Abstract

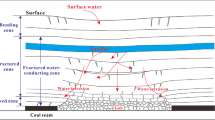

The movement and failure of overlying strata induced by underground coal mining cause “three zones,” including the caving zone, the water-conductive fractured zone, and the sagging zone from the bottom up. For knowledge about the height of the water-conductive fractured zone, there has been no empirical or theoretical formulae for thick coal seam using fully mechanized longwall mining with sublevel caving. This paper presents a methodology of determining the height of the water-conductive fractured zone based on the radial basis function neural networks (RBFNN) model in MATLAB software. Before modeling, the relationship between the height of the water-conductive fractured zone and mining thickness, the lithologic character of the overburden and its composite structures, and workface parameters was studied. After that, 32 and 7 measured data were used as training and testing samples, respectively. It has been found that the average relative error is 6% and the maximum relative error is 10% for 7 test samples by comparing actual results with predicted results. The model was applied to the no. 31503 workface in the Gaozhuang coal mine for safety evaluation. The predicted value is 59.6 m, and the measured value is 55.9 m. The RBF-based model shows much better performance than empirical formulae in the Regulations for Coal Mining and Coal Pillar Design under Buildings, Water-bodies, Railways and Main Shafts for the prediction of the height of the water-conductive fractured zone for fully mechanized mining with sublevel caving.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Underground coal mining causes movement and failure, with a result of “three zones” in overlying strata, including the caving zone, the water-conductive fractured zone, and the sagging zone (Liu 1995). When the coal seams are close to the surface or underground waterbodies, setting up the safety coal and rock pillar is an important measurement. If the size of the safety coal and rock pillar is ill-suited, the water-conductive fractured zone could connect with the waterbodies. One key problem of this contradiction among safety, coal resources, water protection, and ecology is how to retain a reasonable safety coal and rock pillar under waterbodies, including the determination of the water-conductive fractured height and the selection of protective-layer thickness. It is important to accurately predict the height of the water-conductive fractured zone to protect the waterbodies, to retain ecological environment, and more importantly, to ensure safety in production.

For the height of the caving zone and the water-conductive fracture zone, the determination methods mainly adopt empirical formulae (State Bureau of Coal Industry 2000), statistical analysis (Zhao et al. 2015; Ma et al. 2008; Yang et al. 2015; Hu et al. 2012), theoretical analysis (Miao et al. 2011; Xu et al. 2012; Shi et al. 2012; Wang et al. 2012), numerical simulation (Wu et al. 2008; Jia et al. 2015), physical simulation (Zhang et al. 2011a), and field measurement (Liu et al. 2000; Liu et al. 2005; Zhang et al. 1996; Gan et al. 2006; Zhang et al. 2000). Among them, the empirical formulae are mainly based on Appendix 6 in the Regulations for Coal Mining and Coal Pillar Design under Buildings, Water-bodies, Railways and Main Shafts, but these formulae are not applicable to fully mechanized longwall mining with sublevel caving. Fully mechanized longwall mining with sublevel caving has been widely applied to thick coal seam mining with the improvement of mechanization. But when using this technology, the height of the water-conductive fractured zone increases markedly, and the existing formulae have been unable to meet the demand of engineering. Therefore, it is necessary to establish a new formula or a model applicable to thick coal seam mining using fully mechanized longwall mining with sublevel caving.

A complete set of technical system for coal mining under waterbodies has been developed in the recent decade. Industrial experiments at the no. 11201, no. 14141, and no. 14191 workface under the Xiaolangdi reservoir were successfully carried out using numerical simulations combined with geophysical methods (Xu et al. 2010). The field measurements were carried out in the upward-inclined drillhole using the measuring instrument in the Beizao coal mine for mining coal seam undersea (Gao et al. 2009). The leakage of washing fluid and color-imaging observations in the bolehole were used for mining in the fully mechanized mining with sublevel caving workface under the river (Liu et al. 2013). The empirical formulae were obtained suitable for medium-hard and soft strata using regression analysis of mathematical statistics (Xu et al. 2011). The back-propagation (BP) neural networks were established to predict the height of the water-conductive fractured zone, based on six influencing factors, including the mining height, bedrock thickness, dip angle, uniaxial compressive strength of roof strata, proportion of mudstone, and structure of overlying strata (Chen et al. 2005; Chen 2008). Field measurement and similar material simulation were combined to determine the height of the water-conductive fractured zone (Zhang et al. 2011b; Chen et al. 2006). These achievements provide a successful practice for the evaluation and application of coal mining under large waterbodies. Thus, on the premise of determinate hydrogeological conditions, it is an effective way of improving the safety mining limit, mining the resting coal resources under waterbodies (including rivers, lakes, seas, reservoirs, and the bottom aquifer of the Quaternary System) by predicting the height of the water-conductive fractured zone, reducing the thickness of the safety coal and rock pillar.

Based on multiple measured data of the height of the water-conductive fractured zone, this paper investigates the relationship between the height of the water-conductive fractured zone and the mining height, and the lithology of overlying strata with its combination, and establishes the neural network prediction model of the height of the water-conductive fractured zone for fully mechanized longwall mining with sublevel caving. This method guides practice for the reasonable retainment of the safety coal and rock pillar using fully mechanized longwall mining with sublevel caving, and provides a scientific basis for safe mining of coal seams close to waterbodies.

Background

Gaozhuang coal mine is located in Fucun town of Weishan county, and the coal seams belong to Tengnan coalfield. The strata of coal-bearing formation from the top down are as follows: (1) Quaternary alluvium, about 70~86 m thick, is mainly composed of sand, sandy loam, clayey sand, loam, and clay alternately. Quaternary alluvium, which is the main aquifer in this coalfield, is divided into upper and lower formations according to its sedimentary conditions and water yield property; the upper formation has the character of rich water bearing and strong permeability, but the lower formation is just the opposite. There is no hydraulic connection between the upper and lower formations because of the loam deposits. (2) Shihezi Formation of the Permian System, about 55 m thick, is mainly composed of sandstone and sandy mudstone. (3) Shanxi Formation of the Permian System, about 80 m thick, in conformity with the Taiyuan Formation above, has a lithology that includes sandstone and sandy mudstone, which appeared alternately. This formation includes three coal seams, among them no. 32 coal seam which is the main mining coal seam in this coalfield because it is relatively stable. (4) Taiyuan Formation of the Upper Carboniferous System, about 80 m thick, in disconformity with the Benxi Formation above, has a lithology that includes sandstone and mudstone. This formation includes 15 coal seams, among them most of no. 122, no. 16, and no. 17 coal seams are minable and others are nonrecoverable. (5) Benxi Formation of the Carboniferous System, about 35 m thick, is mainly composed of alternating variegated mudstone, limestone, etc. (6) Ordovician System, about 650 m thick, is the base of coal-bearing strata, and its composition is mainly laminated limestone with developed fractures and water-eroded caves.

The 31503 workface in Gaozhuang coal mine adopts fully mechanized longwall mining with sublevel caving method. The strike length is 1065 m, and the inclined width is 170 m. The dip angle of the coal seam is about 11°~17°, the average value is 14°, and the average thickness of the coal seam is 4.6 m. Therefore, the coal seam in this workface has a simple structure and stable occurrence condition. The main influential overlying waterbody for the 31503 workface is a weak water-abundance fissured sandstone aquifer. The water yield is strong in the shallow region due to the existence of developed fractures. In order to predict whether the workface has an inrush of water from the roof, it is necessary to calculate the height of the water-conductive fractured zone in this workface before mining, relying on an effective and efficient decision-making method.

Methodology

Back-propagation (BP) neural networks easily appear in the local minimum; in order to overcome the problem, the artificial neural networks based on the radial basis function are adopted in this paper. Radial basis function neural networks (RBFNN), which have the characteristics of simple structure, fast convergence, and the ability of approximating any nonlinear function, are widely used in data modeling, prediction, pattern recognition, and function optimization.

In comparison with the BP function, the radial basis function could train networks both online and offline, and could dynamically determine the networks’ structure, the data center, and expansion constant in the hidden layer. RBF neural networks have a faster speed in learning and a better performance in algorithm than BP neural networks.

Structure and algorithm of the RBF neural network model

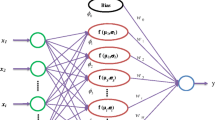

The RBF neural network model is a kind of forward networks, composed of three layers including the input layer, the hidden layer, and the output layer. Among them, the number of nodes in the input layer is equal to the dimension of input data, the number of nodes in the hidden layer is determined based on the complexity of the model, and the number of nodes in the output layer is equal to the dimension of the output data. The typical structure of a RBFNN is shown in Fig. 1.

The neurons in the hidden layer of the RBF neural network model are determined by the following function:

where x is the data of input samples, c i is the central point, σ is the width of the radial basis function around the central point, G(⋅) is the radial basis function, ‖x − c i ‖ is the distance function on behalf of the distance between the central point and the sample value, and ψ i (x) is the output data of networks.

The neurons in the hidden layer usually adopts the Gaussian function, then the above neuron model becomes as follows:

Model establishment

In this section, the components of establishing the RBF neural network model are introduced for the height prediction of the water-conductive fractured zone, and the following steps are employed to establish the RBF neural network model.

-

Selection of factors which influence the height of the water-conductive fractured zone

-

Collection of sample data for network training and testing

-

Optimization of the proposed RBFNN model by changing the basic parameter in the networks

-

Comparison of the developed RBFNN model with actual results in the testing samples

Influencing factors of the water-conductive fractured zone

The factors influencing the height of the water-conductive fractured zone mainly include (1) the lithology of the overlying strata and its combination. The lithology of the overlying strata is classified into four types including ultra-soft, soft, medium-hard, and hard. The combination is divided into four types, namely soft-soft, soft-hard, hard-soft, and hard-hard. (2) Mining method and roof management method. This paper is mainly aimed at fully mechanized longwall mining with sublevel caving, without considering the influence of the mining method and the roof management method. (3) Mining depth and the dip angle of the coal seam. Generally speaking, fully mechanized longwall mining with sublevel caving is only applicable to a gently inclined seam (smaller extent variation in the dip angle of the coal seam), so the dip angle has little influence on the water-conductive fractured zone. (4) Geological structure. (5) The time process. Generally, the height of the water-conductive fractured zone reaches a maximum value of 1~2 months later after the coal seam is mined. (6) Workface parameters. Full subsidence of the workface slightly affects the water-conductive fracture zone, which appears when both the length and width of the goaf meet or exceed 1.2~1.4 H 0 (H 0 is the average mining depth).

In light of the above analysis, the mining height and the lithology of the overlying strata were selected as the influencing factors in this paper. Because the lithology of the overlying strata is a qualitative factor, this factor was quantized using numerical values 1, 2, and 3 as soft, medium-hard, and hard, respectively.

Sample datasets for network training

Based on the multiple measured datasets of the height of the water-conductive fractured zone, the 32 measured data (in Table 1) were selected as training samples of the RBF neural networks.

Network training

Radial basis networks are created by the Newrb function in the neural network toolbox using MATLAB software. In this model, the error is 1e−8, the diffusion factor is 45, the maximum number of neurons is 100, and the number of nodes in the hidden layer constantly adjusts based on the error target.

Model testing

Measured datasets (in Table 2) are used for model testing to check the performance of RBF neural networks. From the results in Fig. 2 and Fig. 3, the predicted values of seven test samples are very close to the actual value. The average relative error is 6%, and the maximum relative error is 10% in the seven samples. As a result, the RBF neural network model can accurately establish the relationships between the height of the water-conductive fractured zone and the mining height, and the lithology of overlying strata.

Model application

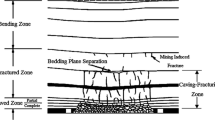

The previous studies on mining-induced failure characteristics of overlying strata using numerical simulation and physical simulation are shown in Fig. 4 and Fig. 5. These methods are only as auxiliary ways to investigate the height of the water-conductive fractured zone.

According to the predicted formulae of the height of the water-conductive fractured zone for slicing of thick coal seam (in Table 3) in the Regulations for Coal Mining and Coal Pillar Design under Buildings, Water-Bodies, Railways and Main Shafts, the height of the water-conductive fractured zone in 31503 workface is about 41.9 ± 5.6 m. Based on the prediction model of RBF neural networks for fully mechanized mining with sublevel caving workface, the height of the water-conductive fractured zone is 59.6 m.

Model verification

After the coal seam was mined in the 31503 workface, the field measurement was carried out in an upward-inclined hole using the water injection system; the observation system is shown in Fig. 6. The photos of the water injection work station and plugging work station are shown in Fig. 7a, and the photo of the probe is shown in Fig. 7b.

The ichnography and the profile masp of field measurement are shown in Fig. 8 and Fig. 9. Three drill holes which are numbered no. 1, no. 2, and no. 3 are designed with different lengths and dip angles in premining and post-mining. During the detection, the leakage of washing fluid was recorded, which could reflect the development height of the fractures.

Results

According to the comparison of leakage of washing fluid in Fig. 10a, b, the height of the water-conductive fractured zone in the no. 2 drill hole is 55.9 m (the corresponding depth of the drill hole is 59.5 m; the dip angle of the drill hole is 70°); the value is 54.9 m (the corresponding depth of the drill hole is 63 m; the dip angle of the drill hole is 60°) in the no. 3 drill hole. Therefore, the height of the water-conductive fractured zone in the 31503 workface is 55.9 m.

The results of field measurement show that the maximum height of the water-conductive fractured zone is 55.9 m. The predicted value is 59.6 m using the RBFNN model. Consequently, the calculated result using RBF neural networks is closer to the measured values than empirical formulae results with low error and high precision.

Discussion

Artificial intelligence tools like neural networks are being attempted and have obtained better results in the prediction of the height of the water-conductive fractured zone, but the RBFNN model which is derived in this paper based on the sample data of field measurement is limited to the ultra-soft overlying strata. Therefore, it is necessary to develop the model by collecting more sample data. The model will be improved in the future with increasing engineering application.

Conclusions

In this study, factors influencing the height of the water-conductive fractured zone were discussed, and multiple sample data were selected; the model was established based on the RBFNN. The following main conclusions are reached: The results of field measurement show that the maximum height of the water-conductive fractured zone is 55.9 m. The predicted value is 59.6 m using the RBFNN model. Consequently, the calculated result using RBF neural networks is closer to the measured values than empirical formulae results.

References

Chen PP (2008) Forecasting of destroyed height of overlying rock with the top coal caving based on ANN. Journal of Coal Science & Engineering 14(2):190–194

Chen RH, Bai HB, Feng MM (2006) Determination of the height of water flowing fractured zone in overburden strata above fully mechanized top coal caving face. Journal of Mining & Safety Engineering 23(2):221–223

Chen PP, Liu HQ, Zhu ZX, Yan Y (2005) Height forecast of water conductive zone with top coal caving based on artificial neural network. J China Coal Soc 30(4):38–442

Gan ZC, Zhang HX, Liu HQ (2006) Application of EH-4 electro-conductibility imaging system in the detection of “two-zones” height. Coal Mining Technology 11(3):14–18

Gao YF, Qu ZJ, Xing F, Qu GL, Li L (2009) Observation of height of excavating face H2106 in Longkoubeizao Mine under sea. Coal Geology and Exploration 37(6):35–38

Hu XJ, Li WP, Cao DT, Liu MC (2012) Index of multiple factors and expected height of fully mechanized water flowing fractured zone. J China Coal Soc 37(4):613–618

Jia HG, Cao QG, Zhang GB, Yu XW, Liu GJ (2015) Failure features of overlying strata in conditions of fully-mechanized caving mining under nearly thick unconsolidated aquifer and safety mining analysis. Safety in Coal Mines 46(8):195–198

Liu TQ (1995) Influence of mining activities on mine rockmass and control engineering. J China Coal Soc 20(1):1–5

Liu WT, Song CW, Ma YC, Kong LZ (2000) Detection technology for damage area of rock in the down hole. Coal Science and Technology 28(6):14–18

Liu WT, Wu Q, Li XZ, Chen DY (2005) Measurement and simulation of damage height of overburden rock. Coal Mine Modernization 5:29–31

Liu G, Zhang HX, Liu ZG, Zou YP, Guo AG, Cui F (2013) Observation and simulation research on development features of overlying strata failure in conditions of fully-mechanized top-coal caving mining under river. J China Coal Soc 38(6):987–993

Ma YJ, Wu Q, Zhang ZY, Hong YQ, Guo LW, Tian HS, Zhang LG (2008) Research on prediction of water conductive fissure height in roof of coal mining seam. Coal Science and Technology 36(5):59–62

Miao XX, Cui XM, Wang JA, Xu JL (2011) The height of fractured water-conducting zone in undermined rock strata. Eng Geol 120:32–39

Shi LQ, Xin HQ, Zhai PH, Li SC, Liu TB, Yan Y, Wei WX (2012) Calculating the height of water flowing fracture zone in deep mining. J China Univ Min Technol 41(1):37–41

State Bureau of Coal Industry (2000) Regulations for coal mining and coal pillar design under buildings, water-bodies, railways and main shafts. China Coal Industry Publishing House, Beijing

Wang LG, Wang ZS, Huang JH, Zhou DL (2012) Prediction on the height of water-flowing fractured zone for shallow seam covered with thin bedrock and thick windblown sands. Journal of Mining & Safety Engineering 29(5):607–612

Wu X, Wang XG, Duan QW, Yu QC, Yang J, Sun YD (2008) Numerical modeling about developing high of water flowing fractured zone. J China Coal Soc 33(6):609–612

Xu YC, Li JC, Liu SQ, Zhou L (2011) Calculation formula of “two-zone” height of overlying strata and its adaptability analysis. Coal Mining 16(2):4–7 11

Xu ZM, Sun YJ, Dong QH, Zhang GW, Li S (2010) Predicting the height of water-flow fractured zone during coal mining under the Xiaolangdi Reservoir. Min Sci Technol 20:434–438

Xu JL, Zhu WB, Wang XZ (2012) New method to predict the height of fractured water-conducting zone by location of key strata. J China Coal Soc 37(5):762–769

Yang GY, Chen C, Gao SL, Feng B (2015) Study on the height of water flowing fractured zone based on analytic hierarchy process and fuzzy clustering analysis method. Journal of Mining & Safety Engineering 32(2):206–212

Zhang PS, Hu XW, Liu SD (2011a) Study of dynamic detection simulation of overburden failure in model workface. Chin J Rock Mech Eng 30(1):78–83

Zhang WQ, Liu WT, Gao YF, Huang ZX, Zheng YR, Xie YL (1996) Study of the characteristics of deformation and failure in overlying strata movement caused by fully-mechanized sublevel caving mining in 63110 face of Nantun mine. Journal of Shandong Mining Institute 15(4):24–28 38

Zhang XM, Yu KJ, Xi JD, Kong FM, Zhang XB, Wang SJ (2000) The research and application of microseismic technology in mine fractured and caving zones monitoring. Journal of China Coal Sciety 25(6):566–570

Zhang B, Zhang K, Xu YC (2011b) Study on failure law of cretaceous overburden strata under conditions of fully mechanized top coal caving mining. Coal Science and Technology 39(10):5–10

Zhao ZM, Liu YL, Li Y, Dong W, Shi TW (2015) Process optimization of height prediction of water flowing fractured zone based on ANN. Mining Safety & Environmental Protection 42(3):47–53

Acknowledgments

This research is financially supported by National Key Research Program of China during 13th Five Year (No. 2016YFC0801801), China National Natural Science Foundation (Grant No. 41572222, No. 41272276, No. 41430318, No. 51274135), Innovation Research Team Program of Ministry of Education (IRT1085). The authors would like to thank the scholars for their sample data in the field measurement. The authors would also like to thank the editor and the reviewers for their constructive suggestions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, Q., Shen, J., Liu, W. et al. A RBFNN-based method for the prediction of the developed height of a water-conductive fractured zone for fully mechanized mining with sublevel caving. Arab J Geosci 10, 172 (2017). https://doi.org/10.1007/s12517-017-2959-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-017-2959-3