Abstract

Pecan nut oil is conventionally obtained by mechanical extraction characterized by a low oil extraction yield (OEY) compared to solvent extraction. Pulsed electric fields (PEF) have been employed as a pretreatment to enhance OEY from several oilseeds, but no studies have been found regarding tree nut oil. Hence, PEF was applied at different specific energy inputs (0.5–17.6 kJ kg−1) to evaluate its impact on OEY, oil acidity, and antioxidant capacity (AC), along with total phenolics (TP), condensed tannins (CT), and AC of the by-product generated from oil extraction. Kernels treated by PEF were compared against untreated and soaked kernels due to sample water immersion during PEF processing. The water immersion reduced the initial oil content of soaked and PEF-treated kernels (7.3–11.7%), transferring between 3.8 ± 0.0 and 6.2 ± 0.1 g of oil into the soaking water (\({o}_{SW}\)). OEYTOTAL of soaked and PEF-treated samples was calculated considering \({o}_{SW}\). The application of 0.5 kJ kg−1 increased OEYTOTAL by 21.4 and 17.6% compared to untreated and soaked kernels, respectively, while oil acidity and AC of PEF-treated kernels were within values reported for pecan nut oil. The highest concentration of TP and CT in the by-product was achieved at 0.8 kJ kg−1, increasing 9.5 and 30.1%, respectively, compared to untreated kernels. Results evidenced that PEF processing might be a suitable technology to increase OEY from pecan nuts, but the oil extracted during kernels water immersion must be recovered. Furthermore, the by-product of PEF-treated kernels displayed an enhanced content of phenolic compounds increasing its potential as food ingredient.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The pecan nut [Carya illinoinensis (Wangenh. K. Koch)] is among the most commonly consumed tree nuts worldwide [24]. At being native from North America, pecan nuts are considered an economically important nut crop to Mexico and the USA, being Mexico responsible for almost 50% of pecan nuts worldwide production [16, 24].

Pecan nuts intake has been associated with positive effects on human health due to their significant concentration of phenolic compounds along with mono- and polyunsaturated fatty acids [2, 6]. Kernels phenolic compounds profile is mostly composed by condensed tannins which have been related to pecan nuts antioxidant capacity [29, 39, 41], while kernels fatty acids profile includes oleic, linoleic, and α-linolenic acids [6, 39]. In comparison to olives, pecan nuts contain a higher concentration of polyunsaturated fatty acids and a lower concentration of saturated fatty acids [51]. Phytosterols and tocopherols have also been identified as minor components of pecan nuts. As a result, pecan nut oil has been recognized as a specialty oil increasing its commercial value [3, 10, 23].

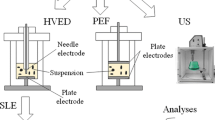

Pecan nut oil is commonly extracted by mechanical processes to preserve its compositional characteristics. In these processes, kernels are pressed using a screw press or expeller with the advantages of low cost and simple use [9, 10]. Furthermore, a by-product, usually named cake, rich in carbohydrates, proteins, dietary fiber, and phenolic compounds is obtained from the oil extraction [2, 42]. The cake has been suggested as an ingredient in bakery products with the potential to enhance products’ functional properties due to its water and oil absorption capacities along with its phenolic compounds concentration [29, 31]. Nevertheless, the main drawback of oil mechanical extraction from pecan nuts is its low oil extraction yield (OEY) compared to solvent extraction (< 60.0%) [10, 11]. In order to increase OEY, drying or enzymatic processes have been applied as pretreatments to oilseeds, modifying the phytochemical profile of the extracted oil and negatively affecting its physicochemical properties [9, 27]. As an alternative to improve extraction processes and maintain oil quality, food processing technologies such as ultrasonics, high voltage electrical discharges, and pulsed electric fields (PEF) have been applied as assisting processes [25, 37].

PEF is a nonthermal technology consisting in the application of high-voltage pulses (1–80 kV cm−1) from µs to ms duration [26, 32]. Its mechanism is based on the cell membrane disruption caused by the increment in the cell membrane conductance leading to pore formation [7]. The cell membrane disruption might occur as a reversible or irreversible process depending on the electrical conditions. In a reversible disruption, the cell membrane closes pores by phospholipids and proteins rearrangement. In an irreversible disruption, the cell membrane is not able to close pores, causing the loss of cell integrity [19]. Recently, PEF is being applied as a pretreatment to induce the secondary metabolism in fruit and vegetables as well as to enhance different industrial processes such as drying, freezing, and frying. For instance, López-Gámez et al. [28] and González-Casado et al. [15] reported an increment in the concentration of carotenoids in carrots and tomatoes treated by PEF after 24 h of storage. Whereas Traffano-Schiffo et al. [49] observed that PEF increased the dehydration rate of kiwifruit by electrolytes’ loss, and Tylewicz et al. [50] reported an improvement in the storage stability of freeze-dried apples pretreated by PEF.

Furthermore, the application of PEF to improve mechanical extraction processes of juices, oils, and other products have been reported to enhance the content of the bioactive compounds and preserve the sensory characteristics of extracted products [12, 46, 48]. Veneziani et al. [52] reported an increment between 2.3 and 6.0% in OEY from olives treated by PEF, producing an oil with a higher concentration of phenolic compounds and no significant changes in its sensory properties. Han et al. [19] used PEF as a pretreatment to oil extraction from microalgae Chlorella pyrenoidosa, reporting an increase of 12.0% in OEY compared to an ultrasound pretreatment. Sarkis et al. [43] reported a higher OEY in sesame seeds treated by PEF in comparison with untreated seeds. In another research, Abenoza et al. [1] evaluated the application of PEF to increase OEY from olive paste reporting an improvement of 13.9%. Guderjan et al. [17] observed an increment of 39.1% in OEY from rapeseeds treated by PEF. Concerning research relating tree nuts and PEF, Manzoor et al. [30] combined PEF and ultrasound technologies to improve phenolic compounds extraction from defatted almonds, increasing their extraction and antioxidant capacity by 33.3 and 41.7%, respectively. However, no studies concerning the impact of PEF technology on OEY and tree nuts oil composition have been found. Therefore, the objective of this work was to apply PEF as a pretreatment to improve oil extraction from pecan nut kernels evaluating the effect of the specific energy input (W) on OEY, oil characteristics (acidity and antioxidant capacity), and cake phenolic compounds (total phenolics, condensed tannins, and antioxidant capacity).

Materials and Methods

Chemicals

Acetone, ethyl acetate, hexane, methanol (MeOH), 2,2-diphenyl-1-picrylhydrazyl (DPPH), 6-hydroxy-2,5,7,8-tetramethylchromane-2-carboxylic acid (trolox), catechin, Folin-Ciocalteu reagent, gallic acid, hydrochloric acid (HCl), potassium hydroxide (KOH) solution (0.1 M), sodium carbonate (Na2CO3), acetic acid (CH3COOH), and vanillin were purchased from Sigma-Aldrich (USA). Solutions were protected from light and stored at 4 °C.

Pecan Nuts

Fresh pecan nuts (Carya illinoinensis, Western variety) were harvested in autumn 2018 directly from the orchard [Sonora, Mexico (27° 29′ 38″ N, 109° 56′ 20″ W)]. In-shell nuts were vacuum-packaged (EVD 4, TORREY, Mexico) and immediately delivered by air to the University of Lleida in Spain where experiments were conducted. In the laboratory, in-shell nuts were shelled, placed in polyethylene bags (Cryovac Europe, Spain), vacuum-sealed (Egarvac® Basic 9, Egarvac S. C. P., Spain), and stored at 4 °C until experiments. Kernel halves were manually sectioned in half and divided into three different groups: (i) a reference that consisted of kernels without soaking nor PEF treatment, (ii) a control of kernels soaked in tap water (1:3 w/w) for 20 min, and (iii) pecan nuts treated by PEF. Experiments were performed at room temperature, and the conductivity of tap water was 463 µS cm−1. Among PEF treatments, the temperature of the soaking water was randomly measured, not being higher than 30 °C. Control and PEF-treated kernels were drained for 10 min; then, samples were taken to moisture determination. Before oil extraction, reference, control, and PEF-treated kernels were frozen at − 16 °C for 24 h and freeze-dried (− 50 °C, 1 mbar) for 72 h (Cryodos 50, Telstar Cryodos, Spain).

Pulsed Electric Field Application

PEF treatments were conducted in a batch equipment with a 0.1-µF capacitor (Physics International, USA) delivering monopolar exponential-wave pulses (pulse width, 4 µs) using a TG-70 gas control unit and a pulse generator (PT-55, Pacific Atlantic Electronics Inc., USA). Kernel halves were manually sectioned in half, immersed in tap water with a conductivity of 463 µS cm−1 (1:3 w/w), and placed in parallelepiped methacrylate containers (20 × 8 cm) equipped with stainless steel parallel electrodes. Treatments were performed at different electric field strengths (E, 2.0, 5.0, 7.5 kV cm−1) and pulse number (n, 10, 55, 100) (Table 1). The specific energy input (W), expressed as kJ per kg of kernels in wet basis (kJ kg−1 wb), was calculated according to Eqs. 1 and 2:

where \(V\) is the input voltage (kJ Coulomb−1), \(E\) is the electric field strength (kV cm−1), \(d\) is the distance between electrodes (cm), \(C\) is the capacitance of the energy storage capacitor (Coulomb2 kJ−1), \(n\) is the number of pulses, and \(m\) is the initial mass of kernels (kg wb).

Mechanical Extraction of Pecan Nut Oil

Freeze-dried reference, control, and PEF-treated kernels (85.0 g) were placed in an expeller type screw press (YD-ZY-02A, Yoda Europe, China) for oil mechanical extraction. All samples were submitted to the same preset conditions while kernels feeding along with oil and cake recovery were standardized to prevent oil and cake loss. The extracted oil was stored at − 40 °C in 50-mL centrifuge tubes avoiding oil oxidation by flushing N2 in the head-space. The tubes were sealed with parafilm until analyses. The cakes generated from the oil extraction were placed in 12 × 15 cm polyethylene bags, vacuum-sealed, and stored at − 40 °C.

Oil Extraction Yield

The oil extraction yield (OEY, %) of reference, control, and PEF-treated kernels was calculated as follows:

where \({m}_{K}\) and \({m}_{C}\) are the mass (g) of freeze-dried kernels and cakes, respectively, while \({L}_{K}\) and \({L}_{C}\) are the oil content expressed as g of oil per 100 g of freeze-dried kernels and cakes, respectively, all in dry basis (g 100 g−1 db).

The oil extracted into the soaking water (\({o}_{SW}\)) was calculated to determine the total OEY (OEYTOTAL) of control and PEF-treated kernels using Eqs. 4 and 5:

where \({o}_{SW}\) is the mass (g) of oil retained into the soaking water and \({L}_{Reference}\) is the oil content of reference kernels expressed as g·100 g−1 db.

Moisture

The AOAC 920.151 method was employed to moisture determination of reference, control, and PEF-treated kernels [5]. Results were expressed as g·100 g−1 db.

Oil content

Oil content of freeze-dried kernels and cakes were determined by solvent extraction as reported by Villarreal-Lozoya et al. [53] with modifications. Freeze-dried kernels were ground in a laboratory mortar (2.5 g) while cakes were directly weighed (2.5 g). Samples were mixed with hexane (1:10 w/v) for 1.5 min at 6000 rpm (IKA® T25 Ultra-turrax, IKA, Germany) then centrifuged (8500 rpm, 15 min, 20 °C) (Beckman Avanti™ J-25, Beckman Instruments Inc., USA) and supernatants collected. This procedure was repeated three times. Pooled supernatants were concentrated using a rotary evaporator (25 rpm, 45 °C) (BÜCHI Rotavapor R-3000, BÜCHI Labortechnik AG, Spain), and the extracted oil was used to determine oil content gravimetrically based on the AOAC 960.39 procedure [5]. Oil content of freeze-dried kernels and cakes was expressed as g 100 g−1 db.

Oil Analysis

Acidity

Oil acidity was determined following the AOAC 940.28 method [5], and results were expressed as mg KOH per 100 g of pecan nut oil (mg KOH·100 g−1).

Antioxidant Capacity

Antioxidant capacity (AC) was evaluated using the DPPH radical scavenging capacity method reported by Gao et al. [14] with modifications. A DPPH solution was prepared by dissolving 0.05 g of DPPH in 250 mL of MeOH. Pecan nut oil (200 µL) diluted in ethyl acetate (2 mL) was mixed with the DPPH solution (2 mL). The reaction was left 15 min in darkness and absorbance measured at 515 nm using a UV-VIS spectrophotometer (Cecil CE 1010, Cecil Instruments Ltd., England). Trolox was used for the standard curve (0.003–0.030 mg mL−1) to express results as mg trolox equivalents per 100 g of pecan nut oil (mg trolox EQ·100 g−1).

Cake Analysis

A defatted cake was obtained after oil content determination by allowing to evaporate overnight the remaining hexane. Defatted cakes were sieved, placed in 6 × 15 cm polyethylene bags, vacuum sealed, and stored at − 40 °C. Aqueous and methanolic extractions were performed as described by Rábago-Panduro et al. [39].

In the aqueous extraction, defatted cake samples (0.3 g) were mixed with an extraction solution consisting on acetone:H2O:CH3COOH (70:29.5:0.5) in 1:10 w/v proportion. The mixture was sonicated in an ultrasonic bath for 30 min, centrifuged (8500 rpm, 15 min, 20 °C), and supernatants collected. The extraction process was performed twice. Next, the extraction solution was evaporated using N2 and the concentrated was diluted to 5 mL with distilled water. Aqueous extracts were stored in 15-mL centrifuge tubes at 4 °C until total phenolics (TP) and AC analysis. The methanolic extraction was performed by mixing defatted cakes (0.1 g) with a 1% MeOH:HCl solution (1:30 w/v). The mixture was placed in a water bath (20 min, 30 °C). After this time, supernatants were collected by centrifugation (8,500 rpm, 15 min, 20 °C) and diluted to 5 mL with 1% MeOH:HCl solution. Methanolic extracts were stored in 15-mL centrifuge tubes at 4 °C until condensed tannins (CT) analysis.

Total Phenolics

Folin-Ciocalteu method reported by Singleton and Rossi [47] and adapted by Villarreal-Lozoya et al. [53] was followed to TP determination. Aqueous extracts (13 µL) were pipetted into a 96-well flat-bottom plate (Costar® Assay Plate #9017, Corning, USA) followed by Folin-Ciocalteu solution (221 µL) and led to react for 3 min in the dark. Next, 0.50 M Na2CO3 solution (26 µL) was added and the plate was incubated for 2.5 h in darkness. A microplate reader (Multiskan™ GO, Thermo Scientific™, Finland) was used to absorbance measurement at 765 nm employing a curve of gallic acid (0.1–1.0 mg mL−1) as standard. Results were expressed as mmol gallic acid equivalents per 100 g of defatted cake db (mmol gallic acid EQ·100 g−1 db).

Antioxidant Capacity

DPPH radical scavenging capacity was employed to evaluate cakes antioxidant capacity [53]. A DPPH stock solution (1.3 mM) was diluted (1.5:10 v/v) in MeOH. Aqueous extracts (26 µL) were loaded into a 96-well flat bottom plate (Costar® Assay Plate #9017, Corning, USA) along with 234 µL of diluted DPPH. Absorbance measurements were made in the microplate reader at 515 nm and registered every minute until 15 min of reaction. Trolox was used for the standard curve (0.02–0.10 mg mL−1) to express the results as mmol trolox equivalents per 100 g of defatted cake db (mmol trolox EQ·100 g−1 db).

Condensed Tannins

The HCl-vanillin method reported by Price et al. [36] and modified by Herald et al. [22] was employed to analyze CT. From a vanillin stock solution (0.065 M), a dilution (1:1 v/v) was made with 8% MeOH:HCl. Methanolic extracts (30 µL) were pipetted in a 96-well flat-bottom plate (Costar® Assay Plate #9017, Corning, USA) followed by the vanillin dilution (150 µL) and led to react for 20 min at 30 °C. The blank was 1% MeOH:HCl and absorbance was measured at 500 nm using the microplate reader. A curve of catechin (1.0–3.5 mg mL−1) was utilized as standard and results expressed as mmol catechin equivalents per 100 g of defatted cake db (mmol catechin EQ·100 g−1 db).

Soaking Water Analysis

Given the low water solubility of condensed tannins, TP was selected to follow the release of the water-soluble phenolic compounds present in pecan nuts into the soaking water [21]. Aliquots of the soaking water (500 µL) were centrifuged (8000 rpm, 15 min, 20 °C) (Hettich® Universal 320R, Hettich, Germany), and supernatants were employed to measure TP as described in the “Total Phenolics” section. Results were expressed as mmol gallic acid equivalents per 100 g of soaking water (mmol gallic acid EQ·100 g−1).

Statistical Analysis

Reference, control, and PEF processing along with oil and cake analytical determination were performed by duplicate. Results were analyzed through a one-way ANOVA followed by the Dunnett test and calculation of correlation coefficients using Minitab 18 software (Minitab® 18.1, USA). Pearson (r) and Spearman (ρ) correlation coefficients were determined based on data distribution; r for data normally distributed, and ρ for not normally distributed data or data with outliers [45].

Results and Discussion

Moisture and Oil Content of Pecan Nut Kernels

Moisture and oil content of reference, control, and PEF-treated kernels are shown in Table 2. Reference samples contained a moisture and oil content of 3.2 ± 0.1 and 61.2 ± 3.0 g 100 g−1 db, respectively. Moisture increased up to 24.9 ± 0.7 g 100 g−1 db in control kernels while the moisture content of PEF-treated kernels ranged from 18.7 ± 2.3 to 21.7 ± 2.3 g 100 g−1 db (Table 2). According to the Dunnett test, no significant differences between moisture of control and PEF-treated samples were observed (α = 0.05). The oil content of reference kernels was 61.2 ± 3.0 g 100 g−1 db decreasing to 54.9 ± 0.8 g 100 g−1 db in control kernels, whereas in PEF-treated kernels reduced between 54.0 ± 2.9 and 56.7 ± 1.1 g 100 g−1 db. Regarding the \({o}_{SW}\), control and PEF-treated samples displayed comparable values ranging from 3.8 ± 0.0 to 6.2 ± 0.1 g with the lowest \({o}_{SW}\) observed in kernels pretreated at 5.0, 7.8, and 17.6 kJ kg−1 (Table 2). Moisture and oil content of control and PEF-treated samples were similar, suggesting that these changes might be related to the soaking process. The oil retained into the soaking water could be related to kernels grinding and water immersion, modifying their microstructure. Fatty acids are located in small and spherical structures called oleosomes; these organelles are constituted by a core of triacylglycerols stabilized by a monolayer of phospholipids and proteins found in the cotyledon tissue of pecan nut kernels [20, 39, 54]. According to Zhang et al. [54], it is possible to extract oleosomes from the cotyledon tissue of pecan nuts by grinding and water immersion. In this line, it is suggested that the exposure of cotyledon tissue due to kernels sectioning and the moisture gained during water immersion might facilitate oleosomes transfer to the soaking water.

Effect of PEF Processing on OEY, Acidity, and AC

OEY

The effect of PEF processing on OEY of pecan nut kernels along with those of reference and control kernels are displayed in Fig. 1. The OEY of reference samples was 63.8 ± 1.5% being comparable to OEY reported for the mechanical extraction of pecan nut oil [11, 35, 44]. Water immersion of control kernels decreased OEY to 54.2 ± 2.0%, representing a loss 14.9% compared to reference samples. The reduction of OEY due to water immersion was also reported by Polmann et al. [35] and Sarkis et al. [43] for pecan nuts and sesame seeds, respectively. Concerning the application of PEF, kernels treated at 0.5, 1.8, 4.3, 5.0, and 17.6 kJ kg−1 equaled OEY of reference kernels (Fig. 1). No linear relationship between W and OEY was observed (Table 3).The OEYTOTAL estimated by \({o}_{SW}\) determination was used to analyze the PEF effect on oil extraction yields. OEYTOTAL of control kernels was 65.8% being comparable to OEY of reference kernels. On the other hand, PEF-treated samples displayed OEYTOTAL that ranged from 68.9 to 77.4% improving oil extraction between 8.0 and 21.4% compared to reference samples (Fig. 1). The application of PEF as a pretreatment to increase oil extraction from pecan nut kernels displayed higher OEY than the enzymatic pretreatment reported by Polmann et al. [35] (65.2%). Furthermore, the OEYTOTAL of PEF-treated kernels was comparable to OEY achieved in the extraction of pecan nut oil using pressurized CO2 and n-butane (65.3–70.5%) [3, 44].

The improvement of oil extraction processes after PEF has been reported for maize, olives along with sunflower and sesame seeds, being associated with irreversible cell disruption due to the electroporation mechanism [18, 34, 43]. However, it is proposed that rather than irreversible cell disruption, pecan nut kernels pretreated by PEF might undergo reversible electroporation, producing changes in the cell structure that facilitates oil extraction. Han et al. [19] suggested that the improvement of OEY by PEF application could be related to the fusion of oil bodies within the cell and the release of intracellular water-soluble compounds. Furthermore, kernels water immersion reduced OEY, demonstrating that not only PEF parameters (W, E, n, pulse shape, and width) and food characteristics contribute to the OEY but also processing steps such as soaking, drying, and grinding. Andreou et al. [4] observed that more intense PEF pretreatments (≥ 20 kJ kg−1) lead to higher OEY, attributing this effect to a combination of cell disruption and demulsification of oil-in-water emulsions formed at the malaxation step during olive oil extraction. In contrast, Guderjan et al. [18] reported higher OEY of maize germ by combining a PEF processing of 0.6 kJ kg−1 with incubation and drying previous to oil extraction, and Sarkis et al. [43] reported higher OEY from sesame seeds pretreated at 40 kJ kg−1 followed by drying.

Oil Acidity and Antioxidant Capacity

Acidity and AC of oil extracted from reference, control, and PEF-treated kernels are shown in Table 4. Oil acidity of PEF-treated kernels varied from 21.3 ± 1.3 to 38.3 ± 1.4 mg KOH 100 g−1 being within values reported for cold-pressed and virgin oils of the Codex Standards for Fats and Oils from Vegetable Sources (≤ 40.0 mg KOH 100 g−1 oil) [13]. Similar results were described by Guderjan et al. [17], Puértolas and Martínez de Marañón [38], Andreou et al. [4], Moradi and Rahimi [34], and Veneziani et al. [52] for the acidity of oil extracted from rapeseeds, olives, and sunflower seeds pretreated by PEF. Guderjan et al. [17] reported that increments in oil acidity of rapeseeds pretreated by PEF might be due to the degradation of triacylglycerols by lipase activity. Likewise, Mohseni et al. [33] suggested that changes of intracellular materials and cell membrane rupture, as a consequence of PEF application followed by mechanical extraction, might favor the lipid-water interface changes necessary to lipase activation. Concerning oil antioxidant capacity, no significant differences were observed in AC of oil extracted from reference, control, and PEF-treated samples, except at 17.6 kJ kg−1 which produced the lowest AC (49.4 ± 2.6 mg trolox EQ 100 g−1) (Table 3). AC reduction at the most intense PEF treatment could be related to the loss of phenolic compounds into the soaking water evidenced by its increment in TP, as discussed below.

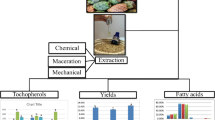

Effect of PEF Processing on TP, CT, and AC of Cakes and TP of Soaking Water

Total phenolics and condensed tannins of the cake generated from oil extraction of reference, control, and PEF-treated samples along with TP of the soaking water are shown in Fig. 2. TP and CT values of the cake of reference kernels were 24.2 ± 1.8 mmol gallic acid EQ 100 g−1 db and 24.7 ± 2.9 mmol catechin EQ 100 g−1 db, respectively, being comparable to values reported by Maciel et al. [29] for pecan nut cakes. PEF-treated samples resulted in cakes with similar TP values to those from control samples but below to the reference, except at 0.8 kJ kg−1. The application of 0.8 kJ kg−1 increased TP by 17.8 and 9.5% compared to control and reference cakes, respectively. Whereas PEF pretreatments greater than 0.8 kJ kg−1 led to an increment in TP in the soaking water directly proportional to the W applied (r = 0.866) (Fig. 2a). CT concentration of pecan nut cakes also increased with the specific energy input applied (W ≥ 5.0 kJ kg−1) except at 0.8 kJ kg−1, where the highest CT value was achieved (32.1 ± 3.0 mmol catechin EQ 100 g−1 db) (Fig. 2b). No significant differences were found between AC of cakes from kernels pretreated by PEF and those from control and reference samples (Tables 3, 5).

Effect of PEF pretreatments on total phenolics (TP) (a) and condensed tannins (CT) (b) of the cakes generated from pecan nut kernels and TP of the soaking water. Concentrations were expressed as mmol equivalents (EQ) per 100 g of defatted cakes in dry basis (db) and 100 g of soaking water, respectively. Means with an asterisk were significantly different from the control according to the Dunnett test (α = 0.05)

Extraction of phenolic compounds by PEF processing has also been described on sesame seeds [43], grape seeds [8], and defatted almonds [30], attributing it to electroporation of the cell membrane improving the release of hydrophilic compounds. Based on the changes of TP and CT concentration of cakes obtained after PEF pretreatment, it is suggested that a rearrangement of intracellular materials (ions and small molecules movement, vacuoles rupture, and enzyme activation) might occur at less-intense PEF processing conditions (W < 1.8 kJ kg−1), not being enough the intensity to initiate phenolic compounds release evidenced by TP of the soaking water, and also by the fact that the highest TP and CT values were observed at 0.8 kJ kg−1. Contrarily, at higher W (≥ 1.8 kJ kg−1), the release of phenolic compounds starts increasing along with the specific energy input applied, promoting the interaction between CT and cell wall materials [40] and retaining condensed tannins in the cake.

Conclusion

In this study, pecan nut kernels were immersed into water in order to apply PEF processing, which led to an increment of moisture (18.7–24.9 g 100 g−1 db) and a decrement of oil content (54.0–56.7 g 100 g−1 db). After considering oil extracted into the soaking water, OEYTOTAL of PEF-treated samples increased up to 68.9 and 77.4%. The highest OEYTOTAL was achieved at 0.5 kJ kg−1, being 21.4 and 17.6% higher than the values of reference and control samples, respectively. The acidity and antioxidant capacity of extracted oils were not affected by PEF processing. Moreover, an increase of TP and CT of 17.8 and 39.3%, respectively, was observed in the cake produced from the oil extraction of kernels pretreated at 0.8 kJ kg−1. This is probably due to the rupture of condensed tannins vacuoles. The increment of the specific energy input applied (≥ 1.8 kJ kg−1) increased phenolic compounds release into the soaking water. These data demonstrate that PEF technology might be an appropriate pretreatment to enhance mechanical extraction of pecan nut oil with no effect in neither its acidity nor AC, leading to a cake that is a valuable by-product with potential functional properties due to its enhanced content of phenolic compounds. However, oil recovery from the soaking water might be a necessary step to achieve higher OEY employing PEF technology, affecting the feasibility of PEF as an assisting process in pecan nut oil extraction. Further research related to microscopy, enzymatic, and compositional analysis is also needed to corroborate the mechanism of PEF and understand kernels microstructural changes involved with the application of PEF to improve oil extraction from pecan nuts.

References

Abenoza M, Benito M, Saldaña G, Álvarez I, Raso J, Sánchez-Gimeno AC (2013) Effects of pulsed electric field on yield extraction and quality of olive oil. Food Bioprocess Technol 6(6):1367–1373. https://doi.org/10.1007/s11947-012-0817-6

Alvarez-Parrilla E, Urrea-López R & de la Rosa LA (2018) Bioactive components and health effects of pecan nuts and their byproducts: A review. Journal of Food Bioactives, 1, 56–92. https://doi.org/https://doi.org/10.31665/jfb.2018.1127

dos Alves JS, Confortin TC, Todero I, Rodrigues AS, Ribeiro SR, Boeira CP et al (2019) Simultaneous extraction of oil and bioactive compounds from pecan nut using pressurized solvents. J Supercrit Fluids 153:1–8. https://doi.org/10.1016/j.supflu.2019.104598

Andreou V, Dimopoulos G, Alexandrakis Z, Katsaros G, Oikonomou D, Toepfl S et al (2017) Shelf-life evaluation of virgin olive oil extracted from olives subjected to nonthermal pretreatments for yield increase. Innovative Food Science and Emerging Technologies 40:52–57. https://doi.org/10.1016/j.ifset.2016.09.009

AOAC International (1996) Official Methods of Analysis. Gaithesburg, MD

Atanasov AG, Sabharanjak SM, Zengin G, Mollica A, Szostak A, Simirgiotis M et al (2018) Pecan nuts: A review of reported bioactivities and health effects. Trends Food Sci Technol 71:246–257. https://doi.org/10.1016/j.tifs.2017.10.019

Barbosa-Canovas GV, Pierson MD, Zhang QH, Schaffner DW (2000) Pulsed electric fields. J Food Sci. https://doi.org/10.1111/j.1750-3841.2000.tb00619.x

Boussetta N, Vorobiev E, Le LH, Cordin-Falcimaigne A, Lanoisellé JL (2012) Application of electrical treatments in alcoholic solvent for polyphenols extraction from grape seeds. LWT - Food Science and Technology 46(1):127–134. https://doi.org/10.1016/j.lwt.2011.10.016

Çakaloğlu B, Özyurt VH, Ötleş S (2018) Cold press in oil extraction A review. Ukrainian Food Journal 7(4):640–654. https://doi.org/10.24263/2304-974x-2018-7-4-9

Cockerham S, Gorman W, Maness N & Lillywhite J (2012) Feasibility assessment of investing in a pecan oil and flour processing facility using new extraction technology.

Costa-Singh T, Jorge N (2015) Characterization of Carya illinoiensis and Juglans regia oils obtained by different extraction systems. Acta Scientiarum Technology 37(2):279. https://doi.org/10.4025/actascitechnol.v37i2.25033

El Kantar S, Boussetta N, Lebovka N, Foucart F, Rajha HN, Maroun RG et al (2018) Pulsed electric field treatment of citrus fruits: Improvement of juice and polyphenols extraction. Innovative Food Science and Emerging Technologies 46:153–161. https://doi.org/10.1016/j.ifset.2017.09.024

Food and Agriculture Organization of the United Nations (2015) SECTION 2. Codex Standards for Fats and Oils from Vegetable Sources.https://www.fao.org/3/y2774e/y2774e04.html Accessed 29 January 2020.

Gao P, Liu R, Jin Q, Wang X (2019) Comparative study of chemical compositions and antioxidant capacities of oils obtained from two species of walnut: Juglans regia and Juglans sigillata. Food Chem 279:279–287. https://doi.org/10.1016/j.foodchem.2018.12.016

González-Casado S, Martín-Belloso O, Elez-Martínez P, Soliva-Fortuny R (2018) Induced accumulation of individual carotenoids and quality changes in tomato fruits treated with pulsed electric fields and stored at different post-treatments temperatures. Postharvest Biol Technol 146:117–123. https://doi.org/10.1016/j.postharvbio.2018.08.013

Grauke LJ, Wood BW, Harris MK (2016) Crop vulnerability: Carya. Hort. Science 51(6):653–663

Guderjan M, Elez-Martínez P, Knorr D (2007) Application of pulsed electric fields at oil yield and content of functional food ingredients at the production of rapeseed oil. Innovative Food Science and Emerging Technologies 8(1):55–62. https://doi.org/10.1016/j.ifset.2006.07.001

Guderjan M, Töpfl S, Angersbach A, Knorr D (2005) Impact of pulsed electric field treatment on the recovery and quality of plant oils. J Food Eng 67(3):281–287. https://doi.org/10.1016/j.jfoodeng.2004.04.029

Han SF, Jin W, Yang Q, El-Fatah Abomohra A, Zhou X, Tu R et al (2019) Application of pulse electric field pretreatment for enhancing lipid extraction from Chlorella pyrenoidosa grown in wastewater. Renewable Energy 133:233–239. https://doi.org/10.1016/j.renene.2018.10.034

Heldt H-W, Piechulla B & Heldt F (2011) Plant Biochemistry. Elsevier.

Hemingway RW & Karchesy JJ (1996) Chemistry and significance of condensed tannins (Vol. 2). Plenum Press. https://doi.org/10.1007/978-1-4684-7511-1

Herald TJ, Gadgil P, Perumal R, Bean SR, Wilson JD (2014) High-throughputmicro-plate HCl–vanillin assay for screening tannin content in sorghum grain. J Sci Food Agric 94:2133–2136. https://doi.org/10.1002/jsfa.6538

Hernandez EM (2016) Specialty oils. Elsevier, Functional Dietary Lipids. https://doi.org/10.1016/B978-1-78242-247-1.00004-1

International Nut & Dried Fruit Council. (2020). Nuts & Dried Fruits - Statistical Yearbook 2019–2020. Statistical Yearbook. https://www.nutfruit.org/files/tech/1553521370_INC_Statistical_Yearbook_2018.pdf

Jia J, Liu D, Ma H (2019) Advances in food processing technology. Advances in Food Processing Technology. https://doi.org/10.1007/978-981-13-6451-8

Knorr D, Ade-Omowaye BIO, Heinz V (2002) Nutritional improvement of plant foods by non-thermal processing. Proc Nutr Soc 61:311–318. https://doi.org/10.1079/PNS2002162

Liu Z, Esveld E, Vincken JP, Bruins ME (2019) Pulsed electric field as an alternative pre-treatment for drying to enhance polyphenol extraction from fresh tea leaves. Food Bioprocess Technol 12(1):183–192. https://doi.org/10.1007/s11947-018-2199-x

López-Gámez G, Elez-Martínez P, Martín-Belloso O, Soliva-Fortuny R (2020) Enhancing phenolic content in carrots by pulsed electric fields during post-treatment time: effects on cell viability and quality attributes. Innovative Food Science and Emerging Technologies 59:1–10. https://doi.org/10.1016/j.ifset.2019.102252

Maciel LG, Ribeiro FL, Teixeira GL, Molognoni L, Nascimento dos Santos J, Larroza Nunes I, Mara Block J (2020) The potential of the pecan nut cake as an ingredient for the food industry. Food Res Int 127:1–10. https://doi.org/10.1016/j.foodres.2019.108718

Manzoor MF, Zeng XA, Rahaman A, Siddeeg A, Aadil RM, Ahmed Z et al (2019) Combined impact of pulsed electric field and ultrasound on bioactive compounds and FT-IR analysis of almond extract. J Food Sci Technol 56(5):2355–2364. https://doi.org/10.1007/s13197-019-03627-7

Marchetti L, Romero L, Andrés SC, Califano AN (2018) Characterization of pecan nut expeller cake and effect of storage on its microbiological and oxidative quality. Grasas Aceites 68(4):226. https://doi.org/10.3989/gya.0667171

Mohamed M, Eissa A (2012) Pulsed electric fields for food processing technology. Structure and Function of Food Engineering. https://doi.org/10.5772/1615

Mohseni NM, Mirzaei H, Moghimi M (2020) Optimized extraction and quality evaluation of Niger seed oil via microwave-pulsed electric field pretreatments. Food Science and Nutrition 8(3):1383–1393. https://doi.org/10.1002/fsn3.1396

Moradi N, Rahimi M (2018) Effect of simultaneous ultrasound/pulsed electric field pretreatments on the oil extraction from sunflower seeds. Sep Sci Technol 53(13):2088–2099. https://doi.org/10.1080/01496395.2018.1443131

Polmann G, Badia V, Frena M, Teixeira GL, Rigo E, Block JM, Camino Feltes MM (2019) Enzyme-assisted aqueous extraction combined with experimental designs allow the obtaining of a high-quality and yield pecan nut oil. LWT - Food Science and TechnologyLwt 113:1–7. https://doi.org/10.1016/j.lwt.2019.108283

Price ML, Scoyoc SV, Butler LG (1978) A critical evaluation of the vanillin reaction as an assay for tannin in sorghum grain. Journal of Agricultural and Food Chemistry 26(5):1214–1218. https://doi.org/10.1021/jf60219a031

Puértolas E, Barba FJ (2016) Electrotechnologies applied to valorization of by-products from food industry: Main findings, energy and economic cost of their industrialization. Food Bioprod Process 100:172–184. https://doi.org/10.1016/j.fbp.2016.06.020

Puértolas E, Martínez de Marañón I (2015) Olive oil pilot-production assisted by pulsed electric field: Impact on extraction yield, chemical parameters and sensory properties. Food Chem 167:497–502. https://doi.org/10.1016/j.foodchem.2014.07.029

Rábago-Panduro, L. M., Martín-Belloso, O., Welti-Chanes, J., & Morales-de la Peña, M. (2020). Changes in bioactive compounds content and antioxidant capacity of pecan nuts [Carya illinoinensis (Wangenh. K. Koch)] during storage. Revista Mexicana de Ingeniería Química, 19(3), 1439–1452. https://www.redalyc.org/articulo.oa?id=62029966013

Renard CMGC, Watrelot AA, Le Bourvellec C (2017) Interactions between polyphenols and polysaccharides: Mechanisms and consequences in food processing and digestion. Trends Food Sci Technol 60:43–51. https://doi.org/10.1016/j.tifs.2016.10.022

Robbins KS (2012) Bioactive constituents of pecans [Carya illinoinensis (Wangenh.) K. Koch]. Virginia Polytechnic Institute and State University.

Sarkis JR, Côrrea APF, Michel I, Brandeli A, Tessaro IC, Marczak LDF (2014) Evaluation of the phenolic content and antioxidant activity of different seed and nut cakes from the edible oil industry. Journal of the American Oil Chemists’ Society 91(10):1773–1782. https://doi.org/10.1007/s11746-014-2514-2

Sarkis JR, Boussetta N, Tessaro IC, Marczak LDF, Vorobiev E (2015) Application of pulsed electric fields and high voltage electrical discharges for oil extraction from sesame seeds. J Food Eng 153:20–27. https://doi.org/10.1016/j.jfoodeng.2014.12.003

Scapinello J, Magro JD, Block JM, Di Luccio M, Tres MV, Oliveira JV (2017) Fatty acid profile of pecan nut oils obtained from pressurized n-butane and cold pressing compared with commercial oils. J Food Sci Technol 54(10):3366–3369. https://doi.org/10.1007/s13197-017-2771-9

Schober P, Boer C, Schwarte LA (2018) Correlation coefficients: appropriate use and interpretation. Anesth Analg 126(5):1763–1768. https://doi.org/10.1213/ANE.0000000000002864

Silve A, Papachristou I, Wüstner R, Sträßner R, Schirmer M, Leber K et al (2018) Extraction of lipids from wet microalga Auxenochlorella protothecoides using pulsed electric field treatment and ethanol-hexane blends. Algal Res 29:212–222. https://doi.org/10.1016/j.algal.2017.11.016

Singleton VL, Rossi JA (1965) Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am J Enol Vitic 16:144–158

Tehrani MG, Elhamirad AH, Azarpazhooh E, Pedramnia A, Sharayei P (2019) Natural valuable compound extraction from onion by-products using a pulsed electric field. International Journal of Biology and Chemistry 12(1):171–180

Traffano-Schiffo MV, Laghi L, Castro-Giraldez M, Tylewicz U, Romani S, Ragni L et al (2017) Osmotic dehydration of organic kiwifruit pre-treated by pulsed electric fields: Internal transport and transformations analyzed by NMR. Innovative Food Science & Emerging Technologies 41:259–266. https://doi.org/10.1016/j.ifset.2017.03.012

Tylewicz U, Aganovic K, Vannini M, Toepfl S, Bortolotti V, Dalla Rosa M et al (2016) Effect of pulsed electric field treatment on water distribution of freeze-dried apple tissue evaluated with DSC and TD-NMR techniques. Innovative Food Science & Emerging Technologies 37:352–358. https://doi.org/10.1016/j.ifset.2016.06.012

U.S. Department of Agriculture (2020) Food Data Central. https://fdc.nal.usda.gov/. Accessed 31 March 2020

Veneziani G, Esposto S, Taticchi A, Selvaggini R, Sordini B, Lorefice A et al (2019) Extra-virgin olive oil extracted using pulsed electric field technology: Cultivar impact on oil yield and quality. Frontiers in Nutrition 6:1–8. https://doi.org/10.3389/fnut.2019.00134

VillarrealLozoya JE, Lombardini L, CisnerosZevallos L (2007) Phytochemical constituents and antioxidant capacity of different pecan Carya illinoinensis Wangenh K Koch cultivars. Food Chem 102(4):1241–1249. https://doi.org/10.1016/j.foodchem.2006.07.024

Zhang P, Bari VD, Briars R, Taher ZM, Yuan J, Liu G, Gray D (2017) Influence of pecan nut pretreatment on the physical quality of oil bodies. J Food Qual 2017:1–9. https://doi.org/10.1155/2017/3864126

Acknowledgments

Authors acknowledge Enrique Orozco Parra for the donation of pecan nuts utilized in this study.

Funding

The authors recognize the support from Tecnológico de Monterrey and Consejo Nacional de Ciencia y Tecnología (CONACyT) scholarship programs (CVU 418204).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rábago-Panduro, L.M., Morales-de la Peña, M., Martín-Belloso, O. et al. Application of Pulsed Electric Fields PEF on Pecan Nuts Carya illinoinensis Wangenh. K. Koch: Oil Extraction Yield and Compositional Characteristics of the Oil and Its By-product. Food Eng Rev 13, 676–685 (2021). https://doi.org/10.1007/s12393-020-09267-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-020-09267-4