Abstract

Foods in general are excellent sources for growth of fungi. These microorganisms can infect food and grow whenever the ideal temperature and moisture conditions for the particular species are present, causing large losses during storage. Furthermore, some fungal species produce mycotoxins, which are compounds that are toxic to humans and animals. The use of electron beams has been shown effective in decontaminating foods, packaging materials, plastic articles and surgical and biological materials, among others. The ease of handling, low cost and employment of electricity to generate ionizing radiation instead of radioactive material such as cobalt-60 are factors that have increased the use of this method. Because of the growing use of electron beams on foods to control pathogenic microorganisms, this review focuses on their use to control fungi that produce mycotoxins on foods, covering the suitable doses, effects on food quality, microorganism reduction rates, applications in the food industry and legislation on use and operational safety.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fungi are microorganisms that can contaminate foods in various steps of the productive chain. They grow when the ideal temperature and moisture conditions are present. Fungi cause various damages to foods, leading to large production losses. When associated with agricultural pests, considerable losses are observed during growing, transport and storage, both before and after sale to the end consumer (15 % for cereals, 20 % for fish and dairy products and up to 40 % for fruits and vegetables) [42].

Fungi can produce mycotoxins, which pose a risk to consumers. Mycotoxins are secondary metabolites produced by different fungal genera, with Aspergillus, Penicillium and Fusarium being the genera most often isolated from grains and other foods [2]. During food storage, Aspergillus and Penicillium are predominant, while Fusarium spp are important pathogens of plants in the field. Aflatoxins are the mycotoxins most often found on foods, particularly on grains such as peanuts. The aflatoxins produced by the fungus Aspergillus flavus are considered the most toxic among the mycotoxins produced by this fungus (B1, B2, G1 and G2). In turn, patulin is the mycotoxin produced by the fungus Penicillium expansum. It is most often found on apples or in juice made from contaminated apples [24].

The use of ionizing radiation has been recognized as an effective method to decontaminate food products. This radiation is one of the most powerful tools to combat fungi during food storage and to extend the shelf life of some foods [54]. The technique is particularly advantageous for phytosanitary treatment of fresh products because it does not raise the temperature, as is the case of thermal treatment, nor does represent risk to health as the fumigation treatments [26].

In recent years, irradiation has become one of the most successful technologies to extend the shelf life of foods [30]. In the past, factors such as high cost, lack of treatment logistics and low acceptance by uninformed or misinformed consumers [43, 44, 51] hampered to spread of this technology, but the situation has now changed.

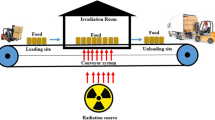

Irradiation consists of exposure of the food to a radiation source, the most common being cobalt-60 (Co-60) or electron beams (e-beams). Co-60 works by emitting gamma rays, while e-beams are generated by linear accelerators, using electricity to generate electrons.

The use of e-beams to irradiate foods is growing due to the simplicity of operation and low cost in comparison with irradiation by Co-60. Various studies have demonstrated the potential of e-beam treatment to decontaminate foods [8, 47, 57, 60], minimize the incidence of agricultural pests [1, 23, 64] and extend the shelf life of various products [40, 41], without altering the quality.

Based on the growing importance of e-beam treatment of foods, the aim of this article was to review the use of this technique on foods to control fungi and the associated mycotoxins, as well as to discuss the effects on foods and microorganisms in general and applications in the food industry, among other aspects.

General Properties of Electron Beams

High-energy electron beams are produced by electron-accelerating machines. X-ray production starts with high-energy electrons: X-ray machines convert electron energy to electromagnetic X-rays called Bremsstrahlung. These types of radiation are chosen since they produce the desired food preservative effects, do not induce radioactivity in foods or packaging materials, and are available in quantities and at costs that allow commercial use of the irradiation process [19].

E-beams are a type of ionizing radiation with short wavelength and high energy. They are typically applied to foods at levels up to 10 MeV [27] for purposes of preservation. The electricity is responsible for generating the electrons, which are accelerated and concentrated into beams by a linear accelerator.

The use of e-beams on foods has various benefits in comparison with Co-60 (Table 1), such as easy handling, no need to recharge the source, ample availability, ability to turn the equipment on and off at will and absence of radioactive material. These factors have helped increase the use of e-beam treatment of foods and can lead to the construction of irradiators at ports to treat foodstuffs for export [42, 60].

E-beam irradiation is a faster process than using Co-60, due to the high intensity of the beam generated by the accelerator, reducing the degradation of the product [5]. Another difference between e-beam and gamma ray treatment is the penetration power. The smaller penetration of e-beams in comparison with other types of ionizing radiation (Fig. 1) is because the electrons are easily attenuated and dispersed by the food. Electrons can only penetrate between 8 and 10 cm into the food, so the dimensions of the product must be taken into account [55]. Nevertheless, despite the restricted penetration, e-beam is a good alternative to gamma radiation [12].

Penetration power of an e-beam generated by an accelerator (a) and gamma rays emitted by the radioactive isotope cobalt-60. Adapted from Tahergorabi and collaborators [55]

Another difference between these two types of ionizing radiation is the source of the radiation: gamma rays come from a radioactive substance, Co-60, while e-beams only need an electric current, a source that does not cause foreboding among the population.

With respect to the radiation dose, a lower e-beam dose (1 kGy) was necessary to obtain the same result and to produce a higher content of phenolic compounds and greater antioxidant activity in chestnuts in comparison with gamma rays (3 kGy) [14]. The e-beam technique is more efficient than gamma ray application because the electrons can be aimed directly at the product or microorganism, while gamma rays are emitted in all directions (Fig. 1) [6].

Types of E-beam Accelerators

The e-beam is formed by linear particle accelerators, which accelerate and concentrate electrons into a beam [37]. Accelerators for use to irradiate foods must be compact and relatively inexpensive to enable meeting the developing demand. This will require a large number or simple and reliable machines, with electron energy ratings between 5 and 10 MeV and e-beam power of 150 kW or more [3]. Installations with electron accelerators have increased in comparison with those using Co-60 in recent years [5]. The most important industrial accelerators and their parameters are shown in Table 2.

The use of electron accelerators has been increasing with over 1,500 units operating worldwide. In South America, until 2012, there were 23 industrial e-beam accelerators with energy from 200 keV to 10 MeV, operating in private companies and governmental institutions. Currently, Brazil stands out with 16 accelerators in use with different applications, most of them being used to improve the physical and chemical properties of different materials. Very little emphasis has been given to e-beam application in post-harvest treatment of agricultural products (Table 3) [13].

The Sirius Project is currently being developed in Brazil by the National Synchrotron Light Laboratory (LNLS) in Campinas, São Paulo, for construction of one of the most powerful electron accelerators in the world [21]. With planned start of operation in 2016, this is considered one of the largest projects of Brazilian science.

The main advantages of the accelerators used for food irradiation are generation of an e-beam with high intensity, well-defined electron penetration and irradiation zone, ease of altering the operating parameters and the possibility of rapid shutdown [5]. The accelerator’s high yield makes the process more effective and reduces costs.

Dose and Exposure Time

The quantity of radiation absorbed by the food is measured in kiloGrays (kGy) (Grays: the quantity of energy per unit of mass). It is determined by the time the food is exposed to the e-beam [9, 51]. The product’s exposure time is controlled by adjusting the speed of the belt carrying the product through the beam.

The dose employed must be balanced between what is necessary to control the microorganisms and what can be tolerated by the particular food without altering its sensory characteristics [19, 39, 42]. To control pathogenic microorganisms, the dose varies in function of the resistance and the number or organisms of the species present in the food [19], as well as the degree of reduction desired and type of food [9, 39]. Some doses have been established based on the purpose of the irradiation and type of food (Table 4).

Effects of E-beam Treatment on DNA, Microorganisms and Insects

The beam electrons act on microorganisms in two ways: directly and indirectly [2, 27, 38, 56]. In direct form, the electrons act on the atoms of the microorganisms’ molecules, causing disintegration of essential biological molecules, such as DNA, RNA, enzymes and proteins of cell membranes. In DNA, the electrons have the capacity to break the bonds between the guanine (G) and cytosine (C) bases and the adenine (A) and thymine (T) bases, resulting in disintegration of the DNA’s double helix, preventing the microbial cells from reproducing (cell death) [34, 55]. Indirect effects are due to the formation of free radicals, generated during the interaction of the e-beam with the water molecules, a process known as radiolysis of water [1, 38, 55]. Free radicals are highly reactive molecules that can cause damage to the cells of microorganisms, leading to cell death.

The effects of the e-beam dose on the target microorganism depend on the absorption rate, total dose absorbed and environmental conditions, such as temperature, moisture and environmental atmosphere composition during the radiation process [9]. The difference in sensitivity to ionizing radiation among microorganisms varies due to chemical and physical differences of their structures and also each species’ ability to recover from the damage caused by the radiation [11, 42, 55]. Therefore, the lethal dose varies according to the organism. Fungi are more resistant than vegetative forms of bacteria, and yeasts are more resistant than filamentous fungi [2, 42]. For example, resistance to an e-beam dose of 1.5 kGy was observed in the yeast species Candida sake and Candida santamariae var. membranifaciens [46]. The fungi Fusarium sp. and Alternaria sp. are more resistant to radiation than Penicillium sp. and Aspergillus sp. because the former have multicellular spores, so the spore can still be able to germinate if only one cell survives the e-beam [42], although this may be retarded.

In insects, the radiation also acts at the cellular level, in regions of the organism where cell division is continuous, such as the digestive and reproductive systems, by interrupting these two functions and preventing the insect’s complete development and reproduction [27]. In one experiment, the fecundity of adult armyworm moth (Spodoptera litura), a global agricultural pest, that had developed from pupae irradiated by e-beam was totally inhibited at a dose of 0.15 kGy [64].

Effects of E-beam Application on Food: Nutrition, Bioactive Compounds and Other Quality Parameters

The purpose of e-beam treatment is to preserve the quality of the food in question. However, in some cases, the treatment can degrade this quality [2, 36]. These changes are greater or lesser depending on the dose used. The smaller the dose, the lower the changes will be in the quality parameters.

E-beam irradiation typically does not notably raise the temperature of the food, since most of the energy absorbed (dose) acts to generate free radicals and induce chemical reactions among these radicals or between them and other molecules. Hence, only a small fraction of the energy absorbed is converted into heat [52].

In general, most of the micronutrients, macronutrients, water-soluble vitamins, carbohydrates, proteins and fats are not affected by the ionizing radiation, up to the dose established as safe for use in foods (10 kGy) [42]. Doses up to 10 kGy appear to be effective in deactivating some antinutrients, such as inhibitors of proteases, lectins, phytic acid, non-starch polysaccharides and oligosaccharides, without altering the nutritional quality of foods [52].

According to Carocho and collaborators [15], e-beam irradiation is a good alternative to preserve chestnuts, since no significant alterations were observed in the composition of organic acids, antioxidant compounds and nutritional quality at the doses tested. In chyavanaprash, a poly-herbal formulation that is very popular in India for its nutritional value, the use of e-beam doses of 7.5 and 10 kGy did not cause any significant change in the centesimal, chemical and sensory properties of the product, while totally eliminating the bacterial and fungal loads at the two doses [45].

An increased level of the majority of aromatic compounds was observed in black truffles (Tuber melanosporum) irradiated with an e-beam dose of 1.5 kGy [16]. In apples, an e-beam dose of 1 kGy was found to be an acceptable decontamination method, since it did not cause large quantitative changes in the levels of volatile organic compounds [53]. In sun-dried apricots, e-beam treatment at doses between 1 and 3 kGy was beneficial by maintaining high levels of β-carotene, ascorbic acid, titratable acidity and total sugars, while not causing any significant alterations in the color and sensory properties, besides reducing the number of viable microorganisms to undetectable levels at the dose of 3.0 kGy [61].

Based on the experiments reported so far, e-beam treatment brings benefits to the majority of irradiated foods. However, some foods are particularly sensitive to ionizing radiation, making it necessary to conduct quality tests before using the process commercially.

Free radicals were found in dates irradiated by e-beam at a dose of 2 kGy, but it was observed that the free radicals dissipated quickly [1]. In any event, the production of free radicals is not exclusively caused by irradiation, since cooking and pasteurization also produce them [52]. Villavivencio and collaborators [60] observed DNA damage and reduced root growth of soybeans treated by e-beam starting at a dose of 1 kGy, with the damage being directly proportional to the radiation dose. Doses above 5 kGy promoted loss of seed viability.

Use of E-beam Treatment in the Food Industry

The latest statistics show that over 500 thousand metric tons (tonnes) of foods are irradiated each year in the world, among them seasonings (spices and herbs) meat, seafood and dried and fresh fruits [42], with the leading category being seasonings, for the purpose of controlling diseases caused by microorganisms [27].

A study was carried out in 2005 into the products irradiated in the world (Table 5). These were divided into five groups: G1-disinfection of dried spices and herbs; G2-disinfection of grains and fruits; G3-disinfection of meat and seafood; G4-inhibition of sprouting of tubers and bulbs; and G5-treatment of other food items (mushrooms, honey, among others) [33].

Based on the above studies and statistics, it can be stated that e-beam irradiation has been successfully used for disinfection and disinfestation of agricultural products and to increase the shelf life of fruits and herbs.

Disinfestation

Yun and collaborators [64] considered electron irradiation to be an ideal technology for disinfestation of agricultural pests, because it is effective against the majority of insects and does not affect the quality of the commodities, so it can be used for phytosanitary treatment to control pests.

Larvae of the oriental leaf worm moth (S. litura) were totally eliminated when subjected to an e-beam dose 0.15 kGy, while the egg hatching was inhibited at doses above 0.1 kGy. Concerning adult females, an e-beam dose of 0.20 kGy did not affect oviposition, but also prevented hatching [64]. E-beam treatment with 1 kGy was effective in treating dates against all life phases of the sawtoothed grain beetle Oryzaephilus surinamensis, besides reducing the microbial load while maintaining the antioxidant compounds [1]. Follet [22] studied the effect of e-beam radiation on the life phases of the tephritid fruit fly, a quarantine pest that particularly attacks papayas, and found that a dose of 0.15 kGy was effective and safe for control of this pest on papayas and other farm products.

Post-harvest

Moreno and collaborators [40] tested e-beam irradiation on blueberries and observed an increase in the shelf life due to the reduction of the respiratory rate of the fruits, without any interference in the density, pH, activity of water, moisture content, acidity and succulence up to a dose of 1.6 kGy, thus considering this to be a feasible dose for decontaminating and preserving the quality of this fruit.

An increase in shelf life by maintenance of post-harvest texture was also observed for white button mushrooms irradiated with 2 kGy [17]. According to Fernandes and collaborators [20], e-beam irradiation is one of the best and safest techniques to preserve mushrooms and increase their shelf life. Moreno and collaborators [41] observed no changes to the sensory quality and chemical characteristics of mangoes irradiated up to a dose of 3.0 kGy, and stated that e-beam treatment is effective for decontamination of this fruit at doses above 1 kGy.

E-beam Applications for Food Safety

Fungi and bacteria are leading causes of food-borne diseases, so they pose a risk to consumers. Foods can be made safer in this respect by e-beam treatment. Various studies have shown reduction or complete inactivation of microorganisms that contaminate foods. However, the use of e-beams against fungi is not as common as against bacteria.

Use of E-beam to Inactivate Fungi

The use of e-beams on stored grains can be a good alternative to minimize the risks caused by fungi and their associated mycotoxins [60].

A dose of 10 kGy on Canavalia marítima beans was effective to eliminate fungal contamination and extend the shelf life in comparison with beans without irradiation, on which the fungi Aspergillus niger, A. flavus, Penicillium chrysogenum and Aspergillus ochraceus were observed [54]. Control of the growth of Phakopsora pachyrhizi, an aggressive phytopathogen that causes soybean rust, was achieved by an e-beam dose of 6 kGy. Although the presence of the pathogen’s DNA was detected after treatment of the samples analyzed, there was no reinfection [60]. An e-beam dose of 3 kGy was effective to control Aspergillus fungi on almonds, while preserving the sensory characteristics [50]. Reduction of Fusarium was observed on barley submitted to e-beam doses between 6 and 8 kGy with only small effects on the malting quality [32].

Irradiation by e-beam of lotus seeds sown individually (total of 100 seeds per treatment) on media containing Czapek Dox agar and dichloran glycerol 18 agar showed potential in reducing the incidence of fungi on the seed coat when compared to the control (Table 6). In this assay, when seeds were treated with 10 kGy dose, there was no incidence of fungi on seeds [4].

The sensitivity of fungal spores of the genera Aspergillus and Penicillium to e-beam irradiation was evaluated in distilled water. Using 5 ml aqueous suspension of spores (105–106 CFU ml−1) treated with 1.2 kGy, the D10 (the dose required to reduce the initial population by 90 %) e-beam values ranged from 0.194 to 0.341 and from 0.198 to 0.243 kGy for Penicillium and Aspergillus species, respectively [6]. In the same work, no viable spore counts were observed nor germination of A. echinulatus, A. fumigatus, A. glaucus, A. niger, A. ochraceus, P. aurantiogtieum, P. granulactum and P. verrucosum.

Aquino [2] reinforces and summarizes that fungi are resistant to radiation due to the natural radioprotective agents (sulfhydryl compounds, pigments, amino acids, proteins and fatty acids) present in mycelia. The cell walls of some fungi contain appreciable fractions of lipids and diverse metabolites, such as alcohols, acids, enzymes, pigments, polysaccharides, and steroids, as well as some complex compounds, such as ergotinine, and antibiotics. Melanin protects organisms against UV rays and ionizing radiation. This black pigment has also been associated with fungal radioresistance, especially among dematiaceous fungi (i.e., Phoma spp. Alternaria alternata, Cladosporium cladosporioides and Curvularia lunata). Although almost all studies in this sense were conducted with gamma radiation, it is possible that the same resistance and sensitivity occurs in dematiaceous fungi submitted to an e-beam radiation.

Considering the evidence of the potential of e-beam on the reduction of microbial load in food, the biggest challenge of this technology is to find a balance in which the applied dose does not interfere with the sensory characteristics of the food. An example of it, this radiation when applied at 1.0 kGy presented a fungicidal effect on packaged romaine lettuce hearts without interfering in the sensory characteristics [28].

Many results in literature indicate that different commodities present molds and yeasts of varying resistance to radiation. In this direction, it is essential for food processing industry to determine empirically the minimum e-beam dose that is capable of reducing or eliminating the bioburden of yeasts and fungi in their specific commodities.

Use of E-beam for Mycotoxin Degradation

The degradation of mycotoxins by e-beam application was demonstrated in some studies. In split beans (Canavalia maritima) aflatoxins B1 and B2 were found in quantities below to the detection level in both control samples and e-beam treatments at doses of 2.5 and 5 kGy, whereas 10 kGy dose, aflatoxins were degraded completely [54].

A similar result was obtained in lotus seeds and it was established that the best dose of e-beam irradiation for complete decontamination was between 10 and 15 kGy. It is important to note that this interval presents minimal effects on the nutritional and functional properties of seeds [4].

In other study, low amount of aflatoxin (0.5 µg kg−1) was found in almond (Prunus amygdalus) flour, this sample was subjected to e-beam processing at 1.5 kGy and after that the aflatoxin was not detected [35].

Other factors play a major role during the process of radiation, e.g., water acts on destruction of aflatoxins by ionizing radiation, since the radiolysis of water generates reactive free radicals that can promptly attack the aflatoxins, producing products with lower biological activity [48].

The e-beam irradiation has also been shown to be effective at reducing mycotoxin in fungi culture. The reduction of aflatoxin B1 and B2 was demonstrated after e-beam irradiation in A. flavus cultures grown on coconut agar medium for 7 days at 25 °C. Plates irradiated with 5 kGy resulted in a 75.5 % of aflatoxin B1 reduction of when compared to control plates (33 µg kg−1) (average concentration) [49], while at 50 kGy aflatoxins B1 and B2 were 100 % degraded [48]. This situation highlights the power of e-beam to degrade mycotoxins; hence, the need to study other mycotoxins producing fungi present in many commodities.

Use of E-beam for Bacteria Inactivation

According to Tahergorabi and collaborators [55], e-beam treatment has the potential to control Salmonella on fresh products like eggs, fruits and greens, foods that cannot be subjected to heat treatments such as pasteurization and sterilization. Salmonella is an important agent causing food-borne diseases throughout the world.

Trinetta and collaborators [57] tested the efficiency of e-beam irradiation to control food-borne diseases, mainly caused by the bacteria Salmonella enterica and Escherichia coli O157:H7, and found that the process has the potential to reduce S. enterica on melon and tomato seeds and E. coli on lettuce seeds. A similar result was obtained by [47], who tested the use of e-beam irradiation to control pathogenic bacteria. Brescia and collaborators [8] also found that e-beam treatment was able to reduce the pathogenic microorganisms present on the surfaces of fruits and vegetables.

Reduced levels of natural micro-flora were observed on strawberries, shrimps and minced chicken breast through treatment with an e-beam dose of 2 kGy [12]. In strawberries, the treatment reduced the appearance of mold and the count of mesophilic microorganisms, while in shrimps it reduced the presence of Staphylococcus spp. and Pseudomonas spp. and in chicken meat, reduced fecal coliforms, Staphylococcus spp. and Pseudomonas spp.

On meat slices with uniform thickness (≤1.5 cm), e-beam irradiation at a dose of 1 kGy was effective at inactivating serotypes of Escherichia coli (VTEC) and serovars of Salmonella [34]. In salmon fillets, e-beam application at a dose of 0.5 kGy increased the shelf life by 6 days compared with fillets not irradiated, because of the inhibited growth of degrading bacteria [63].

On natural sausage casings there was a significant reduction in the count of total aerobic bacteria by irradiation with an e-beam dose of up to 3 kGy, without causing any effects on the physical–chemical and sensory properties, and the treatment also improved the stability of the product during 5 weeks [31]. In salami, treatment with an e-beam dose of 1.3 kGy was found to assure the safety of the product without altering its sensory characteristics [10].

Baby formula has recently been reported as a possible vehicle for transmission of the pathogen Enterobacter sakazakii, resulting in high mortality rates. E-beam treatment at low temperature and under anaerobic conditions was effective in controlling this pathogen without affecting nutrients in the product [56]. In another study, Bacillus cereus and Salmonella typhimurium were eliminated from baby formula at a dose of 8 kGy [29].

Finally, lower resistance to heat was observed in spores of B. cereus, a bacterium known to cause food poisoning, when the spore suspension in distilled water was submitted to an e-beam dose of 3.1 kGy [59].

Aspects of Toxicity, Safety and Regulation

In 1981, an expert committee established by the United Nations Food and Agriculture Organization (FAO), International Atomic Energy Agency (IAEA) and World Health Organization (WHO) established at a meeting in Geneva that the irradiation of any food product up to a total dose of 10 kGy does not represent a toxicity risk and hence does not need any toxicological tests of the treated foods [62].

During irradiation, the food does not come into contact with the radiation source, so irradiated foods pose no risk of radioactivity to consumers. Furthermore, e-beams do not come from radioactive material, and since low doses are generally effective for the targeted purpose, there are few changes in the product’s quality.

Various countries have issued regulations on maximum irradiation doses for treatment of various food products. China is the leading country in terms of food irradiation facilities, with more than 200 in operation [42]. Worldwide, irradiation of foods has been approved by more than 60 countries. According to the Codex General Standard for Irradiated Foods [11], accelerated electron radiation for food processing is allowed for energies up to 10 MeV.

The use of irradiation on stored products to control insects is currently permitted in 33 countries (Table 7), of which 14 have approved the use for all stored products. Nevertheless, not all these countries actually use e-beam irradiation commercially [27].

In Australia and New Zealand, the regulation for irradiation of tropical fruits, persimmon, tomato and pepper is authorized up to a dose of 1.0 kGy, whereas for herbs and spices the maximum dose allowed is 30 kGy. At the moment, eleven more fruits are being considered for irradiation permission [25].

According to current international legislation, all irradiated foods must bear identification on the label with the international Radura symbol (Fig. 2) and the notice “Food treated by irradiation process [7].”

This labeling informs many consumers [23, 27] since this also deters some retailers from purchasing irradiated fruits and vegetables because they fear the mention of the treatment is a warning and will discourage customers. Hence, there is a need for public information campaigns on the scientific advantages of food irradiation to increase public acceptance [42].

The lack of awareness among consumers of the food irradiation process in Brazil was demonstrated by a survey. The results showed that 89 % of the respondents had never heard of the process, and only 17 % had seen and/or were aware of the Radura symbol [43].

The Radura symbol has two interpretations, depending on the type of public consumers [18]. Among people involved with agriculture, the center of the symbol is considered to be a representation of a farm product, with the plant represented by the dot and two leaves surrounded by the circle, being irradiated from above by penetration of the ionizing rays through the upper gaps in the circle. In turn, for professionals in the food processing and marketing area, the central dot means the radiation source, the leaves below the dot are shields for protection of workers and the environment and the outside circle represents the food transport system, with the lower part protected from the radiation and the upper part open to the ionizing rays. The second interpretation is more comprehensive in relation to the products that can be irradiated, not being restricted to agricultural products as in the first interpretation.

Concluding Remarks and Trend

There is an increasing trend for use of new food preservation technologies in response to growing consumer concern over the use of additives by the food industry. The initial applications have shown good results in resolving important problems, such as contamination by fungi and mycotoxins. Despite the existence of studies reporting promising results of e-beam treatment, there are still many gaps regarding the byproducts formed by degradation of residues and chemical contaminants present in food (e.g., mycotoxins, acrylamides, and pesticides). Through emerging new techniques, as well as improvements and innovations in e-beam application, this subject certainly will be evaluated more effectively in the future, facilitating enhanced control of both the quality and safety parameters of foods. For effective and safe use in food processing, optimum dosage and other associated parameters need to be defined for all products, by pilot testing in each case before starting commercial application.

The results highlight the value of employing E-beam irradiation to reduce public health risks but also the critical importance of adhering to good agricultural practices that limit microbial contamination at the farm and in packing houses.

In light of the information reviewed, it can be concluded that e-beam irradiation is feasible for control of pathogenic microorganisms on foods. More research involving phytopathogenic and pathogenic fungi needs to be conducted to establish the safe dosage levels for application on foods. This treatment method will inevitably expand in the future due to its favorable characteristics, and it has the potential to be a common phytosanitary treatment for products for export.

References

Al-Farisi M, Abuagla A, Mohamed E, Gohs U (2013) The effect of electron beam on dates infestation. Food Control 33:157–161

Aquino S (2011) Gamma radiation against toxigenic fungi in food, medicinal and aromatic herbs. In: Méndez-Vilas A (ed) Science against microbial pathogens: communicating current research and technological advances, 3rd edn. Badajoz, Spain

Auslender VL, Bryazgin AA, Faktorovich BL, Gorbunov VA, Kokin EN, Korobeinikov MV, Krainov GS, Lukin AN, Maximov SA, Nekhaev VE, Panfilov AD, Radchenko VN, Tkachenko VO, Tuvik AA, Voronin LA (2002) Accelerators for E-beam and X-ray processing. Radiat Phys Chem 63:613–615

Bhat R, Sridhar KR, Karim AA (2010) Microbial quality evaluation and effective decontamination of nutraceutically valued lotus seeds by electron beams and gamma irradiation. Radiat Phys Chem 79:976–981

Bigolas J, Kulinski S, Maciszewski W, Pachan M, Plawski E, Zimek Z (2002) Current approach to design of high-power electron accelerators to match actual requirements of radiation technology in Poland. Radiat Phys Chem 63:595–599

Blank G, Corrigan D (1995) Comparison of resistance of fungal spores to gamma and electron beam radiation. Food Microbiol 26:269–277

Brasil (2001). Agência Nacional de Vigilância Sanitária/Resolução n° 21, de 26 de janeiro de 2001. http://portal.anvisa.gov.br. Acessado 26 Jan 2014

Brescia G, Moreira R, Braby L, Castell-Perez E (2003) Monte Carlo simulation and dose distribution of low energy electron irradiation of an apple. J Food Eng 60:31–39

Brewer MS (2009) Irradiation effects on meat flavor: a review. Meat Sci 81:1–14

Cabeza MC, Hoz L, Velasco R, Cambero MI, Ordóñez JA (2009) Safety and quality of ready-to-eat dry fermented sausages subjected to E-beam radiation. Meat Sci 83:320–327

CAC (Codex Alimentarius Commission) (2003). Codex general standard for irradiated foods. CODEX STAN 106-1983. Rev. 1-2003

Calenberg SV, Cleemput OV, Mondelaers W, Huyghebaert A (1999) Comparison of the effect of X-ray and electron beam irradiation on the microbiological quality of foodstuffs. Lebenesm Wiss Technol 32:372–376

Calvo WAP, Duarte CL, Machado LDB, Manzoli JE, Geraldo ABC, Kodama Y, Silva LGA, Pino ES, Somessari ESR, Silveira CG, Rela PR (2012) Electron beam accelerators-trends in radiation processing technology for industrial and environmental applications in Latin America and the Caribbean. Radiat Phys Chem 81:1276–1281

Carocho M, Antonio AL, Barros L, Bento A, Botelho ML, Kaluska I, Ferreira ICFR (2012) Comparative effects of gamma and electron beam irradiation on the antioxidant potential of Portuguese chestnuts (Castanea sativa Mill.). Food Chem Toxic 50:3452–3455

Carocho M, Barros L, Antonio AL, Barreira JCM, Bento A, Kaluska I, Ferreira ICFR (2013) Analysis of organic acids in electron beam irradiated chestnuts (Castanea sativa Mill.): effects of radiation dose and storage time. Food Chem Toxic 55:348–352

Culleré L, Ferreira V, Venturini ME, Marco P, Blanco D (2012) Evaluation of gamma and electron-beam irradiation on the aromatic profile of black truffle (Tuber melanosporum) and summer truffle (Tuber aestivum). Innov Food Sci Emerg Technol 13:151–157

Duan Z, Xing Z, Shao Y, Zhao X (2010) Effect of electron beam irradiation on postharvest quality and selected enzyme activities of the white button mushroom, Agaricus bisporus. J Agric Food Chem 58:9617–9621

Ehlermann DAE (2009) The RADURA-terminology and food irradiation. Food Control 20:526–528

Farkas J (2006) Irradiation for better foods. Trends Food Sci Technol 17:148–152

Fernandes A, Antonio AL, Oliveira MBPP, Martins A, Ferreira ICFR (2012) Effect of gamma and electron beam irradiation on the physico-chemical and nutritional properties of mushrooms: a review. Food Chem 135:641–650

Flório V (2013) O acelerador Sirius: governo investe em tecnologia de ponta. Cienc Cult 65:10–11

Follett PA (2006) Irradiation as a phytosanitary treatment for white peach scale (Homoptera: Diaspididae). J Econ Entomol 99:1974–1978

Follett PA, Weinert ED (2012) Phytosanitary irradiation of fresh tropical commodities in Hawaii: generic treatments, commercial adoption, and current issues. Radiat Phys Chem 81:1064–1067

Freitas-Silva O, Venâncio A (2010) Ozone applications to prevent and degrade mycotoxins: a review. Drug Metab Rev 42:612–620

FSANZ (2013) Food Standards Australia New Zealand. Food irradiation, May 2013. http://www.foodstandards.gov.au/consumer/foodtech/irradiation/Pages/default.aspx. Accessed on 13 Mar 2014

Hallman GJ (2011) Phytosanitary applications of irradiation. Compr Rev Food Sci Food Saf 10:143–151

Hallman GJ (2013) Control of stored product pests by ionizing radiation. J Stored Prod Res 52:36–41

Han J, Gomes-Feitosa CL, Castell-Perez E, Moreira RG, Silva PF (2004) Quality of packaged romaine lettuce hearts exposed to low-dose electron beam irradiation. Lebensm Wiss Technol 37:705–715

Hong YH, Park JY, Park JH, Chung MS, Kwon KS, Chung K, Won M, Song KB (2008) Inactivation of Enterobacter sakazakii, Bacillus cereus, and Salmonella typhimurium in powdered weaning food by electron-beam irradiation. Radiat Phys Chem 77:1097–1100

Jeong IS, Kim JS, Hwang IM, Choi SH, Choi JY, Nho EY, Khan N, Kim BS, Kim KS (2013) Detection of hydrocarbons induced by electron beam irradiation of almond (Prunus amygosalus L.) and peanut (Arachis hypogaea). Korean J Food Sci Technol 45:20–24

Kim HW, Choi JH, Choi YS, Kim HY, Hwang KE, Song DH, Lee JW, Kim CJ (2012) Effects of electron beam irradiated natural casings on the quality properties and shelf stability of emulsion sausage. Radiat Phys Chem 81:580–583

Kottapalli B, Wolf-Hall CE, Schwarz P (2006) Effect of electron-beam irradiation on the safety and quality of Fusarium-infected malting barley. Int J Food Microbiol 110:224–231

Kume T, Furuta M, Todoriki S, Uenoyama N, Kobayashi Y (2009) Status of food irradiation in the world. Radiat Phys Chem 78:222–226

Kundu D, Gill A, Lui C, Goswami N, Holley R (2014) Use of low dose e-beam irradiation to reduce E. coli O157:H7, non-O157 (VTEC) E. coli and Salmonella viability on meat surfaces. Meat Sci 96:413–418

Lanza CM, Mazzaglia A, Paladino R, Auditore L, Barnà RC, Loria D, Trifir A, Trimarchi M, Bellia G (2013) Characterization of peeled and unpeeled almond (Prunus amygdalus) flour after electron beam processing. Radiat Phys Chem 86:140–144

López-Gómez A, Fernández PS, Palop A, Periago PM, Martinez-López A, Marin-Iniesta F, Barbosa-Cánovas GV (2009) Food safety engineering: an emergent perspective. Food Eng Rev 1:84–104

Madhu LN, Kumari NS, Vijay R (2012) Validation of DNA damage progression with days after single exposure of sublethal dosage of electron beam radiation. J Appl Pharm Sci 2:23–26

Maruthi YA, Das NL, Hossain K, Rawat KP, Sarma KSS, Sabharwal S (2013) Appliance of electron beam technology for disinfection of sewage water to minimize public health risks. Eur J Sustain Dev 2:31–42

Molins RA, Motarjemi Y, Kaferstein FK (2001) Irradiation: a critical control point in ensuring the microbiological safety of raw foods. Food Control 12:347–356

Moreno MA, Castell-Perez ME, Gomes C, Silva PF, Moreira RG (2007) Quality of electron beam irradiation of blueberries (Vaccinium corymbosum L.) at medium dose levels (1.0–3.2 kGy). Lebenesm Wiss Technol 40:1123–1132

Moreno MA, Castell-Perez ME, Gomes C, Silva PF, Kim J, Moreira RG (2007) Optimizing electron beam irradiation of “Tommy Atkins” mangoes (Mangifera indica L.). J Food Process Eng 30:436–457

Mostafavi HA, Mirmajlessi SM, Fathollahi H (2012) The potential of food irradiation: benefits and limitations In: Eissa AH (ed) Trends in Vital Food and Control Engineering. doi:10.5772/2354

Oliveira IB, Sabato SF (2004) Dissemination of the food irradiation process on different opportunities in Brazil. Radiat Phys Chem 71:493–497

Ornellas CBD, Gonçalves MPJ, Silva PR, Martins RT (2006) Atitude do consumidor frente à irradiação de alimentos. Sci Food Technol 26:211–213

Ramathilaga A, Murugesan AG (2011) Effect of electron beam irradiation on proximate, microbiological and sensory characteristics of chyavanaprash–ayurvedic poly herbal formulation. Innov Food Sci Emerg Technol 12:515–518

Rivera CS, Venturini ME, Marco P, Oria R, Blanco D (2011) Effects of electron-beam and gamma irradiation treatments on the microbial populations, respiratory activity and sensory characteristics of Tuber melanosporum truffles packaged under modified atmospheres. Food Microbiol 28:1252–1260

Rodriguez O, Castell-Perez ME, Ekpanyaskun N, Moreira RG, Castillo A (2006) Surrogates for validation of electron beam irradiation of foods. Int J Food Microbiol 110:117–122

Rogovschi VD, Aquino S, Zorzete P, Reis TA, Corrêa B, Villavicencio ALCH (2007) Use of gamma radiation and electron beam treatment on decontamination of coconut agar medium used in the production of aflatoxins. AccApp’07: 1026–1027

Rogovschi VD, Aquino S, Nunes TCF, Gonçalez E, Corrêa B, Villavicencio ALCH (2009) Use of electron beam on aflatoxins degradation in coconut agar. In: Proceedings of the International Nuclear Atlantic Conference, INAC, Rio de Janeiro, Brazil

Sánchez-Bel P, Martínez-Madrid MC, Egea I, Romojaro F (2005) Oil quality and sensory evaluation of almond (Prunus amygdalus) stored after electron beam processing. J Agric Food Chem 53:2567–2573

Satin M (2002) Use of irradiation for microbial decontamination of meat: situation and perspectives. Meat Sci 62:277–283

Siddhuraju P, Makkar HPS, Becker K (2002) The effect of ionising radiation on antinutritional factors and the nutritional value of plant materials with reference to human and animal food. Food Chem 78:187–205

Song HP, Shim SL, Lee SI, Kim DH, Kwon JH, Kim KS (2012) Analysis of volatile organic compounds of ‘Fuji’ apples following electron beam irradiation and storage. Radiat Phys Chem 81:1084–1087

Supriya P, Sridhar KR, Ganesh S (2014) Fungal decontamination and enhancement of shelf life of edible split beans of wild legume Canavalia maritima by the electron beam irradiation. Radiat Phys Chem 96:5–11

Tahergorabi R, Matak KE, Jaczynski J (2012) Application of electron beam to inactivate Salmonella in food: recent developments. Food Res Int 45:685–694

Tesfai A, Beamer SK, Matak KE, Jaczynski J (2014) Effect of electron beam on chemical changes of nutrients in infant formula. Food Chem 149:208–214

Trinetta V, Vaidya N, Linton R, Morgan M (2011) A comparative study on the effectiveness of chlorine dioxide gas, ozone gas and e-beam irradiation treatments for inactivation of pathogens inoculated onto tomato, cantaloupe and lettuce seeds. Int J Food Microbiol 146:203–206

Tsai D (2006) Aplicação da radiação por feixe de elétrons como agente esterilizante de microrganisms em substrato turfoso.105p. Dissertação (Mestrado em Ciência). Tecnologia Nuclear, Instituto de Pesquisas Energéticas e Nucleares, São Paulo

Valero M, Sarrías JA, Álvarez D, Salmerón MC (2006) Modeling the influence of electron beam irradiation on the heat resistance of Bacillus cereus spores. Food Microbiol 23:367–371

Villavicencio ALCH, Fanaro GB, Araújo MM, Aquino S, Silva PV, Mancini-Filho J (2007) Detection of Phakopsora pachyrhizi by polymerase chain reaction (PCR) and use of germination test and DNA comet assay after e-beam processing in soybean. Radiat Phys Chem 76:1878–1881

Wei M, Zhou L, Song H, Yi J, Wu B, Li Y, Zhang L, Che F, Wang Z, Gao M, Li S (2014) Electron beam irradiation of sun-dried apricots for quality maintenance. Radiat Phys Chem 97:126–133

WHO-World Health Organization (1981) In: Wholesomeness of irradiated food. Report of a joint FAO/IAEA/WHO Expert Committee, WHO-Technical Report Series 659, Geneva

Yang Z, Wang H, Wang W, Qi W, Yue L, Ye Q (2014) Effect of 10 MeV E-beam irradiation combined with vacuum-packaging on the shelf life of Atlantic salmon fillets during storage at 4 & #xB0;C. Food Chem 145:535–541

Yun SH, Lee SW, Koo HN, Kim GH (2014) Assessment of electron beam-induced abnormal development and DNA damage in Spodoptera litura (F.) (Lepidoptera: noctuidae). Radiat Phys Chem 96:44–49

Acknowledgments

Patrícia Souza de Oliveira is a recipient of a PhD fellowship from National Council for the Improvement of Higher Education (CAPES).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Freita-Silva, O., de Oliveira, P.S. & Freire Júnior, M. Potential of Electron Beams to Control Mycotoxigenic Fungi in Food. Food Eng Rev 7, 160–170 (2015). https://doi.org/10.1007/s12393-014-9093-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-014-9093-8