Abstract

Three Pd/CeO2 catalysts were, respectively, prepared by reduction–deposition and impregnation method (IMP) to investigate the effect of chemical state of Pd on CO oxidation. Two kinds of surface Pd species, namely PdO and Pdδ+ (2 < δ ≤ 4) in PdxCe1−xO2, were identified in all Pd/CeO2 samples although their relative ratios in each sample were different. Surface PdxCe1−xO2 species were found to be very active for CO oxidation, and it could act as a channel by which active oxygen species can be transferred from CeO2 to Pd species for CO oxidation. Our results reveal that the preparation method can severely influence the chemical state of Pd which can further determine the activity for CO oxidation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Catalytic oxidation of CO has been widely investigated due to its extensive industrial application and academic value. Supported noble metal catalysts have been proved to behave high activity for CO oxidation [1, 2]. Among them, supported Pt and Pd catalysts are generally recognized to be excellent catalysts at high temperature [3,4,5,6,7]; however, they show poor activities for low-temperature CO oxidation due to the competitive adsorption between CO and O2 on the surface [8,9,10]. This CO poisoning effect can be well suppressed by choosing proper supports [11].

Ceria (CeO2) possesses unique oxygen storage capacity (OSC) and high redox property through Ce4+/Ce3+ redox pairs, which could efficiently decrease the formation energy of oxygen vacancies [12,13,14]. Hence, CeO2 can not only be directly used as the active component of the catalyst [15,16,17], but also be used as the support for noble metals (such as Pd and Pt) catalysts for the oxidations of CO and propane and automotive emission control [13]. Meanwhile, the strong interaction between CeO2 and Pd can be used to modify the chemical state of Pd, which further affects the activity and stability for catalytic combustion reactions [18,19,20,21,22,23].

Hu et al. [24] investigated the chemical state of Pd on CeO2 with different morphologies and found that Pd species mainly existed as PdxCe1−xO2−σ on CeO2 nanorods and nanocubes, but they were in the form of PdOx nanoparticles on the surface of CeO2 nanooctahedrons, which showed the inverse effects on the catalytic oxidation of CO and propane. Recently, we have prepared Pd/CeO2 catalyst using CeO2 nanorods as support to exclude the effects of crystal plane of CeO2 and found that there were also two different kinds of Pd species: PdO nanoparticles and Pdδ+ (2 < δ ≤ 4) in the form of PdxCe1−xO2, and the activities of Pd/CeO2 for CH4 combustion directly correlated with the surface concentration of PdO [25].

In order to further clarify the effects of Pd chemical state on the catalytic oxidation of CO, three Pd/CeO2 catalysts with different Pd chemical states were prepared by reduction–deposition and impregnation methods, respectively. Combined with the characterization results, we correlate the CO oxidation activity of catalysts with the chemical states of Pd species and conclude that the activity of CO oxidation was linearly correlated with surface amount of PdxCe1−xO2.

2 Experimental

2.1 Catalyst preparation

The CeO2 nanorods were synthesized by NaOH hydrothermal method [26, 27]. NaOH solution (6 mol·L−1) was rapidly added in Ce(NO3)2·6H2O solution with vigorous stirring for 60 min; then, the mixture was transferred into a stainless steel Teflon-lined autoclave and heated to 100 °C for 24 h. After reaction, the formed precipitate was separated and washed by distilled water several times. The CeO2 nanorods were obtained by drying at 60 °C for 12 h and calcining at 600 °C in air for 4 h. High-resolution transmission electron microscopy (HRTEM) images were recorded on a JEM-2100 instrument operating at 200 kV. The results showed that the average diameter of obtained CeO2 nanorods was about (12 ± 2) nm, and length distribution was in the range of 50–80 nm.

Pd/CeO2 (HHA) and Pd/CeO2 (FA) catalysts were prepared by reduction–deposition method [25]. After the addition of Pd(NO3)2 solution into the mixture of CeO2 support and H2O under stirring, the mixture was heated to 100 °C; then, N2H4 (HHA) or HCHO (FA) aqueous (2 times that of the mole of Pd) was introduced under drastic stirring. After reaction for 3 h, the formed solids were washed by deionized water, dried at 60 °C overnight and calcined at 450 °C for 4 h to obtain Pd/CeO2 (HHA) and Pd/CeO2 (FA), respectively. Meanwhile, Pd/CeO2 (IMP) was prepared as a reference sample by incipient wetness impregnation method and further treated as Pd/CeO2 (HHA) and Pd/CeO2 (FA) did. HRTEM images showed that the deposition of Pd did not change the morphology of CeO2.

CeO2 nanorods as control samples were treated by the same procedure as that of Pd/CeO2 (HHA) and Pd/CeO2 (FA) except the introduction of Pd(NO3)2, and the prepared CeO2 nanorods were correspondingly assigned to CeO2 (HHA) and CeO2 (FA), respectively.

2.2 Evaluation of catalytic activity for CO oxidation

The activity of the catalysts was tested in a fixed-bed reactor (inner diameter of 6 mm) at atmospheric pressure, and 200-mg catalysts (250–425 μm) were used. The feed gas containing 1 vol% CO, 20 vol% O2 and N2 balance was passed through the catalytic bed at a weight hourly space velocity (WHSV) of 15000 ml·g−1·h−1. The temperature of catalyst bed was programmed from − 50 to 450 °C at the heating rate of 4 °C·min−1, and the concentration of CO in the outlet was measured by an online gas chromatograph (model GC-2060) to calculate CO conversion at a temperature interval of 15 °C.

2.3 Catalyst characterization

The loadings of Pd in synthesized Pd/CeO2 were in the range of 0.75%–0.79%, which were measured by inductively coupled plasma atomic emission spectroscopy (ICP-AES) on a Varian 710 instrument. N2 adsorption at 77.4 K on a NOVA 4200e instrument was used to measure the specific surface areas of the catalysts. As shown in Table 1, all the pure CeO2 and Pd/CeO2 show similar specific surface area in the range of 71–79 m2·g−1.

The X-ray diffraction patterns (XRD) were obtained in a 2θ ranged from 10° to 80° with a scan rate of 0.2 (°)·s−1 on a Bruker D8 focus diffraction spectrometer using a Cu Kα radiation (0.154056 nm, 40 kV and 40 mA).

X-ray photoelectron spectroscopy (XPS) was performed to characterize the surface chemical state of Pd on a Thermo ESCALAB 250 instrument with a monochromated Al Kα X-ray source (1486.6 eV). XPS spectra of the selected elements were measured with a constant analyzer pass energy of 30.0 eV. All binding energies (B.E.) were referenced to the adventitious C 1s peak (284.8 eV).

Temperature-programmed reduction of CO (CO-TPSR) was performed on a chemisorption analyzer (Micromeritics Autochem II 2920) equipped with an online mass spectrometer detector (HPR-20 QIC Benchtop). The 100-mg catalyst was pretreated in 3 vol% O2/He (50 min·ml−1) at 450 °C for 40 min. After cooling to − 30 °C, the TPSR tests were performed in the flow of 5 vol% CO/He (50 ml·min−1) from − 30 to 900 °C at a heating rate of 10 °C·min−1. CO2 signals in the outlet were monitored at mass-to-charge ratio (m/e) of 44. Temperature-programmed reduction of hydrogen (H2-TPR) was performed using the same reaction apparatus as for CO-TPSR. The samples were pretreated at 400 °C in the flow of 3 vol% O2/He for 40 min, and then, the samples were cooled to − 50 °C. After switching the gas to 10 vol% H2/Ar (40 ml·min−1), the samples were heated from − 50 to 850 °C at the rate of 10 °C·min−1.

Diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS) absorption spectra were recorded on a Nicolet Model Nexus 670 FTIR spectrometer equipped with an MCT detector. The DRIFTS spectra of CO adsorption were obtained with a resolution of 4 cm−1 (accumulating 64 scans). Before CO adsorption, the catalyst was heated at 200°C for 30 min and cooled to 40 °C in the flow of He. After pretreatment, the sample was exposed to 1% CO/Ar (30 ml·min−1) and DRIFTS spectra were recorded.

3 Results and discussion

3.1 Catalytic activity of different pretreated CeO2 and Pd/CeO2 for CO oxidation

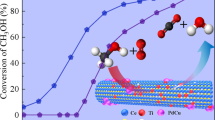

As shown in Fig. 1a, the pristine CeO2 nanorods show very limited activity for CO oxidation, and the T90 (the reaction temperature corresponding to 90% conversion) of CO is higher than 350 °C. After pre-reduction by N2H4 or HCHO, the T90 of CO on CeO2 (HHA) and CeO2 (FA) catalysts is about 70–113 °C lower than that of pristine CeO2 nanorods, indicating that the reducing treatment during the synthesis process could obviously improve the catalytic activity of CeO2 nanorods.

The introduction of Pd promotes CO oxidation on CeO2 significantly, and T90 obviously shifts to lower temperature. Among them, Pd/CeO2 (FA) shows the highest activity; the T90 is as low as 55 °C, which is around 33 and 60 °C lower than that of Pd/CeO2 (IMP) and Pd/CeO2 (HHA). Moreover, Pd/CeO2 (FA) catalyst exhibits the highest reaction rate and turnover frequency (TOF) value for CO oxidation, as shown in Table 1, which is 5.9 and 1.9 times higher than that of Pd/CeO2 (HHA) and Pd/CeO2 (IMP), respectively. Meanwhile, the Pd dispersion on Pd/CeO2 (HHA) catalyst is the highest, but its catalytic activity for CO oxidation is the worst, which indicates that the dispersion of Pd is not the key factor that determines the catalytic activity of Pd/CeO2, while the chemical state of Pd may play more important role in CO oxidation.

The prepared CeO2 nanorods have fcc fluorite structure, and the introduced Pd species are highly dispersed on CeO2 which do not change the crystal structure of CeO2 [25]. However, the lattice constant decreases after the introduction of Pd, as shown in Table 1, which suggests that some Pd species enter the lattice of CeO2 and lead to the lattice shrinkage due to smaller ionic radius of Pd species (r2+Pd = 0.0860 nm, r4+Pd = 0.0615 nm). The diffusion of metal atoms at high temperature was also observed in other systems [28, 29].

For Pd/CeO2 catalyst, there are two different chemical states of Pd species: Pd2+ in the form of PdO particles and Pdδ+ (2 < δ ≤ 4) in the form of PdxCe1−xO2 [25]. According to XPS results, the surface ratios of PdxCe1−xO2/(PdO and PdxCe1−xO2) for Pd/CeO2 (FA), Pd/CeO2 (IMP) and Pd/CeO2 (HHA) were calculated to be about 63%, 40% and 21%, respectively. As shown in Fig. 2, the activity of Pd/CeO2 catalyst for CO oxidation linearly increases with the increase in surface concentration of PdxCe1−xO2, indicating that PdxCe1−xO2 is the active species for CO oxidation over Pd/CeO2 which is contrary to the catalytic combustion of CH4 [25]. As Pdδ+ (2 < δ ≤ 4) is the main existing form in PdxCe1−xO2, so it is reasonable to consider Pd species with chemical state of Pdδ+ (2 < δ ≤ 4) as the active sites.

3.2 Temperature-programmed surface reaction of CO (CO-TPSR)

The redox properties of CeO2 and Pd/CeO2 were investigated by H2-TPR; the results showed that the introduction of Pd not only promotes the reduction property of the surface lattice oxygen species on CeO2, but also increases the amount of active oxygen species significantly [25]. In order to further identify the chemical state of finely dispersed PdO and the surface oxygen species in catalytic oxidation of CO, a series of CO-TPSR experiments over CeO2 and Pd/CeO2 catalysts were carried out; the signals of CO2 (m/z = 44) detected by MS are shown in Fig. 3.

For pure CeO2, there are no CO2 signals detected before 100 °C, which means that CO is hard to be oxidized on the surface of CeO2. Three CO2 peaks can be detected at higher temperatures. The peak at around 150 °C can be ascribed to the oxidation of CO by the chemically adsorbed oxygen species on CeO2 surface (CO + Oads →CO2), the CO2 peak at around 250-350 °C could be assigned to the oxidation of CO by the surface active lattice oxygen species (CO + Olatt→CO2), while the CO2 peak at around 800 °C is attributed to the oxidation of CO by the bulk lattice oxygen species of CeO2 (CO + Olatt→CO2).

The presence of Pd enhances the redox ability of the catalyst significantly. For Pd/CeO2 (HHA) catalyst, three CO2 peaks are observed in the temperature range of 50–150 °C, 200–350 °C and 450–650 °C, respectively. H2-TPR of Pd/CeO2 (HHA) shows that the deposition of Pd promotes the co-reduction of PdO and CeO2 [25]. Hence, the CO2 peak in the low temperature range could be assigned to the co-reaction between CO with PdO and surrounding CeO2, the peak at the moderate temperature range is suggested to be the oxidation of CO by surface oxygen on the CeO2, while the peak at the high temperature range is ascribed to the reaction between CO and bulk oxygen of CeO2.

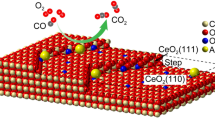

Pd/CeO2 (FA) and Pd/CeO2 (IMP) show the similar reaction behavior. Compared with that of Pd/CeO2 (HHA), the CO2 peaks in the low and moderate temperature range split into two CO2 peaks on Pd/CeO2 (FA) and Pd/CeO2 (IMP), respectively. Meanwhile, the amount of CO2 formed in the high temperature range decreases significantly. The previous research confirmed that the ratio of PdxCe1−xO2/PdO increases in the trend of Pd/CeO2 (HHA) < Pd/CeO2 (IMP) < Pd/CeO2 (FA), and the existence of PdxCe1−xO2 acts as transition layer between PdO and CeO2 [25]. Therefore, the split of CO2 peaks in the low and moderate temperature is suggested to be caused by the increased amount of PdxCe1−xO2 on Pd/CeO2 (FA) and Pd/CeO2 (IMP), and the bulk lattice oxygen also promotes following more Pd species entering the lattice of CeO2.

DRIFTS spectra of CO adsorbed at 40 °C on different Pd/CeO2 catalysts are shown in Fig. 4. The bands at 1800-2300 cm−1 are associated with CO adsorption on the catalyst. For Pd/CeO2 (HHA), the peaks at 2172 and 2119 cm−1 are ascribed to the gas CO or linear adsorption of CO on Pd2+ and Pd+ (Pd2+ - CO and Pd+ - CO), respectively [30,31,32] (Fig. 4a). Combined with the results in Fig. 3, only limited Pd species could be reduced by CO at 40°C. The peak intensity and the ratio of the intensity of the two peaks remain stable from 4 to 16 min, which indicates that CO could adsorb Pd species on Pd/CeO2 and reach saturation rapidly, and the chemical state of Pd on Pd/CeO2 (HHA) maintains during CO adsorption.

For Pd/CeO2 (IMP), the adsorption band at 2179, 2139 and 2099 cm−1 can be ascribed to CO linearly adsorbed on Pd2+, Pd+ and Pd0 (Pd2+ - CO, Pd+- CO and Pd0 - CO), respectively (Fig. 4b). Compared with Fig. 4a, it is apparent that more Pd species are reduced to Pd0 and Pd+. Besides, a new emerged adsorption band at 1911 cm−1 can be associated with the absorption of CO bridged adsorbed on Pd+ (Pd+2 –CO), which indicates that Pd species could be partially reduced by CO at 40 °C. Compared with Pd/CeO2 (HHA), most of the Pd species on Pd/CeO2 (IMP) are reduced to Pd0, and the ratio of Pd0 - CO is much higher than that of Pd+ - CO and Pd2+ - CO.

For Pd/CeO2 (FA), the adsorption band at 2175 and 2097 cm−1 can be associated with CO linearly adsorbed on Pd2+ and Pd0 (Pd2+ - CO and Pd0 - CO), respectively (Fig. 4c). The adsorption band at 1910 cm−1 can be associated with CO bridged adsorbed on Pd+ (Pd+2 –CO). Compared with Pd/CeO2 (HHA) and Pd/CeO2 (IMP), Pd species on Pd/CeO2 (FA) are much easier to be reduced to Pd0 by CO, which is in line with CO-TPSR results. For catalytic oxidation of CO on Pd/CeO2 catalyst, the catalytic activity is closely related to the redox ability of the catalysts: Higher redox ability leads to higher catalytic activity.

4 Conclusion

Pd/CeO2 catalysts with different chemical states of Pd species were prepared by reduction–deposition and impregnation method (IMP), respectively. With formaldehyde as reductant, the synthesized Pd/CeO2 (FA) had the highest PdxCe1−xO2 concentration on the surface, while with hydrazine as reductant, the obtained Pd/CeO2 (HHA) had least PdxCe1−xO2 concentration, and Pd/CeO2(IMP) prepared by incipient wetness impregnation had moderate PdxCe1−xO2 concentration. Among them, Pd/CeO2 (FA) showed the best activity and had a T90 of 55 °C, 33 and 60 °C lower than that of Pd/CeO2 (IMP) and Pd/CeO2 (HHA), respectively. The activity for CO oxidation was linearly correlated with the concentration of PdxCe1−xO2 concentration, indicating that Pd with the chemical state of Pdδ+ (2 < δ ≤ 4) is the active form for Pd. The result of H2-TPR and FTIR showed that PdxCe1−xO2 can act as a transfer channel of active oxygen species between CeO2 and PdO. All the results prove that the activity of Pd/CeO2 for CO oxidation is severely influenced by preparation method.

References

Fan C, Tang X, Wang L, Wang HF, Zhan WC, Guo Y. Performance of AgIr/MCM-41 catalysts for CO oxidation. Chin J Rare Met. 2019;43(7):686.

Xu L, Pu C, Wang L, Guo Y, Guo YL, Lu GZ. Effect of Calcination temperature on Meso-Pd/Fe(OH)x for CO oxidation at low temperature. Chin J Rare Met. 2018;42(2):161.

Westerholm R, Christensen A, Rosén Å. Regulated and unregulated exhaust emissions from two three-way catalyst equipped gasoline fuelled vehicles. Atmos Environ. 1996;30(20):3529.

Ivanova A, Slavinskaya E, Gulyaev R, Zaikovskii V, Stonkus O, Danilova I, Plyasova L, Polukhina I, Boronin A. Metal–support interactions in Pt/Al2O3 and Pd/Al2O3 catalysts for CO oxidation. Appl Catal B. 2010;97(1–2):57.

Gaudet JR, de la Riva A, Peterson EJ, Bolin T, Datye AK. Improved low-temperature CO oxidation performance of Pd supported on La-stabilized alumina. ACS Catal. 2013;3(5):846.

Arnby K, Törncrona A, Andersson B, Skoglundh M. Investigation of Pt/γ-Al2O3 catalysts with locally high Pt concentrations for oxidation of CO at low temperatures. J Catal. 2004;221(1):252.

Zhang Y, Cai Y, Guo Y, Wang H, Wang L, Lou Y, Wang Y. The effects of the Pd chemical state on the activity of Pd/Al2O3 catalysts in CO oxidation. Catal Sci Technol. 2014;4(11):3973.

Chen Z, Cao FX, Gao W, Dong QC, Qu YQ. Uniform small metal nanoparticles anchored on CeO2 nanorods driven by electroless chemical deposition. Rare Met. 2019. https://doi.org/10.1007/s12598-019-01266-7.

Qiao B, Liu L, Zhang J, Deng Y. Preparation of highly effective ferric hydroxide supported noble metal catalysts for CO oxidations: from gold to palladium. J Catal. 2009;261(2):241.

Sergeant GA, Bartlett AFF. The poisoning of palladium catalyst for the reaction between hydrogen and oxygen. J Appl Chem. 1955;5(5):208.

Suchorski Y, Kozlov SM, Bespalov I, Datler M, Vogel D, Budinska Z. The role of metal/oxide interfaces for long-range metal particle activation during CO oxidation. Nat Mater. 2018;17(6):519.

Migani A, Vayssilov GN, Bromley ST, Illas F, Neyman KM. Greatly facilitated oxygen vacancy formation in ceria nanocrystallites. Chem Commun. 2010;46(32):5936.

Cargnello M, Doan-Nguyen VV, Gordon TR, Diaz RE, Stach EA, Gorte RJ, Rupprechter G. Control of metal nanocrystal size reveals metal-support interface role for ceria catalysts. Science. 2013;341(6147):771.

Nolan M, Fearon JE, Watson GW. Oxygen vacancy formation and migration in ceria. Solid State Ionics. 2006;177(35–36):3069.

Zhao R, Wang Y, Guo Y, Guo Y, Liu X, Zhang Z, Wang Y, Zhan W, Lu G. A novel Ce/AlPO5 catalyst for solvent-free liquid phase oxidation of cyclohexane by oxygen. Green Chem. 2006;8(5):459.

Huang H, Dai Q, Wang X. Morphology effect of Ru/CeO2 catalysts for the catalytic combustion of chlorobenzene. Appl Catal B. 2014;158:96.

Dai Q, Wang W, Wang X, Lu G. Sandwich-structured CeO2@ ZSM-5 hybrid composites for catalytic oxidation of 1, 2-dichloroethane: an integrated solution to coking and chlorine poisoning deactivation. Appl Catal B. 2017;203:31.

Cargnello M, Jaén JD, Garrido JH, Bakhmutsky K, Montini T, Gámez JC, Gorte RJ, Fornasiero P. Exceptional activity for methane combustion over modular Pd@CeO2 subunits on functionalized Al2O3. Science. 2012;337(6095):713.

Gulyaev R, Stadnichenko A, Slavinskaya E, Ivanova A, Koscheev S, Boronin A. In situ preparation and investigation of Pd/CeO2 catalysts for the low-temperature oxidation of CO. Appl Catal A. 2012;439:41.

Du C, Guo Y, Guo Y, Gong XQ, Lu G. Polymer-templated synthesis of hollow Pd–CeO2 nanocomposite spheres and their catalytic activity and thermal stability. J Mater Chem A. 2015;3(46):23230.

Dai Q, Bai S, Lou Y, Wang X, Guo Y, Lu G. Sandwich-like PdO/CeO2 nanosheet@HZSM-5 membrane hybrid composite for methane combustion: self-redispersion, sintering-resistance and oxygen, water-tolerance. Nanoscale. 2016;8(18):9621.

Feng X, Li W, Liu D, Zhang Z, Duan Y, Zhang Y. Self-assembled Pd@CeO2/γ-Al2O3 catalysts with enhanced activity for catalytic methane combustion. Small. 2017;13(31):1700941.

Senftle TP, van Duin AC, Janik MJ. Methane activation at the Pd/CeO2 interface. ACS Catal. 2016;7(1):327.

Hu Z, Liu X, Meng D, Guo Y, Guo Y, Lu G. Effect of ceria crystal plane on the physicochemical and catalytic properties of Pd/ceria for CO and propane oxidation. ACS Catal. 2016;6(4):2265.

Ma J, Lou Y, Cai Y, Zhao Z, Wang L, Zhan W, Guo YL, Guo Y. The relationship between the chemical state of Pd species and the catalytic activity for methane combustion on Pd/CeO2. Catal Sci Technol. 2018;8(10):2567.

Mai HX, Sun LD, Zhang YW, Si R, Feng W, Zhang HP, Liu HC, Yan CH. Shape-selective synthesis and oxygen storage behavior of ceria nanopolyhedra, nanorods, and nanocubes. J Phys Chem B. 2005;109(51):24380.

Wang R, Dangerfield R. Seed-mediated synthesis of shape-controlled CeO2 nanocrystals. RSC Adv. 2014;4(7):3615.

Ramade J, Langlois C, Pellarin M, Piccolo L, Lebeault MA, Epicier T, Aouine M, Cottancin E. Tracking the restructuring of oxidized silver–indium nanoparticles under a reducing atmosphere by environmental HRTEM. Nanoscale. 2017;9(36):13563.

Choi I, Lee HK, Lee GW, Kim J, Joo JB. Inorganic shell nanostructures to enhance performance and stability of metal nanoparticles in catalytic applications. Rare Met. 2019. https://doi.org/10.1007/s12598-019-01203-8.

Fernández-Garcıa M, Martınez-Arias A, Iglesias-Juez A, Hungrıa A, Anderson J, Conesa J, Soria J. CO oxidation as a test reaction for strong metal–support interaction in nanostructured Pd/FeOx powder catalysts. Appl Catal A. 2015;502:8.

Fernández-Garcıa M, Martınez-Arias A, Iglesias-Juez A, Hungrıa A, Anderson J, Conesa J, Soria J. New Pd/CexZr1−xO2/Al2O3 three-way catalysts prepared by microemulsion: Part 1. Characterization and catalytic behavior for CO oxidation. Appl Catal, B. 2001;31(1): 39.

Martınez-Arias A, Fernández-Garcıa M, Iglesias-Juez A, Hungrıa A, Anderson J, Conesa J, Soria J. New Pd/ CexZr1−xO2/Al2O3 three-way catalysts prepared by microemulsion: Part 2. In situ analysis of CO oxidation and NO reduction under stoichiometric CO+NO+O2. Appl Catal, B. 2001;31(1): 51.

Acknowledgements

This work was financially supported by the National Key Research and Development Program of China (No. 2016YFC0204300) and the National Natural Science Foundation of China (Nos. 21171055 and 21571061).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, GF., Ma, J., Bai, S. et al. CO catalytic oxidation over Pd/CeO2 with different chemical states of Pd. Rare Met. 39, 800–805 (2020). https://doi.org/10.1007/s12598-019-01347-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-019-01347-7