Abstract

Settlement during an earthquake occurs due to the permanent change in volume, which reduces the shear strength of the soil. Reduction of shear strength in soil leads to considerable damage in pile-supported structures due to the generation of extra lateral loads to piles by lateral movement of loose soil. Tests were carried out to examine the behavior of the pile foundation in colloidal silica treated sand under the application of vertical, lateral, and combined loading conditions at different initial relative densities. Dry sand (untreated), fully saturated sands (untreated), and colloidal silica treated sands were used to examine the property enhancement of colloidal silica sand under different load conditions. PLAXIS 3D geotechnical professional software was used for the numerical analysis of the tests mentioned above. The soil parameters, as well as the pile considerations which were obtained from the laboratory, were used in the present analysis. The numerical results obtained from the investigations were similar to the experimental test results for all the loading cases. Colloidal silica stabilization in sand increases the vertical, lateral, and combined loading capacity of the pile. The pile bending moment of the colloidal silica treated sands was lower than untreated sands. Results indicated that colloidal silica treatment could be an effective ground improvement technique to enhance the vertical and lateral load-carrying capacity of the pile.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Foundation resting on soil plays an essential part in the safety and efficiency of different structures, including buildings, dams, bridges, tunnels, and pavements. The catastrophic failure of foundations in these structures due to vibrations and earthquakes causes severe damages to mankind and property. Hence, proper care should be taken while constructing the foundation in poor soil and earthquake-prone areas. In general, earthquake triggers settlement, which produces landslides, surface rupture, ground amplification, and variations in ground surface motions (Kramer 1996; Wang et al. 2017). So, earthquake-resistant structures, as well as foundations, are essential criteria to be evaluated at present. Liquefaction induced lateral spreading is a phenomenon that occurs in saturated or partially saturated soil when the strength and stiffness of soil are reduced by earthquake shaking or other rapid loading leading to the liquid-like behavior of sand.

Pile foundations support the construction and transfer the load at the desired depth, either by end-bearing or skin friction. Lateral spreading reduces the stiffness and strength of the soil during lateral spreading is the main difficulty associated with the pile foundation after an earthquake (Finn 2005; Shanker et al. 2007; Haldar and Babu 2010; Haskell et al. 2013). The failure modes of a pile foundation are very complex during an earthquake due to ground motions (Makris and Gazetas 1992; Guin and Banerjee 1998; Boulanger et al. 1999; Curras et al. 2001; Bhattacharya et al. 2004; Dash et al. 2010; Finn 2015). The failure mechanisms of pile foundations are mainly due to bending, buckling, shear, and settlement. The performance of pile behavior under lateral spreading thus remains a topic of considerable research interest. During lateral spreading, the failure of the pile foundation was due to the combined action of buckling and bending (Abdoun et al. 2003; Bhattacharya et al. 2003, 2004, 2005; Triantafyllidis et al. 2004). Excessive settlements, along with additional stresses, may develop on the pile due to movements in soil caused by the lateral forces. These might reduce the stability and thus destruct the serviceability of pile foundation-supported structures in unpredictable situations. So, it is essential to evaluate the axial and lateral load in pile foundation during earthquake-induced settlements. Various situations in which pile foundation is subjected to lateral spreading are next to deep excavations or embankment structures, piles next to the pile installation jobs, and tunnel construction. Abdoun et al. (2003) reported that the final bending moment in a pile foundation appeared at the boundaries of liquefied and non-liquefied layers.

Damage induced by a reduction in shear strength to ground commonly comprises foundation settlement and lateral spreading (Iwasaki 1986; Berrill et al. 2001; Takahashi 2002; Cubrinovski et al. 2012; Tamura 2014; Yang et al. 2018). Many researchers have conducted experimental studies on untreated sands to examine the behavior of pile foundations during lateral spreading (Bhattacharya et al. 2004; Kagawa et al. 2004; Brandenberg et al. 2005; Dungca et al. 2006; Motamed and Towhata 2010; Motamed et al. 2010). Bhattacharya et al. (2004) studied an alternative mechanism of pile failure in loose sand deposits during earthquakes. They introduced a new parameter called the slenderness ratio of a pile to classify the pile performance in such soils. Kagawa et al. (2004) studied the centrifuge simulations of large-scale shaking table tests. They reported that carefully designed centrifuge tests could reproduce the key features of the responses of the large-scale models. Brandenberg et al. (2005) considered the behavior of pile foundations in laterally spreading ground during centrifuge tests. They evaluated procedures for estimating the total horizontal loads on embedded piles and pile caps. Dungca et al. (2006) conducted shaking table tests on a pile buried in sand to study the lateral response. They noticed that the cylinder displacement required for the lateral resistance becomes smaller with the increase in loading rate. Motamed and Towhata (2010) conducted shaking table model tests on pile groups behind quay walls subjected to lateral spreading. They noticed that displacement and velocity of soil are the most critical parameters that affect the distribution of the lateral forces in the group pile, and these two parameters are highly dependent on the configuration of the ground. Experimental modeling of large pile groups was done by Motamed et al. (2010), conducted model tests on pile groups subjected to lateral flow in sloping ground. They reported that factors such as amplitude, frequency, and direction of input motion should be considered for analysis and design purposes. Furthermore, the density, slope of the ground and the thickness of a nonliquefiable layer at the surface were significant for the analysis and design purposes.

Soil stabilization methods by grouting and by introducing geotextiles are used to improve the structural and mechanical properties of sand. The various grouting techniques can be classified as cement grouting, clay grouting, chemical grouting, chrome-lignin grouting, polymer grouting, and bituminous grouting. Chemical grouting of the foundation soil is considered to be a potential tool to improve the strength, permeability, durability, and compressibility of native soil, thereby safeguard the building above it (Han et al. 2007; Anagnostopoulos et al. 2011; Homauoni and Yasrobi 2011; Ajalloeian et al. 2013; Zang et al. 2015). Gallagher and Mitchell (2002) introduced a new concept called passive site stabilization to mitigate liquefaction during earthquakes in existing buildings. Passive site stabilization is a nondisruptive mitigation method introduced in areas that are vulnerable to settlement. The stabilization is executed by injecting a stabilizing material slowly at the upgradient edge of a site and delivering the stabilizer to the liquefiable area using the groundwater flow augmented by injection and extraction wells. The innovative chemicals for stabilization are polyester, colloidal silica, acrylate, red mud, polyvinyl acetate, epoxy resin, and polyurethane (Han 2004; Pamuk et al. 2007; Lim et al. 2009; Mollamahmutoglu and Yilmaz 2009; Anagnostopoulos et al. 2011, 2014; Ajalloeian et al. 2013; S. Mohammed et al. 2015; Çelik et al. 2019; Chhun et al. 2019). Due to the researches mentioned above, colloidal silica has become popular among researchers for soil stabilization because of its low viscosity and its capacity for managing gel time (Pamuk et al. 2007; Conlee et al. 2012; Hamderi and Gallagher 2015; Moradi and Seyedi 2015; Vranna and Tika 2015; Georgiannou et al. 2017; Nouri Delavar and Noorzad 2017; Wong et al. 2018; Krishnan and Shukla 2019; Krishnan et al. 2020). Many researchers studied the static and dynamic behavior of colloidal silica treated sand, but pile behavior in such treated soils has not received enough attention. However, Pamuk et al. (2007) have conducted some physical modeling tests in deep foundation rested on colloidal silica treated sand. They noticed that treatment with dilute colloidal silica stabilizer minimized permanent lateral deformations and reduced the liquefaction potential of the colloidal silica treated soil. Most of the previous studies concentrated only on liquefaction mitigation in general. However, overlooking building tilt failure due to settlement of pile foundation is more important considering the damages.

The present study was conducted to overcome the gap in pile behavior in past research works. The performance under a vertical and then lateral load was adapted to provide insights on the behavior of a single pile in colloidal silica treated sand. The experimental research was conducted on instrumented piles embedded in colloidal silica treated sand to examine the axial load distribution under vertical loads and bending moments under lateral loads. The present study deals with stabilization for controlling construction problems on sandy soil with low bearing capacity.

Equipment and experimental procedures

The experimental facility of the present study consists of a model tank, the prototype of the pile, load testing facilities, and essential instrumentation.

Materials used

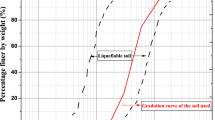

The materials used in the present study include sand, colloidal silica, and pile foundation. The properties of materials used in the present study are shown in Table 1. The sand used for the study was having an angular shape with D10 and D50 of 0.21 mm and 0.35 mm, respectively and can be classified as poorly graded sand (SP). Ludox SM colloidal silica with particle size 7 nm was used for the current study. Hydrochloric acid (0.6 N) and reagent grade NaCl (0.1N) was used for controlling the gel time of colloidal silica. The optimum colloidal silica content of 12.5, 11, and 10 wt. % of colloidal silica was used for stabilizing the sand, having initial relative densities of 30%, 40%, and 60%, respectively, as per studies conducted by Krishnan et al. (2020).

All the tests were conducted after a curing period of 7 days. Any substantial increment in strength was not reported after 7 days of curing in colloidal silica treated sand in the previous research (Krishnan et al. 2020). The pile prototypes are made of steel. The physical and mechanical properties of the steel were obtained by utilizing the universal testing machine. A pile diameter of 20 mm was used in the present work to avoid the dilatancy effects associated with smaller diameter piles. ASTM (2011) recommends that the minimum specimen diameter for circular specimens should not be less than ten times the maximum particle size to avoid the size effects. The sand used for the model testing was sieved through a 2 mm sieve, and the grain size distribution curve is shown in Fig. 1. The structural dimension (diameter) of the pile was kept 20–30 times larger than the mean particle size of the soil particles (Nunez 1988).

Test soil description and sand distribution system

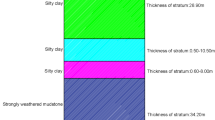

The performance of a single pile under vertical and lateral loading was studied using a model tank made of steel. All tests (27) were performed on a single pile foundation on sand having three different initial relative densities (30%, 40%, and 60%). The experimental tests were conducted on a single pile under vertical loads, lateral loads, and combined vertical and lateral loads applied to the pile head at ground elevation. For the computation of settlements of foundations, evaluation of the vertical load is necessary. Prototypes for the experiment, i.e., pile foundation, were fabricated with steel. The pile foundation was equipped with strain gages at five different heights (top, bottom, and middle) to measure the axial forces and bending moment during loading. The strain gage was covered with waterproof material to prevent it from damaging and as a moisture barrier. The dimension of the tank for the model testing was selected so that the boundary of the model tank is more than the active stress zone of the soil mass. The depth of boundary should be two times greater than the pile length, and the diameter of the tank should be at least ten times higher than the pile diameter (Matlock 1970; Narasimha Rao et al. 1998; Horikoshi and Randolph 1999; Lee 2002; Lee et al. 2010). All the laboratory model tests were conducted in a tank with an internal diameter of 300 mm and a height of 600 mm. In the present study, the model tank dimensions were chosen according to the boundary conditions mentioned above. The sand was filled in the test tank by sand pluviation using stationary pluviators by maintaining a fixed height of fall during pluviation. In order to achieve the appropriate relative density, sand was filled in layers in which each layer was divided into a thickness of 50 mm. Relative densities from 30 to 100 % are easily achievable using this technique (Okamoto and Fityus 2006; Hariprasad et al. 2016; Tabaroei et al. 2017).

In order to fix the height of the fall of sand in the tank for different relative densities, a series of preliminary tests were also performed. For the initial tests, a pouring cylinder having internal dimensions 101.6 mm × 152.4 mm, as shown in Fig. 2, was used. The height of fall was maintained until the collecting jar was filled, and the excess soil was then scrapped off to level the surface and calculated for three different relative densities (Fig. 3). The height of fall was maintained by attaching a scale to the cylinder's extension pipe. The tests were performed at different heights of fall, and independent tests were done (7–10 times) with the same method to calculate the repeatability and ensure the observed falling height of sand. The height of fall method was more manageable and repeatable to provide accurate results. Drop height, and the rate of pouring of sand particles are the various factors that influence the density achieved through pluviation (Hariprasad et al. 2016). Therefore, the current study uses dropping sand from a predefined height of fall to develop uniform sand layers. The saturation process of untreated sand was done by adding 25% of water (precalculated for saturated condition) to the tank before pouring the sand. Sand was then poured loosely into the water using the wet pluviation method.

The loading structure comprised of 1500 mm height vertical columns, two on each side and connected with two parallel beams. The horizontal shaft was also incorporated with a multi loading testing machine and a pre-calibrated load cell fixed at the center of the loading frame. LVDTs were placed along the outer peripheries of the loading platform to measure the vertical displacements on the pile foundation. After filling the sand to a certain height (50 mm from top), the pile foundation was placed in a vertical position. Extreme care was taken to ensure the penetration of the pile foundation to 2–5 mm to make sure the proper seating to keep the piles in position until the tank was completely filled. Later, the load was applied to the loading plate at a strain rate of 1.5 mm/min (Chen 1999). The failure loads were considered to have a close similarity to a settlement of 10% of the pile diameter. The tests were repeated three times to authenticate the repeatability and reliability of the analysis obtained from the experimental model. The measurement devices such as LVDT, load cell, strain gages were connected to data logging systems. The strain gages in the instrumented pile were connected to 16 channel strain indicators to record the strain values. The test setup is shown in Fig. 4.

Dry sand (untreated), fully saturated sands (untreated), and colloidal silica treated sands are used to examine the property enhancement of colloidal silica sand under vertical and then lateral load. Saturation of the specimen was ensured by adding 25% water to sand having different initial relative densities, and densities refer to the initial densities after specimen preparations. 25% of water content was obtained by substituting Sr=100% (i.e., fully saturated condition) by using the equation shown below.

where,

- w:

-

water content

- e:

-

void ratio

- Sr:

-

degree of saturation (Kept 100% to ensure saturation)

- G:

-

specific gravity

Colloidal silica treated sample preparation was conducted as per the procedures given by Krishnan et al. (2020). The sample preparation technique adopted in the present study involved the pluviation of dry sand into the colloidal silica solution. In order to thoroughly saturate the sample, the volume of colloidal silica solution (required weight %) added to sand was equal to the volume of void spaces of the sample. In treated samples, the soil voids were completely filled with colloidal silica solution. Colloidal silica treatment reduced the settlement in loose saturated samples (Pamuk et al. 2007; Conlee et al. 2012; Krishnan et al. 2020). In order to have a better understanding of such responses, the current study also compares the results of saturated untreated specimens with colloidal silica treated specimens. A total of 27 tests were examined in the laboratory.

FEM simulations

Mohr-Coulomb material model was quantitatively compared to experiments performed in the laboratory. Within the Mohr-Coulomb framework, the soil was modeled as an elastoplastic material. Various researchers recommend Mohr-Coulomb models due to its accuracy, simplicity and applicability (Chen et al. 1983; Johnson et al. 2006; Mendoza et al. 2017). Geotechnical Finite Element Software PLAXIS 3D was used to compare the experimental results. Trial analyzes were conducted with increasing mesh dimensions and mesh density to determine the best fit mesh and density for the study.

Furthermore, it was observed that the standard fine meshing was adequate to capture the settlement behaviors by conducting trial analysis with increasing mesh dimensions and mesh density. An element of the interface was also applied to simulate the interaction between the pile and soil. The analysis of the model started when the geometry was created and loads were applied. Thus, the same load test results were extended to simulate the load-settlement behavior of pile using the Plaxis 3D approach. The optimum values of colloidal silica for sand with initial relative densities of 30%, 40%, and 60% was 12.5 wt. %, 11 wt. %, and 10 wt. %, respectively. Any substantial increment in strength was not reported after 7 days of curing in colloidal silica treated sand. Therefore, the present research adopted a curing time of 7 days for all tests in colloidal silica treated sand. The reference confining pressure of 100 kPa was considered from the unconsolidated undrained triaxial tests from which the mechanical parameters such as ɸ, c, and E were obtained (Krishnan et al. 2020). The input parameters used in the current study for sand with three different initial relative densities (RD) are presented in Table 2. A weight density of 92 kN/m3, a Young's Modulus of 200 GPa, Shear modulus of 79.30 GPa, and a Poisson's ratio of 0.30 were used for the steel pile.

Results and discussions

Soil behavior during vertical loading

The variation of the vertical load with pile in untreated and colloidal silica treated sand was studied in the present research and explained in the current section. The results showed that the vertical load-bearing capacity of the foundation increases with the increase in initial relative densities of untreated dry sand (Fig. 5a). At a load of 0.2 kN, the settlement decreases from 1.5 to 0.5 mm when the relative density increases from 30% to 40%. On the other hand, a negligible settlement was observed for 60% relative density sand for the load of 0.2 kN. The same pattern was observed in the variation of the load-carrying capacity of untreated saturated sand at different relative densities (Fig. 5b). The bearing capacity of the foundation increases with the increase in relative densities of untreated saturated sand.

At a 2 mm settlement, the load-carrying capacity of untreated dry sand having a relative density of 30% was 0.24 kN. The load-bearing capacity for a sample having a relative density of 40% and 60% was 0.41 kN and 0.63 kN, respectively.

Treatment with the optimum amount of colloidal silica at different initial relative densities showed a substantial increment in load-carrying capacities for all relative densities (Fig. 5c). The treatment of colloidal silica increases the load-carrying capacity to 1.15 kN at the same settlement of 2 mm. For a sample having 40%, 60% initial relative densities, the load-carrying capacity increases to 1.66 kN, and 1.95 kN in the colloidal silica treated samples. Also, the load-carrying capacity was increased by a factor of 5, 4, and 3 for sand having initial relative densities of 30%, 40%, and 60% with the treatment of colloidal silica.

The influence of colloidal silica treatment on load settlement curves of the 40RD sand sample is shown in Fig. 5d. A relatively higher gain in the bearing capacity during the treatment with colloidal silica was observed in loose sands compared to sand samples having higher densities. The comparison of the ultimate vertical load-carrying capacity of sands having three different initial relative densities is shown in Fig. 6.

Soil behavior during lateral loading

The variation of the lateral load with pile in untreated as well as colloidal silica treated sand was studied in the present research and is explained in the current section. The results showed that the bearing capacity of the foundation increases during lateral loading with the relative density of untreated dry sand (Fig. 7a). In the case of untreated saturated sand, the lateral load-carrying capacity is lower than that of untreated dry sand (Fig. 7b). However, the bearing capacity of the foundation increases with the relative density of untreated saturated sand. This could be due to the reduction in soil strength in untreated saturated soil with the application of lateral load. The soil particles move apart with the application of lateral load, which was unable to support the lateral readjustment of soil due to the presence of water. At a 2 mm settlement, the load-carrying capacity of untreated dry sand having relative densities of 30%, 40%, and 60% was 0.10 kN, 0.11 kN, and 0.15 kN, respectively.

Also, treating sand with colloidal silica reduced the settlement. Treatment with colloidal silica at different initial relative densities showed a substantial increment in load-carrying capacity (Fig. 7c). At a 2 mm settlement, the load-carrying capacity of colloidal silica treated sand with initial relative densities of 30%, 40%, and 60% was 0.18 kN, 0.21 kN, and 0.28 kN, respectively for 2 mm settlement. Therefore, the lateral load-carrying capacity was evidently increased by a factor of 1.8, 1.9, and 1.9 for sand having initial relative densities of 30%, 40%, and 60%, respectively, with the treatment of colloidal silica. The p-y curve of 30RD sand is shown in Fig. 7d. In various density conditions, almost similar gain in the bearing capacity during the treatment with colloidal silica were observed. The comparison of the horizontal ultimate load-carrying capacity of sands having three different initial relative densities is shown in Fig. 8.

Soil behavior during combined loading

It was observed that the lateral load-carrying capacity of untreated dry and untreated saturated sand increased under the application of vertical load at the pile head at all relative densities (Fig. 9a and b). Cohesion in sand increases the lateral loading capacity of sand when subjected to vertical load.

The load-carrying capacity of untreated dry sand with relative densities of 30%, 40%, and 60% was 0.11 kN, 0.155 kN, and 0.175 kN, respectively. The ultimate combined load capacity of the pile in colloidal silica treated sand at all relative densities was found to be higher with the addition of vertical load on the pile head. Treatment with colloidal silica enhances the load-bearing capacity by a factor of 2, 1.9, and 1.8 in sands having initial relative densities of 30%, 40%, and 60%, respectively. The samples with a lower relative density have a higher void ratio. So, the effect of treatment would be more for such samples, and this could be the reason why the smallest density samples showed a higher increase in load-carrying capacity. Colloidal silica treatment is considered a successful ground improvement technique to enhance the lateral load-carrying capacity of the pile with vertical load (Fig. 9c). Figure 9d shows the influence of colloidal silica treatment on combined load settlement curves of 60 RD sand samples. The comparison of the combined load-carrying capacity of sands having three different initial relative densities is shown in Fig. 10. The effect of vertical load on the pile foundation is inevitable because it induces a p-Δ moment on the pile foundation, which later reduces the lateral stiffness of the pile. Also, this could cause a significant improvement in the lateral capacity of the pile to withstand the kinematic loads from lateral spreading. The vertical load application in a pile increases the major principal stress compared to the pile under the application of pure lateral load. The increase in major principal stress increases the mobilized shear strength of the soil thus increases the resistance of the soil-pile system to lateral loading.

Bending moment

The pile was equipped with strain gages in vertical and horizontal directions to measure bending moments. The bending moment was calculated using Eq. (2). shown below

where,

- BM:

-

Bending moment

- ε:

-

strain obtained from strain gage

- EPile:

-

modulus of elasticity of pile

- IPile:

-

Area moment of inertia of the pile

- y(na):

-

neutral axis along the cross-section of pile

Strain gages were connected along the length of the pile. Strain gages used in a pile were utilized to quantify the bending moment with the addition of colloidal silica in sand. A reduction of 84%, 83%, and 82% were observed in bending moment with the addition of colloidal silica in sand having 60%, 40%, and 30% initial relative densities, respectively, during horizontal loading (Fig. 11). Colloidal silica treatment in sand generates greater soil resistance to pile deflection, thus significantly reducing the bending moment. Also, vertical load plays a significant role in the bending moment response of the pile. The application of vertical load on the pile considerably reduces the bending moment in a pile.

To examine the effect of vertical load on lateral response of a pile in untreated and colloidal silica treated sand, an experimental study on combined loading was also conducted. The comparison of maximum bending moment profiles of untreated dry sand with colloidal silica treated sand with different initial relative densities is shown in Figs. 11 and 12. A substantial reduction in the bending moment was observed in a pile for all the combined loading cases compared to horizontal loading (Fig. 12). A decrement of 58%, 54%, and 46% in the maximum bending moment was observed in the case of untreated sands having relative densities of 30%, 40%, and 60%, respectively. An increase in relative density increases the soil resistance, which thereby reduces the bending moment in a pile. On the other hand, a decrease of 28%, 23%, and 14% in the maximum bending moment was observed in treated sands with initial relative densities of 30%, 40%, and 60%, respectively. A significant reduction in bending moment in a pile could be due to the generation of soil resistance due to the colloidal silica treatment in sand. The pile bending moment of the colloidal silica treated sands was also lower than in the case of untreated sands. It was due to the advancement in properties like soil subgrade modulus and the shear strength by adding colloidal silica in sand. The increment in soil confinement during treatment reduced the bending moment. Also, with lateral load application, the soil resistance near the bottom of the pile leads to tensile stresses in the soil. Maximum bending moment in a pile occurred at a depth equivalent to twice the pile diameter since the developed bending moments were restricted to the upper part of the pile. These interpretations recommend that model test piles had a plastic hinge formation during lateral loading.

Comparison between laboratory tests and plaxis 3D analysis

The load-deflection behavior of the pile was found to be nonlinear at all loading cases: vertical, horizontal, and combined loading. It was also noted that the response of the pile was consistent at all relative densities as well. A numerical analysis was performed to compare the experimental results. The numerical results were found to be in good agreement with the experimental data, which confirms the accuracy of the numerical model predictions (Table 3). Both experimental and numerical results reveal that colloidal silica treatment in sand decreases the displacements during vertical as well as lateral loading, thus making them more suitable for soil improvement applications. Since both untreated saturated and untreated dry sand show similar results, untreated dry sand was compared with treated sand with different initial relative densities.

The numerical analysis was investigated with the help of PLAXIS 3D geotechnical professional three-dimensional finite element method software. Models for pile foundation and soils were established as per the size and material property used in the laboratory. The comparison of the load settlement curve of Plaxis 3D was in agreement with that of Laboratory model tests. The comparison of load-displacement curves obtained from experimental as well as PLAXIS 3D finite element analysis is shown in Fig. 13. The results showed that the numerical model satisfactorily predicts lateral response of bored piles in colloidal silica stabilized sand when the cohesion component of soil resistance was considered. The settlement equal to 10% of pile diameter (2 mm) was adopted to define the ultimate load-carrying capacity (Briaud 2007). As expected from the typical triaxial test results, the bonding in sand increases the lateral loading capacity of the pile. All other observations of numerical analysis and experimental test values are presented in Table 3. In all the cases, it was observed that the deviations of the values obtained by numerical and experimental methods are within a range of ±10%. Increasing the amount of colloidal silica in sand did not continuously improve the bearing capacity of sand. It is a prerequisite for engineers to minimize the cost and time before considering the ultimate bearing capacity needed for the construction. So the experimental study on load-settlement behavior of colloidal silica treated footing is essential for geotechnical researchers to improve ground economically. The colloidal silica needed for 30 RD, 40 RD, and 60 RD sand was observed to be 12.5 wt. %, 11 wt. %, and 10 wt. %, respectively, through triaxial testing by Krishnan et al. (2020) and the current study reported that colloidal silica improved the bearing capacity of the pile in colloidal silica treated sand as well.

Conclusions

This study presents a static load analysis carried out on a single pile to examine the behavior of vertical, lateral, and combined load on colloidal silica treated sand. Based on the experiments conducted in the present work, conclusions of the present study are as follows:

-

Treatment of sand with colloidal silica content increases the bearing capacity of the soil.

-

The application of vertical load increases the lateral load-carrying ability by as much as 15%, 24%, and 28% of the pile in the case of colloidal silica treated sand having initial relative densities of 30%, 40%, and 60%, respectively.

-

Treatment of sand with colloidal silica reduces the pile bending moment.

-

The pile bending moment of the colloidal silica treated sands was lower than untreated sands due to the advancement in properties like soil subgrade modulus and the shear strength.

-

Adding colloidal silica in sand increases the lateral loading capacity at the same load.

-

The effect of vertical load on the pile foundation induces a p-Δ moment on the pile foundation, which later reduces the lateral stiffness of the pile. Also, this could cause a significant improvement in the lateral capacity of the pile to withstand the kinematic loads from lateral spreading.

-

The addition of colloidal silica in sand improved the shear strength of the soil.

-

The numerical results obtained from the analysis are in good agreement with the experimental test results for all the loading cases.

-

Thus, the numerical simulations which precisely predict the results of physical experiments with the addition of colloidal silica in sand could be a strong recommendation to extend the research to field applications.

Future scope

-

Centrifuge models are recommended to evaluate the performance of the pile foundation under a vertical and lateral load in colloidal silica treated sand to validate the test results further.

-

Seismic analysis of the machine foundation in colloidal silica treated sand under simulated base shaking should be investigated in the future. It will help design the foundation soil to prevent damage occurring due to shocks and vibrations.

References

Abdoun T, Dobry R, O’Rourke TD, Goh SH (2003) Pile response to lateral spreads: centrifuge modeling. J Geotech Geoenviron Eng 129:869–878. https://doi.org/10.1061/(ASCE)1090-0241(2003)129:10(869

Ajalloeian R, Matinmanesh H, Abtahi SM, Rowshanzamir M (2013) Effect of polyvinyl acetate grout injection on geotechnical properties of fine sand. Geomech Geoengin 8:86–96. https://doi.org/10.1080/17486025.2012.705897

Anagnostopoulos CA, Papaliangas T, Manolopoulou S, Dimopoulos T (2011) Physical and mechanical properties of chemically grouted sand. Tunn Undergr Sp Technol 26:718–724. https://doi.org/10.1016/j.tust.2011.05.006

Anagnostopoulos CA, Kandiliotis P, Lola M, Karavatos S (2014) Improving properties of sand using epoxy resin and electrokinetics. Geotech Geol Eng 32:859–872. https://doi.org/10.1007/s10706-014-9763-6

ASTM (2011) D3080/D3080M-11. Standard test method for direct shear test of soils under consolidated drained conditions. ASTM Int. https://doi.org/10.1520/D3080

Berrill JB, Christensen SA, Keenan RP, Okada W, Pettinga JR (2001) Case study of lateral spreading forces on a piled foundation. Geotechnique. 51:501–517. https://doi.org/10.1680/geot.2001.51.6.501

Bhattacharya S, Madabhushi SPG, Bolton M (2003) Pile Instability during Earthquake Liquefaction

Bhattacharya S, Madabhushi SPG, Bolton MD (2004) An alternative mechanism of pile failure in liquefiable deposits during earthquakes. Geotechnique. 54:203–213. https://doi.org/10.1680/geot.2004.54.3.203

Bhattacharya S, Bolton MD, Madabhushi SPG (2005) A reconsideration of the safety of piled bridge foundations in liquefiable soils. Soils Found 45:13–25

Boulanger RW, Curras CJ, Kutter BL, Wilson DW, Abghari A (1999) Seismic soil-pile-structure interaction experiments and analyses. J Geotech Geoenviron Eng 125:750–759. https://doi.org/10.1061/(ASCE)1090-0241(1999)125:9(750

Brandenberg SJ, Boulanger RW, Kutter BL, Chang D (2005) Behavior of pile foundations in laterally spreading ground during centrifuge tests. J Geotech Geoenviron Eng 131:1378–1391. https://doi.org/10.1061/(ASCE)1090-0241(2005)131:11(1378

Briaud JL (2007) Spread footings in sand: load settlement curve approach. J Geotech Geoenvironmental Eng. https://doi.org/10.1061/(ASCE)1090-0241(2007)133:8(905)

Çelik S, Majedi P, Akbulut S (2019) Granular soil improvement by using polyester grouts. Iran J Sci Technol Trans Civ Eng 43:599–606. https://doi.org/10.1007/s40996-018-0203-3

Chen FH (1999) Soil engineering: testing, design, and remediation. CRC Press; 1st edition

Chen WF, Saleeb AF, Dvorak GJ (1983) Constitutive Equations for Engineering Materials, Volume I: Elasticity and Modeling. J Appl Mech 50:703. https://doi.org/10.1115/1.3167127

Chhun KT, Lee SH, Keo SA, Yune CY (2019) Effect of Acrylate-Cement Grout on the Unconfined Compressive Strength of Silty Sand. KSCE J Civ Eng 23:2495–2502. https://doi.org/10.1007/s12205-019-1968-z

Conlee CT, Gallagher PM, Boulanger RW, Kamai R (2012) Centrifuge modeling for liquefaction mitigation using colloidal silica stabilizer. J Geotech Geoenviron Eng 138:1334–1345. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000703

Cubrinovski M, Robinson K, Taylor M, Hughes M, Orense R (2012) Lateral spreading and its impacts in urban areas in the 2010-2011 Christchurch earthquakes New Zeal. J Geol Geophys 55:255–269. https://doi.org/10.1080/00288306.2012.699895

Curras CJ, Boulanger RW, Kutter BL, Wilson DW (2001) Dynamic experiments and analyses of a pile-group-supported structure. J Geotech Geoenviron Eng 127:585–596. https://doi.org/10.1061/(ASCE)1090-0241(2001)127:7(585

Dash SR, Bhattacharya S, Blakeborough A (2010) Bending-buckling interaction as a failure mechanism of piles in liquefiable soils. Soil Dyn Earthq Eng 30:32–39. https://doi.org/10.1016/j.soildyn.2009.08.002

Dungca JR, Kuwano J, Takahashi A, Saruwatari T, Izawa J, Suzuki H, Tokimatsu K (2006) Shaking table tests on the lateral response of a pile buried in liquefied sand. Soil Dyn Earthq Eng 26:287–295. https://doi.org/10.1016/j.soildyn.2005.02.021

Finn WDL (2005) A study of piles during earthquakes: issues of design and analysis. Bull Earthq Eng 3:141–234. https://doi.org/10.1007/s10518-005-1241-3

Finn WDL (2015) 1st Ishihara Lecture: an overview of the behavior of pile foundations in liquefiable and non-liquefiable soils during earthquake excitation. Soil Dyn Earthq Eng 68:69–77. https://doi.org/10.1016/j.soildyn.2014.09.009

Gallagher PM, Mitchell JK (2002) Influence of colloidal silica grout on liquefaction potential and cyclic undrained behavior of loose sand. Soil Dyn Earthq Eng 22:1017–1026

Georgiannou VN, Pavlopoulou E-MM, Bikos Z (2017) Mechanical behaviour of sand stabilised with colloidal silica. Geotech Res 4:1–11. https://doi.org/10.1680/jgere.16.00017

Guin J, Banerjee PK (1998) Coupled soil-pile-structure interaction analysis under seismic excitation. J Struct Eng 124:434–444. https://doi.org/10.1061/(ASCE)0733-9445(1998)124:4(434

Haldar S, Babu GLS (2010) Failure mechanisms of pile foundations in liquefiable soil: parametric study. Int J Geomech 10:74–84. https://doi.org/10.1061/(ASCE)1532-3641(2010)10:2(74

Hamderi M, Gallagher PM (2015) Pilot-scale modeling of colloidal silica delivery to liquefiable sands. Soils Found 55:143–153. https://doi.org/10.1016/j.sandf.2014.12.011

Han TC (2004) Gel time of calcium acrylate grouting material. J Zhejiang Univ (Sci) 5:928–931. https://doi.org/10.1631/jzus.2004.0928

Han Z, Wang T, Dong Z, Hu Y, Yao Z (2007) Chemical stabilization of mobile dunefields along a highway in the Taklimakan Desert of China. J Arid Environ 68:260–270. https://doi.org/10.1016/j.jaridenv.2006.05.007

Hariprasad C, Rajashekhar M, Umashankar B (2016) Preparation of Uniform Sand Specimens Using Stationary Pluviation and Vibratory Methods. Geotech Geol Eng 34:1909–1922. https://doi.org/10.1007/s10706-016-0064-0

Haskell JJM, Madabhushi SPG, Cubrinovski M, Winkley A (2013) Lateral spreading-induced abutment rotation in the 2011 Christchurch earthquake: observations and analysis. Geotechnique. 63:1310–1327. https://doi.org/10.1680/geot.12.P.174

Homauoni ZJ, Yasrobi SS (2011) Stabilization of Dune Sand with Poly(Methyl Methacrylate) and Polyvinyl Acetate Using Dry and Wet Processing. Geotech Geol Eng 29:571–579. https://doi.org/10.1007/s10706-011-9404-2

Horikoshi K, Randolph MF (1999) Estimation of overall settlement of piled rafts. Soils Found 39:59–68. https://doi.org/10.3208/sandf.39.2_59

Iwasaki T (1986) Soil liquefaction studies in Japan: state-of-the-art. Soil Dyn Earthq Eng 5:2–68. https://doi.org/10.1016/0267-7261(86)90024-2

Johnson K, Lemcke P, Karunasena W, Sivakugan N (2006) Modelling the load-deformation response of deep foundations under oblique loading. Environ Model Softw 21:1375–1380. https://doi.org/10.1016/j.envsoft.2005.04.015

Kagawa T, Sato M, Minowa C, Abe A, Tazoh T (2004) Centrifuge simulations of large-scale shaking table tests: case studies. J Geotech Geoenviron Eng 130:663–672. https://doi.org/10.1061/(ASCE)1090-0241(2004)130:7(663

Kramer SL (1996) Geotechnical Earthquake Engineering. Prentice Hall

Krishnan J, Shukla S (2019) The behaviour of soil stabilised with nanoparticles: an extensive review of the present status and its applications. Arab J Geosci 12:436. https://doi.org/10.1007/s12517-019-4595-6

Krishnan J, Sharma P, Shukla S, Pancholi V, Dwivedi VK (2020) Cyclic Behaviour and Durability Analysis of Sand Grouted with Optimum Colloidal Silica Content. Arab J Sci Eng 45:8129–8144. https://doi.org/10.1007/s13369-020-04643-y

Lee CY (2002) Discrete layer analysis of laterally loaded piles. Electron J Geotech Eng

Lee JH, Kim Y, Jeong S (2010) Three-dimensional analysis of bearing behavior of piled raft on soft clay. Comput Geotech 37:103–114. https://doi.org/10.1016/j.compgeo.2009.07.009

Lim SK, Hussin MW, Zakaria F, Ling TC (2009) GGBFS as potential filler in polyester grout: flexural strength and toughness. Constr Build Mater 23:2007–2015. https://doi.org/10.1016/j.conbuildmat.2008.08.030

Makris N, Gazetas G (1992) Dynamic pile-soil-pile interaction. Part II: lateral and seismic response. Earthq Eng Struct Dyn 21:145–162. https://doi.org/10.1002/eqe.4290210204

Matlock H (1970) Correlations for design of laterally loaded piles in soft clay. In: Proceedings of the Annual Offshore Technology Conference

Mendoza CC, Caicedo B, Cunha R (2017) Determination of Vertical Bearing Capacity of Pile Foundation Systems in Tropical Soils with Uncertain and Highly Variable Properties. J Perform Constr Facil 31:04016068. https://doi.org/10.1061/(ASCE)CF.1943-5509.0000918

Mohammed SN, Abdul Rahman AB, Nur NH (2015) Polyester grout incorporating fly ash as potential infill material for grouted connections. J Teknol. https://doi.org/10.11113/jt.v77.6309

Mollamahmutoglu M, Yilmaz Y (2009) Pre- and post-cyclic loading strength of silica-grouted sand. Proc Inst Civ Eng - Geotech Eng:343–348. https://doi.org/10.1680/geng.2010.163.6.343

Moradi G, Seyedi S (2015) Effect of sampling method on strength of stabilized silty sands with colloidal nano silica. J Civ Eng Res. https://doi.org/10.5923/j.jce.20150506.01

Motamed R, Towhata I (2010) Shaking table model tests on pile groups behind quay walls subjected to lateral spreading. J Geotech Geoenviron Eng 136:477–489. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000115

Motamed R, Sesov V, Towhata I, Anh NT (2010) Experimental modeling of large pile groups in sloping ground subjected to liquefaction-induced lateral flow: 1-g shaking table tests. Soils Found 50:261–279. https://doi.org/10.3208/sandf.50.261

Narasimha Rao S, Ramakrishna VGST, Babu Rao M (1998) Influence of rigidity on laterally loaded pile groups in marine clay. J Geotech Geoenviron Eng. https://doi.org/10.1061/(ASCE)1090-0241(1998)124:6(542

Nouri Delavar I, Noorzad R (2017) Drained shear strength parameters of silty sand grouted by colloidal silica. Int. J. Geotech. Eng.

Nunez IL (1988) Driving and tension loading of piles in sand on a centrifuge. Proc Int Conf Centrifuge 88, Paris, Corté, J F (ed), Balkema, Rotterdam 353–362

Okamoto M, Fityus S (2006) An evaluation of the dry pluviation preparation technique applied to silica sand samples. In: Proceedings of the International Symposium on Geomechanics and Geotechnics of Particulate Media - Geomechanics and Geotechnics of Particulate Media

Pamuk A, Gallagher PM, Zimmie TF (2007) Remediation of piled foundations against lateral spreading by passive site stabilization technique. Soil Dyn Earthq Eng 27:864–874. https://doi.org/10.1016/j.soildyn.2007.01.011

Shanker K, Basudhar PK, Patra NR (2007) Buckling of piles under liquefied soil conditions. Geotech Geol Eng 25:303–313. https://doi.org/10.1007/s10706-006-9111-6

Tabaroei A, Abrishami S, Hosseininia ES (2017) Comparison between Two Different Pluviation Setups of Sand Specimens. J Mater Civ Eng 29:04017157. https://doi.org/10.1061/(asce)mt.1943-5533.0001985

Takahashi A (2002) Soil—pile interaction in liquefaction-induced lateral spreading of soils. PhD Dissertation at Tokyo Institute Of Technology

Tamura K (2014) Seismic design of highway bridge foundations with the effects of liquefaction since the 1995 Kobe earthquake. Soils Found 54:874–882. https://doi.org/10.1016/j.sandf.2014.06.017

Triantafyllidis T, Bhattacharya S, Bolton M (2004) Pile failure during seismic liquefaction —theory and practice. In: Cyclic Behaviour of Soils and Liquefaction Phenomena. Bochum, Germany, 31st Mar-2nd Apr

Vranna AD, Tika T (2015) The mechanical behaviour of a clean sand stabilized with colloidal silica. In: Geotechnical Engineering for Infrastructure and Development - Proceedings of the XVI European Conference on Soil Mechanics and Geotechnical Engineering, ECSMGE 2015. ICE Publishing, pp 3443–3448

Wang Z, Carpenter NS, Zhang L, Woolery EW (2017) Assessing Potential Ground-Motion Hazards from Induced Earthquakes. Nat Hazards Rev 18:04017018. https://doi.org/10.1061/(ASCE)NH.1527-6996.0000264

Wong C, Pedrotti M, El Mountassir G, Lunn RJ (2018) A study on the mechanical interaction between soil and colloidal silica gel for ground improvement. Eng Geol 243:84–100. https://doi.org/10.1016/j.enggeo.2018.06.011

Yang ZJ, Zhang XR, Yang R, Zhou X, Niu F (2018) Shake table modeling of pile foundation performance in laterally spreading frozen ground crust overlying liquefiable soils. J Cold Reg Eng 32:04018012. https://doi.org/10.1061/(asce)cr.1943-5495.0000171

Zang YX, Gong W, Xie H, et al (2015) Chemical sand stabilization: a review of material, mechanism, and problems. Environ. Technol. Rev.

Acknowledgement

The authors of the present paper are thankful to the Applied Mechanics section of the Civil engineering department at SVNIT, Surat, for all the valuable support. We wish to convey the wholehearted gratitude to TEQIP, the All India Council for Technical Education, Government of India for the significant financial support for the current study. The first author would like to thank Dr Vipin Nair, Dept. of Mechanical Engineering, NIT Calicut, for his support and patience in the language editing of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all other authors, the first author confirms that there are no known conflicts of interest associated with this publication.

Additional information

Responsible Editor: Zeynal Abiddin Erguler

Highlights

•The experimental facility helped to identify possible reasons behind the improvement of the bearing capacity of sand.

•Colloidal silica treatment can be considered an effective ground improvement technique to enhance the vertical and lateral load-carrying capacity of the pile.

•The numerical results obtained from the investigations were similar to the experimental test results for all the loading cases.

Rights and permissions

About this article

Cite this article

Krishnan, J., Yadav, S.L. & Shukla, S. Experimental investigations of a pile in colloidal silica stabilized sand under vertical and lateral loads. Arab J Geosci 14, 1314 (2021). https://doi.org/10.1007/s12517-021-07689-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-021-07689-w