Abstract

The objective of this study was to monitor the occurrence and levels of fumonisin B1 (FB1) and fumonisin B2 (FB2) in animal feeds distributed in South Korea in 2011. The contamination levels of FB1 and FB2 were investigated in 150 samples of compound feeds and in 40 samples of feed ingredients. The contamination rate of feed ingredients with FB1 and FB2 was 50 and 40 %, respectively. FB2 was only found in samples contaminated with FB1. Of the compound feeds, 85 % were contaminated by FB1 and 47 % were contaminated by FB2. The highest contamination rate of FBs was observed in compound feeds for cattle (FB1: 100 %; FB2: 80 %), followed by poultry feed (FB1: 78 %; FB2: 40 %) and swine feed (FB1: 76 %; FB2: 22 %). The highest contamination level (14,600 ng/g) for FB1 were found in poultry broiler feed (early feeding period) samples, which had 82 % contamination rate (9/11), and the highest level of FB2 (2,280 ng/g) was found in feed for fatting calves,which had a contamination rate of 100 %.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Fusarium species can produce a wide range of mycotoxins with a large variety of structures and chemistries (Flannigan 1991), which are responsible for toxic effects in animals, and in some cases they have also been suspected of toxicity for humans (Bottalico et al. 1989; D'Mello et al. 1999; Nair 1998). The most hazardous Fusarium mycotoxins from the viewpoints of animal health and productivity are FBs, trichothecenes, ZEA, and moniliformin (Bauer et al. 1989; D'Mello and Macdonald 1997).

FBs, diesters of propane-1,2,3-tricarboxylic acid (tricarballylic acid) and various 2-amino-12,16-dimethylpolyhydroxyeicosanes, are natural contaminants in various maize and maize-based feeds and foods worldwide (Placinta et al. 1999). So far, various analogues have been isolated. At present, the most important FBs seem to be FB1, FB2, and FB3, in which the hydroxyl groups on C14 and C15 are esterified with a terminal carboxyl moiety of the tricarballylic acid (Shephard 1998). The FBs are also structurally similar with the host-specific AAL-toxins that are produced by Alternaria alternata, the cause of Alternaria stem canker of tomato (Placinta et al. 1999). At least 12 FB analogues have so far been characterized, with the most important being the B group.

FBs such as FB1, FB2, and FB3 are produced particularly by F. verticillioides and the related F. proliferatum, although other fungal species such as F. napiforme, F. dlamini, and F. nygamai are also able to produce FBs (US-NTP United States National Toxicology Program Technical Report 1999; WHO-IPCS World Health Organization - International Programme on Chemical Safety 2000). In most cases, the predominant FB in naturally contaminated samples is FB1, which is the most toxic and is responsible for 70 % of food contamination in the world (Ritieni et al. 1997). This mycotoxin is associated with leukoencephalomalacia (LEM) in horses, pulmonary oedema in swine, and hepatocarcinoma in rats, in addition to being related to an inhibition of sphingolipid synthesis and an increased risk of oesophageal cancer in humans (Martins et al. 2012). Various studies have been done on the occurrence of Fusarium mycotoxins in food and feeds around the world (Chulze et al. 1996; Wang et al. 1995; Martins et al. 2012; Sebastià et al. 2012; Stankovic et al. 2012; Waskiewicz et al. 2012; Pleadin et al. 2013). Martins et al. (2012) reported that the proportion of samples of corn-based products in Brazil contaminated with fumonisins was high, with the highest proportion of contamination observed in cornmeal (96.6 %). The levels of FBs in positive samples ranged from 126 to 4,350 μg/kg (FB1 + FB2). FB1 was also detected in 82.1 % of wheat grain samples in the range 750–5,400 μg/kg (mean, 2,080 μg/kg) in 2005 and in 92.0 % of samples ranging from 750 to 4,900 μg/kg (mean 919 μg/kg) in 2007 (Stankovic et al. 2012).

Recently, the occurrence of mycotoxins in feeds has become a major concern in animal feed science because they can induce significant toxic effects in animals and eventually humans (Arai and Hibino 1983; Busby et al. 1984; Placinta et al. 1999; Wang et al. 2013). The high concentrations of FB1 and FB2, mainly found in feeds containing maize are more concerning, particularly when maize is imported from warm regions. Furthermore, the contaminations by FBs and other mycotoxins are expected to increase with global warming, including in South Korea (Lee et al. 2010). The commission regulation (EC) of the European community (EU Commission Regulation (2007) has already set the maximum levels (Mls) of FBs in various animal feeds; however, there has so far been no guidance value for fumonisins in animal feeds in Korea. From this point of view, this research aimed to determine the occurrence and level of FB1 and FB2 in animal feeds distributed in South Korea in order to understand the contamination rate and level of FBs in feeds.

Materials and methods

Samples

Feed ingredients and compound feeds samples collected from various regions in South Korea were obtained from the National Agriculture Products Quality Management Service-Experiment Research Institute in 2011. Samples were collected and prepared according to the sampling guide in the code for the control of feeds (FAO/WHO 2004). One kilogram of sample was taken randomly from every ton of feed ingredients or compound feeds. Four different collected samples were mixed together and divided into four groups. Five hundred grams of the divided sample were analyzed for FB1 and FB2 contamination.

The amounts of FB1 and FB2 were determined in 150 samples of compound feeds including cattle feed, swine feed, and poultry feed, and in 40 samples of feed ingredients such as vegetable proteins, bran, and others. Samples were stored at 4 °C before FB1 and FB2 analysis was performed.

Extraction and purification of FB1 and FB2

The analysis of FB1 and FB2 in feed ingredients and compound feeds and its validation has been described by the AOAC official method for the determination of fumonisins B1 and B2 in corn and corn flakes (AOAC Official Method 2001).

Feed samples were milled (particle size, 600 μm), and a test portion of 20 g was extracted with 100 ml of extraction solvent (methanol/acetonitrile/water at 25/25/50, v/v/v) in a polytron homogenizer (Kinematica, Littau/Lucerne, Switzerland) for 2 min (10,000 rpm). The extract was filtered through Whatman No. 4 filter paper. Ten milliliters of the filtered extract were diluted with 40 ml of phosphate-buffered saline (PBS; Sigma-Aldrich, St. Louis, MO, USA). Ten milliliters of the diluted extract were collected for purification through an immunoaffinity column (IAC; Vicam, Fumonitest). Ten milliliters of this filtrate were applied to the IAC column that contained antibodies specific for FB1 and FB2 for purification. The IAC column was washed with 10 ml of PBS, and then FB1 and FB2 were eluted from the column with 4 ml of 80 % methanol/water at 1 drop/s. The eluted fraction was evaporated to dryness under nitrogen steam at 60 °C and stored in a vial at 4 °C for derivatization and analysis by high-performance liquid chromatography (HPLC).

Derivatization of FBs for HPLC analysis

The purified residue was re-dissolved in 200 μl of acetonitrile:water (50/50, v/v). For derivatization, o-phthalaldehyde (OPA) reagent was prepared according to the AOAC official method (AOAC Official Method 2001). The derivatized samples (20 μl) were analyzed using HPLC (Agilent Technology 1200 series; Agilent, USA) equipped with Agilent Technology 1260 Infinity Fluorescence Detector. The isocratic mobile phase was methanol/0.1 mol NaH2PO4 (pH 3.3 adjusted with H3PO4), 77/23, v/v. The analytical column was a ZORBAX Eclipse XDB-C18 column, 4.6 × 150 mm, 5 μm (Agilent, USA). FBs were analyzed within 15 min at a constant flow rate of 1 ml/min at 30 °C. Fluorescence detection of FB1 and FB2 was performed using 335 nm excitation and 440 nm emission wavelength. The peak areas of FB1 and FB2 were used for quantification by comparing with standard curves.

Validation of the method

Sensitivity, linearity, repeatability (RSD%), and recovery were used as criteria for method validation.

The sensitivity of the analysis method was expressed by the limit of detection (LOD) and the limit of quantification (LOQ) value for FBs. Stock solutions (1 mg/ml) of FB1 and FB2 were prepared in 50 % acetonitrile/water and stored at −20 °C until use. LOD was calculated at 3 times the signal to noise ratio, whereas LOQ was calculated at 10 times the signal to noise ratio. Blank feed samples that were fortified with FB1 and FB2 at standard concentrations ranging from 15 to 40 ng/g were analyzed in order to determine the on-column instrumental LOD and LOQ.

The standard samples of FB1 and FB2 at concentrations ranging from 0.05 to 10.00 μg/ml were analyzed in order to establish standard curves. For linearity, a linear equation and coefficient of regression (R2) of the analytical method were determined.

Feed samples with no detectable FB1 and FB2 levels were selected to be used as blanks. Studies of recovery and repeatability were performed by spiking FB1 and FB2 in 3 replicated blank feed samples at concentrations of 100, 200, and 400 ng/g of FB1 and FB2.

LC-MS/MS analysis

Liquid chromatography-tandem mass spectrometry (LC-MS/MS) (LTQ Velos, Accela HPLC, Thermo, USA) was applied to confirm the type of mycotoxins in the positive electrospray ionization (ESI+) mode. A Thermo Hypersil Gold C18 column (2.1 × 100 mm, 1.9 μm) was used under gradient conditions at a flow rate of 0.3 ml/min with the mobile phase consisting of acetonitrile (containing 0.1 % formic acid) and water (containing 1.0 % formic acid).

Statistical analysis

All experiments were done in duplicate and the results (ng/g) were expressed as mean ± standard deviation (SD).

Results and discussion

Validation of the method

The LOD concentrations for FB1 and FB2 were 20 and 25 ng/g, respectively. The LOQ concentrations were 30 ng/g for FB1 and 35 ng/g for FB2. In previous research, Krska et al. (2007) reported the LOD of FBs in feeds was generally inbetween the concentration of 0.001–0.05 μg/g sample dry weight which was in accordance with our result. However, LOQ of FBs in feeds was mentioned to be in range of 70–90 μg/kg (Binder et al. 2007), relatively higher than the result of the present research.

Because no interfering peaks could be detected when analyzing blank samples, we concluded that the method was specific. The standard solutions for FB1 and FB2 at various concentrations were injected into a C18 column for HPLC analysis. The area under the peaks at each concentration exhibited standard curves for FB1 and FB2. The coefficient of correlation in these curves for FB1 and FB2 were 0.9994 and 0.9990, respectively. The FB1 and FB2 standards were eluted with retention times of 3.7 and 8.7 min, respectively.

The recoveries of FBs in fortified feed samples are summarized in Table 1. The average recovery for FB1 ranged from 96.5 to 106.1 %, and that for FB2 ranged from 85.4 to 110.1 %. Moreover, the repeatability (RSDr) obtained for FB1 and FB2 were 2.03–5.44 and 2.56–14.7 %, respectively. Ultimately, the recovery (%) and repeatability (RSDr%) results were comparable with those of the EU Commission Regulation (2006) (spiked level ≤ 500 ng/g, FB1 or FB2 should show RSDr% ≤ 30 and recovery between 60 and 120 %). As a result, this HPLC method was suitable for the analysis of FB1 and FB2 in the feed samples.

Contamination levels of FB1 and FB2 in feed ingredients

As shown in Table 2, FB1 was detected in 20 samples (50 %) of feed ingredients, and the levels of detection ranged from 106 to 4,200 ng/g. The mean detection level was 1,200 ng/g. Bran exhibited the highest level of FB1 contamination. Importantly, 100 % of corn gluten samples and corn germ meal samples were contaminated with FB1, and the levels of detection ranged from 326 to 1,400 ng/g. Therefore, FB1 contamination rate of compound feed containing corn seem to be an important factor.

Overall, 40 % of the analyzed feed ingredient samples were found to be contaminated with FB2, with a mean concentration of 326 ng/g (Table 3). Bran samples exhibited the highest levels of FB2 contamination (1,100 ng/g) and vegetable proteins (including soybean meal, corn gluten, corn germ meal, etc.) contained the lowest amount of FB2 (29 ng/g).

Similar results have also been reported by Binder et al. (2007), who analyzed the presence of FBs (FB1, FB2, and FB3) in feed ingredients in Asia and Oceania. The highest FB contamination was found in a feed ingredient from China at a level of 14,700 ng/g, which was similar to that observed in this study. In addition, the total incidence of contamination was 16 % in feed ingredients that were collected in the same regions. This level of contamination is much lower than the result of the present study.

The regulation values of FBs are not yet set for feed in Korea. However, the commission regulation (EC) has already set the Mls values for Fusarium mycotoxins such as FBs, deoxynivalenol, zearalenone, etc. Even though the mean contamination values of our samples were not at dangerous levels when compared with Mls of the commission regulation (2007), some samples showed very high concentrations of contamination exceeding the guidance values. This could be a threat to both animal and human health if there is no appropriate investigation and management of mycotoxins in feeds.

Contamination levels of FB1 and FB2 in compound feeds

FB1 was detected in 100 % of the cattle feeds with concentrations ranged between 365 and 13,900 ng/g (Table 4). The breeding pregnancy feed exhibited the highest contamination value of FB1 with mean detection level of 3,600 ng/g. Seventy-six percent of the swine feed from 50 samples were contaminated with FB1 ranged from 363 to 14,600 ng/g. The mean toxin level was 3,800 ng/g. The samples of swine feed intended for fatting and growing appeared to be most highly contaminated with FB1 among all types of swine feed. Martins et al. (2011) reported that 17 % of swine feed samples were contaminated with FB1 in 2010; this value was much lower than that observed in this study.

Seventy-eight percent of the poultry feed samples were contaminated with FB1, and the level of detection ranged from 73 to 14,600 ng/g. The mean detected level of FB1 was 2,500 ng/g. Broiler feed (early feeding period) exhibited the highest contamination value for FB1 in our study. In Portuguese corn-based feed products, Waskiewicz et al. (2012) reported that FB1 was found in all analyzed corn flour samples and FB2 was detected in 70.7 % of tested samples in the concentration range from 50 to 1,300 ng/g and from 100 to 450 ng/g, respectively.

As shown in Table 5, FB2 was found in 80 % of the cattle feed samples. The mean detection level was 606 ng/g. Fatting calves feed exhibited the highest contamination level of FB2 (2,300 ng/g), while breeding feed for gravid cows had the lowest levels (37 ± 17 ng/g). In contrast, only 12 % of the swine feed samples were contaminated with FB2, with a mean concentration of 187 ng/g. For poultry feeds, 40 % of the samples were contaminated with FB2 with a mean detection level of 128 ng/g. Layer laying feed showed the highest contamination for FB2 (214 ng/g). In accordance with another study (Chehri et al. 2010), the frequency of FB2 was lower than that of FB1. However, the level of FB2 contamination ranged from 12 to 86 ng/g in the report of Chehri et al. (2010) and was therefore very low compared with the result of the present study.

Some of compound feed samples showed the maximum levels of FB1 or FB2 (Table 4, 5) higher than the Mls of guidance values, which indicated that the contamination rate of FBs in animal feeds commercialized in Korea were relatively high and would lead to serious problems concerning animal health and eventually human health. To improve this situation, clear regulations should be set on the levels of Fusarium mycotoxins allowed in cereals as well as other raw materials in animal feeds in South Korea, and a proper evaluation need to be implemented for feeds and food safety.

LS-MS/MS analysis

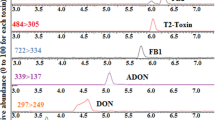

The mass spectra for FB1 and FB2 showed the protonated molecular ion at m/z 722 and 706, respectively. Detected FB1 and FB2 in feed samples by HPLC were found to have the same protonated molecular ion as the standards. Additional LC-MS/MS analysis of the standards and FB-positive samples (by HPLC) therefore confirmed the result obtained from HPLC with fluorescence detection (Figs. 1 and 2).

Conclusion

Among the tested compound feeds and feed ingredients, 50 % of the feed ingredients were contaminated with FB1. In addition, 40 % of the feed ingredients were contaminated by FB2. Of the compound feeds, 85 % were contaminated by FB1 and 47 % were contaminated by FB2. The highest level of FB1 contamination was observed in compound feeds for cattle (100 %). However, poultry broiler (the early period) feed exhibited the highest contamination value (14,600 ng/g) for FB1 in compound feeds. The contamination of compound feeds by FB1 and FB2 was higher than that of feed ingredients because these feeds are manufactured by combining feed ingredients.

This study reports the occurrence of FB1 and FB2 in feeds that are distributed in South Korea. So far, survey data about the contamination by FBs in feeds have been few, and no studies on the occurrence of FBs in stockbreeding products have been performed in South Korea. The results suggest that FBs are present at high levels in livestock feeds commercialized in South Korea. Therefore, more intensive and continuous monitoring of FBs is necessary for feed safety related to animal health.

References

Arai M, Hibino T (1983) Tumorigenicity of citrinin in male F344 rats. Cancer Lett 17:281–287

AOAC Official Method (2001) Determination of fumonisins B1 and B2 in corn and corn flakes. J AOAC Int 84:1828–1830

Bauer J, Gareis M, Gedek B (1989) Metabolism of the trichothecens T-2 toxin, diacetoxyscirpenol and deoxynivale-nol by farm animals. In: Chekowski J, Fusarium M, Taxonomy P (eds) Fusarium, Mycotoxins, Taxonomy and Pathogenicity. Elsevier, Amsterdam, pp 139–166

Binder EM, Tan LM, Chin LJ, Handl J, Richard J (2007) Worldwide occurrence of mycotoxins in commodities, feeds and feed ingredients. Anim Feed Sci Technol 137:265–282

Bottalico A, Logrieco A, Visconti A (1989) Fusarium species and their mycotoxins in infected cereals in the field and in stored grains. Topics Secondary Metabol 2:85–119

Busby WF Jr, Goldman ME, Newberne M, Wogan GN (1984) Tumorigenicity of fluoranthene in a newborn mouse lung adenoma bioassay. Carcinogenesis 5:1311–1316

Chehri K, Jahromi ST, Reddy KRN, Abassi S, Salleh B (2010) Occurrence of Fusarium spp. and fumonisins in stored wheat grains marketed in Iran. Toxins (Basel) 2(12):2816–2823

Chulze SN, Ramirez ML, Farnochi MC, Pascale M, Visconti A, March G (1996) Fusarium and fumonisin occurrence in Argentinian corn at different ear maturity stages. J Agric Food Chem 44:2797–2801

D'Mello JPF, Placinta CM, Macdonald AMC (1999) Fusarium mycotoxins: a review of global implications for animal health, welfare and productivity. Anim Feed Sci Technol 80:183–205

D'Mello JPF, Macdonald AMC (1997) Mycotoxins. Anim Feed Sci Technol 69:155–166

EU Commission regulation No. 401 (2006) Laying down the methods of sampling and analysis for the official control of the levels of mycotoxins in foodstuffs. Official Journal of the European Union: 12–34

EU Commission regulation (EC) No. 1126/2007 of 28th September 2007. Official Journal of the European Union L 255/14

FAO/WHO (2004) The Codex General Guidelines on Sampling – CAC/GL 50–2004

Flannigan B (1991) Mycotoxins. In: D'Mello JPF, Duffus CM, Duffus JH (eds) Toxic Substances in Crop Plants. The Royal Society of Chemistry, Cambridge, pp 226–257

Krska R, Welzig E, Boudra H (2007) Analysis of Fusarium toxins in feed. Anim Feed Sci Technol 137:241–264

Lee KE, Kim BH, Lee C (2010) Occurrence of Fusarium mycotoxin beauvericin in animal feeds in Korea. Anim Feed Sci Technol 157:190–194

Martins FA, Ferreira FMD, Ferreira FD, Bando E, Nerilo SB, Hirooka EY, Machinski M Jr (2012) Daily intake estimates of fumonisins in corn-based food products in the population of Parana, Brazil. Food Contr 26:614–618

Martins HML, Almeida IFM, Camacho CRL, Santos SMO, Costa JMG, Bernardo FMA (2011) Occurrence of fumonisins in feed for swine and horses. Rev Iberoam Micol 29(3):175–177

Nair MG (1998) Fumonisins and human health. Ann Trop Paed Supp S:47–52

Placinta CM, D'Mello JPF, Macdonald AMC (1999) A review of worldwide contamination of cereal grains and animal feed with Fusarium mycotoxins. Anim Feed Sci Technol 78:21–37

Pleadin J, Vahcic N, Persi N, Sevelj D, Markov K, Frece J (2013) Fusarium mycotoxins’ occurrence in cereals harvested from Croatian fields. Food Contr 32:49–54

Ritieni A, Moretti A, Logrieco A, Bottalico A, Randazzo G, Monti SM, Ferracane R, Fogliano V (1997) Occurrence of fusaproliferin, fumonisin B1, and beauvericin in maize from Italy. J Agric Food Chem 45:4011–4016

Sebastià N, Meca G, Soriano JM, Manes J (2012) Presence of Fusarium emerging mycotoxins in tiger-nuts commercialized in Spain. Food Contr 25:631–635

Shephard GS (1998) Chromatographic determination of the fumonisin mycotoxins. J Chromatogr A 815:31–39

Stankovic S, Levic J, Ivanovic D, Krnjaja V, Stankovic G, Tancic S (2012) Fumonisin B1 and its co-occurrence with other fusariotoxins in naturally-contaminated wheat grain. Food Contr 23:384–388

US-NTP (United States National Toxicology Program) Technical Report (1999) Toxicology and carcinogenesis studies of fumonisin B1 (CAS no 116355-83-0) in F344/N Rats and B6C3F Mice (Feed studies). Publication No 99–3955, U.S. Department of Health and Human Services, Research Triangle Park, North Carolina, USA

Wang DS, Liang YX, Iijima K, Sugiura Y, Tanaka T, Chen G, Yu SZ, Ueno Y (1995) Cocontamination of mycotoxins in corn harvested in Haimen, a high risk area of primary liver cancer in China. Mycotoxins 41:67–70

Wang UK, Shi YB, Zou Q, Sun JH, Chen ZF, Wang HA, Li SQ, Yan YX (2013) Development of a rapid and simultaneous immunochromatographic assay for the determination of zearalenone and fumonisin B1 in corn, wheat and feedstuff samples. Food Contr 31:180–188

Waskiewicz A, Beszterda M, Golinski P (2012) Occurrence of fumonisins in food - An interdisciplinary approach to the problem. Food Contr 26:491–499

WHO-IPCS (World Health Organization - International Programme on Chemical Safety) (2000) Fumonisin B1. Environmental Health Criteria 219. World Health Organization, Geneva. http://www.inchem.org/documents/ehc/ehc/ehc219.htm Accessed 07 May 2013

Acknowledgement

This work was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology (2012R1A2A2A01003635).

Conflict of interest

None

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Seo, DG., Phat, C., Kim, DH. et al. Occurrence of Fusarium Mycotoxin Fumonisin B1 and B2 in Animal Feeds in Korea. Mycotoxin Res 29, 159–167 (2013). https://doi.org/10.1007/s12550-013-0172-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12550-013-0172-0