Abstract

Mining-induced water inrush is a sudden and destructive underground disaster caused by a mining disturbance. This disaster occurs frequently in the northern region of Shaanxi province in China due to overburden fractures in shallow seam mining, which pose a great threat to residents’ safety. It is therefore essential to construct an accurate prediction model. This study first applies selection hierarchy analysis to the main controlling factors of roof water inrush to study their weights using an analytic hierarchy process (AHP) including five factors: surface water catchment features, wateriness of the aquifer, water-resistant characteristics of aquiclude, combined influence of overburden, and mining disturbance characteristics. The grey relational analysis (GRA) method is used to calculate the correlation degree of each water inrush. The AHP-GRA method presents a comprehensive evaluative model combining the advantages of both approaches to analyze mining safety. Qualitative and quantitative indicators of the roof water inrush prediction model in shallow seam mining are established. Secondly, risk prediction of roof water inrush points and comprehensive water inrush is determined using engineering examples from the Hanjiawan coal mine. Results indicate that during safety mining, water inflow data are consistent with our prediction, thereby substantiating the model’s accuracy and providing a new method for predicting roof water inrush in shallow seam mining.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Mining-induced water inrush disasters are common in China coal mines; they have resulted in grievous casualties and large economic losses (Hou et al. 2016; Shi et al. 2017). These disasters are characterized by abruptness, high speed, large volume, and high pressure. Once an inrush occurs, the mine roadway is flooded, and facilities are damaged (Wu et al. 2017; Yang and Feng 2002; Fang et al. 2016). After the shallow seam in northern Shaanxi was mined, a longitudinal development fracture formed in the overburden. After the cracks penetrated the aquiclude, the aquifer flowed to the working face along the conduit pipe due to the overburden and the aquifer’s water head pressure, leading to roof water inrush (Zhang et al. 2017; Zhu et al. 2009). Other accidents have also occurred: in 2001, a large roof water inrush flooded a roadway for 420 m. In 2009, a flood current formed in the surface gully of the 1201 fully mechanized mining face of the Fengjiata coal mine. The water reached up to 1300 m3/h, and three large lanes were flooded underground. In 2011, after the working face of the S1201 first mining of the Ningtiaota coal mine was impelled for 600 m, roof water inrush brought water reaching up to 2000 m3/h. These accidents were characterized by large sudden water inrushes and subsequent destruction. The coal seam is shallow, and the water-flowing fracture zone of coal seam mining is connected to the aquifer by surface water. It is therefore essential to conduct a qualitative and quantitative evaluation to predict roof water inrush risk before shallow seam coal mining to guide corresponding prevention measures to mitigate disasters.

Many researches have been published regarding the prediction of roof water inrush in coal seam mining. Wu et al. (2000) established a “three maps-two predictions” method via a roof water inrush condition quantitative evaluation of the coal seam at two coal mines. The pre-mining drainage program of working face water inflow and a roof direct water-filling aquifer were dynamically predicted using Visual MODFLOW software (Yang et al. 2015). Zhang et al. (2005) tested a prediction model based on a multi-information complex analysis method using geographic information systems (GIS) to fit actual water inrush points. They proposed an indirect prediction function to express the spatial variety of fissured water. Based on the results of the location of primary key strata in the overburden, Yi et al. (2008) forecasted a dangerous area for roof water inrush in the actual working face. Other scholars have proposed the concept of a water inrush risk coefficient under the quaternary loose aquifer to predict and evaluate the location’s condition (Meng et al. 2013). Considering that roof water inrush in shallow seam mining is affected by various factors, the weights of controlling factors should be evaluated and summarized using an analytic hierarchy process (AHP). Although widely implemented, AHP is a relatively subjective method (Luo 2014), and factor correlations are generally not considered in analysis. Other popular objective analysis methods include GRA (Li and Chen 2016), variation coefficients, and the entropy method. Although objective analysis can mitigate the influence of human factors, it relies too heavily on quantitative methods (e.g., statistics and mathematics) while neglecting subjective qualitative analysis of index system. Meanwhile, controlling factors are especially relevant to each other while also being complex and ambiguous. Therefore, during comprehensive evaluation, a more precise way to determine index weights is to combine subjective and objective weighting methods. GRA is superior to other methods in its ability to describe the multi-factor influence of roof water inrush. Based on the above problems and extant research on roof water inrush disasters, a combined AHP-GRA method may reflect the multi-factor evaluation model of controlling factors and roof water inrush. Roof water inrush in shallow seam mining is qualitatively and quantitatively predicted in this study. Results provide accurate and effective pre-mining information to prevent water inrush accidents.

In this paper, a multi-factor prediction model for roof water inrush in shallow seam mining based on AHP-GRA evaluation is proposed to identify controlling factors and risk classes. Then, the model is applied to predict roof water inrush points and cumulative risk in the Hanjiawan coal mine (Yang et al. 2017). Results indicate that during safety mining, water inflow data is consistent with our prediction; thus, the model’s rationality and accuracy are supported. Finally, our research provides qualitative and quantitative analysis of roof water inrush prediction and effective early warning before mining.

Methodology

The AHP method

Roof water inrush in shallow seam mining is affected by multiple factors, which the AHP methods can summarize. AHP was proposed in the early 1970s by American operation research scientist Thomas Saaty from the University of Pittsburgh. In AHP, controlling factors are condensed to establish a corresponding evaluation indicator system where the weight of each factor is determined quantitatively. Factors are combined according to their objective and subjective relationships (Liu et al. 2007), forming a multi-level analytical structure that provides a comprehensive picture of the predicted objective. The AHP method can also determine the weight of the evaluation factor. Essentially, the evaluative process consists of three steps:

-

(1)

Establish the hierarchical model. According to the relationship among controlling factors, the selected targets, considered factors, and decision objectives are divided into a target layer, middle layer, and decision layer, respectively. Same-layer factors are subordinate to those in the upper layer and superior to those in the lower layer.

-

(2)

Construct the judgment matrix. A consistent matrix method is used to determine the relative influence value by comparing each factor with others in the same layer, facilitating comparisons between factors with different properties to improve evaluative accuracy.

-

(3)

Hierarchical ranking and consistency checks. Hierarchical ranking refers to the importance ranking each factor in the middle layer, corresponding to another factor in the upper layer. For judgment matrix A, we calculated the characteristic root and characteristic vector using the formula AW = λmaxW, where λmax is the largest eigenvalue of matrix A, W is the eigenvector of regularization corresponding to the λmax, and w i is the component of W corresponding to the element’s weight.

The judgment matrices are usually not identical, but to use a matrix’s eigenvector as the proper weight for comparative factors, its inconsistency should be within an allowable range. The matrix’s consistency test is reflected in Eq. (1); this is the basic formula in AHP analysis along with a consistency test of the AHP matrix.

where CR is the consistency ratio; when CR < 0.1, the degree of inconsistency is acceptable.

where CI is the consistency characteristic indicator. If CI = 0, then matrix A is consistent; if CI is close to 0, the consistency is satisfactory. The larger the CI value, the greater the inconsistency. n is the number of comparison factors. RI is the random consistency indicator obtained from Table 1.

The GRA method

GRA is a new method in grey system theory, a quantitative approach describing the degree of correlation between objects and factors with relational value. For factors between two systems, the measure of correlation size that varies over time or across different objects is called the correlation degree. If a trend between two factors is consistent, then the degree of synchronous change is relatively high, as is the degree of correlation between the factors; otherwise, the correlation degree is relatively low. The GRA method uses similarity or dissimilarity development trends across given factors, namely the grey correlation degree, to measure factors’ extent of correlation. The premise of GRA is to determine whether the links between different sequences are close according to the sequence curve’s geometry. The basic idea is to convert a discrete behavioral observation of the system factor into a segmented, continuous broken line via linear interpolation and then construct a model of correlation degree measurement according to the broken line’s geometric features (Liu et al. 2013). The evaluation procedures are as follows:

-

(1)

Determine the reference series and comparative series. The values of the evaluation standard indicator and studied objectives are listed as reference series and comparative series, respectively. The initial evaluation matrix is formed after the comparison; the dimensionless evaluation matrix is obtained using the dimensionless method.

-

(2)

Determine the grey correlation coefficient solution, calculated as

where γ i (k) is the correlation coefficient between the kth indicator and kth optimal indicator of the ith assessment objective; x i (k) is the corresponding value of the evaluation objective matrix; xj(k) is the corresponding value of the evaluation standard matrix; η is the resolution ratio (general value = 0.5); k = 1,2,…,n; and i = 1,2,…,m.

-

(3)

Calculate the grey weighted related degree. Based on the weight of each indicator according to AHP, the grey weighted related degree that considers the weight difference between indicators is calculated as follows:

where Ri is the grey weighted related degree of the evaluation standard for the ith evaluation objective; ω k is the weight of each controlling factor; k = 1,2,…,n; and i = 1,2,…,m.

-

(4)

Comprehensive evaluation. According to the scale of the calculated grey weighted related degree, the resultant evaluation objectives are established. The correlation degree is sorted in descending order from large to small; the larger the correlation, the better the degree of correlation with the class set. The comprehensive evaluation will allow us to identify the roof water inrush risk class and coal seam danger points in the prediction area.

The prediction model based on AHP-GRA evaluation

A single analytic method cannot uniformly evaluate relationships among various factors in nonlinear complicated problems such as roof water inrush in a coal seam; such models would reduce predictive accuracy. The AHP method qualitatively confirms the weight of each controlling factor, and GRA quantitatively analyzes uncertain relationships among factors. A comprehensive evaluation model combining the advantages of AHP and GRA is proposed in this study to analyze mining safety. The prediction model is shown in Fig. 1.

Controlling factors of roof water inrush in shallow seam mining

To construct a prediction model to forecast roof water inrush in shallow seam mining, controlling factors must be analyzed first before establishing the evaluation indicator system. Chen and Liu (2010) found that roof water inrush in coal mines is affected by many factors. Selecting a reasonable evaluation indicator ensures the evaluation system’s accuracy. In this study, controlling factors are as follows:

-

(1)

Surface water catchment features. The coal mine in northern Shaanxi is located in an arid and semi-arid region of northwest China with an average annual rainfall of 436.7 mm, most of which occurs from July to September. A loess gully developed on the Earth’s surface, and intermittent surface runoff in the gully has become an important water source in mine water disasters (Zhang et al. 2016a). As for the mining area landscape, the channel’s large falling gradient and the small infiltration coefficient of atmospheric precipitation in the gully area are conducive to flood formation; however, the infiltration coefficient in the wind-blown sand beach area is relatively large, offering centralized precipitation during the wet season (Xu et al. 2012a; Zhang et al. 2011; 2013).

-

(2)

Wateriness of the aquifer. The aquifer in the coal seam roof is a source of water inrush and an important factor in related disasters. The wateriness of the aquifer determines the size of an outburst and inrush duration. Unit inflow, rinse consumption, aquifer permeability, and aquifer thickness are secondary indicators of wateriness.

-

(3)

Water-resistant characteristics of aquiclude. Aquiclude is a natural geological preventer of roof water inrush and plays a key role in preventing water from flowing downward. Aquiclude’s water resistance is based on its thickness, integrity, and permeability coefficient. If the soil layer is very thick, the interconnected aquifer is more difficult to permeate (Wang et al. 2016). Meanwhile, high soil integrity and a low permeability coefficient can effectively reduce the development height of the water suture zone and the degree of water seepage, decreasing the likelihood of water inrush.

-

(4)

Combined influence of overburden. Different types of overburden have distinct crack development characteristics (Ning et al. 2017), and the type of strata described by thickness is insufficient for water inrush prediction. Five indicators—the ratio of basement to loadings, Jz (Li et al. 2013); ratio of rock to mining, Jc (Wang et al. 2010); location of bedrock to key strata (Xu et al. 2009); degree of structural development (Dong et al. 2009); and proportion coefficient of hard rock (Hu et al. 2012)—classify combined overburden features.

-

(5)

Mining disturbance characteristics. As coal seam mining thickness increases, the development height of the water-flowing fracture zone increases and decreases with the amount of stratified mining. In the traditional empirical formula, mining thickness is the only parameter that influences expected water flow height, an important indicator when evaluating mining disturbances. Serious damage occurs to the overburden in the long-wall collapse method. Column mining can control the extent of damage to the aquifer to better protect it (Zhang et al. 2015). The mining method and dip angle of the coal seam are also included in this indicator.

Construction of the hierarchical structure model

In this study, risk assessment was divided into four classes from small to large: I, II, III, and IV. Considering relevant industry standards and research (Zhang et al. 2016b), we constructed a risk assessment system of water inrush reduction in shallow seam mining using five main factors in the first hierarchy (as shown in Fig. 2) and 19 secondary indicators underneath; the hierarchical model appears in Fig. 3 and includes qualitative and quantitative indicators. Quantitative indicators were calculated using measured data; however, class demarcation for qualitative indicators was vague by comparison. In this paper, a general target hierarchy method was used to evaluate qualitative indicators, which were quantified according to certain criteria. Roof water inrush risk had four scales—smaller, small, large, and larger—based on corresponding class scores, ranging from 0.1, 0.4, and 0.7 to 1. The larger the score, the greater the risk. The corresponding indicator in the prediction area was quantified according to class scores. All indicators are shown in Table 2.

Results

Profile of working face and water inrush controlling factors in the Hanjiawan coal mine

Profile of working face

The Hanjiawan coal mine is located in the northernmost part of the Shenfu coal field in northern Shaanxi, whose 2404 working face corresponds to the west Budaihao Village on the surface. To the east of this mine is the 0.8 line of the 2−2 coal seam, to the west is the no. 4 panel return airway, to the south is the 2405 working face, and to the north is the goaf of the 2403 working face. The coal seam thickness ranges from 3.4 to 5.2 m with an average thickness of 4.3 m. The coal seam is stable with a simple structure and incline of 1°–3°. The roof-caved method of fully mechanized long-wall retreating mining is adopted for roof coal mining. The advanced length of the working face is 2797 m, and the length of the working face is 206.6 m.

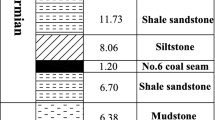

The stratigraphic columns of the working face and the geomorphic map of the Hanjiawan coal mine are shown in Figs. 4 and 5, respectively.

Controlling factors of roof water inrush in the working face

Surface water catchment features

The surface of the Hanjiawan mine is in a loess hilly valley area, where the Tangjiangqu River flows through the south of the coal mine at a rate of up to 28 m3/h. During the rainy season, precipitation reaches about 331.8 mm with a maximum daily rainfall of 84.6 mm. The maximum surface valley depth is 32 m, and the maximum slope angle is approximately 52°. A torrent can form easily in the valley with excessive daily rainfall.

Wateriness of the aquifer

The aquifer of the coal mine is mostly covered by a Holocene alluvium layer pore-phreatic aquifer (Q4al) and a quaternary upper Pleistocene Salawusuan group aquifer (Q3s). The former (Q4al), which contains little water, can be ignored; the latter (Q3s) is highly permeable and easily accumulates precipitation to form a pore-phreatic aquifer while consuming less washing fluid at the same time. The Q3s overburden falls into the low watery aquifer, whose water inflow in watery areas is up to 1.66 L·s−1·m−1 with a permeability coefficient of 5.20 e−5cm/s.

Water-resistant characteristics of aquiclude

The overlying aquiclude is Neogene baode red clay group aquiclude (N2b) with a thickness of 4.8 m, belonging to the thin aquifuge layer. N2b is a loose and relatively compact silty clay lithology with a light red or pale brown color and permeability coefficient of 1.85 e−10cm/s. It has good water-resistant properties.

Combined influence of overburden

Geological conditions in the mining area are simple with no large geological structures. The mechanical properties of the coal roof rock are hard caving, and the proportion coefficient of hard rock β is 0.37. Local river erosion and deposition may occur during mining. The thickness of the base rock is 41.7 m, the thickness of the load layer is 40.20 m, and the mining height (M) is 4.3 m. The ratio of rock to loading (Jz) is 1.04, and the ratio of rock to mining (Jc) is 9.70. The key stratum is located 10.40 m above the roof of the coal seam and is far less than (7–10) M, placing the key stratum in the lower level of the hierarchical model (IV) (Xu et al. 2012b).

Construction of judgment matrix and weight calculations

According to Fig. 3, the scaling method of 1–9 and the reciprocals were applied to compare two factors to construct the judgment matrix for each level. We constructed the first-hierarchy indicator for the A-B judgment matrix and weight of X (see Table 3) and then constructed the secondary hierarchy indicator for the B-C judgment matrix and weight of Y. Finally, the weight of the Z indicator (each factor of C for target layer A) was obtained from the weights of X and Y.

Formulas (1) and (2) were used to calculate the consistency characteristics of the judgment matrix, where \( CI=\frac{\lambda_{\mathrm{max}}-n}{n-1} \) = 0.0198. When n = 5, RI = 1.12, and the consistency ratio is \( CR=\frac{CI}{RI} \) = 0.0177 < 0.1. The judgment matrix passed the consistency check. The same method was used to calculate each indicator’s weight and verify its consistency (see Table 4).

The weights of the second-hierarchy indicators were ordered, and the influence coefficient of each factor was determined for roof water inrush (see Table 5).

Risk class of first-hierarchy factors

Determination of comparative series and reference series

The indicator value of surface catchment characteristics was ordered in Table 2 as a comparative series, denoted as x i (k) = (84.6, 32, 52). Class criteria in Table 2 comprised the reference series. Data were processed using a dimensionless initial value with the following outcome:

Correlation coefficient calculation

|x i (k) − x j (k) was calculated by Formula (3), and the absolute value was taken after subtracting corresponding data within the matrix:

In this formula, η is the resolution coefficient, and 0.5 was taken. We determined the correlation coefficient γ1 of surface catchment characteristics:

Calculation of the grey weighted related degree

In AHP, the surface catchment characteristic indicator’s weight is guaranteed. According to Formula (4), the related degree was calculated as follows:

The maximum grey weighted related degree was R1max = 0.7292, and surface catchment characteristics corresponding to water inrush risk belonged to class III (i.e., large risk).

The related degree for wateriness of the aquifer was as follows:

R2 = [1.6827 1.6796 1.5086 1.4103], where R2max = 1.6827. The wateriness of the aquifer corresponding to water inrush risk belonged to class I (i.e., small risk).

For the water-resistant characteristics of aquiclude,

R3 = [1.6834 1.5960 1.5299 1.5342], where R3max = 1.6834, belonging to class I (i.e., small water inrush risk).

For the combined overburden features corresponding to water inrush risk,

R4 = [1.6413 1.6466 1.6523 1.6586], where R4max = 1.6586, belonging to class IV (i.e., large risk).

For mining disturbance characteristics,

R5 = [1.5049 1.5145 1.5103 1.5034], where R5max = 1.5145, belonging to class II (i.e., small risk).

Cumulative risk of roof water inrush

The weights of first-hierarchy factors and related degrees in the Hanjiawan coal mine are shown in Table 6. The cumulative grey weighted related degree of the working surface was calculated using Formula (4).

oThe comprehensive evaluation of the maximum grey weighted related degree was Rmax = 1.5525, and the corresponding water inrush risk belonged to class I (i.e., small risk).

Prediction of water inrush points

Although the comprehensive water inrush risk in the 2204 working face was very low, the surface catchment characteristics corresponding to inrush risk belonged to class III and the combined overburden features belonged to class IV, indicating a relatively large risk. An abnormal change in roof water flow could lead to water inrush, which may occur based on the surface catchment indicator value and abnormal indicator value corresponding to combined overburden features. When the water catchment indicator value exceeds class III and the combined overburden indicator value exceeds class IV, we can identify a predicted water inrush point. Judgment indicators are shown in Table 7.

Based on the three-dimensional integrated GIS development platform of the above-ground, ground surface, and underground areas, correlative indicator data from the 2404 working face were compared with the risk judgment indicators and distribution graph of predicted risk points on the working face as shown in Fig. 6. During working face mining, most water-flowing fractured zones did not sweep to the aquifer in Sarah Wusu. However, due to the relatively thin roof bedrock in certain positions and the relatively low position of key layers, the surface gully development stripped some bedrock; thus, the water-flowing fracture zone could sweep the aquifer in Sarah Wusu and even go through the valley, increasing the possibility of a water inrush disaster if a rainstorm accompanies the flood flow. Therefore, surface water and pre-warning signs of underground water in the rainy season should be monitored to prevent local water inrush.

Water feedback on the site

Mining of the 2404 working face of the Hanjiawan coal mine was completed safely; no water inrush accidents occurred. However, the water flow fluctuated throughout the mining process. High-peak periods were as follows:

-

(1)

When the 2404 working face was pushed 36 m from the open-off cut, a roof water-flowing fracture zone developed rapidly, and water inflow increased suddenly because the key layer position of overburden for this region was very low. After the coal seam was mined, static water storage capacity and dynamic flow within the area of the first collapse filled simultaneously, bringing the peak value to 269 m3/h. However, this fluctuation had no influence on production following a sharp reduction in water flow to 100 m3/h.

-

(2)

When the working face was pushed to a relatively weak bedrock area, water inflow fluctuated from 98 m3/h (normal) to 130 m3/h but remained within the scope of safe mining.

-

(3)

During a period of heavy rainfall (i.e., continuous daily rainfall of over 30 mm), water flow in the mining region increased significantly given the extent of precipitation and the mine’s proximity to landforms and geomorphy. The mine showed enhanced monitoring of surface and underground water across the gully and in low-lying areas during the rainy season. We also took advanced drainage measures of gully water to prevent roof water inrush. Results showed this program was effective: daily precipitation was less than 10 mm and did not affect mining surface water inflow.

Conclusion

According to the factors influencing roof water inrush in shallow seam mining, indicators were selected based on five characteristics. We then constructed an evaluation indicator system and class division criteria for roof water inrush with cumulative qualitative and quantitative indicators.

The combined evaluation model greatly reduced subjective judgment. This model can discriminate and assess the respective risks of individual water inrush factors. The model can also accurately predict the risk class and risk points of comprehensive water inrush for the working face, facilitating future water inrush prevention.

Water inflow data during mining showed that the model not only accurately evaluated comprehensive water inrush classes but also prevented coordinated risk points, which can allow professionals to explore water inrush risk points before coal seam mining to guide prevention and control. Therefore, the likelihood of roof water inrush accidents is greatly reduced.

References

Chen PP, Liu XE (2010) Research and application of water inrush early warning system to mine roof. Coal Sci and Technol 38(12):93–96

Dong DL, Wang HZ, Wu CX, Chen SK, Lu ZQ, Li YH (2009) Seepage characters of roof aquifers in faults and sliding structure and risk analysis of water inrush. Chin J Rock Mech Eng 28(2):73–379

Fang J, Li QS, Du WF, Cao ZG (2016) Water disaster control in overlying thick loose layer on bedrock in Shendong coal mining area. Coal Geol Explor 44(4):94–97

Hou TX, Yang XG, Xing HG, Huang KX, Zhou JW (2016) Forecasting and prevention of water inrush during the excavation process of a diversion tunnel at the Jinping II Hydropower Station, China. Spring 5(1):700

Hu XJ, Li WP, Cao DT, Liu MC (2012) Index of multiple factors and expected height of fully mechanized water flowing fractured zone. J China Coal Soc 37(4):613–620

Li B, Chen YL (2016) Risk assessment of coal floor water inrush from underlying aquifers based on GRA-AHP and its application. Geotech Geol Eng 34(1):143–154

Li FS, Zhang Y, Xu LF (2013) Influence of ratio of basement and loadings on mining face rock pressure in thin basement rock thick surface soil. J China Coal Soc 38(10):1749–1755

Liu YJ, Mao SJ, Mei L, Yao JM (2007) Study of a comprehensive assessment method for coal mine safety based on a hierarchical Grey analysis. J China Univ Min Technol 17(1):6–10

Liu SF, Cai H, Yang YJ, Cao Y (2013) Advance in grey incidence analysis modelling. Syst Eng Theory Pract 33(8):2041–2046

Luo B (2014) Comprehensive analysis and evaluation of water hazards conditions on coal seams roof based on GIS techniques and multisource information—a case study in 39110 working face of 3rd underground coalmine. Dissertation. China University of Mining & Technology

Meng ZP, Gao YF, Lu AH, Wang R, Qiao X, Huang CY (2013) Water inrush risk evaluation of coal mining under quaternary alluvial water and reasonable design method of waterproof coal pillar. J Min Saf Eng 30(1):23–29

Ning JG, Wang J, Tan YL, Zhang LS, Bu TT (2017) In situ investigations into mining-induced overburden failures in close multiple-seam longwall mining: a case study. Geomech Eng 12(4):657–673

Shi W, Yang T, Yu Q, Li Y, Liu HL, Zhao YC (2017) A study of water-inrush mechanisms based on geo-mechanical analysis and an in-situ groundwater investigation in the Zhongguan Iron Mine, China. Mine Water Environ 36(3):409–417

Wang SM, Huang QX, Fan LM, Yang ZY, Shen T (2010) Study on overburden aquclude and water protection mining regionazation in the ecological fragile mining area. J China Coal Soc 35(1):7–14

Wang WX, Sui WH, Faybishenko B, Stringfellow WT (2016) Permeability variations within mining-induced fractured rock mass and its influence on groundwater inrush. Environ Earth Sci 75(4):326

Wu Q, Huang XL, Dong DL, Yin ZR, Li JM, Hong YQ, Zhang HJ (2000) “Three maps two predictions” method to evaluate water bursting conditions on roof coal. J China Coal Soc 25(1):60–65

Wu GJ, Chen WZ, Yuan JQ, Yang DS, Bian HB (2017) Formation mechanisms of water inrush and mud burst in a migmatite tunnel: a case study in China. J Mt Sci 14(1):188–195

Xu JL, Wang XZ, Liu WT, Wang ZG (2009) Effects of primary key stratum location on height of water flowing fracture zone. Chin J Rock Mech Eng 28(2):380–385

Xu JL, Zhu WB, Wang XZ, Zhang ZQ (2012a) Influencing mechanism of gully terrain on ground pressure behaviors in shallow seam longwall mining. J China Coal Soc 37(2):179–185

Xu JL, Zhu WB, Wang XZ (2012b) New method to predict the height of fractured water-conducting zone by location of key strata. J China Coal Soc 37(5):762–769

Yang P, Feng WL (2002) Research on disaster of water inrush and sand inrush in shallow seam of Shenfu Dongsheng mining area. Coal Sci Technol 30(s):65–69

Yang JS, Son MW, Chung ES, Kim IH (2015) Prioritizing feasible locations for permeable pavement using MODFLOW and multi-criteria decision making methods. Water Resour Manag 29(12):4539–4555

Yang BB, Sui WH, Duan LH (2017) Risk assessment of water inrush in an underground coal mine based on GIS and fuzzy set theory. Mine Water Environ 36(4):617–627

Yi MS, Zhu WB, Li L, Zhao X, Xu JL (2008) Water inrush mechanism and prevetion for fourth panel roof in bulian coalmine. J China Coal Soc 33(3):241–245

Zhang HR, Zhou RF, Guo DZ, Du PJ (2005) Investigation on predicting roof water gush in coal mines based on multi-factor analysis. J China Univ Min Technol 34(1):115–119

Zhang ZQ, Xu JL, Wang L, Zhu WB (2011) Study on influencing laws of gully slope angle on ground pressure of working face in shallow coal seam. J Min Saf Eng 28(4):560–565

Zhang ZQ, Xu JL, Liu HL, Li HW (2013) Influencing laws study of depth of gully on dynamic strata pressure of working face in shallow coal seams. J Min Saf Eng 30(4):501–505 +511

Zhang J, Yang T, Tian YP, Wang B (2015) Experimental test for destruction law of aquiclude under action of mining and seepage. Rock Soil Mech 36(1):219–224

Zhang GL, Ju JF, Xu JL (2016a) Fluence of longwall mining on surface runoffs in gully terrain area. J China Coal Soc 45(5):1219–1226

Zhang W, Li B, Yu H (2016b) The correlation analysis of mine roof water inrush grade and influence factors based on fuzzy matter-element. J Intell Fuzzy Syst 31(6):3163–3170

Zhang J, Yang T, Wang B, Zhao Q, Liu D, Ren YB (2017) Predictive analysis of roof water-inrush under gully runoff in shallow coal seam. J Min Saf Eng 34(5):868–875

Zhu WB, Wang XZ, Kong X, Liu WT (2009) Study of mechanism of stope water inrush caused by water accumulation in overburden separation areas. Chin J Rock Mech Eng 28(2):306–311

Acknowledgements

This study was supported by the National Natural Science Foundation of China (5147173, 51774229). The agency’s funding is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, J., Yang, T. Study of a roof water inrush prediction model in shallow seam mining based on an analytic hierarchy process using a grey relational analysis method. Arab J Geosci 11, 153 (2018). https://doi.org/10.1007/s12517-018-3498-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-018-3498-2