Abstract

In this paper, high-efficiency solar cells were synthesized using the following compounds (Al/Si/BHJ(Cu-PcTs/GO)/PEDOT:PSS/Au), this compound has important, promising and inexpensive properties due to its ability to convert solar energy over a large area. In this paper, Cu-PcTs/GO compounds will be used to make and improve the properties of solar energy. The best efficiency value for Cu-PcTs/GO composite was 0.927 at the mixing ratio of 1/0.25 at 28 ℃ while the best efficiency value for the Cu-PcTs/GO composite was 2.094 at the mixing ratio 1/0.75 when annealing at 150℃.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

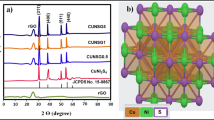

A solar cell or photovoltaic cell may be described as large place electric device (p-n) junction structure that has been designed to that converts mild strength at once to electricity via photovoltaic (PV) impact. Previously, a solar cell was obtained by building the structure from compounds (Cu-PcTs/GO) because of their important and highly efficient properties [1], These compounds have unique properties in the field of optics and chemistry used in the development of solar cells by increasing the mixing ratio and different temperatures [2]. GO is an exciting nanomaterial with a first-class electronic large-area capability [3]. Previously the surface morphology of cross-volume AFM for thin films (GO), (Cu-PcTs) was studied and confirmed that the treatment resulted in obtaining a nanostructure to the nano-length [4]. When studying the Hall effect, it was found that the resistance increases with a decrease in proportion GO. There are many conductive organic thermoelectric compounds, but PEDOT: PSS has a high performance in this field and therefore can be used in flexible thermal power plants. Yet its biggest utility is as a transparent, conductive polymer with excessive [6]. However, this compound is of great use as it is a highly transparent conductive polymer. There are many researches done by researchers on this material and it has been used in different applications [5,6,7,8,9,10,11,12,13,14,15].

In this paper, the results of the following quantities: ISc, FF, and Voc were studied and analyzed, which represent the important performance characteristics of a solar cell. These important parameters must be studied and determined under specific lighting conditions. The power and current density graph as a function of the voltage of the solar cell along with the main parameters is shown in Fig. 1.

Graphs of the current density and power as a voltage function for the solar cell along with the key parameters [17]

Experimental details

In this work, nano graphene oxide colloid water-based concentration 1 mg/ml was used a concentration of 10 mg/1 ml was obtained when Cu-PcTs nanopowder was added to non-ionized water. Practically, four different ratios of the GO nano compound were changed with fixed the ratio of Cu-PcTs nano compound, as shown in Table 1.

To dissolve the mixture (the two nano compounds) a magnetic stirrer was used for two hours and at a 28 ℃. To study the structural properties of these samples, quartz substrates with measurements 2.5 × 2.5 cm are first prepared after being cleaned completely with distilled water and acetone, then using an ultrasound device, and then drying them with special drying paper.

Spin coating technique was used to prepare the samples (thin films), where quartz substrates are placed inside the device and the spin coating speed was 2000 rpm for 10 m and the second speed was 300 rpm for 10 s.

In the same way as before, the samples are prepared in the same previous conditions and with the same mixing ratios, but with an annealing temperature of 150 ℃ for a period of three hours, as shown in Table 2. A comparison was made between the results of cases, the room temperature condition and the degree of annealing.

For measuring the voltage and current of a device used a solar cell. The solar cell is made of a silicon slide (Si-n type) with dimensions 2.5 × 2.5 cm, and thickness 500 μm, where aluminum (Al) was deposited on the back of the slide using vacuum coating unit. The second side up was deposited the Cu-PcTs/GO with different maxing ratios using spin coating method to get the first layer of solar cell. The PEDOT: PSS component (with low resistivity (< 0.0012 Ω cm) (from Ossila. Company UK)) was deposited on the first layer to increase cell efficiency as a second layer. Finally, Gold (Au) had been deposited on the second layer of solar cell to get another electrode, so the formed cell is (Al/Si/BHJ(CuPcTs/GO)/PEDOT:PSS/Au), as shown in Fig. 2. To investigate from solar cell efficiency, the solar cell was connecting with system "solar cell I-V Teacer IV-26 type" IRASOL Company, as shown in Fig. 3. The distance from solar cell to halogen light was 10 cm and the power of light was 100 mW. The solar cell was connected as inverse bias. The (I-V) characteristic was studying where the efficiency (η), and fill factor (F.F) of the solar cell was calculated [16].

Parameter of solar cell

There are many parameters were appear in solar cell these parameters are fill factor (F.F) and efficiency η, where represent the ratio of the maximum power (Pm) divided by the short circuit current (ISc) times the open circuit voltage (Voc) [16]:

The shunt resistors and the cell series directly affect the values of the fill factor. The value of the fill factor increases to its highest value by decreasing the series resistance (RS) and increasing the shunt resistance (Rsh). The cell power is given by [16]:

At the maximum power point and the cells operating point, the value of P is as high as possible. This happened at a corresponding current Im with some voltage Vm. The efficiency of the cell η is calculated by the power out by the power of the incident light (Pin) [16]:

Efficiency is related to ISc and Voc using F.F then:

So, the following solar cell characteristics, F.F, Voc, ISc and Pin determine the performance and efficiency of the solar cell.

Results and discussion

To study the structural properties of the prepared thin films before and after annealing, the SEM device was used, where the grain size was approximately 50 nm. The results showed a change in the structural properties of the prepared films at an annealing 150 ℃, as shown in Figs. 2 and 3. By changing the annealing temperature, it was observed that the structures of both GO and Cu-PcTs nanocomposites changed and became smaller compared to the room temperature condition. Accordingly, this phenomenon indicates that the thin films have grown parallel to the surface of the substrate and become more little size with increasing temperature. It was observed that the grains (like island) became separated at the annealing temperature.

By using the setup in Figs. 4 or 5 and when highlighting (halogen source) all the samples previously prepared and shown in Table 1 and using the reverse bias, changes were observed in the 4th part of the characteristic curve of current and voltage (I-V), and this confirms the work of the samples as a solar cell, as shown in Figs. 6 and 7, this does not apply to the sample 61 sample at 28 ℃. To measure the solar cell efficiency, a fluctuation in efficiency value of manufactured solar cells was observed, as shown in Table. The best value for the efficiency of compound Cu-PcTs/GO was at the mixing ratio of 1/0.25 at 28 ℃, and the best value for the calculated efficiency of the compound was 1/0.75 when annealing. This brings good solar cell improvement. As for filling coefficient, note the lower its value decrease when its value GO decreases and after annealing except the samples 52 and 62. Through the above results, we were able to manufacture a highly efficient solar cell by mixing different proportions of nanostructures, and this work is new in this field (Table 3).

Conclusions

Through the foregoing, we conclude, the SEM indicates to the existence of smooth grain morphology of the film and the movie preferentially grows parallel to the surface; which means that they have become nano as the annealing temperature extended. Also in this case the solar cell manufactured in this way has a high efficiency for converting solar energy into electrical energy. The best value for the efficiency of compound CuPcTs/GO was at the mixing ratio of 1/0.25 at 28 ℃, and the best value for the calculated efficiency of the compound was 1/0.75 when annealing.

References

Y. Hernandez, V. Nicolosi, M. Lotya, F.M. Blighe, Z. Sun, S. De, I.T. McGovern, B. Holland, M. Byrne, Y.K. Gun’Ko, J.J. Boland, P. Niraj, G. Duesberg, S. Krishnamurthy, R. Goodhue, J. Hutchison, V. Scardaci, A.C. Ferrari, J.N. Coleman, High-yield production of graphene by liquid-phase exfoliation of graphite. Nat. Nanotechnol. 3, 10 (2008)

A. Gómez, C. Sánchez, I. Fleitman, J. Arenas, J. Alonso, M. Vergara, Optical absorption and visible photoluminescence from thin films of silicon phthalocyanine derivatives. Materials (Basel) 6, 9 (2014)

W. Mayada, J.K. Raied, Characterization of copper phthalocyanine-tetrasulfonic acid tetrasodium salt/graphene oxide. Iraqi J. Sci. 62, 6 (2020)

N. Satoh, M. Otsuka, T. Ohki, A. Ohi, Y. Sakurai, Y. Yamashita, T. Mori, Organic π-type thermoelectric module supported by photolithographic mold: a working hypothesis of sticky thermoelectric materials. Sci. Technol. Adv. Mater. 19(1), 517–525 (2018)

H. He, J. Klinowski, M. Forster, A. Lerf, A new structural model for graphite oxide. Chem. Phys. letters 287(1–2), 53–56 (1998)

A. Reina, X. Jia, J. Ho, D. Nezich, H. Son, V. Bulovic, Large area, few-layer graphene films on arbitrary substrates by chemical vapor deposition. Nano Lett. 9, 1 (2009)

M.D. Stoller, S. Park, Z. Yanwu, J. An, R.S. Ruoff, Graphene-based ultracapacitors. Nano Lett. 8, 10 (2008)

X. Li, G. Zhang, X. Bai, Highly conducting graphene sheets and Langmuir-Blodgett films. Nat. Nanotechnol. 3, 9 (2008)

K.S. Novoselov, Z. Jiang, Y. Zhang, Room temperature quantum hall effect in graphene. Sience 315, 5817 (2007)

A.A. Balandin, S. Ghosh, W. Bao et al., Superior thermal conductivity of single-layer graphene. Nano Lett. 8, 3 (2008)

S. Ghosh, I. Calizo, D. Teweldebrhan, Extremely high thermal conductivity of graphene: prospects for thermal management applications in nanoelectronic circuits. Appl. Phys. Lett. 92, 15 (2008)

K. Potje Kamloth, Semiconductor junction gas sensors. Chem. Rev. 108, 367 (2008)

T.D. Anthopoulos, J.P. Markham, E.B. Namdas, I.D. Samuel, S.C. Lo, P.L. Burn, Solution processable red phosphorescent dendrimers for light-emitting device applications. Appl. Phys. Lett. 82, 4824 (2004)

A.T. Smith, A.M. LaChance, S. Zeng, B. Liu, L. Sun, Synthesis, properties, and applications of graphene oxide/reduced graphene oxide and their nanocomposites. Nano Mater. Sci. 1(1), 31–47 (2019)

M.T. Hussein, Theoretical IR spectroscopic study of Copper Phthalocyanine (CuPc). Al-Nahrain J. Eng. Sci. 11(2), 303–306 (2008)

R.K. Jamal, Band energy outline of NiO: Au/Si thin-film for solar cell. Iraqi J. Sci. 58, 3C (2017)

W.J. Potscavage Jr, Physics and engineering of organic solar cells. Georgia Institute of Technology Ph. D. Thesis (2011).

Funding

The present research did not receive any grant from funding agencies in the public, Commercial or not-for profit sectors. So its personal work and the statement of declaration of interests are only mine and support has been subjective during the research work for the past year.

Author information

Authors and Affiliations

Contributions

M.W.K. Conceptualization, preparation samples, writing-original draft. R.K.J investigation, supervision, analysis, methodology, writing-reviewing and editing.

Corresponding author

Ethics declarations

Conflict of interests

Authors would like to declare that they do not have any conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kadhim, M.W., Jamal, R.K. Fabrication of a novel solar cell using copper phthalocyanine tetrasulfonic acid tetrasodium salt / graphene oxide. J Opt 52, 1507–1512 (2023). https://doi.org/10.1007/s12596-022-00960-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12596-022-00960-7