Abstract

The present work focuses on the preparation of solid polymer electrolytes (SPEs) based carboxymethyl cellulose, CMC as host polymer doped with ammonium chloride, AC (0–20 wt.%) as ionic dopant via solution casting technique. The ionic conductivity and transport parameter of SPEs films were analyzed using electrical impedance spectroscopy in the frequency range of 1 Hz–50 MHz at selected temperature of 303–383 K. The highest ionic conductivity of 1.43 × 10−3 S/cm was obtained at 16 wt.% AC. Temperature-dependent ionic conductivity showed that the ionic conductivity obeys Arrhenius rule where R2~1 and thermally assisted. Transport studies showed that the ionic conductivity was influenced by the ionic mobility and diffusion coefficient.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the world of a new era, there are so many products of battery with high cost fabrication but not environmental friendly. The use of environmental awareness materials as solid polymer electrolyte (SPE) can help to minimize environmental issues [1]. Generally, SPE have advantages over liquid electrolytes such as light weight, improve leakage problem, mechanically stable and flexible for packaging design. Additionally, the performance of solid electrolytes based devices demands on the understanding of the mechanism of ions transportation in this system [2].

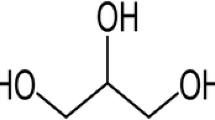

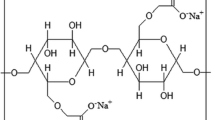

Carboxymethyl cellulose (CMC) is a cellulose derivative depends on the degree of substitution (DS) of the hydroxyl group of the glucose unit [3]. CMC has good film forming properties, can form a transparent film and possesses high mechanical strength. It is natural anionic polysaccharide and the most abundant organic substances on earth which is widely used in the food industry as a thickener and a binder, in the oil industry as a lubricant for drilling and in the cosmetic industry as a stabilizer and a binder [4]. Because of its non-toxic, renewable, available in abundance, biocompatible and biodegradable, CMC solution has also been widely used as a carrier for bone graft or polymer host [3].

One of proton-conducting polymer electrolytes is the polymer-ammonium complex, in which NH4 + is responsible for the ionic conduction [4]. AC has been chosen as the dopant since ammonium salts were regarded as good proton donors to the polymer matrix and endowed its high efficient proton conduction [4, 5]. Besides that, the CMC and ammonium ion are easily to chelate because of strong contributions of hydrogen bonding and coordination interaction of H+ to the (COO−) moiety between CMC and AC as found in other similar system using carboxymethyl cellulose [6]. There are two possible charge carrier elements in these polymer–ammonium complex systems which are cation and anion. The cation carrier could be either H+ and NH3 + or NH4 + [2].

These present study focuses on the preparation of CMC-AC solid polymer electrolytes with varied AC concentrations and characterization of polymer electrolytes by using electrical impedance spectroscopy and transference number measurement for electrochemical application.

Material and methods

Sample preparation

2.0 g of CMC (Acros Organic Co.) was dissolved in 100 ml distilled water at room temperature. The varied amount of AC (Sigma Aldrich) in weight percentage (0–20 wt.%) was added into the CMC solution and stirred until completely dissolved. The mixtures were casted into several petri dishes and dried at room temperature for 3 to 4 weeks depending on the percentage of AC. Complete drying when SPE film that looks clean and clear will be formed as shown in Fig. 1. When the film looks like a plastic and it is rubbery then SPE films ready to be used.

Conductivity measurement

The ionic conductivity and transport parameters of SPE films were investigated by electrical impedance spectroscopy (EIS) HIOKI 3532–50 LCR Hi-Tester over the frequency range of 50 Hz to 1 MHz at different temperatures between 303 and 353 K. SPE film was placed between the blocking stainless steel electrodes of a conductivity cell which connected by leads to a computer. The ionic conductivity (σ) was determined from the equation below [4, 5, 7].

where, t is the thickness of the SPE film; R b is bulk resistance obtained from the Nyquist plot and A (cm2) is the electrode-electrolyte contact area of SPE film.

Transference number measurement (TNM)

Transference number measurements (TNM) were performed to show a relationship between the diffusion of ion to the conductivity behavior of CMC-AC solid polymer electrolytes using DC polarization technique. This technique determines the transference number (t + ion ) by monitoring the current as a function of time on application of a fixed dc voltage (1.5 V) across the sample sandwiched between two stainless steel electrodes.

Results and discussion

Temperature dependence of ionic conductivity

The thermal behavior of SPE films were investigated between temperature of 303 and 353 K. Figure 2 shows the temperature dependence of ionic conductivity for selected SPE films. This figure shows that the ionic conductivity has been increased with the increment of temperatures. Thus, confirmed the Arrhenius behavior of SPE films [8]. The Arrhenius plots are almost unity, (R 2~1) indicating that the ionic conductivity is thermally activated [9]. The graph also revealed that there is no phase transition occurs between polymer matrix and salts. Therefore, H+ ions might migrate through the conduction path formed by the lattice structure of the CMC chains [10].

The plots obey Arrhenius rule with the relation [2–5, 7, 10]:

where \( \sigma \) 0 is the pre-exponential factor, E a is the activation energy, k is the Boltzmann constant and T is the absolute temperature.

Activation energy, E a is the energy required for the first step ions to move. In polymer electrolytes, the ion is usually “loosely bound” to a site with donor electrons. When the ion has acquired sufficient energy, it is able to break away from the donor site and move to another donor site [11]. The movement from one site to another site in the conduction of charge and the energy for this conduction is the activation energy.

The activation energy and ionic conductivity as a function of salt concentration are shown in Fig. 3. The E a was calculated from the slope of the log conductivity, σ versus 1000/T plots from Fig. 2. It is shown that the ionic conductivity was increased with the increment in salt concentration. The highest ionic conductivity was achieved at 1.43 × 10−3 Scm−1 by the concentration of 16 wt.% AC. The increment in ionic conductivity with the addition of AC up to 16 wt.% is due to the increment in the number of mobile ions (η) as reported in [12]. As the concentration of salts increase, more protons (H+) ions are supplied due to the dissociation of AC. Above 16 wt.% AC, the ionic conductivity starts to decrease and this behavior can be attributed by association of ions at higher salt concentration, which leads to the formation of ion clusters and thus the number of charge carriers and their mobility are decreased [6]. From Fig. 3, ionic conductivity was observed inversely proportional to E a . It can be concluded that the concentration of number of mobile ions have influenced by ionic conductivity.

Transport studies

By obtaining the activation energy, E a , the number of mobile ions (η) can be determined by using Rice and Roth model [10]. Rice and Roth model hypothesized that for an ionic carrier of mass, m after receiving energy, E, gets excited from a localized ionic state to another state, in which the ion propagates throughout the solid with velocity, υ [13]. The velocity of mobile ions is given by:

The Rice and Roth stated that:

where e is the charge of conducting species and k is the Boltzmann constant. \( \tau \) is the time to travel between sites, and can be determined from ℓ = vτ. By referring to Fig. 4, ℓ is the length of oxygen atoms to carbon atoms of a monomer. Yokota et al. [14] reported that, the length of 40 rigid chain segments of bendable molecular cellulose is (60 ± 15) nm. Therefore, the length of one chain segments is 1.5 nm. This value is slightly similar by Gaussian software method. From measurement, the length of rigid monomer segment of cellulose is 1.45 nm.

The value of 1.45 nm is then used in the Rice and Roth equation [15]. The ionic mobility (μ) and diffusion coefficient (D) can be identified by using Eqs. (5) and (6);

The conductivity (\( \sigma \)), number of ions (\( \eta \)), ionic mobility (μ) and diffusion coefficient (D) of SPE films at 303 K are tabulated in Table 1.

Previous study by [16] stated that the number and mobility of mobile ions involved in SPE system is generally related to the conductivity value of polymer electrolytes. In the presents work, number of ions, η does not totally contributed to the conductivity enhancement of SPE electrolytes, where η was observed irregularly increase with the addition of NH4Cl concentration [10]. Table 1 clearly shows that the values of ionic mobility and diffusion coefficients were found to exhibit similar behavior with σ. The value of ionic mobility calculated from the Rice and Roth model lies between (0.001 and 47.840) × 10−8 cm2V−1 s−1 and diffusion coefficient between (0.003 and 12.502) × 10−9 cm2s−1. The conductivity of the polymer electrolyte is found to be controlled by the mobility and diffusion coefficient. These results proved that ionic mobility, μ and diffusion coefficient, D were strongly affected by conductivity in SPEs system. Further investigation on the effect of ionic mobility and diffusion coefficient of SPE system has been conducted using TNM [17].

TNM study

The plot of normalized polarization current versus time is shown in Fig. 5. The initial total current, I i decreases with time and becomes constant in the fully depleted situation. The decrease of I i is due to the reduction of the ionic species in the SPE films [5]. At the steady state, the cell is polarized and the current flows due to electron migration across the electrolyte and interfaces. This is because of ionic currents through an ion-blocking electrode fall rapidly with the time if the electrolyte is primarily ionic [16].

The t + ion (Fig. 5) can determine from the equation below:

where I i is initial current and I f is final current.

The ionic mobility can be defined according to the following equations:

The diffusion coefficient of cations and anions in each of the samples was calculated from the measured values of conductivity and transference number, t+ according to the following equations [18]:

Table 2 represents the value of D +, D −, μ + and μ − for selected AC concentration. From the table, the conductivity shows that the sample AC-16 wt.% highest conductivity followed by other composition salt. It also can be observed, the values of μ + are greater than μ − and the values of D + are greater than D −. The charge transport in these SPE films is predominantly ions accompanied by mass transport and electronic contribution to the total current is negligible [18]. The main conducting species in these SPE films is cation. These proved that a CMC-AC film was a proton conductor.

Conclusions

The transparent films of proton-conducting solid polymer electrolytes based carboxymethyl cellulose and ammonium chloride have been successfully prepared via solution casting technique. The temperature dependence of conductivity SPE films showed an Arrhenius behavior. The highest conducting sample containing AC-16 wt.% exhibited the lowest value of E a. The conducting species in SPE films were identified as cation. The μ + and D + were found to influence the ionic conductivity in SPE films. These proved that a CMC-AC film was a proton conductor.

References

Woo HJ, Majid SR, Arof AK (2012) Dielectric properties and morphology of polymer electrolyte based on poly(ε–caprolactone) and ammonium thiocyanate. Mater Chem Phys 134:755–761

Samsudin AS, Lai HM, Isa MIN (2014) Biopolymer materials based carboxymethyl cellulose as a proton conducting biopolymer electrolyte for application in rechargeable proton battery. Electrochim Acta 129:1–13

Samsudin AS, Isa MIN (2012) Characterization of carboxy methylcellulose doped with DTAB as new types of biopolymer electrolytes. Bull Mater Sci 35:1123–1131

Samsudin AS, Isa MIN (2012) Structural and electrical properties of carboxy methylcellulose- dodecyltrimethyl ammonium bromide-based biopolymer electrolytes system. Int J Polym Mater 61:30–40

Du JF, Bai Y, Chu WY, Qiao LJ (2010) The structure and electric characters of proton-conducting chitosan membranes with various ammonium salts as complexant. J Polym Sci 10:880–885

Kamarudin KH, Isa MIN (2013) Structural and DC Ionic conductivity studies of carboxy methylcellulose doped with ammonium nitrate as solid polymer electrolytes. Int J Phys Sci 8:1581–1587

Rani MSA, Rudhziah S, Ahmad A, Mohamed NS (2014) Biopolymer electrolyte based on derivatives of cellulose from Kenaf Bast fiber. Polymers 6:2371–2385

Hema M, Selvasekerapandian S, Sakunthala A, Arunkumar D, Nithya H (2008) Structural, vibrational and electrical characterization of PVA-NH4Br polymer electrolyte system. Physica B 403:2740–2747

Winie T, Arof AK (2006) FT-IR studies on interactions among components in hexanoyl chitosan-based polymer electrolytes. J Spectrochem Acta Part A 63:677–684

Idris NK, Nik Aziz NA, Zambri MSM, Zakaria NA, Isa MIN (2009) Ionic conductivity studies of chitosan-based polymer electrolytes doped with adipic acid. Ionics 15:643–646

Selvasekarapandiana S, Hirankumara G, Kawamurab J, Kuwatab N, Hattorib T (2005) H solid state NMR studies on the proton conducting polymer electrolyte. Mater Lett 59:2741–2745

Buraidah MH, Teo LP, Majid SR, Arof AK (2009) Ionic conductivity by correlated barrier hopping in NH4I doped chitosan solid electrolyte. Physica B 404:1373–1379

Majid SR, Arof AK (2004) Proton-conducting polymer electrolyte films based on chitosan acetate complexed with NH4NO3 salt. Physica B 355:78–82

Yokota S, Ueno T, Kitaoka T, Wariishi H (2007) Molecular imaging of single cellulose chains aligned on a highly oriented pyrolytic graphite surface. Carbohydr Res 342:2593–2598

Shuhaimi NEA, Teo LP, Majid SR, Arof AK (2010) Transport studies of NH4NO3 doped methyl cellulose electrolyte. Synth Met 160:1040–1044

Samsuddin AS, Kuan ECH, Isa MIN (2011) Investigation of the potential of proton-conducting biopolymer electrolytes based methyl cellulose-glycolic acid. J Polym Anal Charact 16:477–485

Nik Aziz NA, Idris NK, Isa MIN (2010) Solid polymer electrolytes based on methylcellulose: FT-IR and ionic conductivity studies. Polym Anal Charact 15:319–327

Chai MN, Ramli MA, Isa MIN (2013) Proton conductor of propylene carbonate–plasticized carboxyl methylcellulose–based solid polymer electrolyte. Int J Polym Anal Charact 18:297–302

Acknowledgments

The authors would like to thank Ministry of Education Malaysia for financial support through ERGS 55101 and FRGS 59271, Department of School of Fundamental Sciences, Universiti Malaysia Terengganu for the help and support throughout the research. N.H. Ahmad gratefully acknowledges MyBrain PhD for the scholarship awarded.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ahmad, N.H.B., Isa, M.I.N.B.M. Proton conducting solid polymer electrolytes based carboxymethyl cellulose doped ammonium chloride: ionic conductivity and transport studies. Int J Plast Technol 19, 47–55 (2015). https://doi.org/10.1007/s12588-015-9110-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12588-015-9110-7