorganisms, inactivate the enzymes, and prevent the discoloration [16]. Fruits were then peeled, cut into 0.5-cm thick slices, drained the juices for 5 min, and grinded in a laboratory mixer.

Free or encapsulated cells (1 g corresponding to 3 × 109 ± 0.1 CFU/g for L.acidophilus and 2 × 109 ± 0.1 CFU/g for L.casei.) were incorporated into 30 g of banana paste and refrigerated at − 32 °C for 72 h prior to freeze drying. The frozen free and encapsulated probiotics banana pastes were then transferred to a freeze dryer and let to operate for 24 h at − 40 °C (100 kPa). The freeze-dried inoculum was grinded using an electric grinder and filtered to obtain a powder without lumps. Probiotic organisms were enumerated manually by pour plates counting after incubation on a modified MRS agar at 42 °C for 48 h under aerobic conditions. Strains were further identified by the microbiology tests as mentioned earlier.

Cells Survival During Storage at 4 °C and 25 °C

After freeze drying, cell stability in powders was evaluated during 30 days of storage at 4 °C and 25 °C. Powders were rehydrated by adding 2 mL of peptone water and enumerated after incubation on MRS agar at 42 °C for 48 h under aerobic conditions.

Chemical Properties of the Product During Storage

Following the freeze-drying process, the samples were stored at 4 °C and 25 °C and were characterized for their pH, moisture content, total soluble sugars, reducing sugars, and buffering capacity on day 0, 7, 15, 20, and 30. Free and encapsulated probiotic banana powders were extracted by shaking with water (1:4; w/v) for 40 min at 100 rpm and centrifuged at 6000 × g for 30 min at room temperature. The supernatants (extracts) were used for chemical analysis.

Total soluble sugars and reducing sugars were determined by the phenol-sulfuric acid method [18] and dinitrosalicylic method [19] respectively. A set of glucose solutions was used to determine a standard curve.

The moisture content of freeze-dried free and encapsulated banana powders were determined in triplicate by oven, drying the powders at 102 °C, determining the difference in weight, and expressing the weight loss as a percentage of the powder weight according to the powder moisture routine method [20].

pH was measured by an electronic pH meter (PHS-3C, Shanghai Precision & Scientific Instrument Co., Ltd), and buffering capacity was determined by titrating 100 mL of the extract with 1 N HCl. The values were expressed as mmol of HCl required to lower 1 pH of 1 L extract [21].

Sensory Evaluation of the Banana Powder

A series of acceptability trials were carried out using simple triangle test at the laboratory scale and a selection of a panel of ten judges between the age group of 18 to 35 years as suggested by Jellinek et al. [22]. Sensory evaluation of the developed banana preparations were carried out using score cards based on a ten points hedonic scale by the panelists. The quality attributes namely appearance, color, flavor, texture, and taste and overall acceptability were evaluated.

Survival of Bacteria in Simulated Gastrointestinal Fluids

Simulated gastric fluid (SGF) was prepared according to Lian et al. [23] with slight modifications. Briefly, pepsin (3 g/L) was suspended in sterile NaCl solution (0.5% w/v). The pH of the solution was adjusted to pH 2.0 with 12 M HCl, and filtered through a 0.22-μm filter membrane (Pall Corporation, USA). SIF was prepared according to US Pharmacopeia [24]. Briefly, 6.8 g of monobasic potassium phosphate (Sigma, St. Louis, MO, USA) was dissolved in 250 mL of distilled water, followed by addition of 77 mL of 0.2 M NaOH, and 500 mL of distilled water. The solution was vortexed for 30 min and 10 g of pancreatin was added and mixed. pH of the solution was adjusted to 6.8 with 0.2 M NaOH or 0.2 M HCl. The total volume of the solution was made up to 1000 mL, followed by filtration through a 0.45 μm filter membrane to remove particulate material, and then filter sterilized through a 0.22-μm filter membrane.

One gram of non-encapsulated and encapsulated samples was then dispersed into separate test tubes containing 9 mL of SGF (pH 2.0). The tubes were vortexed for 30s and incubated at 37 °C in a shaker incubator (Lasec, LM-575R) at 50 rpm for 2 h. One milligram sub-samples were withdrawn from each tube at 30 min intervals and the cell density was enumerated using plate count assay followed by strain identification. Remaining culture was pelleted by centrifugation using a LabnetPrism™ microcentrifuge at 7267 × g for 5 min. The pellets were re-suspended in 9 mL of SIF (pH 6.8) and incubated as before. One milligram sub-samples were taken at 2 h intervals until 6 h for bacterial enumeration. After removal of each sub-sample, equal volume of sterile SGF or SIF was replaced to maintain the concentration of the sample.

Statistical Analysis

The experiment data for banana powder pH, moisture content, and other chemical analyses were expressed as mean ± standard deviation of three replicates in a completely randomized design. The data were subjected to a one-way ANOVA and a comparison of differences between means was carried out with a least significant difference test (p ≤ 0.05) using SPSS 22 Advanced Statistics (IBM; Armonk, NY, USA).

Results and Discussion

Encapsulation Yield

The encapsulation yield is a key factor to determine the success of the encapsulation method and to evaluate the efficiency of the selected encapsulating agents. Selecting the appropriate coating materials will decide the physical and chemical properties of the resultant microcapsules [25]. For both probiotics L.acidophilus and L.casei, the EY was calculated for different formulations such as when encapsulated with only (WPI), or (FOS), and combination of (WPI + FOS). For each formulation, the EY was calculated according to Eq. (1) and expressed in Fig. 1. For the three formulations WPI, FOS, and WPI + FOS, the EY values were 86%, 90%, and 98% respectively. It can be seen that for all three types of microspheres, there was no significant reduction in cell viability (p < 0.05) which can be attributed to the low temperature application of the freeze-drying process (− 40 to 30 °C) preserving the cell surface. Similar results were previously reported by Patricia Bolla et al. [26] where the application of freeze drying for the microencapsulation of a microbial mixture of selected probiotics resulted in higher encapsulation yields. Hence, the microspheres (WPI + FOS) showed the highest encapsulation yield (98%) compared to the formulations containing a single encapsulating agent WPI and FOS, (80, 90% respectively). These findings indicate the efficiency in associating WPI and FOS for probiotics encapsulation. It is in conformity with previous study which reported higher survival rates for the encapsulation of L. plantarum when using WPI coupled with FOS as coating material [9]. WPI, on its account, has been proved to exert excellent protective capacity. Indeed, just like the gelatin, WPI is able to form gels in the favorable conditions which is suitable for the formation and solidification of the wall material. Ainsley Reid et al. [8] reported that the process of microencapsulation in WPI microspheres can help in protecting the freeze-dried cells against subsequent conditions such as freezing of food products. Hence, WPI used alone were not as efficient as when used combined with FOS, therefore, our results suggest that the protective effect provided by microspheres (WPI + FOS) is as well due to the adjunction of FOS. Fructooligosaccharides are hydrocolloids and they thereby play a protective role towards probiotic microorganisms. Kaplan et al. [27] also reported this complimentary role of FOS revealing that among many prebiotics tested (inulin, hi-maize, FOS, etc.), FOS was found to be the most effective in retaining the viability of probiotics organisms. More FOS was successfully used to enhance probiotic cell viability in yogurt during freeze-drying process [28].

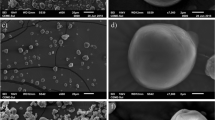

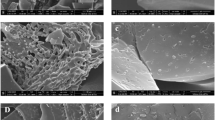

Morphological Characterization by Scanning Electron Microscopy

The morphological characteristics of the freeze-dried microcapsules (WPI + FOS) were determined by scanning electron microscopy as shown in Fig. 2. The SEM photograph of (WPI + FOS) microcapsules (Fig. 2a) showed generally spherical shapes with wrinkled and rough surfaces. Similar morphologies for freeze-dried microcapsules were reported by previous studies [9, 28]. The variations in microstructures observed in cells encapsulated with (WPI + FOS) (Fig. 2a) are due to the differences in viscoelastic and film forming properties of each wall material [9]. In addition, it was observed that the bacteria were randomly distributed in the wall materials (Fig. 2b) which proved a total embedding of the bacteria in the matrix.

Survival of Bacteria During Storage at 4 °C and 25 °C

To benefit consumers, probiotics incorporated functional food should be able to maintain probiotics recommended amount during their storage period (≥ 106 CFU). The survival of free and encapsulated cells during the storage period is shown in Figs. 4 and 5. The survival rates of freeze-dried cells for both bacteria L.acidophilus and L.casei in banana powder at 4 °C was greater than that at 25 °C (Figs. 4 and 5). At 25 °C, the number of free and encapsulated bacteria reduces in time while these numbers slightly change at 4 °C. The reduction rate of the initial population of probiotics was significant in all media when stored at 25 °C (p < 0.05). Results showed that the combination of coating material (WPI–FOS) enabled the bacteria to survive maintaining the recommended bacterial amount during the storage period of 30 days. Results obtained (Figs. 4 and 5) strongly suggest that microspheres (WPI–FOS) played an efficient protective action on the bacteria during the storage period in plastic containers. The better survival rate observed when stored at 4 °C can be explained by the fact that low temperatures affect growth kinetics and preserve cells [29]. Many studies reported a better stability at lower temperatures [30]. The lower stability at room temperature could induce higher moisture and relative humidity which are favorable factors for bacterial growth [19]. L.casei exerted a better survival behavior at 25 °C compared to L.acidophilus which can be linked to its ability to tolerate higher temperatures than L.acidophilus.

Chemical Properties of the Product During Storage

The chemical properties of the samples were studied over 30 days of storage (Table 1). For each sample, it can be observed that the addition of probiotic bacteria lower the pH value of the banana preparation. The lowering of the pH values caused by the addition of probiotic bacteria is a typical observation with lactic acid bacteria due to their properties to acidify the medium in which they are used. The pH values recorded during the storage period (5.11–5.28) were within the optimal pH range of the selected bacteria L.acidophilus and L.casei which indicates the suitability of banana powder as the food carrier. These pH values observed for medium containing microspheres of WPI + FOS could be considered as a positive indication. Such medium can safely protect the bacteria in the low pH of the acidic environment of the human stomach. In Table 1, it can be seen that the inoculum system containing (WPI + FOS) encapsulated bacteria had the highest buffering capacity, thus it potentially protects the bacteria from undesirable acidic conditions. Moisture content of the various bacterial preparations (Table 1) shows that microsphere containing (WPI + FOS) encapsulated bacteria had lower moisture contents compared to free cells. This lower moisture content is a good indicator for the storage of the product, as lower moisture rate could extend the shelf life by reducing the chance of proliferation by spoilage-inducing microorganisms.

Sensory Evaluation of the Banana Powder

The results of the sensory evaluation graphically represented in Fig. 3 revealed that the freeze-drying process maintained the product’s sensory qualities. Indeed, during the freeze-drying process, small amounts of the product are frozen in; and due to the vacuum, the ice will evaporate immediately without turning into water again. Consequently, the majority of the taste, the texture, and the nutrients will stay intact. As revealed in Fig. 3, the mean score for appearance, color, and taste, and overall acceptability of the encapsulated powder samples were liked very much (between 8 and 9 in hedonic scale) while texture and flavor were moderately liked (between 7 and 8 in hedonic scale). The slightly low acceptance with regard to texture and flavor could be attributed to the encapsulated form of bacteria with WPI and FOS which also affect the flavor.

Cells survival during storage at 4 °C; the data represent the means of four experiments. Error bars represent standard deviation. All mean survival rates were significantly different (p < 0.01). Free Lactobacillus casei (Free.Lc), free Lactobacillus acidophilus (Free.L.a), encapsulated Lactobacillus casei (Enc.L.c), and encapsulated Lactobacillus acidophilus (Enc.L.a)

Cells survival during storage at 25 °C; the data represent the means of four experiments. Error bars represent standard deviation. All mean survival rates were significantly different (p < 0.01). Free Lactobacillus casei (Free.Lc), free Lactobacillus acidophilus (Free.L.a), encapsulated Lactobacillus casei (Enc.L.c), and encapsulated Lactobacillus acidophilus (Enc.L.a)

Survival of free and encapsulated Lactobacillus acidophilus and Lactobacillus casei. Under simulated gastric fluid (SGF) pH 2. Data are expressed as the mean ± SD of three experiments. Free Lactobacillus casei (Free.Lc), free Lactobacillus acidophilus (Free.L.a), encapsulated Lactobacillus casei (Enc.L.c), and encapsulated Lactobacillus acidophilus (Enc.L.a)

Survival of free and encapsulated Lactobacillus acidophilus and Lactobacillus casei under simulated intestinal fluid (SIF) pH 7.4. Data are expressed as the mean ± SD of three experiments. Free Lactobacillus casei (Free.Lc), free Lactobacillus acidophilus (Free.L.a), encapsulated Lactobacillus casei (Enc.L.c), and encapsulated Lactobacillus acidophilus (Enc.L.a)

Viability Under Simulated Gastric Fluid (Low pH)

According to the results of the studies of bacterial preparations in SGF (Fig. 6), it can be seen that although both free and (WPI + FOS) encapsulated bacterial numbers decreased during the exposure period, at the end of the 90-min exposure, only encapsulated bacteria were in sufficient amount to be beneficial to human consumption (> 106 CFU) [1]. Hence, the microspheres (WPI + FOS) were able to procure an efficient protective effect to the bacteria when exposed to SGF. The survival was maintained throughout the 90 min of exposure averaging 7.85 log CFU/g and 7.52 log CFU/g for L.acidophilus and L.casei respectively. Free cells of L.acidophilus decreased by about 4.69 log CFU/g, and free cells of L.casei decreased by about 5.64 log CFU/g. Encapsulated cells of L.acidophilus were 2.8 log CFU/g higher than those of L.casei after 90 min under same conditions with a significant difference between free and encapsulated bacteria (p < 0.05). These positive results suggest that microspheres (WPI + FOS) were effective at protecting probiotic bacteria while undergoing the detrimental conditions created in the SGF. These findings are in accordance with those previously reported by Zou Qiang et al. [31] who assessed the efficiency of WPI microspheres to protect strains of Bifidobacteriumbifidum under simulated gastric conditions. Studies reported the ability of WPI to create a buffered microenvironment within the hydrated colloid particle surrounding the embedded bacteria, thus isolating the bacteria from the stresses of the low pH external environment [32]. This improved survival could also be linked to the synergic action of FOS acting as nutrient supporting bacterial resistance [33]. More, the high buffering capacity exhibited by encapsulated probiotics in microspheres (WPI–FOS) might have played an important role in resisting acidity. Strain of bacteria may also have a role in this buffering effect. Indeed, Rius et al. [34] have reported that L. acidophilus have high cytoplasmic buffering capacity (pH 3.72–7.74), which may allow them to resist changes in cytoplasmic pH and gain stability under acidic conditions. Free cells considerably decreased between the 10 and 30 min of incubation. Many studies reported a loss of lactic acid bacteria during the first 30 min of exposure to SGF [35,36,37]. Therefore, as the recommended amount of probiotics about 106 CFU live microorganisms per gram, it can be stated that the microcapsules (WPI + FOS) can be used to enhance viability of probiotics bacteria at low pH conditions.

Survival of Bacteria in Simulated Intestinal Fluid

The overall bacteria revival (Fig. 7) can be linked to the recovery of some cells sub-lethally injured during the incubation in SGF by phenomena of resuscitation. Similar results have been reported by Chaikham et al. [38] where strains of encapsulated L.acidophilus and L.casei in processed Logan juices were able to exert antibacterial activity after undergoing SIF. Moreover, Charteris et al. [39] reported that whey protein isolate is able to protect lactic acid bacteria from gastrointestinal stress by acting as a buffering agent and inhibiting activity of digestive enzyme. High survival of WPI–FOS encapsulated bacteria can also be attributed to the property of FOS. Indeed, Corcoran et al. [40] assessed that sugar provides ATP to F0F1-ATPase via glycolysis, enabling proton exclusion and thereby enhancing bacteria survival during gastrointestinal transit. On contrary to free cells, encapsulated bacteria were not dramatically affected by the SGIF indicating the efficiency of microspheres (WPI–FOS) for the safe delivery of viable probiotics to the human gastrointestinal tract.

Conclusion

In this study, the potential of microencapsulation by freeze drying using whey protein isolate and fructooligosaccharides as wall material to maintain the viability of two probiotics incorporated in a freeze-dried banana powder was evaluated. Among three formulations tested including WPI, FOS, and WPI + FOS, microspheres (WPI + FOS) exerted the highest encapsulation yield. More, encapsulation by freeze drying in WPI coupled with FOS was effective in protecting the viability of probiotics bacteria L.acidophilus and L.casei during storage at a preferable temperature of 4 °C. The total count of (WPI + FOS) encapsulated bacteria was significantly higher than free cells under simulated gastrointestinal conditions. From the results, it can be concluded that microcapsules (WPI + FOS) represent an effective and promising method to maintain the survival of viable probiotics bacteria and their safe delivery into the gut. The supplementation of the banana powder with (WPI–FOS) microcapsules did not alter its sensory qualities, suggesting its use as a potential probiotic food carrier. In vivo, clinical studies are required to further investigate the potential health attributes of (WPI–FOS) microcapsules to consumers.

References

Shah NP (2007) Functional cultures and health benefits. Int Dairy J 17:1262–1277

Gibson GR, Roberfroid MB (1995) Dietary modulation of the human colonic microbiota – introducing the concept of prebiotics. J Nutr 125:1401–1412

Doleyres Y, Lacroix C (2005) Technologies with free and immobilized cells for probiotic bifidobacteria production and protection. Int Dairy J 15:973–988

Fu N, Chen XD (2011) Towards a maximal cell survival in convective thermal drying processes. Food Res Int 44:1127–1149

Hsu YL, Chu IM (1992) Poly(ethylenimine)-reinforced liquid-core capsules for the cultivation of hybridoma cells. Biotechnol Bioeng 40:1300–1308

Picot A, Lacroix C (2004) Encapsulation of bifidobacteria in whey protein-based microcapsules and survival in simulated gastrointestinal conditions and in yogurt. Int Dairy J 14:505–515

Guerin D, Vuillemard J, Subirade M (2003) Protection of bifidobacteria encapsulated in polysaccharide-protein gel beads against gastric juice and bile. J Food Prot 66:2076–2084

Ainsley Reid A, Champagne CP, Gardner N, Fustier P, Vuillemard JC (2007) Survival in food systems of Lactobacillus rhamnosus R011 microentrapped in whey protein gel particles. J Food Sci 72:31–37

Rajam R, Bharath Kumar S, Prabhasankar P, Anandharamakrishnan C (2015) Microencapsulation of Lactobacillus plantarum MTCC5422 in fructooligosaccharide and whey protein wall systems and its impact on noodle quality. LWT Food Sci Technol 52(7):4029–4041

Wang J, Zhi LY, Chen RR, Bao JW, Yang GM (2007) Comparison of volatiles of banana powder dehydrated by vacuum belt drying, freeze-drying and air-drying. Food Chem 104(4):1516–1521

Thompson Coon J, Ernst E (2002) Systematic review: herbal medicinal products for non-ulcer dyspepsia. Aliment Pharmacol Ther 16:1689–1699

Lee HM, Lee Y (2008) A differential medium for lactic acid-producing bacteria in a mixed culture. Lett Appl Microbiol 46:676–681

Rajam R, Karthik P, Parthasarathi S, Joseph G, Anandharamakrishnan C (2012) Effect of whey protein–alginate wall systems on survival of microencapsulated Lactobacillus plantarum in simulated gastrointestinal conditions. J Funct Foods 4:891–898

Dissanayake M, Vasiljevic T (2009) Functional properties of whey proteins affected by heat treatment and hydrodynamic high-pressure shearing. J Dairy Sci 92:1387–1397

Heidebach T, Först P, Kulozik U (2009) Transglutaminase-induced caseinate gelation for the microencapsulation of probiotic cells. Int Dairy J 19(2):77–84

Manica I (1997) Banana. Porto Alegre: Cinco Continentes. Frutic Trop 4:485

Aurore G, Parfait B, Fahrasmane L (2009) Bananas raw materials for making processed food products. Trends Food Sci Technol 20:78–91

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colormetric method for determination of sugars and related substances. Anal Chem 28:350–356

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31(3):426–428

De Knegt RJ, Brink HVD (1998) Improvement of the drying oven method for the determination of the moisture content of milk powder. Int Dairy J 8:733–738

Van Slyke DD (1992) On the measurement of buffer values and on the relationship of buffer value to the dissociation constant of the buffer and reaction of the buffer solution. J Biol Chem 52:525–570

Jellinek G (1985) Sensory evaluation of food - theory and practice. Ellis Horwood Ltd. John Wiley and Son, Chichester England and VCH Verlagsgesellschaft mbh, Weinheim, p 218

Lian WC, Hsiao HC, Chou CC (2003) Viability of microencapsulated bacteria in simulated gastric juice and bile solution. Int J Food Microbiol 86:293–301

United States Pharmacopeia and National Formulary (2002) United States Pharmacopeial Convention Inc., Rockville, MD, USA, 25th edn

Agnihotri N, Mishra R, Goda C, Arora M (2012) Microencapsulation- a novel approach in drug delivery: a review. Indo Global J Pharm Sci 2:1–20

Bolla PA, de Serradell ML, de Urraza PJ, De Antoni GL (2011) Effect of freeze-drying on viability and in vitro probiotic properties of a mixture of lactic acid bacteria and yeasts isolated from kefir. J Dairy Res 78:15–22

Kaplan H, Hutkins RW (2000) Fermentation of fructooligosaccharides by lactic acid bacteria and bifidobacteria. Appl Environ Microbiol 66:2682–2684

Capela P, Hay TKC, Shah NP (2006) Effect of cryoprotectants, prebiotics and microencapsulation on survival of probiotic organisms in yoghurt and freeze-dried yoghurt. Food Res Int 39(2):203–211

Heidebach T, Först P, Kulozik U (2010) Influence of casein-based microencapsulation on freeze-drying and storage of probiotic cells. J Food Eng 98(3:309–316

Bielecka M, Biedrzycka E, Majkowska A (2002) Selection of probiotics and prebiotics for synbiotics and confirmation of their in vivo effectiveness. Food Res Int 35:139–144

Sanders ME, Marco MLF (2010) Food formats for effective delivery of probiotics. Annu Rev Food Sci Technol 1:65–85

Zou Q, Zhao JX, Liu XM, Tian FW, Zhang HP, Zhang H, Chen W (2011) Microencapsulation of Bifidobacterium bifidum F-35 in reinforced alginate microspheres prepared by emulsification/internal gelation. Int J Food Sci Technol 46(8):1672–1678

Ying D, Schwander S, Weerakkody R, Sanguansri L, Gantenbein-Demarchi C, Augustin MA (2013) Microencapsulated Lactobacillus rhamnosus GG in whey protein and resistant starch matrices: probiotic survival in fruit juice. J Funct Foods 5:98–105

Rius N, Sole M, Francia A, Lorén JG (1994) Buffering capacity and membrane H+ conductance of lactic acid bacteria. FEMS Microbiol Lett 120:291–296

Kailasapathy K, Masondole (2005) Survival of free and microencapsulated Lactobacillus acidophilus and Bifidobacterium lactis and their effect on texture of feta cheese. Aust J Dairy Technol 60:252–258

Shan NP, Jelen P (1990) Survival of lactic acid bacteria and their lactases under acidic conditions. J Food Sci 55:506–509

Van de Guchte M, Serror P, Chervaux C, Smokvina T, Ehrlich SD, Maguin E (2002) Stress responses in lactic acid bacteria. Antonie Van Leeuwenhoek 82(1–4):187–216

Chaikham P, Apichartsrangkoon A, Worametrachanon S, Supraditareporn W, Chokiatirote E, Van de Wiele T (2013) Activities of free and encapsulated Lactobacillus acidophilus LA5 or Lactobacillus casei 01 in processed Logan juices on exposure to simulated gastrointestinal tract. J Sci Food Agric 93(9):2229–2238

Charteris WP, Kelly PM, Morelli L, Collins JK (1998) Development and application of an in vitro methodology to determine the transit tolerance of potentially probiotic Lactobacillus and Bifidobacterium species in the upper human gastrointestinal tract. J Appl Microbiol 84:759–768

Corcoran BM, Ross RP, Fitzgerald GF, Stanton C (2003) Comparative survival of probiotic lactobacilli spray-dried in the presence of prebiotic substances. J Appl Microbiol 96:1024–1039

Funding

This work was supported by Applied Technology Research and Development Project of Harbin in 2017 (2017RAQXJ087).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

This article does not contain studies with human or animal subjects.

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Massounga Bora, A.F., Li, X., Zhu, Y. et al. Improved Viability of Microencapsulated Probiotics in a Freeze-Dried Banana Powder During Storage and Under Simulated Gastrointestinal Tract. Probiotics & Antimicro. Prot. 11, 1330–1339 (2019). https://doi.org/10.1007/s12602-018-9464-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12602-018-9464-1