Abstract

Anisotropic MnBi/NdFeB (MnBi contents of 0 wt%, 20 wt%, 40 wt%, 60 wt%, 80 wt%, and 100 wt%) hybrid bonded magnets were prepared by molding compression using MnBi powders and commercial hydrogenation disproportionation desorption and recombination (HDDR) NdFeB powders. Magnetic measurements at room temperature show that with MnBi content increasing, the magnetic properties of the MnBi/NdFeB hybrid bonded magnets all decrease gradually, while the density of the hybrid magnets improves almost linearly. In a temperature range of 293–398 K, the coercivity temperature coefficient of the hybrid magnets improves gradually from −0.59 %·K−1 for the pure NdFeB bonded magnet to −0.32 %·K−1 for the hybrid bonded magnet with 80 wt% MnBi, and the pure MnBi bonded magnet exhibits a positive coercivity temperature coefficient of 0.61 %·K−1.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Recently, low-temperature-phase (LTP) MnBi compound with NiAs-type hexagonal crystal structure has received considerable attention due to its good magnetic properties [1–6], especially its high coercivity and prominent positive temperature coefficient below 300 °C [7]. However, despite many efforts, it is difficult to obtain single-phase MnBi through conventional synthesis techniques. In addition, as LTP MnBi decomposes at high temperatures, bonding the magnet will be necessary. Another challenge is to increase its relatively low saturation magnetization. One possible way to enhance the magnetization is to mix the MnBi with NdFeB powders to synthesize a hybrid bonded magnet.

NdFeB bonded magnets are important functional materials and have been widely used for decades in various applications due to their good magnetic properties [8–11]. However, the coercivity temperature coefficient of NdFeB bonded magnets is about −0.4 %·K−1, which restricts the use of NdFeB bonded magnets at elevated temperatures [12], such as in electric motors. Hence, hybrid bonded magnets mixed with different magnetic powders appear to fill the magnetic property gap of single-component magnets [13]. In the common hybrid magnets, ferrite with positive temperature coefficient of coercivity is used to compensate the undesirable thermal stability of NdFeB [14]. Unfortunately, the poor coercivity of the ferrite undermines the application of such hybrid magnets. However, the MnBi/NdFeB hybrid bonded magnets combine the advantages of both single magnets and are expected to bear good magnetic properties and thermal stability. Although studies on the fabrication of anisotropic MnBi/SmFeN hybrid magnets by hot compaction without resin binder have been reported before [15], only few studies were on the fabrication of MnBi/NdFeB hybrid bonded magnets.

This paper reports the fabrication of anisotropic MnBi/NdFeB hybrid bonded magnets with different MnBi contents by conventional molding compression method. These magnets were prepared from commercially available hydrogenation disproportionation desorption and recombination (HDDR) NdFeB powders with high coercivity and fine grains MnBi powders. The magnetic properties and thermal stability of the hybrid bonded magnets under different MnBi contents were investigated in detail.

2 Experimental

MnBi alloy with nominal composition Mn48Bi52 was produced by induction melting. The alloy was annealed at 593 K for 20 h and melt-spun under argon atmosphere. The MnBi ribbons were annealed at 673 K for 30 min and ball milled for 4 h in a high-energy ball mill. Commercial HDDR NdFeB powders were mixed with MnBi powders to prepare MnBi/NdFeB hybrid bonded magnets. The amounts of MnBi in the hybrid bonded magnets were 0 wt%, 20 wt%, 40 wt%, 60 wt%, 80 wt%, and 100 wt%. The MnBi/NdFeB powders were mixed with 2.5 wt% epoxy resin, aligned by mold compression, and finally consolidated at 423 K for 90 min. The crystal structures were studied using X-ray diffraction (XRD, Shimadzu XRD-7000) with Cu Kα radiation. The mass densities of the bonded magnets were determined by Archimedes method. The magnetic properties of the bonded magnets at room temperature and elevated temperatures were measured by a vibrating sample magnetometer (VSM, VersaLab) in a field of up to 1.75 MA·m−1.

3 Results and discussion

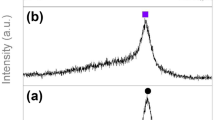

XRD pattern of ball-milled MnBi powders is shown in Fig. 1. Characteristic intensity peaks of the LTP MnBi are dominant, and other small peaks due to Bi also appear, indicating the difficulty in producing single-phase MnBi. Figure 2 shows a hysteresis loop of the as-milled MnBi powders measured at 300 K. Magnetization remanence (M s) of 0.54 T and magnetization saturation (M r) of 0.37 T are obtained, and the coercivity (H c) is as high as 883.56 kA·m−1. Figure 2 also shows that the MnBi powders are not fully saturated and the magnetic properties of MnBi powders should have even higher values.

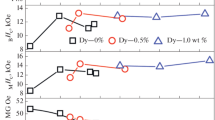

Figure 3 shows the room temperature magnetic properties and density of the anisotropic MnBi/NdFeB hybrid bonded magnets as a function of MnBi content. The pure anisotropic NdFeB bonded magnet possesses the best remanence (B r), coercivity (H c), and maximum energy product ((BH)max) of 0.72 T, 1122.36 kA·m−1, and 92.34 kJ·m−3, respectively, while the pure MnBi bonded magnet has the lowest values of the magnetic properties. As MnBi content increases, the remanence, coercivity, and maximum energy product of the hybrid magnets all drop simultaneously. However, the mass density of the hybrid magnets increases with the MnBi content increasing since the theoretical density of MnBi is 20 % higher than that of NdFeB.

Figure 4 shows the coercivity of the MnBi/NdFeB hybrid magnets as a function of MnBi content at elevated temperatures. At 293 K, the slight decrease in the coercivity with MnBi content increasing can be explained by the somewhat larger coercivity of NdFeB compared to that of MnBi. As the temperature increases from 293 to 398 K, the temperature characteristics of the MnBi are more evident. The coercivity of the hybrid magnets improves with MnBi content increasing. When the MnBi content is below 60 wt%, the coercivity of the hybrid magnets only improves slightly, while when the MnBi content is more than 80 wt%, the coercivity of the hybrid magnets at elevated temperature increases even more. The improvement in the coercivity is clear due to the positive coercivity temperature coefficient of the MnBi phase in the hybrid magnets.

The coercivity temperature coefficients of the MnBi/NdFeB bonded magnets (293–398 K) are shown in Fig. 5. Throughout this temperature range, the pure MnBi bonded magnet exhibits a positive coercivity temperature coefficient of 0.61 %·K−1, while pure NdFeB bonded magnet possesses a negative one of −0.59 %·K−1. As for the hybrid bonded magnets, the coercivity temperature coefficient remains negative but slightly improves compared to pure NdFeB bonded magnet. For the hybrid bonded magnet with 80 wt% MnBi, the coercivity temperature coefficient is about −0.32 %·K−1, indicating that the MnBi/NdFeB bonded magnets exhibit better thermal stability in temperature range of 293–398 K. So the MnBi/NdFeB bonded magnets could be a good candidate for high-temperature applications.

4 Conclusion

Anisotropic MnBi/NdFeB hybrid bonded magnets with different MnBi contents (0 wt%, 20 wt%, 40 wt%, 60 wt%, 80 wt%, and 100 wt%) can be prepared by mold compression. Pure NdFeB bonded magnet exhibits negative temperature coefficient of coercivity. But for MnBi/NdFeB hybrid bonded magnets, an appropriate addition of MnBi is beneficial to the coercivity of the hybrid magnets at elevated temperatures. In a temperature range of 293–398 K, the temperature coefficient of coercivity for the hybrid magnets improves gradually from −0.59 %·K−1 for the pure NdFeB bonded magnet to −0.32 %·K−1 for the hybrid bonded magnet with 80 wt% MnBi, indicating the improved thermal stability of the MnBi/NdFeB hybrid bonded magnets.

References

Guo X, Zaluska A, Altounian Z, Ström-Olsen JO. The formation of single-phase equiatomic MnBi by rapid solidification. J Mater Res. 1990;5(11):2646.

Chen T, Stutius WE. The phase transformation and physical properties of the MnBi and Mn1.08Bi compounds. IEEE Trans Magn. 1974;10(3):581.

Chen T. Contribution to the equilibrium phase diagram of the Mn–Bi system near MnBi. J Appl Phys. 1974;45(5):2358.

Adams E, Hubbard WM, Syeles AM. A new permanent magnet from powdered manganese bismuthide. J Appl Phys. 1952;23(11):1207.

Lou C, Wang Q, Liu T, Liu T, Wei N, Wang CJ, He JC. Effects of a high magnetic field on the coarsening of MnBi grains solidified from isothermal annealed semi-solid melt. J Alloy Compd. 2010;505(1):96.

Koyama K, Mitsui Y, Choi ES, Ikehara Y, Palm EC, Watanabe K. Change of the equilibrium state of ferromagnetic MnBi by high magnetic fields. J Alloy Compd. 2011;509(5):L78.

Saha S, Huang MQ, Thong CJ, Zande BJ, Chandhok VK, Simizu S, Obermyer RT, Sankar SG. Magnetic properties of MnBi1−x R x (R = rare earth) systems. J Appl Phys. 2000;87(9):6040.

Ma BM, Herchenroeder JW, Smith B, Suda M, Brown DN, Chen Z. Recent development in bonded NdFeB magnets. J Magn Magn Mater. 2002;239(1):418.

Brown D, Ma BM, Chen ZM. Developments in the processing and properties of NdFeB-type permanent magnets. J Magn Magn Mater. 2002;248(3):432.

Li J, Liu Y, Gao SJ, Li M, Wang YQ, Tu MJ. Effect of process on the magnetic properties of bonded NdFeB magnet. J Magn Magn Mater. 2006;299(1):195.

Gao RW, Zhang JC, Zhang DH, Dai YY, Meng XH, Wang ZM, Zhang YJ, Liu HQ. Dependence of the magnetic properties on the alignment magnetic field for NdFeB bonded magnets made from anisotropic HDDR powders. J Magn Magn Mater. 1999;191(1):97.

Schneider J, Knehans-Schmidt R. Bonded hybrid magnets. J Magn Magn Mater. 1996;157(1):27.

Ormerod J, Constantinides S. Bonded permanent magnets: current status and future opportunities. J Appl Phys. 1997;81(8):4816.

Susarek B, Dudzikowski I. Application of permanent magnets made from NdFeB powder and from mixtures of powders in DC motors. J Magn Magn Mater. 2002;239(1):597.

Rao NVR, Gabay AM, Hadjipanayis GC. Anisotropic hybrid magnets fabricated by hot compaction. IEEE Trans Magn. 2013;49(7):3255.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51271005), the Beijing Municipal Natural Science Foundation (No. 2122006), the Scientific Research Foundation for the Returned Overseas Chinese Scholars, State Education Ministry (No. 32009001201301), the Project from Samsung Advanced Institute of Technology (No. 46009001201402), and the Fundamental Research Foundation of Beijing University of Technology (No. 009000514313002). The author appreciates Prof. Zaven Altounian from Mcgill University, Canada, and Dr. Yun Gao for helpful advices.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, DT., Wang, PF., Yue, M. et al. High-temperature magnetic properties of anisotropic MnBi/NdFeB hybrid bonded magnets. Rare Met. 35, 471–474 (2016). https://doi.org/10.1007/s12598-015-0668-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0668-1