Abstract

Sorption characteristics of ion exchange resins 001×7, 005×8, D72 regarding rare earth metals (REM) during extraction from barren solution of uranium sorption in dynamic conditions were investigated. It was identified that D72 resin capacity on analyzed REM was 2.46 mg·cm−3 after passing 220 BV (bed volume) of initial solution with 95 % recovery of element of REM with the lowest affinity. Researches on REM desorption in dynamic conditions from investigated ion exchange resins by solution of 1.7 mol·L−1 HNO3 and 8.0 mol·L−1 NH4NO3 with 0.2 mol·L−1 HNO3 passing were carried out. It was identified that using desorption solution based on ammonium nitrate allows to achieve acceptable recovery degree of REM from the resin. The possibility of organization of a circulating desorption solution system increases the perspectives of nitrate ammonium solution usage.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Rare earth metals (REM) are a group of 17 chemical elements, also known as technological metals because of their widespread use in a lot of high-tech products manufacture (computers, mobile phones, flat panels, wind turbines, etc.) [1]. Considering the high urgency of researches for alternative sources of rare metals and innovative technologies for its recovery [2], the possibility of REM recovery from in situ leaching (ISL) process solutions of uranium was studied. This kind of raw material is promising because of the absence of minerals leaching costs, due to the organization of an associated extraction with the uranium, the comprehensive utilization of mineral raw material and the significant amount of process solution.

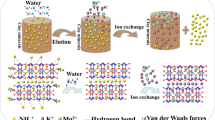

Ion exchange and solvent extraction are the most efficient methods for the extraction of REM which owns significant similarities of chemical properties. Considering the extremely low concentrations of REM in the process solutions of uranium, the most promising method of extraction is the ion exchange [3].

A large number of works are already devoted to REM sorption researches. Li and co-workers studied the recovery of heavy REM from hydrochloric acid solution by using impregnated resins, which contains Cyanex 272 and 1-hexyl-4-ethyloctyl-isopropylphosphonic acid (HEOPPA) [4, 5]. It is indicated that the degree of REM sorption on resins strongly depends on pH and the degree of sorption is characterized by the following order of importance: Lu(III)>Yb(III)>Tm(III)>Er(III)>Y(III)>Ho(III).

Alexandratos et al. [6–8] synthesized a bifunctional phosphinic acid resin by the reaction of Friedel–Crafts based on polystyrene-divinylbenzene with the use of AlCl3 as catalyst. The synthetic bifunctional phosphinic acid resin is considered as an efficient sorbent of uranium and actinides from different acid medium [9–11]. Nagaphani et al. [12] researched the recovery of the group of heavy REM on phosphonic acid resin with polystyrene–divinylbenzene matrix Tulsion CH-96 and phosphonic acid resins with cross-linked polyacrylic matrix T-PAR. In the initial solution containing 25 mg·dm−3 of each REM and 4 mol phosphoric acid, the degree of heavy REM extraction, which depends on phosphoric acid concentration and the ratio of the phases, was studied. The americium and REM separation and recovery from nitric acid solution on polymeric fibrous sorbents, modified by ferro- and ferricyanides, were carried out by Myasoedova et al. [13]. There are researches of sorbents based on monofunctional derivaties of polystyrene phosphonic acid with ionogenic groups of polystyrenealkylphosphonic acids (I) and monoesters of polystyrenephophonic acids (II) [14].

The results of the researches about the Am, Cm, Cf, Eu, Bk, and Pu behaviors during the sorption on TVEX, impregnated by different extractants, in order to identify the most promising recovery of the mentioned elements from nitric acid solutions, are known [15].

Experiments on REM recovery from sea waters, which contains 1 × 10−9 mol·dm−3 of REM isotopes, by amorphous iron oxyhydroxide FeOOH, were occurred [16]. An important affinity between the REM and the iron oxide surface was established, and besides a higher level of sorption was observed for lightweight subgroup of REM than for heavy subgroup of REM. Turanov et al. [17] searched for REM and scandium recovery from HClO4 on phosphorylmethyl-substituted butylphenylphosphinates. Despite the microconcentrations of extracted components (concentration of each element in the initial solution around 2 × 10−5 mol·dm−3), the possibility of REM and scandium enrichment from HClO4 solutions by complexing sorbent, synthetized by non-covalent immobilization of the studied compounds on macroporous polymer matrix, was established. Marhol et al. [18] showed that some ion exchangers, which contain phosphorus in functional groups, can be used for efficient separation of scandium (iron, indium, or gallium) from the lanthanides and from the divalent ions. The order of selectivity was established: Sc>Fe>In>Ga>AI>La>Pb>Cu>Co>Ca.

Researches on REM sorption and desorption on the macroporous ion exchanger D152 with the functional group –COOH were occurred; the optimal pH for sorption was established around 6.70, and desorption was satisfied with the use of 0.5 mol·dm−3 of HCl [19]. Melnyk et al. [20] conducted a study for the evaluation of the sorption capacities of mesoporous silica with a phosphonic acid functional group during the neodymium and dysprosium recovery (concentrations around 2.5 g·dm−3).

Tian et al. [21] published results of researches on REM recovery from the leach liquor of the Chinese weathered crusts. The solutions contained REM (~2 g·dm−3) and a significant amount of impurities: (NH4)2SO4 (~2,000 mg·dm−3), Al3+ (~1,000 mg·dm−3), Fe3+ (~100 mg·dm−3), Ca2+ (~1,000 mg·dm−3). The different methods of pregnant solution processing, including solvent extraction (phosphorus-containing extractants), sorption (cation exchange resin 001×7 and vermiculite), and membrane extraction (emulsion liquid membrane, supported liquid membrane, electrostatic pseudo liquid membrane) were studied. El-Dessouky et al. [22] investigated the sorption of praseodymium(III) from nitrate medium, using TVEX-PHOR. Within the works, the strong acid resin D72 containing a functional group (–SO3H) was studied. It demonstrated the high chemical and physical stability in the conditions of experimental temperatures and a wide working range of pH. D72 has a high exchange capacity, its regeneration is simple and its use for REM recovery in the conditions of low concentrations is possible due to its low cost. Xiong et al. [23] studied the sorption of praseodymium on the macroporous strong acid resin D72. During the sorption from solutions containing 0.286 g·dm−3 of praseodymium, the optimal pH was established at 3.0, and the duration of the reaction to obtain the balance was established around 50 h. Desorption was occurred using the solutions of HCl and NaCl in different concentrations, and managed to achieve a recovery of 99.9 %.

Experiments of erbium sorption studies (III) on macroporous low acid resins D113-III with functional group (–COOH) were occurred [24]. Sorption from solutions with a concentration of erbium at 0.16 g·dm−3 showed that the optimal pH was 6.04.

Thus, different sorbents could be used for the recovery of REM from diluted and complex composition solutions, besides the efficiency of its usage in each particular case depends on number of factors—sorption capacity, degree and complexity of regeneration, mechanical strength, and cost.

2 Experimental

2.1 Reagent and materials

The ion exchange resins 001×7, 005×8, and D72 (description and basic properties are presented in Table 1) were friendly provided by the company Anhui Sanxing Resin Technology Co., Ltd., China.

The initial solution was barren solution after uranium sorption from one of the enterprises of JSC National Atomic Company (NAC) “Kazatomprom.” The composition of the solution is shown in Table 2 (analyzed components).

All other used chemical substances were of analytical grade. During the realization of the experiments distilled water was used.

2.2 Instrumentation

The inductively coupled plasma mass spectrometry method (ICP MS, Agilent 7500CX) was used for the measurements of REM contents in the solutions and in the sorbents. The weight measurements were realized on laboratory analytical balances Mettler Toledo ML54. The multimeter MM40 crison instruments were used for the pH measurements in solutions.

2.3 Sorbent preparation

Ion exchange resins were subjected to conditioning before use. In the separating funnels, sorbents were treated in series by 2 mol·L−1 HCl until complete removal of iron, by water and 5 % NaOH for elimination of organic residue of synthesis. Besides, ionites were prepared to work conditions by holding during 24 h in appropriate medium and by distilled water washing until pH 3.0–3.5.

2.4 Experiments on sorption and desorption

For studying the sorption and desorption processes in dynamic conditions, the pre-soaked ionite, transformed into the desired ionic form, was placed in columns (20 mm × 300 mm) made of Plexiglas, and the studied solution was passed through a packed bed resin until the complete REM saturation. The input of solution was realized by peristaltic pump insuring a constant flow rate of 2.36 cm3·cm−2·min−1 during sorption and a constant flow rate of 0.23 cm3·cm−2·min−1 during desorption. The eluates were fractionally sampled for analysis. Two variants of desorption were realized: using the solution of 1.7 mol·L−1 HNO3 and the solution of 8.0 mol·L−1 NH4NO3 with addition of 0.2 mol·L−1 HNO3. All the experiments were occurred in the room conditions of temperature (25±1) °C.

The sorption capacity (Q) and the degree of desorption (E) were evaluated by the following equations:

where Q is the sorption capacity, mg·g−1; E is the degree of desorption; C 0 and C e are the concentrations of element in initial and equilibrium conditions, mg·cm−3; m is the weight of wet resin, g; V is the total volume of solution, cm3.

3 Results and discussion

3.1 Sorption in dynamic conditions

The breakthrough curves of sorption demonstrate the correlation between the changes of the target component contents in the filtrate and the volume of solution which passes through the sorbent layer. Besides, the relationship between the target element concentration in the eluate (C e) and in the input solution (C 0) was used as a function of time or of volume of passed solution. The calculation of the integral under the breakthrough curve allows to find the quantity of sorbed target element. The total number of sorbed element can be calculated in experimental conditions by the equation:

where V e is the volume of solution, which was passed through column, cm3.

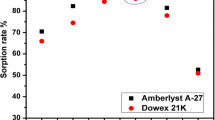

Sorption of REM from process solutions of uranium ISL was realized in dynamic condition on the ionites 001×7, 005×8, D72. The analysis of Figs. 1, 2, and 3 allow highlighting that the sorbent D72 owns the highest capacity for REM among the studied ionites.

The observed differences of degree of elements recovery can be explained by the ionic radius. The ion exchange resins, in general, have a high level of selectivity for the ions with a high valence or charge. Among the ions with the same charge, a greater affinity for ions of high atomic number is observed. A down trend of the affinity is observed for the identically charged ions with the increasing size dimensions of the hydrated ions, which is in a good agreement with a known source [25]: La3+>Ce3+>Pr3+>Nd3+>Sm3+>Eu3+>Gd3+>Tb3+>Dy3+>Y3+>Ho3+>Er3+>Tu3+>Yb3+>Lu3+>Sc3+.

Thereby, during the realization of sorption on three resins until a level of 95 % recovery of the REM element owning the lowest affinity, the following contents will be attained in the ionites (Table 3).

Presented results show a preference of using ion exchange resin with macroporous structure and high degree of crosslinking. D72 allows to achieve capacity on the amount of analyzed REM 2.46 mg·cm−3 after passing 220 bed volumes of initial solution with providing 95 % recovery of an element of REM with the lowest affinity.

3.2 Desorption in dynamic conditions

The evaluation of the sorbent efficiency is based on its sorption and desorption characteristics. Desorption solution should provide a high level of target components recovery to the liquid phase and the possibility of recycling. The last is indispensable condition from ecological and economical points of view. Previous realized studies showed that the use of 2 mol·L−1 H2SO4, 1 mol·L−1 NaCl, and 1 mol·L−1 NH4NO3, during the REM desorption from saturated sulfonic solutions, is not effective [26].

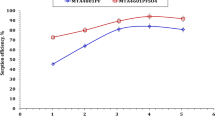

REM desorption was studied on three sorbents 001×7, 005×8, and D72, using a solution of 1.7 mol·L−1 HNO3 and 8.0 mol·L−1 NH4NO3 with an addition of 0.2 mol·L−1 HNO3. The corresponding results are shown in Figs. 4, 5, 6, 7, 8, and 9, respectively.

Breakthrough curves show that pikes obtained at using 8.0 mol·L−1 NH4NO3 with 0.2 mol·L−1 HNO3 exceed that using 1.7 mol·L−1 HNO3 − on height and width.

In Table 4, the REM recovery rate during desorption of ionites 001×7, 005×8, and D72 is shown.

The realized experiments show that the use of desorption solutions based on ammonium nitrate is more efficient than the use of desorption solution of nitric acid. The possibility of organization of a circulating desorption solution system increases the perspectives of nitrate ammonium solution use.

4 Conclusion

The results of these works can serve as a basis for organizing the REM co-recovery at uranium ISL enterprises, which requires the presence of a defined framework during the realization of the sorption from the barren solutions after uranium sorption, i.e., the impossibility to modify the pH and the salt content in initial solutions. Despite the indicated factors and the complex salt composition of the initial raw materials, the use of the ionite D72, which provides high technical performances during the sorption and desorption operations, is established.

The obtained results allow us to consider optimistically the possibility of organization of REM co-recovery from the ISL process solutions of uranium by using recycled desorption solution, which was prepared on the basis of ammonium nitrate.

References

Sahoo DK, Singh H, Krishnamurthy N. Current efficiency in electro-wining of lanthanum and cerium metals from molten chloride electrolytes. Rare Met. 2013;32(3):305.

Li M, Zhang X-W, Liu Z-G, Wang M-T, Liu J, Yang J-P. Mixed rare earth concentrate leaching with HCl–AlCl3 solution. Rare Met. 2013;32(3):312.

Kentish SE, Stevens GW. Innovations in separations technology for the recycling and re-use of liquid waste streams. Chem Eng J. 2001;84(2):149.

Wang Z, Ma G, Li D. Extraction and separation of heavy rare earth(III) with extraction resin containing di(2,4,4-trimethyl pentyl)phosphinic acid (cyanex 272). Solvent Extr Ion Exch. 1998;16(3):813.

Wang ZH, Ma GX, Lu J, Liao WP, Li D. Separation of heavy rare earth elements with extraction resin containing 1-hexyl-4-ethyloctyl isopropylphosphonic acid. Hydrometallurgy. 2002;66(1–3):95.

Alexandratos SD, Strand MA, Quillen DR, Walder AJ. Synthesis and characterization of bifunctional phosphinic acid resins. Macromolecules. 1985;18(5):829.

Alexandratos SD, Wilson DL. Dual mechanism bifunctional polymers: polystyrene-based ion-exchange/redox resins. Macromolecules. 1986;19(2):280.

Alexandratos SD, Hussain LA. Bifunctionality as a means of enhancing complexation kinetics in selective ion exchange resins. Ind Eng Chem Res. 1995;34(1):251.

Sabharwal KN, Vasudevarao PR, Srinivasan M. Extraction of actinides by bifunctional phosphinic acid resin. Solvent Extr Ion Exch. 1994;12(5):1085.

Sabharwal KN, Nandy KK, Srinivasan TG, Vasudevarao PR. Recovery of uranium from acid media by macroporous bifunctional phosphinic acid resin. Solvent Extr Ion Exch. 1996;14(6):1101.

Venkatesan KA, Shyamala KV, Antony MP, Srinivasan TG, Vasudevarao PR. Batch and dynamic extraction of uranium(VI) from nitric acid medium by commercial phosphinic acid resin, Tulsion CH-96. J Radioanal Nucl Chem. 2008;275(3):563.

Nagaphani Kumar B, Radhika S, Ramachandra Reddy B. Solid–liquid extraction of heavy rare-earths from phosphoric acid solutions using Tulsion CH-96 and T-PAR resins. Chem Eng J. 2010;160(1):138.

Myasoedova GV, Molochnikova NP, Kulyako Y, Myasoedov BF. Filled fibrous sorbents modified with transition metal ferro- and ferricyanides for recovery of americium and rare-earth metals. Radiochemistry. 2003;45(1):61.

Miklishanskii AZ, Yakovlev Yu V, Dogadkin NN, Leikin Yu A, Davankov AB. Investigation of the sorption of the rare-earth elements and uranium by phosphorous-containing cation-exchange resins. Izvestiya Akademii Nauk SSSR, Seriya Khimicheskaya. 1968;17(7):1373.

Kremliakova NYu, Barsukova KV, Myasoedov BF. Behaviour of transplutonium and rare earth elements on tvex, iii, nitric acid solutions. J Radioanal Nucl Chem. 1988;122(1):3.

Koeppenkastrop D, Decarlo EH, Roth M. A method to investigate the interaction of rare earth elements in aqueous solution with metal oxides. J Radioanal Nucl Chem. 1991;152(2):337.

Turanov AN, Karandashev VK, Yarkevichand AN, Safronova ZV. Extraction and sorption preconcentration of rare-earth elements(III) and scandium(III) with phosphorylmethyl-substituted butylphenylphosphinates from perchloric acid solutions. Russ J Inorg Chem. 2010;55(8):1305.

Marhol M, Beranov H, Cheng KL. Selective ion-exchangers containing phosphorus in their functional groups. J Radioanal Chem. 1974;21(1):177.

Xiong CH, Liu XZ, Yao CP. Effect of pH on sorption for RE(III) and sorption behaviors of Sm(III) by D152 resin. J Rare Earths. 2008;26(6):851.

Melnyk IV, Goncharyk VP, Kozhara LI, Yurchenko GR, Matkovsky AK, Zub Y, Alonso B. Sorption properties of porous spray-dried microspheres functionalized by phosphonic acid groups. Microporous Mesoporous Mater. 2012;153:171.

Tian J, Yin JQ, Chen KH, Rao GH, Jiang MT, Chi R. Extraction of rare earths from the leach liquor of the weathered crust elution-deposited rare earth ore with non-precipitation. Int J Miner Process. 2011;98(3):125.

El-Dessouky SI, El-Sofany EA, Daoud JA. Studies on the sorption of praseodymium(III), holmium(III) and cobalt(II) from nitrate medium using TVEX–PHOR resin. J Hazard Mater. 2007;143(1–2):17.

Xiong CH, Zhu JF, Shen C, Chen Q. Adsorption and desorption of praseodymium(III) from aqueous solution using D72 resin. Chin J Chem Eng. 2012;20(5):823.

Xiong CH, Meng Y, Yao CP, Shen C. Adsorption of erbium(III) on D113-III resin from aqueous solutions: batch and column studies. J Rare Earths. 2009;27(6):923.

Spedding FH, Daane AH, editors. The Rare Earths. New York: Wiley; 1961. 641.

Kozhakhmetov SK, Kopbayeva MP, Panova EN, Shokobayev NM, Borisenko VA, Toxanbayev BZh, Identification of effective ionites for REM recovery from technological solutions of uranium ISL. In: Proceedings of the International Conference “Rare Earth Elements: Geology, Chemistry, Production and Application”, Moscow. 2012. 110.

Acknowledgments

This work was financially supported by LLP “Institute of High Technologies” (No. RMK-D-018).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shokobayev, N.M., Bouffier, C. & Dauletbakov, T.S. Rare earth metals sorption recovery from uranium in situ leaching process solutions. Rare Met. 34, 195–201 (2015). https://doi.org/10.1007/s12598-014-0237-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0237-z