Abstract

A successful approach to prepare the Pd–Ni nanowire arrays electrode without carbon supports was reported. The morphology and crystallinity of nanowire were characterized by transmission electron microscopy, selected-area electron diffraction (SAED), X-ray diffraction (XRD), and X-ray photoelectron spectroscopy (XPS) analyses, respectively. The results show that the diameters of the nanowire are in the range of 65–75 nm, and the polycrystalline binary solid solution alloy is formed in the Pd–Ni nanowire. Cyclic voltammograms, chronoamperograms, and electrochemical impedance spectroscopy demonstrate that the Pd–Ni nanowire arrays electrodes show excellent electrocatalytic performance for methanol oxidation in alkaline media. The catalytic activity of Pd–Ni nanowire arrays electrode is ~1.39 times higher than that of the Pd nanowire arrays electrode and ~2.28 times higher than that of the commercial Pd/C catalyst. This is mostly owing to the transfer of electron density from Ni to Pd. These results indicate that Pd–Ni nanowire arrays electrode is very promising in an alkaline direct methanol fuel cell.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The electrooxidation of methanol attracts extensive attention because direct methanol fuel cell (DMFC) is considered as a prospective power source [1]. However, the commercialization of DMFC faces serious difficulties due to kinetic constraints of the methanol oxidation reaction (MOR) in acid solution and the high cost of Pt-based electrocatalysts [2, 3]. In recent years, with the application for alkaline anion membrane in fuel cells [4, 5], a great deal of interest has been focused on the choice of Pd-based metals because it has a good electroactivity for methanol oxidation in alkaline media [6, 7]. In addition, Masel and coworkers disclosed that Pd and Pd/C catalysts could overcome the CO-poisoning effect and thereby yield high performance in DMFC [8]. Thus, Pd-based catalysts seem to be promising anode catalysts in an alkaline DMFC.

However, the activity and stability of the Pd-based catalyst are still in need of improvements. The Pd catalytic activity may be increased by the addition of metal or metal oxide promoters [9, 10]. Especially, adding transition metal (Ni, Co, or Fe) to Pd attracts extensive attention [11–13]. Singh et al. [14, 15] obtained binary and ternary composite films of Pd, multiwalled carbon nanotubes (MWCNTs), and Ni on glassy carbon. The results showed that the Pd-1 % MWCNTs-1 % Ni composite electrode exhibited the highest electrocatalytic activity for MOR in alkaline media. The enhanced electrocatalytic activity is ascribed to the improved geometric as well as electronic properties [15].

In order to obtain a maximum in catalytic performance while keeping a minimal mass of noble metals, catalysts are usually well dispersed on conductive carbon supports, such as carbon black [16], carbon nanotubes [17], graphene [18] , and fullerene [19]. However, the kinetic study of electrode process may be disturbed from these carbon supports [14, 15]. The research on no-carbon supports’ catalysts not only may avoid interference of the supports, but also can reflect the intrinsic catalytic ability of active substance. Herein, a successful method was described to prepare Pd–Ni nanowire arrays electrode as electrocatalyst for DMFC. Compared with commercial Pd/C (JM) catalysts and Pd nanowire arrays electrode, the Pd–Ni nanowire arrays electrode exhibited distinctly higher activity and better stability for methanol oxidation in alkaline media.

2 Experimental

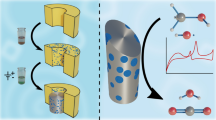

2.1 Preparation of Pd–Ni nanowire

Preparation of Pd–Ni nanowire was carried out with the help of a traditional porous anodic aluminum oxide (AAO) template (with pore diameters in the range of 70–75 nm) [20–22]. Pd–Ni nanowire arrays were fabricated by electrochemical deposition into the nanometer-sized pores. In order to fabricate an array of metal nanowires, the remaining aluminum layer of the AAO acted as the working electrode in a two-electrode electrochemical cell. The electrodeposition solution consists of 0.03 mol·L−1 Pd(NH3)2Cl2, 0.02 mol·L−1 NiSO4·6H2O. and 0.2 mol·L−1 (NH4)2SO4. At room temperature, the electrodeposition was carried out at an alternating voltage of 15 V and at an alternating current frequency of 50 Hz for 30 min, with a piece of Pt foil as the anode. By comparison, Pd nanowire arrays were prepared according to the same method (the electrodeposition solution: 0.03 mol·L−1 Pd(NH3)2Cl2 and 0.2 mol·L−1 (NH4)2SO4).

2.2 Characterization

Transmission electron microscopy (TEM) images were obtained on a JEOL JEM-2100 electron microscope (200 kV). The elemental compositions were measured by an energy dispersive spectroscopy (EDS) detector. The X-ray diffraction (XRD) data were obtained by means of using a Bruker D8 Advance X-ray diffractometer with Cu Kα (0.15406 nm) radiation. X-ray photoelectron spectroscopy (XPS) experiments were performed using a PHI5500 spectrometer using Mg Kα (1,253.6 eV) radiation. Spectral correction was based on adventitious carbon, using the C1s binding energy of 284.8 eV. All the samples were examined after dissolving the AAO template in an aqueous solution of 5 wt% H3PO4.

2.3 Electrochemical measurement

Electrochemical experiments were carried out using a CHI 760C electrochemical workstation at room temperature. A conventional three-electrode cell, consisting of Pd–Ni (or Pd) nanowire arrays as the working electrode (with square area of 1 cm2), Pt foil as the counter electrode, and saturated calomel electrode (SCE) as the reference electrode, was used. All the potentials in this article were quoted against SCE. The elelctrocatalytic performance for the methanol oxidation was evaluated in 0.5 mol·L−1 KOH + 2 mol·L−1 CH3OH solution. The testing solution was purged by nitrogen for 20 min before the electrochemical measurement.

3 Results and discussion

3.1 TEM and EDS analysis

Figure 1 shows TEM images and selected-area electron diffraction (SAED) of Pd and Pd–Ni nanowires. It can be observed that the diameters of nanowires are approximately in the range of 65–75 nm, in good agreement with pore diameter of AAO template. Nanowires are found to be not smooth and not very uniform along the nanowire. The burr structure of nanowires is due to alternate current deposition. However, the burr of Pd–Ni nanowires is more apparent than that of Pd nanowires, and this result can be attributed to the easier dissolution of the Pd–Ni nanowires in the negative half-cycle of alternating current.

As certified by the SAED pattern shown in the top inset of Fig. 1a, the orderly spots could be indexed based on the face-centered-cubic (fcc) structure of Pd. It may be because the electronic exchanges happen in one direction along the nanochannel of AAO template in the process of the growth of Pd nanowire.

However, the ring pattern also can be faintly observed, and it could be due to the remaining AAO after being dissolved. The series of ring pattern shown in the top inset of Fig. 1b indicates the formation of Pd–Ni nanophase’s structure.

An EDS spectrum of the Pd–Ni nanowires is shown in Fig. 2. The peaks of Al and O can be attributed to dissolved AAO template, the peaks of C and P can be attribute to carbon in the air and corrosive liquid H3PO4. The atom ratio of Pd and Ni is found to be 1.32:1.00, nearly the same as the atom ratio of Pd and Ni of the precursor salts. The EDS result shows that the content Pd–Ni metal of the final composite is about 25.5 wt%.

3.2 XRD analysis

Figure 3 shows the XRD patterns of Pd and Pd–Ni nanowires. It can be seen that the diffuse amorphous peak at 2θ values of 15°–35° corresponds to the peak of the glass sample holder. In Fig. 3a, the other three peaks at 2θ values of about 40.1°, 46.7°, and 68.1°, respectively, correspond to the planes (111), (200), and (220) of Pd, indicating that Pd nanowire has face-centered-cubic (fcc) crystalline structure (JCPDS: 05-0681). It is in good agreement with the conclusion from SAED. Compared with the reflections peaks for Pd nanowires, in the XRD patterns for the Pd–Ni nanowires from Fig. 3b, it can be observed that the peak of Pd (220) disappears, the peak of Pd (200) becomes very weak, and the peak of Pd (111) also shows an evident decline and the positive shift, mixing with the peak of Ni (002). The slight shift of the diffraction peak reveals that partial Ni enters into the Pd lattice, and it could be preliminary indication that the solid solution alloy forms in the Pd–Ni nanowire [23, 24], but it may be the polycrystalline binary alloy, which is consistent with the SAED results.

3.3 XPS analysis

Figure 4 shows XPS spectra of Pd3d for Pd and Pd–Ni nanowires. The Pd3d spectrum of Pd nanowires in Fig. 4a shows a doublet containing a low-energy band (Pd3d5/2) and a high-energy band (Pd3d3/2) at 335.29 and 340.61 eV, respectively. However, it can be also observed from Fig. 4b that the energy bands of Pd3d5/2 and Pd3d3/2 of Pd–Ni nanowires locate at 334.84 and 340.13 eV, respectively. The negative shifts of the doublet peaks slightly to the lower binding energies might be attributed to the transfer of electron density from Ni to Pd, since the electronegativity of Ni is 1.91, while that of Pd is 2.20 [15, 25].

3.4 Electrochemical measurement

The electrochemical properties of Pd–Ni nanowire arrays electrode compared with Pd nanowire arrays electrode and the commercial Pd/C (JM) were investigated. As can be seen from Fig. 5a, the cyclic voltammetric curves are similar to those reported in the Refs. [6, 7, 14, 15], and an enhanced activity is observed for Pd–Ni nanowire arrays electrode. The peak current density of Pd–Ni nanowire arrays electrode (3.51 mA·cm−2) is ~1.39 times higher than that of Pd nanowire arrays electrode (2.52 mA·cm−2) and is 2.28 times higher than that of the commercial Pd/C catalysts (1.54 mA·cm−2). The significantly higher anodic current density for methanol oxidation on Pd–Ni nanowire arrays electrode indicates a much higher electrocatalytic activity, which is most likely due to the donated electron of Ni [25].

Figure 5b shows chronoamperometric curves of the Pd–Ni nanowire arrays electrode, Pd nanowire arrays electrode, and the commercial Pd/C catalysts for methanol oxidation. The decrease in current density indicates the poisoning of catalysts, which results from the adsorbed intermediates in methanol oxidation. Nevertheless, the Pd–Ni nanowire arrays electrode is able to maintain the higher current density in the whole process. This indicates that the Pd–Ni nanowire electrode is more stable and poison-tolerant compared with the Pd nanowire arrays electrode and the commercial Pd/C catalysts.

Figure 5c presents the impedance spectra of the Pd–Ni nanowire arrays electrode, Pd nanowire arrays electrode, and the commercial Pd/C catalysts. The diameter of the semicircle is considered as the charge transfer resistance, representing the rate of charge exchange between ions in aqueous and catalysts at electrochemical interface, and indicating the catalytic activity for MOR [26]. It can be observed that the semicircle’s diameter of the impedance spectrum of the Pd–Ni nanowire arrays electrode is much smaller than that of the commercial Pd/C catalysts, indicating a smaller reaction resistance in the Pd–Ni nanowire arrays electrode than in the commercial Pd/C catalysts. This fact may suggest that the transfer of electron density from Ni to Pd can facilitate the effective degree of electron delocalization and enhance the conductivity of catalysts [17].

4 Conclusion

In this article, successful method to prepare Pd–Ni nanowire arrays electrode without carbon supports was reported. As compared with commercial Pd/C (JM) catalysts and Pd nanowire arrays electrode, the prepared Pd–Ni nanowire arrays electrode exhibits distinctly higher activity and better stability for methanol oxidation in alkaline media. The improved electrocatalytic performance of the Pd–Ni nanowire arrays electrode is mostly due to the transfer of electron from Ni to Pd. These results imply that Pd–Ni nanowire arrays electrode is very promising in an alkaline DMFC.

References

Dillon R, Srinivasan S, Arico A, Antonucci V. International activities in DMFC R&D: status of technologies and potential applications. J Power Sour. 2004;127(1):112.

Li L, Xing YC. Pt–Ru nanoparticles supported on carbon nanotubes as methanol fuel cell catalysts. J Phys Chem C. 2007;111(6):2803.

Bensebaa F, Farah AA, Wang D, Bock C, Du XM, Kung J, Le Page Y. Microwave synthesis of polymer-embedded Pt–Ru catalyst for direct methanol fuel cell. J Phys Chem B. 2005;109(32):15339.

Varcoe JR, Slade RC, Yee ELH. An alkaline polymer electrochemical interface: a breakthrough in application of alkaline anion-exchange membranes in fuel cells. Chem Commun. 2006;13:1428.

Pan J, Lu SF, Li Y, Huang AB, Zhuang L, Lu JT. High-performance alkaline polymer electrolyte for fuel cell applications. Adv Funct Mater. 2010;20(2):312.

Zhao YC, Zhan L, Tian JN, Nie SL, Ning Z. Enhanced electrocatalytic oxidation of methanol on Pd/polypyrrole–graphene in alkaline medium. Electrochim Acta. 2011;56(5):1967.

Gao SY, Wu DS, Cao MN, Cao R. Self-assembled Pd-dicyanobiphenyl multilayer films and their application in electrocatalytic oxidation of methanol in alkaline medium. Thin Solid Films. 2012;524:173.

Ha S, Larsen R, Masel RI. Performance characterization of Pd/C nanocatalyst for direct formic acid fuel cells. J Power Sour. 2005;144(1):28.

Wang M, Guo DJ, Li HL. High activity of novel Pd/TiO2 nanotube catalysts for methanol electro-oxidation. J Solid State Chem. 2005;178(6):1996.

Shen PK, Xu CW, Zeng R, Liu YL. Electro-oxidation of methanol on NiO-promoted Pt/C and Pd/C catalysts. Electrochem Solid State. 2006;9(2):A39.

Kumar KS, Haridoss P, Seshadri SK. Synthesis and characterization of electrodeposited Ni–Pd alloy electrodes for methanol oxidation. Surf Coat Technol. 2008;202(9):1764.

Verlato E, Cattarin S, Comisso N, Guerriero P, Musiani M, Vázquez-Gómez L. Preparation of catalytic anodes for methanol oxidation by spontaneous deposition of Pd onto porous Ni or porous Co. Electrochem Commun. 2010;12(8):1120.

Li J, Ren J, Yang GW, Wang P, Li H, Sun X, Chen L, Ma JT, Li R. Simple and efficient deposition of Pd nanoparticles on Fe3O4 hollow nanospheres: a new catalytic system for methanol oxidation in alkaline media. Mater Sci Eng B. 2010;172(3):207.

Singh RN, Anindita SA. Electrocatalytic activity of binary and ternary composite films of Pd, MWCNT, and Ni for ethanol electro-oxidation in alkaline solutions. Carbon. 2009;47(1):271.

Singh RN, Anindita SA. Electrocatalytic activity of binary and ternary composite films of Pd, MWCNT and Ni, Part II: methanol electrooxidation in 1 mol·L−1 KOH. Int J Hydrogen Energy. 2009;34(4):2052.

Zhu LD, Zhao TS, Xu JB, Liang ZX. Preparation and characterization of carbon-supported sub-monolayer palladium decorated gold nanoparticles for the electro-oxidation of ethanol in alkaline media. J Power Sour. 2009;187(1):80.

Zhu ZZ, Wang Z, Li HL. Self-assembly of palladium nanoparticles on functional multi-walled carbon nanotubes for formaldehyde oxidation. J Power Sour. 2009;186(2):339.

Li YJ, Gao W, Ci LJ, Wang CM, Ajayan PM. Catalytic performance of Pt nanoparticles on reduced graphene oxide for methanol electro-oxidation. Carbon. 2010;48(4):1124.

Lim IS, Pan Y, Mott D, Ouyang JY, Njoki PN, Luo J, Zhou SQ, Zhong CJ. Assembly of gold nanoparticles mediated by multifunctional fullerenes. Langmuir. 2007;23(21):10715.

Shingubara S, Okino O, Sayama Y, Sakaue H, Takahagi T. Ordered two-dimensional nanowire array formation using self-organized nanoholes of anodically oxidized aluminum. Jpn J Appl Phys. 1997;36:7791.

Phok S, Rajaputra S, Singh VP. Copper indium diselenide nanowire arrays by electrodeposition in porous alumina templates. Nanotechnology. 2007;18(47):475601.

Gao TR, Yin LF, Tian CS, Lu M, Sang H, Zhou SM. Magnetic properties of Co–Pt alloy nanowire arrays in anodic alumina templates. J Magn Magn Mater. 2006;300(2):471.

Zhao YC, Yang XL, Tian JN, Wang FY, Zhan L. Methanol electro-oxidation on Ni@Pd core–shell nanoparticles supported on multi-walled carbon nanotubes in alkaline media. Int J Hydrogen Energy. 2010;35(8):3249.

Wang ZC, Ma ZM, Li HL. Functional multi-walled carbon nanotube/polysiloxane composite films as supports of PtNi alloy nanoparticles for methanol electro-oxidation. Appl Surf Sci. 2008;254(20):6521.

Wang SY, Yang F, Jiang SP, Chen SL, Wang X. Tuning the electrocatalytic activity of Pt nanoparticles on carbon nanotubes via surface functionalization. Electrochem Commun. 2010;12(11):1646.

Wu G, Li L, Li JH, Xu BQ. Methanol electrooxidation on Pt particles dispersed into PANI/SWNT composite films. J Power Sour. 2006;155(2):118.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (Nos. 51164017 and 20863003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, ML. Electrocatalytic performance of Pd–Ni nanowire arrays electrode for methanol electrooxidation in alkaline media. Rare Met. 33, 65–69 (2014). https://doi.org/10.1007/s12598-013-0204-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-013-0204-0