Abstract

Nb-based alloys are regarded as a vital high temperature structural material. Unfortunately, the low oxidation resistance of the alloys limits their application under aerobic conditions at high temperature. Surface coating technology is considered to be an ideal method to solve this problem. This paper reviewed recent progress on silicide coatings on Nb and Nb-based alloy, and focused on different types of modification techniques. The microstructure, phase composition and oxidation properties of various silicified coatings are analyzed. The effects of modified elements and second phase on the oxidation mechanism of silicide coatings are also summarized. Finally, the existing problems and future development direction of various silicide coatings are pointed out.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Nb-based alloys have a good toughness, high melting point, good electrical and thermal conductivity and sufficient high temperature strength. Therefore, they are widely used in superconducting materials, aerospace, atomic energy, electronics and other industrial fields [1,2,3,4]. However, the low oxidation resistance of the alloys prevents their long-term use in high temperature aerobic environments [5, 6]. At present, the alloying method and surface coating technology are two main methods to solve this problem [7, 8]. The oxidation resistance of Nb can be improved partly by addition of silicon, and Nb-Si based alloys have good mechanical properties [9]. Unfortunately, this is not sufficient to solve the problem of poor oxidation resistance of the alloys [9, 10]. This is because the alloys will be oxidized to form unprotected porous Nb2O5 and NbO2 oxides under high temperatures aerobic conditions, which does not prevent further oxidation of the alloys [11,12,13,14,15]. In addition, adding appropriate amount of Al, Ti, Cr, Hf and other elements to Nb-Si based alloys is also beneficial to improve their oxidation resistance [16, 17]. Among them, Hf and Ti can reduce the growth stress of oxides and maintain the integrity of the oxide layer [18]. Al and Cr are good to reduce the diffusion rate of Nbss and slow down the oxidation of the alloy [19]. However, improper elemental ratio will make the mechanical properties of the alloys unsatisfactory. With the increase of Cr content from 2 to 17%(at%), the room-temperature toughness of Nb-Si based alloys drop to 8.5 MPa·m1/2 from 14.5 MPa·m1/2 [20, 21]. Therefore, the result of alloying is not satisfactory when the mechanical properties and high-temperature oxidation resistance of the alloys taken both into consideration at the same time. Related scholars have realized that surface coating technology is an ideal method to overcome this problem [22, 23]. The researches shows that the silicified coatings have good thermal stability and their operating temperature can reach 1600 °C. The SiO2 protective film formed on the surface of coating can act as a diffusion barrier to prevent the diffusion of oxygen into the substrate. In addition, the viscosity of SiO2 at high temperature is low, and its fluidity is enhanced, which makes the coatings have a certain self-healing and resisting deformation ability [24,25,26]. Moreover, the high-temperature oxidation resistance of the coatings can be further improved with the addition of modified elements and the introduction of second phases. Among them, the addition of Al, B, W, Y, Re, Ge, Ce, Y2O3 and aluminum silicate (mullite) are the most common [27,28,29].

At present, there are many reports on the application of surface coating technology in the oxidation protection of Nb and its alloys [30]. This paper summarizes the researches of domestic and foreign scholars in this field for many years. In this work, the microstructure, phase composition, oxidation behavior and failure mechanism of various silicified coatings on Nb-based alloys are analyzed and summarized, comprehensively. The main silicified coatings are divided into four categories: single silicified coating, composite silicified coating, single element modified silicified coating and composite element modified silicified coating. The effects of the addition of various modified elements on the oxidation behavior of coatings are summarized in depth, and the specific measures improving the oxidation resistance of coatings at high temperature are pointed out.

2 Microstructure and Oxidation Properties of Silicide Coatings

2.1 Single Silicide Coating

2.1.1 Microstructure and Phase Composition of the Coatings

Single silicide coating is formed by interdiffusion between silicon element and substrate and metallurgical bonding, which has a single composition and structure [31, 32]. Halide activated pack cementation(HAPC), a significant surface coating preparation technology, is favored by researchers because of its wide source of raw materials, strong operability, uniform composition of the coating prepared, compact structure and good combination with the substrate. The principle of this process is to mix the donor sources (Si, B, Al, SiC powder, etc.), inert filler (Al2O3 powder) and halide activator (NH4Cl/Na, NaF, etc.) in a certain proportion evenly, put them into the corundum crucible. Then the substrate is embedded into the mixture, through inert gas and covered with Al2O3 plate. The crucible is placed into the furnace, and at high temperature, the donor source in the mixture will be deposited to the substrate surface by thermal diffusion to form a coating, as shown in Fig. 1 [33].

Vishwanadh et al. [34] prepared the NbSi2 coating by halide activated pack cementation (HAPC) at different temperatures, successfully, as shown in Fig. 1. It is observed that the surface of the coatings are composed of uniform silicified particles, and the particle size increases gradually with increasing temperature. This is caused by the recrystallization of NbSi2 particles in the deposition process, as shown in Fig. 2a–d. In addition, the interdiffusion between Si and Nb enhance gradually with increasing temperature, making the thicknesses of NbSi2 and Nb5Si3 layers increase significantly, as shown in Fig. 2e–h. Although a few microcracks are observed on the surface of sample at 1200 °C, but the interior of the sample is very dense, and a thin Nb5Si3 layer forms between the coating and substrate, as shown in Fig. 2a and e. Similar results are also observed in the sample deposited at 1300 °C, as shown in Fig. 2b and f. Moreover, when the temperature is 1400 °C, a mass of pores appear both on the surface and inside of the sample. This is because the temperature is close to the melting point of Si (1410 °C), which makes the precipitated Si particles melt soft, resulting in the formation of pores between NbSi2 particles, as shown in Fig. 2c and g [35]. It is worth noting that when the deposition temperature reaches 1500 °C, the coating has a smooth and dense surface, and there are white pure Si precipitates in local areas. However, obvious cracks were observed inside the coating, which is related to the mismatch of the thermal expansion coefficient (CTE) between the coating and substrate, as shown in Fig. 2d and h.

The images of surface and corresponding cross-section of the NbSi2 coatings were obtained on the surface of Nb-1Zr-0.1C alloy by deposited at different temperatures for 6 h [34]

Liu et al. [36] produced MoSi2 coating on surface of the Nb-10Hf-1Ti alloy by two-step deposition process. It can be seen that the coating has a rough surface with some cracks and holes. Similar phenomena also be observed between the MoSi2 layer and bond layer inside of the coating, as shown in Fig. 3a and b, respectively. The mismatch of CTE between MoSi2 (8.0 × 10−6/°C) and substrate (7.8–8.2 × 10−6/°C) is the main reason for this result [37]. As an important surface engineering technology, supersonic plasma spraying technology(SAPS) has the advantages of high deposition efficiency, low energy consumption, low cost and good coating quality. Its principle is to take the plasma arc as the heat source, the working gas (N2, H2, Ar, He, etc.) is heated to form high temperature and high speed plasma jet (the temperature can reach tens of thousands of degrees Celsius). The plasma jet can heat the spraying material to molten and semi-molten states, and spray it to the substrate surface at high speed to form coating, as shown in Fig. 3 [38].

Schematic diagram of the SAPS process principle [38]

Sun et al. [39] reported the MoSi2 coating obtained by SAPS technology. The surface of the coating is composed of molten and semi-molten particles with poor uniformity and a large number of pores. This is caused by the melting and recrystallization of the spraying material on the coating surface [40, 41]. In addition, some areas of the coating surface oxidized because of the high spraying temperature and the fact that the whole process took place in air. The tests result of XRD shows that both points A and B contain a small quantity of SiO2, as shown in Fig. 4c. While the interior of the coating is relatively dense and the overall thickness is about 200 μm, as shown in Fig. 4d.

2.1.2 Oxidation Properties of the Coatings

Choi et al. [42] researched the oxidation behavior of NbSi2 coatings at different temperatures. The results show that oxidized coatings are composed of an oxide layer, a NbSi2 layer and an interface layer, respectively. In the temperature range of 1000 °C to 1200 °C, some cracks were observed inside the coatings, the thickness and the porosity of the oxide layer increase significantly with the increase of temperature, as shown in Fig. 5a–c. However, the coating has a maximum Δm/S, a thickest oxide layer and a highest porosity at the deposition temperature of 1300 °C, as shown in Fig. 5d. Moreover, a mass of white oxide particles were observed at the sample appearance, as shown in Fig. 6. The authors believe that the volatile NbO2 produced by the decomposition of Nb2O5 during oxidation is the main reason for this result [43]. When the temperature is between 1400 and 1450 °C, the oxide layer of the coatings becomes thinner and tends to be smooth, as shown in Fig. 5e and f. This is attributed to that the c-SiO2 with a high density and certain fluidity is generated, which is spreading along the coating surface and filling up the pores in the oxide layer. It should be noted that the thickness of the interfacial layer (Nb5Si3 layer) increases gradually with increasing temperature because of the principle of thermal diffusion. Overall, the oxidation of the coating is complex and does not show a simple dependence on temperature. The quality of the oxide layer, the stability of the structure and the self-healing ability of the coating all have important effects on its oxidation behavior at different temperatures.

The images of cross-sectional of the oxidized NbSi2 coating observed for 50 h at different temperatures [41]

The Δm/S of NbSi2 coatings varies with time a and the appearance of the coatings varies with temperature b at the oxidation atmosphere of 1000–1450 °C [42]

The pictures of the oxidized MoSi2 coating on the Nb-5 W-2.2Mo-1.6Zr(wt%) alloy are shown in Fig. 7 [39]. The results show oxidized coating has a more smooth and even surface, which is composed of black particles (Mo5Si3) and gray glassy film (SiO2), respectively. However, due to the differences in CTE between Mo5Si3 and SiO2, some microscopic cracks are still observed on the surface of the coating, as shown in Fig. 7a. The oxide layer is mainly composed of SiO2, which shows continuous inhomogeneity because of the high surface roughness of coating. At the same time, SiO2 has good fluidity at high temperature, which is improves the self-healing ability of the coating to some extent, as shown in Fig. 7b [44]. The interior of the coating is mainly composed of MoSi2, Mo5Si3 and SiO2, and contains a large number of pores. Which is caused by the decomposition of MoSi2 and the generation and volatilization of MoO3, as shown in Fig. 7c. Liu et al. [37] reported that the MoSi2 coating can provide effective protection for Nb-10Hf-1Ti alloy for a long time at the temperature of 1200 °C. After 100 h of oxidation, the coated sample still maintained its intact structure, and its mass gain was only 0.64 mg cm−2. However, the bare alloy was completely "powdered" after oxidation for 10 h, as shown in Fig. 8a. The fitting results of oxidation kinetics curves of coating samples show that the process follows a parabolic rule [45]. According to the relevant formula, the oxidation rate kp of the coating is only 1.69 × 10−4 mg2·cm−4·h−1, as shown in Fig. 8b [46].

Surface a and corresponding cross-section b of MoSi2 coating after oxidation at 1500 °C for 43 h, c is detail of the middle layer corresponding to the white rectangle in b [39]

The Δm/S a and (Δm/S)2 b of MoSi2 coating varies with time at oxidation tests at 1200 °C for 100 h [37]

2.2 Composite Silicide Coatings

2.2.1 Microstructure and Phase Composition of Coatings

Composite silicide coating is a kind of coatings obtained through the organic combination of a single silicide coating, and its structure has been further optimized compared with the single silicide coating [47,48,49]. The surface and corresponding cross-section morphologies of typical composite silicide coatings are shown in Fig. 9. Yue et al. [50] prepared the MoSi2-Resi2-NbSi2 coating by HAPC method. XRD results show that there are a lot of SiO2 and Al2O3 particles on the coating surface besides MoSi2. This means that the original oxide layer formed on the coating surface during the HAPC process [51]. In addition, a few micro-cracks were also observed on its surface, as shown in Fig. 9a. However, the inner of coating is relatively dense, composed of MoSi2, ReSi2 and NbSi2 layers from outside to inside. Moreover, there is a thin (Ti,Nb)5Si4 transition layer between the NbSi2 layer and substrate, as shown in Fig. 9e. Zhang et al. [52] prepared 10 wt% and 30 wt% mullite MoSi2 coatings (MM), respectively, on the surface of Nb521 alloy by HAPC and SAPS techniques. Although the surface of coatings was relatively rough, no obvious cracks, holes and other defects were found, as shown in Fig. 9b and c. This is due to the melted mullite filled up the pores on the coating surface during the injection process. The inner coatings was very dense and tightly bonded to the substrate, as shown in Fig. 9f and g, respectively. Notably, many pores and unfused loose particles are observed in the M30 coating. This is related to the insufficient melting of MoSi2 due to the high content of mullite in the sample and its relatively low melting point, as shown in Fig. 9g. In addition, Zhang et al. [53] also studied the WSi2-Mullite-MoSi2 (WMM) composite coating on Nb surface. Compared with MM coating, the surface of the WMM coating was more uniform, the particles were finer, and the typical lamellar structure was presented. The interior of the coating was more dense and its porosity was reduced significantly, as shown in Fig. 9d and h.

2.2.2 Oxidation Properties of the Coatings

The images of the oxidized composite silicide coatings are shown in Fig. 10. It can be seen that the surfaces of MoSi2/ReSi2/NbSi2, M10 and WMM coatings are smooth and compact, with a uniform oxide film, as shown in Fig. 10a, b and d [50, 52, 53]. Unfortunately, a mass of micro-pores were observed in the lamellar Nb2O5 on the surface of MM coating, which may be related to the volatilization of MoO3 and SiO2[54], as shown in Fig. 10c. In addition, many cracks and holes appeared inside the MM coating, and serious exfoliation of the interface layer was observed, and the protective oxide film almost completely disappeared, as shown in Fig. 10g. But, for oxidized MoSi2/ReSi2/NbSi2 coating, a thin MoSi2/ReSi2 layer was still observed at the bottom of the oxide layer of the coating, as shown in Fig. 10e. This shows that the ReSi2 layer improves the adhesion of MoSi2 layer, limits the diffusion of Si, and enhances the oxidation resistance of the coating [55].

Zhang et al. [53] studied the effects of the addition of mullite and WSi2 on the oxidation properties of MoSi2 coating. The results show that the Δm/S of M0 and M30 samples changed significantly after oxidation for 118 h and 30 h. Among them, the oxide layer on the surface of sample M30 darkened and decomposed, and the sample M0 was pulverized completely. However, after 70 h of oxidation, the surface of M10 sample is very smooth and the mass change is quite stable, only −4.06 mg·cm−2, as shown in Fig. 11a. Even after 140 h of oxidation, it still shows stable oxidation resistance, with a smooth and dense surface and a thin and uniform oxide layer, as shown in Fig. 10b and f. Compared with the single MoSi2 coating, more amorphous SiO2 was detected on the surface of MM sample, which means that the addition of mullite inhibited the crystallization of SiO2 and improved its fluidity at high temperature [54]. What is noteworthy is that the mass loss of the WMM coating was only 4.41 mg·cm−2 after 500 h of oxidation, as shown in Fig. 11b. The test results show that solid solution phases of (Mo,W)Si2 with the CTE similar to that of SiO2 are formed on the coating surface, as shown in Fig. 10d. Which is effectively alleviating defects caused by CTE mismatch on the surface of the coating [56,57,58]. The oxidized coating was composed of the oxide layer, outer layer, porous layer and interface layer. The results of chemical composition detection in typical regions of each layer showed that its main components were SiO2, (Mo,W)Si2, (Mo,W)5Si3, (Mo,W,Nb)5Si3 and Nb5Si3, respectively, as shown in Fig. 10h. This means that the WSi2 inhibits the diffusion of Si element, maintains the structure of coating, and ensures the oxidation service life of coating at high temperature [59].

Oxidation kinetics curves and corresponding appearance pictures of different coatings at 1500 °C [53]

3 Microstructure and oxidation behavior of modified silicide coatings

Adding appropriate amount of modified elements to the silicified coating is a vital way to enhance the high-temperature oxidation resistance of coating. Among them, the researches of Al, B, Y, Re, Ge, Ce and other elements to improve the oxidation properties of Nb and its alloy surface silicide coating have been favored by relevant scholars.

3.1 Silicide Coating Modified by Single Element

3.1.1 Microstructure and Phase Composition of the Coatings

Wang et al. [60] produced the Ge-modified silicide coating by HAPC method. The interior of the coating has uniform composition, dense structure, and a few cracks. The results of XRD and EDS analysis show that the main components of inner and outer layers are (Nb,X)5(Si,Ge)3 and (Nb,X)(Si,Ge)2(X represents Ti, Cr, Hf elements), and their thicknesses are 11 μm and 165 μm, respectively, as shown in Fig. 12a. This indicates that during diffusing into the substrate, the concentration of Nb, Ti and other elements increases gradually, while the Si element decreases gradually. In addition, due to the phase with higher Nb content has a larger lattice constant, higher Ge content is detected in the diffusion layer [61,62,63], as shown in Fig. 12e. Qiao et al. [64] prepared the Y-modified silicide coating by Si-Y co-deposition technology. EDS test results show that the coating is composed of light gray (Nb,Cr) Si2 and dark gray (Cr,Nb) Si2, with an overall thickness of more than 200 μm, as shown in Fig. 12b. Noteworthy, there is no obvious change in Si concentration distribution throughout the coating, and the content of Y element on the outer side of coating is slightly higher than that on the inner side, as shown in Fig. 12f. However, the Mo-Si-Al coating has an obvious layered structure, which consists of a dark gray outermost layer, a gray and white inter layer and a light gray inner layer. The analysis results of the components of each layers show that the outer layer is Mo(Si,Al)2 rich layer, the middle layer is Mo5(Si,Al)2 and Al8Mo3 rich layer, and the inner layer is AlMo3 rich layer, as shown in Fig. 12c and g [65], respectively. The Mo-Si-B coating has a relatively uniform and dense surface, which is main components are MoSi2 and B2O3-SiO2, as shown in Fig. 12d [66]. This is due to the presence of a small amount of oxygen in the system during the preparation of coating, resulting in the oxidation of local areas on the surface of coating. The results of WDS analysis show that there is an obvious layered structure inside the coating, and the B element is mainly distributed in the intermediate layer composed of (Nb,Ti)5SiB2, as shown in Fig. 12h. Which means that the solubility of B in MoSi2 (outer layer) and (Nb,Ti) Si2 (inner layer) is low [67].

Cross-section morphology and composition analysis of different coatings on Nb-based alloys; Ge-modified silicide a and e [60], Y-modified silicide b and f [64], cross-sectional morphology c and XRD test results g of the Mo-Si-Al coating [65], BSE pictures of surface d and cross-sectional h of the Mo-Si-B coating [66]

3.1.2 Oxidation Properties of the Coatings

The images of the oxidized silicide coatings modified by single element are shown in Fig. 13. It is observed that the surface of the oxidized Mo-Si-Al coating is covered with a shiny particles layer, and its main ingredients are a-Al2O3 and Mo5(Si,Al)3, as shown in Fig. 13a [65]. In addition, many pores were observed in the Mo5(Si,Al)3 layer, which may be related to the production of volatile MoO3. However, the internal structure of the coating remained intact and tightly bonded to the substrate, as shown in Fig. 13e. The selective oxidation of Al element promoted the formation of protective oxide film on the surface of the coating, prolonged the oxidation service life of the coating, as reported in the study of Majumdar [68, 69]. The results of EDS and XRD test show that a compact B2O3-SiO2 layer formed on the surface of the oxidized Mo-Si-B coating, and the diffraction peak of Mo5Si3 was detected in the area of the thin oxide layer, as shown in Fig. 13b [70]. The internal coating is very dense and uniform, and the bonding between layers is good, as shown in Fig. 13f. This indicates that the addition of B improves the fluidity of SiO2, and promotes the formation of protective B2O3-SiO2 film on the coating surface [71, 72]. The oxidized Ge-modified silicide coating has a smooth and compact surface, which is composed of dark gray glass phase (SiO2) and light gray lamellar phase (TiO2), as shown in Fig. 13c [60]. Its oxide layer is uniform and dense, with a thickness of about 50–60 μm, and trace GeO2 particles are detected in it. The researches show that generation of GeO2 can effectively reduce the viscosity of SiO2 at high temperature and improve its fluidity, which is improving the self-healing ability of the coating under high temperature oxidation [73].

modified by single element on Nb and Nb-based alloys under different conditions; Mo-Si-Al coating a and e [64], Mo-Si-B coating b and f [70], Ge-modified silicide coating c and g [60], Ce-modified MoSi2-NbSi2 coating d and h [74]

The oxidized surface and corresponding cross-sections of the various silicide coatings

Xiao et al. [74] researched the affect of Ce element on the oxidation behavior of MoSi2-NbSi2 composite coating at high temperature. It is observed that the oxidized surface of the Ce-modified MoSi2-NbSi2 coating was covered with a layer of molten SiO2 and granular bulges, the interior of the coating is very dense, and the layers are closely bonded, as shown in Fig. 13d and h, respectively. The surface of the oxidized MoSi2-NbSi2 coating has more granular bulges than that of the modified coating, and their Rsa are 2.027 μm and 1.776 μm, respectively, as shown in Fig. 14. This may be related to the finer surface grains of the modified coating. Further study showed that the average oxidation service life of the modified coating at 1600 °C was 28.5 h, slightly higher than 24.7 h of the MoSi2-NbSi2 coating. Furthermore, the exposure time is proportional to the square of the mass change per unit area (Δm/S) of the coating, and the coatings oxidation parabolic constant kp of the are calculated, as shown in Fig. 15 [75]. Which is due to that element Ce can refine the grain size of the coating, optimize the structure of the coating, and prolong the high-temperature oxidation service life of the coating [76].

Surface roughness analysis of different coatings after oxidation at 1600 °C for 12 h; MoSi2-NbSi2 coating a, Ce modified MoSi2-NbSi2 coating b [74]

Weight gains a and square of weight gains b of MoSi2-NbSi2 coatings with and without CeO2 after oxidation at 1600 °C [74]

3.2 Silicide Coating Modified by Composite Elements

3.2.1 Microstructure and Phase Composition of the Coatings

The images of silicide coating modified by composite element are shown in Fig. 16. It can be seen that the average grain size of Si–Ge–Y coating is only 0.84 μm, which is significantly lower than the 2.47 μm of Si-Ge coating, as shown in Fig. 16a and b. This is due to that the solubility of element Y in the grain is low, and the nanoscale Y3Al5O12 particles are distributed at the grain boundary, which makes the Si–Ge–Y coating has a smaller grain size. The Si–Ge–Y coating is consists of a dense outer layer and a continuous transition layer, and their thickness are 179 μm and 12.1 μm, respectively, as shown in Fig. 16c. The outer layer of the coating is made of (Nb,X)(Si,Ge)2, while the transition layer is composed of dark gray (Ti,Nb)5(Si,Ge)4 phase and bright gray (Nb,X)5(Si,Ge)3 phase and the proportion of the two phases is 66% and 34%, respectively [77]. This indicates that the Si and Ge elements content are gradually reduces in the process of spreading to the substrate [78].

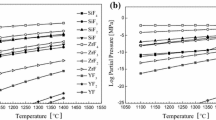

Surface FESEM image of Si-Ge coating a, surface b and cross-sectional c FESEM images of Si–Ge–Y coating [77]. Cross-sectional images of Mo-Si-B/Al2O3 composite coating d and the magnified view of the its IDZ e. Plot of ln(kp) vs. 1/T for the IDZ in samples with and without Al2O3 diffusion barrier f [80]

Plasma-physical vapor deposition (PS-PVD) combines the advantages of traditional plasma spraying and physical vapor deposition, which is a thermal barrier coatings(TBCs) preparation technology with broad application prospects. The principle of this process is to add spray powder to plasma gun, heat the material to liquid or vaporized state with low pressure plasma arc as heat source, and then transport it to the surface of the substrate through plasma air flow to form coating. The whole process is carried out in a vacuum chamber or in a protective atmosphere of inert gas, as shown in Fig. 17a [79]. Hou et al. [80] produced the Mo-Si-B/Al2O3 coating on Nb-Si based alloy by PS-PVD followed by spark plasma sintering (SPS) technology, successively. The preparation process of the coating is shown in Fig. 17b. Firstly, a Al2O3 coating with a thickness of 10 μm was deposited on the alloy surface by PS-PVD technique. Then the molybdenum, silicon and boron powders prepared in proportion are mixed evenly through ball milling. The deposited sample and mixed powder were put into SPS equipment (Model 1050) and sintered at 1300 °C for 5 min in Ar atmosphere, then the Mo-Si-B/Al2O3 coating will be obtained at a pressure of 40 MPa [80]. The Mo-Si-B/Al2O3 coating is composed of dense Mo-Si-B outer layer and continuous Al2O3 transition layer, as shown in Fig. 16d. The main components at point 1, 2 and 3 in the transition layer of the coating are MoSi2, Al2O3 and Cr2Nb in turn, no elements from the substrate are detected in the Mo-Si-B layer, as shown in Fig. 16e. The Ar rhenius plots of kp of Mo-Si-B/Nb-Si and Mo-Si-B/Al2O3/Nb-Si samples are shown in Fig. 16f. It shows that the activation energy Q of the sample containing Al2O3 diffusion barrier is 367 kJ/mol, which is much higher than that of the sample without Al2O3. This means that Al2O3, as a diffusion barrier, can effectively delay the mutual diffusion between the coating and substrate [81].

3.2.2 Oxidation Properties of the Coatings

The images of the oxidized silicified coatings modified by composite elements are shown in Fig. 18. It is observed that the surface of coatings are composed of two phases with significantly different brightness, namely dark gray flaky phase and bright light gray granular phase, as shown in Fig. 18a–c. Table 1 provides the EDS detection results at each point in a typical region of surface of the coatings, from which we can be inferred that their components are mainly SiO2 and TiO2 with a small amount of Al2O3 and Cr2O3. This indicates that Ti, Al, Cr and other elements diffuse outward faster in the oxidation process [78, 82, 83]. The oxidized coating is composed of an oxide outer layer, a (Nb,X)(Si,Ge)2 middle layer and a (Ti,Nb)5Si4 transition layer. Compared to the oxidation before, the thickness of middle layer decreass obviously, and a mass of pores are discovered in the outer coating. This is related to the decomposition of silicides and Kirkendall effects caused by the spread of Si, Ti and Al [84]. The existence of these holes releases the thermal stress in the coating and effectively avoids the generation of cracks [85, 86]. What is noteworthy is that the thickness of (Ti,Nb)5Si4 layer increases significantly with the interdiffusion of the elements in each layer. The interior of all coatings is uniform and dense, demonstrating good metallurgical bonding with the substrate, as shown in Fig. 18d–f [77, 82, 83].

Further researcher shows that that the oxidation rate of Si–Ge–Y coating is slightly higher than that of Si-Ge coating in the initial oxidation stage, this is related to the smaller grain size of the coating. However, the oxidation rate of Si–Ge–Y coating is gradually lower than that of Si-Ge coating as the oxidation reaction enters the stable stage. The Δm/S of the two coatings oxidized for 100 h are 2.78 mg·cm−2 and 5.42 mg·cm−2, respectively, as shown in Fig. 19a. It shows that the formation of Y3Al5O12 particles at the grain boundary refines the grain size and promotes the formation of protective SiO2 and GeO2 oxide films on the surface of the coating, which makes the Si–Ge–Y coating has a better oxidation resistance than that of Si-Ge coating [77]. It is observed that the (Δm/S)2 of the coatings are approximately linear with time, as shown in Fig. 19b. Which is indicating that the oxidation of the coating follows a parabolic law [87].

Weight gains a and square of weight gains b of the coatings exposure at 1250 °C for 100 h [77]

4 Oxidation and Failure Mechanisms of the Coatings

Figure 20 shows the oxidation and failure mechanisms of various coatings on Nb and its alloys. It can be seen that the coating consumption in the oxidation process not only comes from the surface oxidation reaction, but also depends on the diffusion growth of the inner interface layer. For the single coating, with the formation and volatilization of NbO2/(MoO3) during oxidation process, its porosity and the surface roughness increases rapidly, which is not conducive to the formation of protective oxide film on its surface. In addition, due to the single composition and structure of coating, a mass of cracks will appear inside its internal during the oxidation process, which is greatly deteriorates the high temperature oxidation resistance of the coating, as shown in Fig. 20a and b. For the composite silicide coating, the ReSi2 layer can act as a barrier to inhibit the diffusion of Si element and maintain the structural integrity of the coating. Mullite fills the pores on the surface of the coating and promotes the formation of a continuous and stable oxide film. The W element can combine with elements such as Mo, Si and Nb to form (Mo, W)Si2, (Mo, W)5Si3 and (Mo, W, Nb)5Si3 compounds inside the coating, which can uniform the coating composition and inhibit the diffusion of Si element. Moreover, the solid solution phases of (Mo, W)Si2 formed on the coating surface have similar CTE values to that of SiO2, which can alleviate the surface cracking of the coating to a certain extent, as shown in Fig. 20c and d.

The addition of modified elements makes the coating have more uniform composition, compact structure and more stable oxidation resistance. The Al element is preferred to be oxidized to form protective a-Al2O3 oxide film, which reduces the oxygen partial pressure on the surface of the coating and slows down the oxidation rate of the coating. Furthermore, the Al2O3 as the interface layer between the coating and the substrate can effectively alleviate the mutual diffusion between them and maintain the integrity of the coating structure. The B and Ge elements can reduce the viscosity of SiO2 at a high temperature, enhance its fluidity, and promote the formation of a smooth and dense oxide layer on the surface of the coatings. The Ce element can refine the grain size of the coating, optimize the structure of the coating, and enhance the self-healing ability of the coating under high temperature oxidation. The Y3Al5O12 particles formed by the combination of Y element and Al in the oxidation process can effectively refine the grain size of the coating, reduce its surface roughness and promote the formation of a smooth oxide film on its surface. In addition, Some pores generated in the coating during the oxidation process effectively release the thermal stress and avoid the generation of cracks, as shown in Fig. 20 e and f.

5 Conclusions and Prospect

In this paper, the application of various anti-oxidation coatings on Nb and its alloy are introduced in detail, the composition and oxidation characteristics of coatings are summarized as shown in Fig. 21. There is no doubt that the composition and structure of the coatings have an important effect on their oxidation behavior. Due to the single composition and structure of coating, various defects generated during the oxidation process make the single silicide coating unable to be used at high temperatures (1500 °C and above) for long periods of time. Compared with single coating, the structure of composite coating is further optimized. However, defects such as cracks in the coating can not be avoided in the oxidation process as usual. At the same time, the rapid growth of the interface layer also accelerates the consumption of the coating. All these problems result in a significant reduction in the oxidation life of such coatings. The modified silicide coatings prepared by two-step process have smooth surface, compact structure and uniform composition. This makes their have excellent self-healing ability and stable oxidation resistance at high temperature.

By optimizing the coating preparation process, combining two or more processes organically to eliminate the problems existing in the application process of a single process. This will make the coatings have a more uniform composition, denser structure and lower surface roughness. In addition, the coating structure can be further optimized by adding appropriate amount of modified elements or introducing the second phases. It can not only delay the diffusion of Si elements to the substrate, inhibit the formation of low silicon compounds (Nb5Si3, Mo5Si3) with poor oxidation resistance, but also promote the formation of continuous and dense anti-oxidation film on the surface of coating, and reduce the generation of volatile oxides (NbO2, MoO3 etc.). Therefore, the modified silicide coatings obtained by multi-step have a bright application prospect, which will be an important development direction in this field in the future.

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

F. Shen, Y. Zhang, L. Yu, T. Fu, J. Wang, H. Wang, K. Cui, Microstructure and oxidation behavior of Nb-Si-based alloys for ultrahigh temperature applications: a comprehensive review. Coatings 11(11), 1373 (2021). https://doi.org/10.3390/coatings11111373

X. Zhang, T. Fu, K.K. Cui, Y.Y. Zhang, F.Q. Shen, J. Wang, L.H. Yu, H.B. Mao, A. Tolstoguzov, The protection, challenge, and prospect of anti-oxidation coating on the surface of niobium alloy. Coatings 11(7), 742 (2021). https://doi.org/10.3390/coatings11070742

J. Wang, Y. Zhang, L. Yu, K. Cui, T. Fu, H. Mao, Effective separation and recovery of valuable metals from waste Ni-based batteries: A comprehensive review. Chem. Eng. J. 439, 135767 (2022). https://doi.org/10.1016/j.cej.2022.135767

J.H. He, X.P. Guo, Y.Q. Qiao, Effect of Zr content on the structure and oxidation resistance of silicide coatings prepared by pack cementation technique. Corros. Sci. 147, 152–162 (2019). https://doi.org/10.3390/coatings12020141

D.Z. Yao, C.G. Zhou, J.Y. Yang, H.F. Chen, Experimental studies and modeling of the oxidation of multiphase niobium-base alloys. Corros. Sci. 51(11), 2617–2619 (2009). https://doi.org/10.1016/j.corsci.2009.06.053

Y.X. Li, J.H. Nie, Y.X. Yang, P.K. Bai, H.J. Zhang, Z.Y. Zhao, S.Z. Wei, J. Cai, Q.F. Guan, High-temperature oxidation behavior of nicocraly coatings deposited by laser cladding on 304 stainless steel. Met. Mater. Int. 28, 412–420 (2022). https://doi.org/10.1007/s12540-020-00927-y

L. Yu, F. Shen, T. Fu, Y. Zhang, K. Cui, J. Wang, X. Zhang, Microstructure and oxidation behavior of metal-modified Mo-Si-B alloys a review. Coatings 11(10), 1256 (2021). https://doi.org/10.3390/coatings11101256

L. Yu, Y. Zhang, T. Fu, J. Wang, K. Cui, F. Shen, Rare earth elements enhanced the oxidation resistance of Mo-Si-based alloys for high temperature application: a review. Coatings 11(9), 1144 (2021). https://doi.org/10.3390/coatings11091144

S. Zhang, X.P. Guo, Alloying effects on the microstructure and properties of Nb-Si based ultrahigh temperature alloys. Intermetallics 70, 33–44 (2016). https://doi.org/10.1016/j.intermet.2015.12.002

G. Kim, H. Shin, J. Lee, W. Lee, A review on silicide-based materials: thermoelectric and mechanical properties. Met. Mater. Int. 27, 2205–2219 (2021). https://doi.org/10.1007/s12540-020-00609-9

Y.C. Yan, H.S. Ding, Y.W. Kang, J.X. Song, Microstructure evolution and mechanical properties of Nb-Si based alloy processed by electromagnetic cold crucible directional solidification. Mater. Des. 55, 450–455 (2014). https://doi.org/10.1016/j.matdes.2013.10.017

Z.P. Sun, J.M. Guo, C. Zhang, X.P. Guo, X.D. Tian, Effect of Ti and Al interaction on microstructures and mechanical properties of the Nb-Ti-Si-Al alloys. Rare Metal Mater. Eng. 45(7), 1678–1682 (2016). https://doi.org/10.1016/S1875-5372(16)30139-4

I. Grammenos, P. Tsakiropoulos, Study of the role of Hf, Mo and W additions in the microstructure of Nb–20Si silicide based alloys. Intermetallics 19(10), 1612–1621 (2011). https://doi.org/10.1016/j.intermet.2011.06.008

S.S. Zhang, Y.C. Liu, T.W. Xu, M.X. Sun, Q. Zhang, Y. Wan, Effect of texture and microstructure on tensile behaviors in the polycrystalline pure niobium. Met. Mater. Int. 27, 4023–4034 (2021). https://doi.org/10.1007/s12540-020-00925-0

D.L. Pu, Y. Pan, Influence of high pressure on the structure, hardness and brittle-to-ductile transition of NbSi2 ceramics. Ceram. Int. 47(2), 2311–2318 (2021). https://doi.org/10.1016/j.ceramint.2020.09.073

G.M. Karthik, H.S. Kim, Heterogeneous aspects of additive manufactured metallic parts: a review. Met. Mater. Int. 27, 1–39 (2021). https://doi.org/10.1007/s12540-020-00931-2

Y. Pan, Structural Prediction and overall performances of CrSi2 disilicides: DFT investigations. ACS Sustain. Chem. Eng. 8, 11024–11030 (2020). https://doi.org/10.1021/acssuschemeng.0c04737

X. Fang, X.P. Guo, Y.Q. Qiao, Effect of Ti addition on microstructure and crystalline orientations of directionally solidified Nb–Si based alloys. Intermetallics 122, 106798 (2020). https://doi.org/10.1016/j.intermet.2020.106798

I. Grammenos, P. Tsakiropoulos, Study of the role of Al, Cr and Ti additions in the microstructure of Nb-18Si-5Hf base alloys. Intermetallics 18(2), 242–253 (2010). https://doi.org/10.1016/j.intermet.2009.07.020

Y.Y. Zhang, J.M. Qie, K.K. Cui, T. Fu, X.L. Fan, J. Wang, X. Zhang, Effect of hot dip silicon-plating temperature on microstructure characteristics of silicide coating on tungsten substrate. Ceram. Int. 46(4), 5223–5228 (2020). https://doi.org/10.1016/j.ceramint.2019.10.270

S. Zhang, X.P. Guo, Effects of Cr and Hf additions on the microstructure and properties of Nb silicide based ultrahigh temperature alloys. Mater. Sci. Eng. A 638, 121–131 (2015). https://doi.org/10.1016/j.msea.2015.04.003

Y.Y. Zhang, T. Fu, L.H. Yu, F.Q. Shen, J. Wang, K.K. Cui, Improving oxidation resistance of TZM alloy by deposited Si–MoSi2 composite coating with high silicon concentration, Ceram. Int. (2022). https://doi.org/10.1016/j.ceramint.2022.04.080

Y.Y. Zhang, S. Hussain, K.K. Cui, T. Fu, J. Wang, M.S. Javed, Y. Lv, B. Aslam, Microstructure and mechanical properties of MoSi2 coating deposited on Mo substrate by hot dipping processes. J. Nanoelectron. Optoelectron. 14(12), 1680–1685 (2019). https://doi.org/10.1166/jno.2019.2676

Y.Y. Zhang, Y.G. Li, C.G. Bai, Microstructure and oxidation behavior of Si-MoSi2 functionally graded coating on Mo substrate. Ceram. Int. 43(8), 6250–6256 (2017). https://doi.org/10.1016/j.ceramint.2017.02.024

F. Shen, L. Yu, T. Fu, Y. Zhang, H. Wang, K. Cui, J. Wang, S. Hussain, N. Akhtar, Effect of the Al, Cr and B elements on the mechanical properties and oxidation resistance of Nb-Si based alloys: a review. Appl. Phys. A 127, 852 (2021). https://doi.org/10.1007/s00339-021-05013-7

Y.Y. Zhang, T. Fu, K.K. Cui, F.Q. Shen, J. Wang, L.H. Yu, H.B. Mao, Evolution of surface morphology, roughness and texture of tungsten disilicide coatings on tungsten substrate. Vacuum 14, 110297 (2021). https://doi.org/10.1016/j.vacuum.2021.110297

K. Cui, H. Mao, Y. Zhang, J. Wang, H. Wang, T. Tan, T. Fu, Microstructure, mechanical properties, and reinforcement mechanism of carbide toughened ZrC-based ultra-high temperature ceramics. Compos. Interfaces (2022). https://doi.org/10.1080/09276440.2021.2012409

Y.Y. Zhang, K.K. Cui, Q.J. Gao, S. Hussain, Y. Lv, Investigation of morphology and texture properties of WSi2 coatings on W substrate based on contact-mode AFM and EBSD. Surf. Coat. Technol. 396(25), 125966 (2020). https://doi.org/10.1016/j.surfcoat.2020.125966

K. Zelenitsas, P. Tsakiropoulos, Effect of Al, Cr and Ta additions on the oxidation behaviour of Nb-Ti-Si in situ composites at 800 °C. Mater. Sci. Eng. A 416, 269–280 (2006). https://doi.org/10.1016/j.msea.2005.10.017

T. Fu, F.Q. Shen, Y.Y. Zhang, L.H. Yu, K.K. Cui, J. Wang, X. Zhang, Oxidation protection of high-temperature coatings on the surface of Mo-Based alloys-a review. Coatings 12(2), 141 (2022). https://doi.org/10.3390/coatings12020141

Y.Y. Zhang, L.H. Yu, T. Fu, J. Wang, F.Q. Shen, K.K. Cui, Microstructure evolution and growth mechanism of Si-MoSi2 composite coatings on TZM (Mo-0.5Ti-0.1Zr-0.02 C) alloy. J. Alloys Compd. 894(15), 162403 (2022). https://doi.org/10.1016/j.jallcom.2021.162403

Y.Y. Zhang, W.J. Ni, Y.G. Li, Effect of siliconizing temperature on microstructure and phase constitution of Mo–MoSi2 functionally graded materials. Ceram. Int. 44(10), 11166–11171 (2018). https://doi.org/10.1016/j.ceramint.2018.03.136

X. Tian, X. Guo, Z. Sun, Z. Yin, L. Wang, Formation of B-modified MoSi2 coating on pure Mo prepared through HAPC process. Int. J. Refract. Metals Hard Mater. 45, 8–14 (2014). https://doi.org/10.1016/j.ijrmhm.2014.03.003

B. Vishwanadh, R.H. Naina, S. Majumdar, R. Tewari, G.K.A. Dey, A study on the oxidation behavior of Nb alloy (Nb-1 pct Zr-0.1 pct C) and silicide-coated Nb alloys. Metall. Mater. Trans. A 44, 2258–2269 (2013). https://doi.org/10.1007/s11661-012-1554-1

L. Liu, H. Lei, J. Gong, C. Sun, Deposition and oxidation behaviour of molybdenum disilicide coating on Nb based alloys substrate by combined AIP/HAPC processes. Ceram. Int. 45(8), 10525–10529 (2019). https://doi.org/10.1016/j.ceramint.2019.02.115

J.C. Cheng, S. Yi, J.S. Park, Oxidation behavior of Nb-Si-B alloys with the NbSi2 coating layer formed by a pack cementation technique. Int. J. Refract Metal Hard Mater. 41, 103–109 (2013). https://doi.org/10.1016/j.ijrmhm.2013.02.010

S. Majumdar, J. Kishor, B. Paul, R.C. Hubli, J.K. Chakravartty, Isothermal oxidation behavior and growth kinetics of silicide coatings formed on Nb-1Zr-0.1C alloy. Corros. Sci. 95, 100–109 (2015). https://doi.org/10.1016/j.corsci.2015.02.035

E.H. Jordan, L. Xie, M. Gell, N.P. Padture, B. Cetegen, A. Ozturk, X. Ma, J. Roth, T.D. Xiao, P.E.C. Bryant, Superior thermal barrier coatings using solution precursor plasma spray. J. Therm. Spray Technol. 13, 57–65 (2004). https://doi.org/10.1007/s11666-004-0050-6

L. Sun, Q.G. Fu, X.Q. Fang, J. Sun, A MoSi2-based composite coating by supersonic atmospheric plasma spraying to protect Nb alloy against oxidation at 1500 °C. Surf. Coat. Technol. 325, 182–190 (2018). https://doi.org/10.1016/j.surfcoat.2018.07.091

D.L. Pu, Y. Pan, First-principles investigation of oxidation mechanism of Al-doped Mo5Si3 silicide. Ceram. Int. 48(8), 11518–11526 (2022). https://doi.org/10.1016/j.ceramint.2022.01.007

J. Yan, L. Liu, Z. Mao, H. Xu, Y. Wang, Effect of spraying powders size on the microstructure, bonding strength, and microhardness of MoSi2 coating prepared by air plasma spraying. J. Therm. Spray Technol. 23, 934–939 (2014). https://doi.org/10.1007/s11666-014-0120-3

Y.J. Choi, J.K. Yoon, G.H. Kim, W.Y. Yoon, J.M. Doh, K.T. Hong, High temperature isothermal oxidation behavior of NbSi2 coating at 1000–1450 °C. Corros. Sci. 129, 102–114 (2017). https://doi.org/10.1016/j.corsci.2017.10.002

J. Sun, T. Li, G.P. Zhang, Q.G. Fu, Different oxidation protection mechanisms of HAPC silicide coating on niobium alloy over a large temperature range. J. Alloy. Compd. 790, 1014–1022 (2019). https://doi.org/10.1016/j.jallcom.2019.03.229

Y.Y. Zhang, K.K. Cui, T. Fu, J. Wang, F.Q. Shen, X. Zhang, L.H. Yu, Formation of MoSi2 and Si/MoSi2 coatings on TZM (Mo-0.5Ti-0.1Zr-0.02C) alloy by hot dip silicon-plating method. Ceram. Int. 47(16), 23053–23065 (2021). https://doi.org/10.1016/j.ceramint.2021.05.020

L. Liu, H.Q. Zhang, H. Lei, H.Q. Li, J. Gong, C. Sun, Influence of different coating structures on the oxidation resistance of MoSi2 coatings. Ceram. Int. 46(5), 5993–5997 (2020). https://doi.org/10.1016/j.ceramint.2019.11.055

L. Sun, Q.G. Fu, J. Sun, G.P. Zhang, Comparison investigation of hot corrosion exposed to Na2SO4 salt and oxidation of MoSi2-based coating on Nb alloy at 1000 °C. Surf. Coat. Technol. 385, 125388 (2020). https://doi.org/10.1016/j.surfcoat.2020.125388

Y.L. Guo, L.N. Jia, B. Kong, F.X. Zhang, J.H. Liu, H. Zhang, Improvement in the oxidation resistance of Nb-Si based alloy by selective laser melting. Corros. Sci. 127, 260–269 (2017). https://doi.org/10.1016/j.corsci.2017.08.022

S. Majumdar, J. Kishor, B. Paul, R.C. Hubli, J.K. Chakravartty, Isothermal oxidation behavior and growth kinetics of silicide coatings formed on Nb-1Zr-0.1C alloy. Corros. Sci. 95, 100–109 (2015). https://doi.org/10.1016/j.corsci.2015.02.035

Y. Pan, W.M. Guan, The hydrogenation mechanism of PtAl and IrAl thermal barrier coatings from first-principles investigations. Int. J. Hydrog. Energy 45(38), 20032–20041 (2020). https://doi.org/10.1016/j.ijhydene.2020.04.290

G. Yue, X.P. Guo, Y.Q. Qiao, Microstructure and oxidation behaviors at 800°C and 1250°C of MoSi2/ReSi2/NbSi2 compound coating prepared by electrodeposition and then pack cementation. Ceram. Int. 45(9), 11739–11748 (2019). https://doi.org/10.1016/j.ceramint.2019.03.050

A. Allam, P. Boulet, M.C. Record, Linear thermal expansion coefficients of higher manganese silicide compounds. Phys. Proc. 55, 24–29 (2014). https://doi.org/10.1016/j.phpro.2014.07.004

G.P. Zhang, J. Sun, Q.G. Fu, Effect of mullite on the microstructure and oxidation behavior of thermal sprayed MoSi2 coating at 1500 °C. Ceram. Int. 46(8), 10058–10066 (2020). https://doi.org/10.1016/j.ceramint.2019.12.273

G.P. Zhang, J. Sun, Q.G. Fu, Microstructure and oxidation behavior of plasma sprayed WSi2-mullite MoSi2 coating on niobium alloy at 1500 °C. Surf. Coat. Technol. 400, 126210 (2020). https://doi.org/10.1016/j.surfcoat.2020.126210

M.Z. Alam, A.S. Rao, D.K. Das, Microstructure and high temperature oxidation performance of silicide coating on Nb-based alloy C-103. Oxid. Met. 73, 513–530 (2010). https://doi.org/10.1007/s11085-010-9190-x

G. Yue, X.P. Guo, Y.Q. Qiao, C.G. Zhou, Electrodeposition of Mo/Re duplex layer and preparation of MoSi2/ReSi2/NbSi2 compound coating on Nb-Ti-Si based alloy. Corros. Sci. 153, 283–291 (2019). https://doi.org/10.1016/j.corsci.2019.03.053

Y.Y. Zhang, J. Zhao, J.H. Li, J. Lei, X.K. Cheng, Effect of hot-dip siliconizing time on phase composition and microstructure of Mo-MoSi2 high temperature structural materials. Ceram. Int. 45(5), 5588–5593 (2019). https://doi.org/10.1016/j.ceramint.2018.12.018

M.T. Wang, Q.S. Zheng, A.Y. Chen, Y. Li, X.W. Zhang, D.L. Zhang, S. Jin, D.H. Xiong, W. Deng, Crystallization, thermal expansion and hardness of Y2O3–Al2O3–SiO2 glasses. Ceram. Int. 47(17), 25059–25066 (2021). https://doi.org/10.1016/j.ceramint.2021.05.236

A. Anagnostopoulos, A. Alexiadis, Y.L. Ding, Simplified force field for molecular dynamics simulations of amorphous SiO2 for solar applications. Int. J. Therm. Sci. 160, 106647 (2021). https://doi.org/10.1016/j.ijthermalsci.2020.106647

Y.Y. Zhang, K.K. Cui, T. Fu, J. Wang, J.M. Qie, X. Zhang, Synthesis WSi2 coating on W substrate by HDS method with various deposition times. Appl. Surf. Sci. 511, 145551 (2020). https://doi.org/10.1016/j.apsusc.2020.145551

W. Wang, B.F. Yuan, C.G. Zhou, Formation and oxidation resistance of germanium modified silicide coating on Nb based in situ composites. Corros. Sci. 80, 164–168 (2014). https://doi.org/10.1016/j.corsci.2013.11.029

B. Voglewede, V.R. Rangel, S.K. Varma, The effects of uncommon silicides on the oxidation behavior of alloys from the Nb–Cr–Si system. Corros. Sci. 61, 123–133 (2012). https://doi.org/10.1016/j.corsci.2012.04.029

T. Fu, K.K. Cui, Y.Y. Zhang, J. Wang, X. Zhang, F.Q. Shen, L.H. Yu, H.B. Mao, Microstructure and oxidation behavior of anti-oxidation coatings on Mo-Based alloys through HAPC Process: a review. Coatings 11(8), 883 (2021). https://doi.org/10.3390/coatings11080883

M. Fukumoto, Y. Matsumura, S. Hayashi, T. Narita, K. Sakamoto, A. Kasama, R. Tanaka, Coatings of Nb-based alloy by Cr and/or Al pack cementations and its oxidation behavior in Air at 1273–1473 K. Mater. Trans. 44(4), 731–735 (2003). https://doi.org/10.2320/matertrans.44.731

Y.Q. Qiao, M.Y. Li, X.P. Guo, Development of silicide coatings over Nb–NbCr2 alloy and their oxidation behavior at 1250 °C. Surf. Coat. Technol. 285, 921–930 (2014). https://doi.org/10.1016/j.surfcoat.2014.07.058

Y. Liu, W. Shao, C.L. Wang, C.G. Zhou, Microstructure and oxidation behavior of Mo-Si-Al coating on Nb-based alloy. J. Alloy. Compd. 735, 2247–2255 (2018). https://doi.org/10.1016/j.jallcom.2017.11.339

L.F. Su, O.L. Steffes, H. Zhang, J.H. Perepezko, An ultra-high temperature Mo-Si-B based coating for oxidation protection of NbSS/Nb5Si3 composites. Appl. Surf. Sci. 337, 38–44 (2015). https://doi.org/10.1016/j.apsusc.2015.02.061

R. Sakidja, J.S. Park, J. Hamann, J.H. Perepezko, Synthesis of oxidation resistant silicide coating on Mo-Si-B alloys. Scripta Mater. 53(6), 723–728 (2005). https://doi.org/10.1016/j.scriptamat.2005.05.015

T. Tabaru, K. Shobu, H. Hirai, S. Hanada, Influences of Al content and secondary phase of Mo5(Si, Al)3 on the oxidation resistance of Al-rich Mo(Si, Al)2-base composites. Intermetallics 11(7), 721–733 (2003). https://doi.org/10.1016/S0966-9795(03)00072-4

M.Z. Alam, B. Venkataraman, B. Sarma, D.K. Das, MoSi2 coating on Mo substrate for short-term oxidation protection in air. J. Alloy. Compd. 487(1), 335–340 (2009). https://doi.org/10.1016/j.jallcom.2009.07.141

J.Y. Wu, W. Wang, C.G. Zhou, Microstructure and oxidation resistance of Mo–Si–B coating on Nb based in situ composites. Corros. Sci. 87, 421–426 (2014). https://doi.org/10.1016/j.corsci.2014.07.006

P. Ritt, R. Sakidja, J.H. Perepezko, Mo–Si–B based coating for oxidation protection of SiC-C composites. Surf. Coat. Technol. 206(19–20), 4166–4172 (2012). https://doi.org/10.1016/j.surfcoat.2012.04.016

T. Feng, H.J. Li, X.H. Shi, X. Yang, Y.X. Li, X.Y. Yao, Sealing role of B2O3 in MoSi2–CrSi2–Si/B-modified SiC coating for C/C composites. Corros. Sci. 60, 4–9 (2012). https://doi.org/10.1016/j.corsci.2012.04.018

C. Wang, W. Shao, W. Wang, C. Zhou, Oxidation behaviour of a Ge-modified silicide coating on an Nb-Si based alloy in the moderate temperature range. Corros. Sci. 163, 108249 (2020). https://doi.org/10.1016/j.corsci.2019.108249

L.R. Xiao, X.J. Zhou, Y.F. Wang, R. Pu, G. Zhao, Z.Q. Shen, Y.L. Huang, S.N. Liu, Z.Y. Cai, X.J. Zhao, Formation and oxidation behavior of Ce-modified MoSi2-NbSi2 coating on niobium alloy. Corros. Sci. 173, 108751 (2020). https://doi.org/10.1016/j.corsci.2020.108751

Z. Cai, D. Zhang, X. Chen, Y. Huang, Y. Peng, C. Xu, S. Huang, R. Pu, S. Liu, X. Zhao, L. Xiao, A novel ultra-high-temperature oxidation protective MoSi2-TaSi2 ceramic coating for tantalum substrate. J. Eur. Ceram. Soc. 39(7), 2277–2286 (2019). https://doi.org/10.1016/j.jeurceramsoc.2019.02.037

V. Sreedhar, J. Das, R. Mitra, S.K. Roy, Influence of superficial CeO2 coating on high temperature oxidation behavior of Ti–6Al–4V. J. Alloy. Compd. 519, 106–111 (2012). https://doi.org/10.1016/j.jallcom.2011.12.118

W. Wang, C.G. Zhou, Characterization of microstructure and oxidation resistance of Y and Ge modified silicide coating on Nb-Si based alloy. Corros. Sci. 110, 114–122 (2016). https://doi.org/10.1016/j.corsci.2016.04.026

S. Majumdar, P. Sengupta, G.B. Kale, I.G. Sharma, Development of multilayer oxidation resistant coatings on niobium and tantalum. Surf. Coat. Technol. 200(12–13), 3713–3718 (2006). https://doi.org/10.1016/j.surfcoat.2005.01.034

B. Zhang, W. Song, L. Wei, Y. Xiu, H. Xu, D.B. Dingwell, H. Guo, Novel thermal barrier coatings repel and resist molten silicate deposits. Scripta Mater. 163, 71–76 (2019). https://doi.org/10.1016/j.scriptamat.2018.12.028

Q.Y. Hou, W. Shao, M.F. Li, C.G. Zhou, Interdiffusion behavior of Mo-Si-B/Al2O3 composite coating on Nb-Si based alloy. Surf. Coat. Technol. 401, 126243 (2020). https://doi.org/10.1016/j.surfcoat.2020.126243

C.L. Yeh, Y.H. Wang, Formation of zirconium silicide–Al2O3 composites from PTFE-assisted ZrO2/Si/Al combustion synthesis. Vacuum 184, 109877 (2021). https://doi.org/10.1016/j.vacuum.2020.109877

K.K. Cui, T. Fu, Y.Y. Zhang, J. Wang, H.B. Mao, T.B. Tan, Microstructure and mechanical properties of CaAl12O19 reinforced Al2O3-Cr2O3 composites. J. Eur. Ceram. Soc. 41(15), 7935–7945 (2021). https://doi.org/10.1016/j.jeurceramsoc.2021.08.024

Y.Q. Qiao, J.P. Kong, Q. Li, X.P. Guo, Comparison of two kinds of Si–B–Y co-deposition coatings on an Nb-Ti-Si based alloy by pack cementation method. Surf. Coat. Technol. 327, 93–100 (2017). https://doi.org/10.1016/j.surfcoat.2017.07.013

T. Fu, K.K. Cui, Y.Y. Zhang, J. Wang, F.Q. Shen, L.H. Yu, J.M. Qie, X. Zhang, Oxidation protection of tungsten alloys for nuclear fusion applications: a comprehensive review. J. Alloy. Compd. 884, 161057 (2021). https://doi.org/10.1016/j.jallcom.2021.161057

Y. Zhang, L. Yu, T. Fu, J. Wang, F. Shen, K. Cui, H, Wang, Microstructure and oxidation resistance of Si-MoSi2 ceramic coating on TZM (Mo-0.5 Ti-0.1 Zr-0.02 C) alloy at 1500° C. Surf. Coat. Technol. 431, 128037 (2022). https://doi.org/10.1016/j.surfcoat.2021.128037

K. Cui, Y. Zhang, T. Fu, J. Wang, X. Zhang, Toughening mechanism of mullite matrix composites: a review. Coatings 10(7), 672 (2020). https://doi.org/10.3390/coatings10070672

M. Sankar, V.S. Prasad, R.G. Baligidad, M.Z. Alam, D.K. Das, A.A. Gokhale, Microstructure, oxidation resistance and tensile properties of silicide coated Nb-alloy C-103. Mater. Sci. Eng. A 645, 339–346 (2015). https://doi.org/10.1016/j.msea.2015.07.063

Funding

This work was supported by the Anhui Province Science Foundation for Excellent Young Scholars (2108085Y19) and the National Natural Science Foundation of China (No. 51604049).

Author information

Authors and Affiliations

Contributions

The manuscript was written through contributions of all authors. YYZ: Conceptualization, Investigation, and Supervision. YYZ and TF: Writing original draft and image processing. TF, KKC, and JW: Validation, Resources, Investigation, Writing—review and editing. XZ, KCZ, LHY and FQS: Visualization, Writing—review and editing. All authors have given approval to the final version of the manuscript.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Y., Fu, T., Yu, L. et al. Anti-Corrosion Coatings for Protecting Nb-Based Alloys Exposed to Oxidation Environments: A Review. Met. Mater. Int. 29, 1–17 (2023). https://doi.org/10.1007/s12540-022-01222-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01222-8