Abstract

This paper presents an intensive series of laboratory testing results from vane shear and fall cone tests that were conducted on various clay–sand mixtures to understand the link between these methods which are often used for determining the undrained shear strength (su). Three different gradations (2.0–1.0 mm, 1.0–0.6 mm, and 0.6–0.3 mm) of rounded and angular sands were mixed with low-plasticity clay at ratios of 0%, 10%, 20%, 30%, 40%, and 50%. The results of the tests demonstrated that the su values obtained from the vane shear tests were found to be always higher than those obtained from the fall cone tests. It was shown that the sand content used in the mixtures changed the su parameters of the specimens significantly. The results indicated that the su values were significantly influenced by grading characteristics of the sands (d10, d20, d30, d50, d60, cu, cc). The values of su were lower for the samples that had a larger size of sand grains. Finally, shape characteristics of the sand grains were found to be effective on the results. The samples with angular sand grains have higher su values than the samples with rounded sand grains, for all gradations employed in the present study.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Most of the experimental researches for determining the engineering characteristics of cohesive soils focused on the behavior of clean clay specimens. However, site investigations reveal that the cohesive soils may contain different amounts of silt and/or sand grains with different physical properties (shape, gradation). The silt and sand grains in clay should be expected to influence the undrained shear strength of clay samples. It is of great importance to identify the undrained shear strength (su) of such soils in order to make an accurate stability analysis. Two widely used methods for identifying the undrained shear strength are vane shear test and fall cone test. Undrained shear strength, liquid limit, and sensitivity of soils were previously studied using the fall cone test (Terzaghi 1927; Hansbo 1957; Houlsby 1982; Wood 1982, 1985; Leroueil and Le Bihan 1996; Feng 2000; Claveau-Mallet et al. 2012; Westerberg et al. 2015; Cabalar and Mustafa 2015). The principle of this experiment is that a cone with a certain tip angle and weight is released into a soil sample and the penetration depth is measured. An equation that shows the change of undrained shear strength (su) of clay during the penetration of the cone which has a mass of m was given by Hansbo (1957) in Eq. 1 as follows:

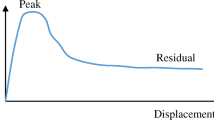

In the above equation, k is constant and is determined by the angle of cone. In a 30° British cone, this value is 0.85 (Wood 1985). Undrained shear strength studies have also been performed using vane shear tests by many researchers (Flaate 1966; Menzies and Merrifield 1980; Mohsen and Ullrich 1985; Seah et al. 2004; Larsson et al. 2009; Wang et al. 2013). Conventionally, the vane shear test is carried out using a four-bladed vane with four different sizes which have the ratio of height/diameter = 2. A torque is applied to the torque rod then to the vane at a rate of about 6°/min, preferably by a geared drive until the specimen fails. The undrained shear strength of a specimen is calculated in compliance with the standard equations (ASTM D 2573-94 2013) given below (Eqs. 2 and 3).

Where, T is torque, K is a coefficient related to dimensions and geometry of the vane, D is diameter of vane, and H is height of vane.

It is understood nowadays that grain shape properties and gradation can change the soils’ engineering properties (Terzaghi 1925; Gilboy 1928; Lees 1964, Olson and Mesri 1970; Abbireddy et al. 2009; Clayton et al. 2009; Goktepe and Sezer 2010; Cabalar et al. 2013; Cabalar and Hasan 2013; Cabalar 2018). When looked in the literature, Terzaghi investigated shape characteristics of soil grains and he was one of the first to make such extensive experiments on soils (Terzaghi 1925). Around the same time, Gilboy (1928) also had performed experiments and concluded that any analysis without regard to the shape of the soil would be false and incomplete. It was also shown by Holubec and D’Appolonia (1973) that the grain shape played a role in dynamic penetration test results. Holtz and Kovacks (1981) presented a relationship between the internal friction angle (φ) and the shape of the grains. Later, Cedergen (1989) showed that the shape of the grains can also affect their permeability. Wadell (1932), Krumbein (1941), Powers (1953), Holubec and D’Appolonia (1973), Youd (1973), and Cho et al. (2006) have done experiments related with grain shapes and shown the relation to the soil properties. The soil grain shape can be characterized simply by two parameters, namely (i) roundness, a parameter which defines the curvature or sharpness of the corners of a grain; (ii) sphericity which defines the more general form of the grain and how it approaches the shape of a sphere. Wadell gave the definition of sphericity (Dmax-insc/Dmin-circ), to be the ratio of maximum inscribed circle to the minimum sphere circumscribing the shape. The definition of roundness (R) given by Wadell (1932) is the ratio of the average diameter of the inscribed circles drawn on the corners to the diameter of the maximum inscribed circle (Di-ave/Dmax-insc). Figures 1, 2, and 3 present a chart that is still used today to determine R and S values (Krumbein 1941; Powers 1953).

Comparison chart (Krumbein and Sloss 1963)

Researchers have been studying undrained shear strength in laboratory, but it has been noted that there is no information available on the experimental study of sand–clay mixtures through both the fall cone and the laboratory vane shear tests. The fundamental relationships between the clay with sands at different physical characteristics and undrained shear strength that characterizes the sands have not been understood and quantified very well. Hence, this investigation reports what is thought to be the first paper ever done to figure out the (i) effects of physical characteristics (shape and gradation) of sand grains; (ii) fine (clay) content; and (iii) amount of water in various sand–clay mixtures on the undrained shear strength results using both fall cone and vane shear tests. The objective of the present investigation was partly scientific curiosity, but moreso to quantify decisive undrained shear strength values of various sand–clay mixtures around many geotechnical applications. In order to conduct such an experimental work, a large number of both fall cone and vane shear tests were undertaken on the sand grains having distinct sizes/shapes mixed with clay at various contents ranging from 0 to 50%. Consequently, series of correlations among the undrained shear strength, size/shape of sand grains, amount of fine (clay), and testing approach were proposed in order to use for further studies.

Experimental study

Materials

Table 1 gives a summary of the testing program followed in the experimental studies. The undrained shear strength (su) of sand–clay mixtures are usually calculated using either vane shear or fall cone tests. These tests were conducted on the samples to understand the relationship between the two kinds of tests. Rounded and angular sands having three different gradations (2.0–1.0 mm, 1.0–0.6 mm, and 0.6–0.3 mm) were mixed with clay having a low plasticity at ratios that ranged from 0 to 50% (by increments, 10%) by weight. The geomaterials used during these tests were Narli Sand (NS) representing round-shaped sand grains, Crushed Stone Sand (CSS) representing angular-shaped sand grains, and a CL-type clay.

The NS is a naturally available river sand obtained from Aksu River in the southern part of Turkey. The CSS sand was supplied from a local mining plant in the same region. The specific gravity (Gs) of the sand grains was calculated to be 2.65 for the NS, and 2.68 for the CSS grains. Three different gradations of the samples falling between 2.0 mm and 1.0 mm, 1.0 mm and 0.6 mm, and 0.6 mm and 0.3 mm were artificially selected (Fig. 4). From the study by Muszynski and Vitton (2012), roundness (R) and sphericity (S) estimates were found to be respectively 0.43 and 0.67 for the NS, and 0.16 and 0.55 for the CSS grains. The clay was obtained from the campus of the University of Gaziantep. The PL of clay is 23 and LL value is 49. The specific gravity of the clay sample is calculated to be 2.61. Figure 5 shows the scanning electron micrograph (SEM) photographs of the NS, CSS, and clay samples.

Testing apparatuses and specimen preparation

The tests were conducted in British fall cone and vane shear apparatuses, confirming to BS 1377, whose manufacturer is Wykeham Farrance. The fall cone apparatus has a cone that weighs 0.785 N with a 30° tip angle, and a cup to hold the specimens that is 55 mm in diameter and 40 mm in height. The vane shear apparatus has blades with the size of 12.5 mm in diameter, 25 mm in height, and 0.01 mm in thickness.

The sand and clay grains were first oven-dried, and de-aired water was added at specified percentages in order to have 20 mm penetration of cone. The mixtures were then left to cure for a time period of 24 h so that they will be saturated completely before the actual tests. Both of the methods will result in the various soil plasticity due to the five different water contents employed. The sand–clay mixture was prepared and inserted into the cup of the equipment while making sure not to trap air. The top part of the cup was leveled to make its surface smooth. Later, the specimen was then mounted on the fall cone and vane shear equipment while making sure that the blades are only touching the surface. At the end of 5 s, the penetration reading from the fall cone was taken. In the vane shear test, the rate of rotation of the blades was constant. At each 5° of rotation, the spring deflections are recorded until the maximum rotation degree of 180 was reached. The experiments were conducted again several times to reproduce similar results. Water content measurements were taken at the end of each test. The testing procedures were repeated with varying water contents.

Results and discussion

The summary of the test results is given in Table 2, in which a total of 125 fall cone tests and 125 vane shear tests were performed for various cases as shown.

To study the influence of the shape characteristics, changes in undrained shear strength (su) with fall cone and vane shear tests for each of the mixtures with sizes 2.0–1.0 mm, 1.0–0.6 mm, and 0.6–0.3 mm of rounded sands and angular sands are shown in the Figs. 6 and 7. As can be seen from Fig. 6, the su parameters obtained through the fall cone tests (su-FCT) reduce as the water content (%) in the sand–clay mixtures increases. In order to interpret the results of the fall cone test that was conducted, water contents of the mixtures corresponding to 20 mm penetration were observed. In Fig. 6, it can be seen that more sand content causes the su-FCT and corresponding water content to decrease. This is a result of the fact that a decrease in the clay content in a sand–clay mixture causes its liquid limit to also decrease, as shown by Nagaraj et al. (1987), Tan et al. (1994), and Cabalar and Mustafa (2015). The fall cone tests showed that the undrained shear strength is affected significantly by the shape of sand particles. It is seen from Fig. 6 that the sand grains with an angular shape have higher su-FCT values for all sand and water contents. Hence, it is likely because of (i) open fabric structure in specimens with angular sand grains, and (ii) higher Gs values of the angular-shaped grains.

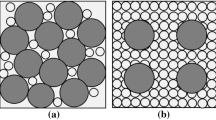

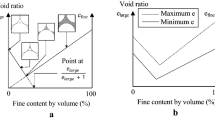

The void ratio (e) of a soil matrix is commonly defined to be the ratio of voids to the volume of solid grains. It was noted that the ordered packing of identical grains leads to void ratio that is grain size independent (Figs. 6 and 7). The resulting void ratios by the clean, angular sand grains are larger than those for clean, rounded grains. However, the testing results described here have not been carried out on the clean sands, rather the results have been obtained on the sand–clay mixtures which are thought as a composite matrix of finer and coarser soil grains. Therefore, in light of the numerous investigations (Ni et al. 2004; Monkul and Ozden 2007; Thevanayagam 1998; Rahman and Lo 2008; Cabalar and Mustafa 2015), separating the effects of sand and clay grains has significant benefits and makes it more versatile to analyze the test results. This is especially true in the case when describing the use of intergranular void ratio (es) as an alternative parameter to define the undrained shear strength behavior of sand–clay mixtures rather than using traditional void ratio (e) values (Yamamuro et al. 1996; Thevanayagam and Mohan 2000; Yamamuro and Wood 2004; Cabalar and Hasan 2013).

The intergranular void ratio concept was first proposed by Mitchell (1976), and followed by Kenny (1977), Lupini et al. (1981), and Thevanayagam (1998), which is an assumption that the sand particles act as the skeleton of the soil matrix while the particles of clay occupy the space in between, which is defined as the intergranular void ratio (es). The researchers showed that the overall behavior of the sand mixture is controlled by the sand grains depending on the amount of clay grains present. On the other hand, the amount of clay grains can be increased to the point where the mixture is controlled by clay grains. When es = emax, that is when intergranular void ratio equals the maximum void ratio of the sand grains, the sand grains are in directly contact with each other (Monkul and Ozden 2007). The clay content in the case of es = emax is referred to as “transition fines content.” The fact is that the value of es is always higher than the value of e employed in both tests performed in the present study due to the characteristics of undrained shear strength tests, although the interactions between es and e were found to be changed in certain testing equipment including oedometer, triaxial compression, cyclic triaxial, and resonant column (Troncoso and Verdugo 1985; Tan et al. 1994; Monkul and Ozden 2007; Cabalar 2010). Hence, the present study assumes that sand grains (rounded and angular) are floating in the clay matrix. Then, it was seen that the clay with angular sand grains resulted in lower su values in vane shear tests, since random packings of angular grains resulting void ratios are larger than those of rounded grains. Thus, it was concluded that the less angularity in sand grains, the more su values obtained in the sand–clay mixtures. This conclusion might also be attributed to the difference in the Gs values, although it is considered to be less effective on the results. As indicated in the preceding section, the Gs of the angular sand grains were found to be slightly higher (2.68) than that of the rounded sand grains (2.65). Therefore, it is postulated that the segregation of rounded sand grains is less likely than that of the angular sand grains in the mixtures. Liquid limit (wL) and corresponding su values in fall cone test are estimated based on the penetration of cone by 20 mm in a cup of that has a height of 40 mm. Considering segregation of sand grains in the mixtures to be tested in the fall cone cup, the su values of the clay with sand grains at various contents would necessarily be different based on the Gs values measured (Fig. 8). A similar series of results illustrated in Fig. 6 was observed in the tests conducted in vane shear testing apparatus, with certain differences in the range of su values estimated. For example, Fig. 7 presents the relationship between su-VST and water content for the clay with 0.6–0.3 mm in size of sand grains. As can be seen from Fig. 7, the clay with angular-shaped CSS grains has higher su-VST values than the round-shaped NS grains for all sand and water contents in the mixtures.

Figure 9 presents the changes in su estimated by vane shear testing equipment for clay with rounded sands (NS) at various gradations. It is seen that the clay with sand grains between 0.6 mm and 0.3 mm has the highest su values, and followed by the specimens with sand grains between 1.0 mm and 0.6 mm, and then the specimens with sand grains between 2.0 mm and 1.0 mm. Obviously, the sand grains with relatively smaller gradations have higher es values than those with larger gradations, and the voids are occupied by much more clay grains, which leads to higher su values in such sand–clay mixtures. The packing of sand grains is likely the cause that this phenomenon occurs. The fact is that void ratio of a sand matrix composed of a random packing of grains is dependent upon the stability given to the matrix by frictional and cohesive forces between grains. There exists a relationship between these forces and the exposed surface area of individual grains, which is inversely proportional to grain size characteristics. This proves that a certain weight of coarse grains would be stabilized at a lower void ratio than the same weight of fine grains, when all the other parameters are the same with each other. McGeary (1961), who carried out a series of experiments to understand the influence of size grain packing, stated that the small particles can find a place inside the spaces of larger particles if their size ratio is a certain value, otherwise they will fall between the contacts. Several researchers have studied the effect of clays to the basic packing behavior of mixed soils using the binary packing concept (Thevanayagam et al. 2001; Ni et al. 2004; Rahman and Lo 2008; Cabalar and Mustafa 2015). However, soil shape and size experiments performed by McGeary (1961) were only with rounded balls having different sizes and shapes. The present study introduces sand, which has irregular shape characteristics compared with rounded balls, and is expected to contribute differently to the intergranular void ratio (es) and the corresponding su characteristics of mixed soils. Thereof, the su estimates by fall cone testing equipment for clay with angular sands (CSS) at various gradations were presented in Fig. 10, in which a very similar behavior for the mixtures was observed.

The fall cone tests and vane shear tests were performed to compare and investigate the relationship of su values by using two testing equipment for various sand–clay mixtures. The estimated parameters given in Table 2 were employed to make a comparison of su determined with two tests. The su values estimated by the fall cone test is plotted against that estimated by the vane shear tests in Figs. 11 and 12 for different mixtures. It can be seen in Figs. 11 and 12 that the vane shear tests estimated higher su values in comparison with the fall cone tests. In the vane shear tests, the clean clay had a value of su ranging between 5.52 and 21.6 kPa, while the values for the fall cone tests were only between 0.66 and 16.44 kPa for the water contents from 36 to 28%. The fall cone tests estimated the su values of rounded (NS) grains (between the sizes of 0.6 and 1.0 mm) to be between 0.42 and 10.42 kPa, while the vane shear tests gave the su values of the same specimens to be between 4.66 and 19.89 kPa for the water contents from 36 to 28% (Fig. 11). Likewise, the su parameters obtained from fall cone tests on angular (CSS) grains between 1.0 and 0.6 mm ranged from 0.34 to 5.25 kPa, while the same parameter obtained from vane shear tests ranged from 3.80 to 16.73 kPa for the water contents from 36 to 18% (Fig. 12). The results from both vane shear and fall cone tests were plotted together in order to observe the change of su with water content. For example, Fig. 13 presents a comparison of su values defined by fall cone and vane shear tests for clean clay and clay with 40% angular sand between 1.0 and 0.6 mm. A trendline is plotted for each of the tests in order to understand the correlation between the su, and the tests and equations were given for the correlation between the two tests. In Table 3, correlations for all the experimental are presented. Actually, numerous researches on the shear strength estimates by means of fall cone testing equipment had previously correlated su values with cone penetration through cone weight and apex angle (Hansbo 1957; Kravitz 1970; Houlsby 1982; Lee 1985; Wood 1985; Stone and Phan 1995; Stone and Kyambadde 2007). The fact is that apex angle parameter (k) was initially developed for the Swedish fall cone by calibrating field vane shear testing equipment rather than laboratory vane shear testing equipment. Following an intensive series of tests (more than 1000 measures) on soft marine clay soils by using both fall cone and laboratory vane shear testing equipment, Tiesong and William (1997) proposed a new k value in order to minimize the large differences observed between the laboratory vane shear testing results and the fall cone testing results. Accordingly, this parameter should be expected to be a reason of the discrepancies in testing results obtained by two different techniques here in the present study as well. Hence, it is concluded that alternative k values to be produced by a sufficient number of tests could minimize the differences between testing results obtained by these two approaches employed in order to estimate the su of various soils.

Conclusions

Fall cone and vane shear tests have been performed on various sand–clay mixtures to investigate the relation between gradation/shape of sand grains in clay and undrained shear strength values of the mixtures. Three different gradations of both angular and rounded sands were mixed with CL-type clay samples at five different ratios. The experimental results have indicated that the undrained shear strengths were higher in samples with the mixture of clay and angular-shaped sand grains than the specimens with round-shaped sand grains. It is attributed to the open fabric structure in samples with the mixture of clay and angular sand grains, and higher Gs values of the angular-shaped grains, which results in a segregation in the mixture. It was also observed that the sand grains with smaller gradations have higher void ratio values than those with larger gradations, and the voids are occupied by much more clay grains, which leads to higher su values in such sand–clay mixtures. It is because of the packing of sand grains in the mixtures. The vane shear tests produce higher su values in samples in comparison with the fall cone tests. Evidently, in order to have a greater understanding of how the characteristics of sand grains influence sand–clay mixtures, further research in fall cone and vane shear testing is required.

References

Abbireddy COR, Clayton CRI, Huvenne VA (2009) A method of estimating the form of fine particulates. Geotechnique 59(6):503–511

ASTM D 2573-94 (American Society for Testing and Materials) (2013) Standard test method for laboratory miniature vane shear test for saturated fine-grained clayey soil. United States, West Conshohocken, pp 19428–12959

Cabalar AF (2010) Applications of the oedometer, triaxial and resonant column tests to the study of micaceous sands. Eng Geol 112:21–28

Cabalar AF (2018) Influence of grain shape and gradation on the shear behavior of sand mixtures. Sci Iran Trans A Civil Eng 25(6):3101–3109

Cabalar AF, Hasan RA (2013) Compressional behaviour of various size/shape sand-clay mixtures with different pore fluids. Eng Geol 164:36–49

Cabalar AF, Mustafa WS (2015) Fall cone tests on clay-sand mixtures. Eng Geol 192:154–165

Cabalar AF, Dulundu K, Tuncay K (2013) Strength of various sands in triaxial and cyclic direct shear tests. Eng Geol 156:92–102

Cedergen HR (1989) Seepage, drainage, and flownets, 3rd edn. Wiley, New York 26

Cho GC, Dodds JS, Santamarina JC (2006) Particle shape effects on packing density, stiffness and strength: natural and crushed sands. J Geotech Geoenviron 132(5):591–602

Claveau-Mallet D, Duhaime F, Chapuis RP (2012) Practical considerations when using the Swedish fall cone. Geotech Test J 35(4):1–11

Clayton CRI, Abbireddy COR, Schiebel R (2009) A method of estimating the form of coarse particulates. Geotechnique 59(6):493–501

Feng TW (2000) Fall-cone penetration and water content relationship of clays. Geotechnique 50(2):181–187

Flaate K (1966) Factors influencing the results of vane tests. Can Geotech J 3:18–31

Gilboy G (1928) The compressibility of sand-mica mixtures. Proc ASCE 2:555–568

Goktepe AB, Sezer A (2010) Effect of particle shape on density and permeability of sands. Proc Instit Civil Eng Geotech Eng 163(6):307–320

Hansbo S (1957) A new approach to the determination of the shear strength of clay by the fall-cone test. R Swed Geotech Inst Proc 14:7–47

Holtz RD, Kovacks WD (1981) An introduction to geotechnical engineering. Prentice-Hall, Englewood Cliffs, NJ, 517

Holubec I, D’Appolonia E (1973) Effect of particle shape on the engineering properties of granular soils. Evaluation of relative density and its role in geotechnical projects involving cohesionless soils. ASTM, STP523, West Conshohocken, pp 304–318

Houlsby GT (1982) Theoretical analysis of the fall-cone test. Geotechnique 32(2):111–118

Kenny TC (1977) Residual strength of mineral mixture. Proc. 9th International Conference of Soil Mechanics and Foundation Engineering, pp 155–160

Kravitz JH (1970) Repeatability of three instruments used to determine the undrained shear strength of extremely weak, saturated, cohesive sediments. J Sediment Petrol 40(3):1026–1037

Krumbein WC (1941) Measurement and geological significance of shape and roundness of sedimentary particles. J Sediment Petrol 11(2):64–72

Krumbein WC, Sloss LL (1963) Stratigraphy and sedimentation, 2nd edn. W.H. Freeman and Company, San Francisco, p 660

Larsson S, Rothhamel M, Jacks G (2009) A laboratory study on strength loss in kaolin surrounding lime-cement columns. Appl Clay Sci 44:116–126

Lee HJ (1985) State of the art: laboratory determination of the strength of marine soils. In: Chaney RC, Demars KR (eds) Strength testing of marine sediments: laboratory and in-situ measurements, ASTM special technical publication 883. ASTM, Philadelphia, pp 181–250

Lees G (1964) A new method for determining the angularity of particles. Sedimentology 3(2):21

Leroueil S, Le Bihan JP (1996) Liquid limits and fall cones. Can Geotech J 33(5):793–798

Lupini JF, Skinner AE, Vaughan PR (1981) The drained residual strength of cohesive soils. Geotechnique 31(2):181–213

McGeary RK (1961) Mechanical packing of spherical particles. J Am Ceram Soc 44(10):513–522

Menzies BK, Merrifield CM (1980) Measurements of shear distribution at the edges of a shear vane blade. Geotechnique 30:314–318

Mitchell JK (1976) Fundamental of soil behaviour. John Wiley & Sons, Inc

Mohsen S, Ullrich CR (1985) Rate of shear effects on vane shear strength. J Geotech Eng 111(1):135–139

Monkul MM, Ozden G (2007) Compressional behavior of clayey sand and transition fines content. Eng Geol 89:195–205

Nagaraj TS, Murthy BRS, Bindumadhava TS (1987) Liquid limit determination further simplified. Geotech Test J 12(4):302–307

Ni Q, Tan TS, Dasari GR, Hight DW (2004) Contribution of fines to the compressive strength of mixed soils. Geotechnique 54(9):561–569

Olson RE, Mesri G (1970) Mechanisms controlling the compressibility of clay. Journal of the Soil Mechanics and Foundations Division, 96 (SM6), Proc. Paper 7649, November, 1863–1878.

Powers MC (1953) A new roundness scale for sedimentary particles. J Sediment Petrol 23(2):117–119

Rahman MM, Lo SR (2008) The prediction of equivalent granular steady state line of loose sand with fines. Geomech Geoeng 3(3):179–190

Seah TH, Sangtian N, Chan IC (2004) Vane shear behavior of soft Bangkok clay. Geotech Test J 27:1–10

Stone KJ, Kyambadde B (2007) Determination of strength and index properties of fine-grained soils using a soil minipenetrometer. J Geotech Geoenviron Eng 133(6):667–674

Stone KJL, Phan KD (1995) Cone penetration tests near the plastic limit. Geotechnique 45(1):155–158

Tan TS, Goh TC, Karunaratne GP, Lee SL (1994) Shear strength of very soft clay-sand mixtures. Geotech Test J 17(1):27–34

Terzaghi K (1925) Erdbaumechanik auf bodenphysikalischer grundlage. Deuticke, Leipzig/Vienna

Terzaghi K (1927) Determination of consistency of soils by means of penetration tests. Public Roads 7(12):240–247

Thevanayagam S (1998) Effect of fines and confining stress on undrained shear strength of silty sands. J Geotech Geoenviron 124(6)

Thevanayagam S, Mohan S (2000) Intergranular state variables and stress–strain behaviour of silty sands. Geotechnique 50(1):1–23

Thevanayagam S, Martin GR, Shenthan T, Liang J (2001) Post-liquefaction pore pressure dissipation and densification in silty soils. In: Prakash S (ed) Proc., 4th International Conferences on Recent Advances in Geotechnical Earthquake Engineering and Soil Dynamics. San Diego

Tiesong L, William RB (1997) Comparison of vane shear and fall cone strengths of soft marine clay. Mar Georesour Geotechnol 15(1):67–82

Troncoso JH, Verdugo R (1985) Silt content and dynamic behavior of tailing sands. Proc. 11th International Conference on Soil Mechanics and Foundation Engineering vol 3, pp 1311–1314.

Wadell H (1932) Volume, shape, and roundness of rock particles. J Geol 40(5):443–451

Wang DX, Zentar R, Abriak NE, Xu WY (2013) Shear strength behavior of cement/lime-solidified Dunkirk sediments by fall cone tests and vane shear tests. Geotech Test J 36(1):1–8

Westerberg B, Muller R, Larsson S (2015) Evaluation of undrained shear strength of Swedish fine-grained sulphide soils. Eng Geol 188:77–87

Wood DM (1982) Cone penetrometer and liquid limit. Geotechnique 32(2):152–157

Wood DM (1985) Some fall cone tests. Geotechnique 35(1):64–68

Yamamuro JA, Wood FM (2004) Effect of depositional method on the undrained behavior and microstructure of sand with silt. Soil Dyn Earthq Eng 24:751–760

Yamamuro JA, Bopp PA, Lade PV (1996) One dimensional compression of sands at high pressures. J Geotech Eng 122(2):147–154

Youd TL (1973) Factors controlling maximum and minimum densities of sands, evaluation of relative density and its role in geotechnical projects involving cohesionless soils. ASTM STP 523:98–112

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Zeynal Abiddin Erguler

Rights and permissions

About this article

Cite this article

Cabalar, A.F., Khalaf, M.M. & Isik, H. A comparative study on the undrained shear strength results of fall cone and vane shear tests in sand–clay mixtures. Arab J Geosci 13, 395 (2020). https://doi.org/10.1007/s12517-020-05351-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-020-05351-5