Abstract

In this paper, we report a graphene based nanoporous silicon immunosensor for detection of aflatoxin B1 (AFB1).The binding density of antibodies on graphene coated nanoporous silicon is estimated by standard optical density method and compared with the conventionally silanized nanoporous silicon substrate. It is observed that the binding capability of antibody on graphene based substrate is nearly 1.5 times higher than that on the conventional substrates. With the application of different concentration of AFB1 in the range of 1 fg/ml–1 pg/ml the impedance response of this biosensor is experimentally verified. It is observed that the impedance decreases with frequency as reported for only nanoporous silicon substrate. However the sensitivity exhibits the presence of both minima and maxima with frequency unlike the previous report. Further the maximum value of sensitivity for AFB1 detection is 1.3 times more than that compared to the ordinary silicon substrate. Thus graphene coated nanoporous silicon substrate is capable of detecting toxin even in sub-femtomolar concentration with distinct frequency characteristics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The presence of toxins in food and water is a serious concern for public health protection. Among the various toxins, AFB1 is known to be highly toxic and carcinogenic [1]. The conventional methods for detection include high performance liquid chromatography (HPLC) and thin layer chromatography (TLC) which are very sensitive but require skilled manpower and expensive equipment for operation [2]. As an alternate method, electrochemical food toxin biosensors are gaining importance due to their advantages of label free detection, miniaturization and low cost mass production. In a recent report, detection of Clostridium difficile Toxin B (Tcd B) with detection limit of 0.7 pg/mL is achieved [3]. In an another report silicon oxide nanoporous structure fabricated electrochemically is observed by ultrasensitive label free method to detect AFB1 down to 1 fg/ml concentration by an interesting frequency based low noise technique [4]. Nanostructured substrate not only improves the binding efficiency of the analyte due to large surface area to volume ratio but also shows a possible catalytic effect in the diffusion of the analyte molecules within the nanopores [5]. Amongst the various nanostructures reported, nanoporous silicon [6, 7] and nanoporous alumina [8] are gained importance due to their simple fabrication and biomolecule tunable pore size. However, the lowest detection limit achievable by electrochemical method for most of the toxin detection except cholera is around 100 fg/ml or equivalently 100 fm [9–12].

Graphene is a promising material used in the field of biosensing for its several advantages like high electron mobility, large surface area and biocompatibility. In a recent work, graphene sensors are reported to be capable of detecting very low concentration of α-fetoprotein (AFP) in a linear range from 0.1 to 100 ng/ml with a detection limit of 0.06 ng/mL [13]. In another report it is presented that the electrochemical response of graphene exhibits high activity to the electrochemical oxidation in detection of ractopamine and clenbuterol resulting in a remarkable increase in sensitivity of detection down to 17 and 15 µg/l respectively [14]. Thus it would be interesting to combine the electrochemical behavior of graphene with the low noise frequency based detection of nanoporous silicon with a view to enhancing the sensitivity.

In this paper, we report an impedimetric graphene based nanoporous silicon biosensor for detection of AFB1. Graphene is prepared from natural graphite according to the modified Hummers method [15]. 30 µl of graphene is pipetted onto the nanoporous silicon oxide and the solution is removed after 20 s. The same process is repeated three times to obtain few layers of graphene sheet. Raman spectroscopy shows the evidence of multiple graphene layer formation on silicon oxide surface. The substrate is then coated with poly-l-lysine (PLL) which acts as a crosslinker to attach the antibodies [16].The binding density of antibodies on graphene coated nanoporous silicon is estimated by standard optical density method [17] and compared with the conventionally silanized nanoporous silicon substrate. It is observed that the binding capability of antibody on graphene based substrate is nearly 1.5 times higher than that on the conventional substrate. The impedance response of this biosensor is experimentally verified with different concentration of AFB1in the range of 1 fg/ml–1 pg/ml. It is observed that the impedance decreases with frequency as reported for only nanoporous silicon substrate [4]. However the sensitivity is exhibited the presence of both a minima and maxima with frequency unlike the previous report [4]. Further the maximum value of sensitivity for 1 fg/ml is more than twice in comparison to the ordinary silicon substrate [4]. Thus graphene coated nanoporous silicon substrate is capable of detecting toxin even in sub-femtomolar concentration with a distinct frequency characteristics.

2 Materials and methods

2.1 Chemical and reagents

Crystalline silicon of 10–20 Ω cm resistivity procured from Silicon Valley Microelectronics is used. Graphite powder flakes, monoclonal Anti-AFB1 antibody, AFB1 antigen, 0.1 % PLL, hydrazine, Bovine serum albumin (BSA) are procured from Sigma Aldrich. All the solutions are prepared with deionized (DI) water (Millipore). Graphene oxide (GO) is synthesized by modified Hummer’s method and reduced by using hydrazine.

2.2 Fabrication of graphene coated nanocrystalline porous silicon

Fabrication is carried out by anodic etching of p-type silicon <100> wafers of 10–20 Ω cm resistivity in a double pond electrochemical bath for 30 min using a constant current density of 2.35 mA/cm2 with an electrolyte mixture of hydrofluoric acid (HF) (48 wt%) and dimethyl sulfoxide (DMSO) in the ratio of 1:9 by volume [18]. The nanopores formed are of about 100 nm thickness and 200–400 nm diameter. The structure is then thermally oxidized to enable uniform coating of antibodies. For this, a dry-wet-dry sequence is followed in an oxidation furnace for 1 h at 900 °C to grow oxide of thickness of around 100 nm. For metallization, lateral metal contacts with aluminium paste are screen printed on nanostructured silicon oxide columns. Interdigitated pattern of gold electrode is used here for sensitivity enhancement. This pattern increases the effective capture area of biomolecules as indicated in [19]. Graphene is prepared from natural graphite according to the modified Hummers method [15]. 30 µl of graphene is pipetted onto the nanoporous silicon oxide and the solution is removed after 20 s. The same process is repeated three times to obtain few layers of graphene sheet.

2.3 Antibody immobilization

After the deposition of graphene sheet, the biosensor is functionalized by immobilization of capture antibody on the surface. For enhanced adhesion and electrochemical detection, PLL is used. It is usually assembled to increase the cell adhesion to the surface depending on few of its unique characteristics e.g. its good biocompatibility against the cells, its active amino groups, its suitable molecular backbone and finally its water soluble nature. Another advantage is that it creates a bridge between the sensing graphene substrate and the further bioactive molecules with the help of its active amide group. The positively charged PLL is strong adhesive characteristics due to its butyl group and creates a matrix of active cells by electrostatic attraction of slightly negative reduced graphene oxide (RGO) [17].

Next, the graphene sensor is incubated for 1 h in AFB1 capture antibody solution at a concentration of 20 µg/ml. After repeating the rinsing step with PBS, the label free sensor is ready for testing. The final view of the sensor is shown in Fig. 1 which shows that the inter-electrode spacing is of the order of 500 μm. To ensure repeatability of measurements, a well like structure is fabricated with polydimethylsiloxane (PDMS) sheets and bonded with the surface of the sensor with plasma treatment to avoid fluctuations due to positioning of the solution droplet.

3 Results and discussion

3.1 Structural characterization

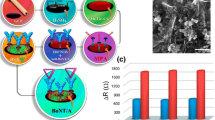

The biosensor surface morphology is characterized by scanning electron microscopy (ZEISS). Figure 2a shows a SEM image of graphene coated oxidized nanocrystalline porous silicon. The antibody immobilization can be observed by a change in surface topology to a speckled, grainy image shown in Fig. 2b. Each of the speckles represents clusters of antibody on the surface of the graphene coated nanoporous silicon. The surface topography shows good definition of antibody particle binding with sensor surface.

3.2 Optical density measurements

The optical density measurements are carried out to estimate the number of Horse radish peroxidase (HRP) conjugated antibody (HIgG) antibodies attached to nanoporous silicon oxide after the optimum antibody immobilization. For estimating the binding density of HIgG antibody, HRP-HIgG is used. Optical density (O.D.) measurements are performed in a UV–Vis spectrophotometer (Perkin Elmer Lamda 25) to estimate the antibody binding intensity. Horse radish peroxidise (HRP) conjugated Human IgG (HRP-HIgG) antibody is used along with a standard colouring reagent solution. The preparation details of the colouring reagent are reported in [17]. The O.D. value is initially standardized with the colour obtained from a known antibody solution, after reaction with the reagent. The O.D. value is proportional to the amount of antibody molecules present in the solution which in turn is proportional to the amount of antibodies bound on the solid substrate. Based on this data, the number of bound antibodies on a solid substrate is estimated. The detailed steps of measurement are reported in [17]. Thus, it is clearly observed from Fig. 3 that the binding density of antibody on RGO coated nanoporous silicon oxide substrate is nearly 1.5 times greater than conventional silanized nanoporous silicon oxide substrate.

3.3 Raman spectroscopy measurements

Raman spectroscopic measurements are performed for characteristics of graphene after each stage of the immunosensor functionalization process shown in Fig. 4. The spectra of the RGO showed three Raman bands at 1195, 1590 and 2570 cm−1 that are assigned to the well-documented D, G and 2D bands respectively in standard graphene or RGO. The G peaks represent the sp2-hybridized carbon atoms, while the D peak is related to the sp3-hybridized carbon atoms of disordered and defected graphite. Since the intensity of the G band increases almost linearly as the graphene thickness increases, it can be used to determine the number of layers in graphene. After antibody immobilization all of the Raman spectra shows distinct bands, which overlap the characteristic bands of standard graphene. The G peak of graphene becomes more intense and broad after antibody and antigen attachments. The broadening of the G peaks for both the cases are clear evidence of immobilization of antibody and antigen on the RGO coated nanoporous silicon oxide substrate.

3.4 Impedance measurement

After the immobilization of monoclonal antibodies for AFB1, impedance spectroscopy measurements are carried out with the help of LCR meter (GW INSTEK LCR 821) with a 50 mV amplitude signal varying from 62.5 Hz to 100 kHz. Before measurement with every AFB1 concentration, a control measurement with PBS is done to establish the reference impedance. All the measurements are carried out in triplicate to estimate the reproducibility of the nanoporous silicon sensors. Figure 5 shows the variation in impedance with frequency with graphene before and after capture of toxin molecules with different concentration of AFB1 in the range of 1, 10 fg/ml and 1 pg/ml. Impedance changes significantly due to a combined effect of the double layer impedance and the quantum capacitance of graphene caused by specific antigen–antibody binding event. It is also observed that the impedance significantly decreases with frequency for both the samples. This is because both the double layer impedances at the electrode–electrolyte interface and the oxide-electrolyte interface decrease with frequency as power law. Sensitivity (S) is calculated as the fractional change in impedance expressed as percentage, given in Eq. 1:

where Z0 = impedance before AFB1 and \( Z^{\prime} \) = impedance after AFB1.

Since measurements for each concentration are carried out in triplicate, the sensitivities for the three measurements are computed and the average of these three sensitivities is indicated as the average sensitivity for each concentration. Table 1 shows the maximum average sensitivities obtained at frequency 62.5 Hz for three different AFB1 concentration.

Figure 6 shows the percentage change in impedance with frequency for different AFB1 concentration with graphene. It is observed that the percentage change in impedance is more in the lower frequency regime. The decrease in the percentage change in impedance is primarily because with increase in frequency, the double layer impedances both at the electrode–electrolyte and graphene–electrolyte interfaces decrease as power law and the solution resistance has a tendency to increase after virus capture since the virus molecules are highly resistive. This reduces the fractional decrease in the overall impedance. For cross-sensitivity, the sensors are tested with non-specific toxins Ochratoxin A (OTA) and the obtained sensitivity is not appreciable shown in Fig. 6. Hence, the sensor has good selectivity.

4 Conclusion

This paper reports a sensitive graphene based nanoporous silicon immunosensor for detection of AFB1. By O.D. measurements, we observe that the binding density of antibody on RGO-nanoporous silicon oxide substrate is nearly 1.5 times compared to silanized nanoporous silicon substrate. This is reflected also in the maximum value of sensitivity for AFB1 detection which is almost 1.3 times more than that compared to the ordinary silicon substrate. Thus, it would be interesting to combine the electrochemical behaviour of graphene with the frequency based detection of nanoporous silicon for performance enhancement of electrochemical immunosensors.

References

Reddy, K.R.N., Reddy, C.S., Muralidharan, K.: Detection of Aspergillus spp. and aflatoxin B1 in rice in India. Food Microbiol. 26, 27–31 (2009)

Chiavaro, E., Dall Asta, C., Galaverna, G., Biancardi, A., Gambarelli, E., Dossena, A., Marchelli, R.: New reversed-phase liquid chromatographic method to detect aflatoxins in food and feed with cyclodextrins as fluorescence enhancers added to the eluent. J. Chromatogr. A 937, 31–40 (2001)

Fang, Y.-S., Chen, S.-Y., Huang, X.-J., Wang, L.-S., Wang, H.-Y., Wang, J.-F.: Simple approach for ultrasensitive electrochemical immunoassay of Clostridium difficile toxin B detection. Biosens. Bioelectron. 53, 238–244 (2014)

Ghosh, H., RoyChaudhuri, C.: Ultrasensitive food toxin biosensor using frequency based signals of silicon oxide nanoporous structure. Appl. Phys. Lett. 102, 243701 (2013)

Park, S., Kim, H.C., Chung, T.D.: Electrochemical analysis based on nanoporous structures. Analyst 137, 3891–3903 (2012)

Zhang, J., Wu, Y., Zhang, B., Li, M., Jia, S., Jiang, S., Zhou, H., Zhang, Y., Zhang, C., Turner, A.P.F.: Single-walled carbon nanotube-induced lyotropic phase behavior of a polymeric system. Anal. Lett. 45, 986–992 (2012)

Bok, S., Korampally, V., Darr, C.M., Folk, W.R., Parada, L.P., Gangopadhyay, K., Gangopadhyay, S.: Femtogram-level detection of Clostridium botulinum neurotoxin type A by sandwich immunoassay using nanoporous substrate and ultra-bright fluorescent suprananoparticles. Biosens. Bioelectron. 41, 409–416 (2013)

Pichetsurnthorn, P., Vattipalli, K., Prasad, S.: Nanoporous impedemetric biosensor for detection of trace atrazine from water samples. Biosens. Bioelectron. 32, 155–162 (2012)

Kalita, P., Singh, J., Singh, M.K., Solanki, P.R., Sumana, G., Malhotra, B.D.: Ring like self assembled Ni nanoparticles based biosensor for food toxin detection. Appl. Phys. Lett. 100, 093702 (2012)

Actis, P., Jejelowo, O., Pourmand, N.: Ultrasensitive mycotoxin detection by sting sensors. Biosens. Bioelectron. 26, 333–337 (2010)

Campas, M., Garibo, D., Simon, B.P.: Novel nanobiotechnological concepts in electrochemical biosensors for the analysis of toxins. Analyst 137, 1055–1067 (2012)

Bacher, G., Pal, S., Kanungo, L., Bhand, S.: A label-free silver wire based impedimetric immunosensor for etection of aflatoxin M1 in milk. Sens. Actuators B 168, 223–230 (2012)

Linn, J., Wei, Z., Zhang, H., Shao, M.: Sensitive immunosensor for the label-free determination of tumor marker based on carbon nanotubes/mesoporous silica and graphene modified electrode. Biosens. Bioelectron. 41, 342–347 (2013)

Wua, C., Sun, D., Li, Q., Wu, K.: Electrochemical sensor for toxic ractopamine and clenbuterol based on the enhancement effect of graphene oxide. Sens. Actuators B 168, 178–184 (2012)

Wang, Y., Li, Y., Tang, L., Lu, J., Li, J.: Application of graphene-modified electrode for selective detection of dopamine. Electrochem. Commun. 11, 889–892 (2009)

Zhang, B., Li, Q., Cui, T.: Ultra-sensitive suspended graphene nanocomposite cancer sensors with strong suppression of electrical noise. Biosens. Bioelectron. 31, 105–109 (2012)

Das, R.D., Maji, S., Das, S., RoyChaudhuri, C.: Optimization of covalent antibody immobilization on macroporous silicon solid supports. Appl. Surf. Sci. 256, 5867–5875 (2010)

Das, R.D., Dey, A., Das, S., RoyChaudhuri, C.: Interdigitated electrode-less high-performance macroporous silicon structure as impedance biosensor for bacteria detection. IEEE Sens. 11, 1242–1252 (2011)

Das, R.D., Mondal, N., Das, S., RoyChaudhuri, C.: Optimized electrode geometry for an improved impedance based macroporous silicon bacteria detector. IEEE Sens. 12, 1868–1877 (2012)

Acknowledgments

The authors would like to acknowledge Professor H. Saha and Mr. Anupam Nandi of Center of Excellence of Green Energy and Sensor Systems, Indian Institute of Engineering Science and Technology, Shibpur, for his help in oxidation and graphene synthesis. Also the authors would like to thank to the TEQIP II for the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Das, N., Basu, J. & RoyChaudhuri, C. Graphene coated nanoporous silicon immunosensor for food toxin detection. Int J Adv Eng Sci Appl Math 7, 204–209 (2015). https://doi.org/10.1007/s12572-015-0144-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12572-015-0144-z