Abstract

The high load and tough nature of loose trash generated after sugarcane harvest hampers the fertiliser placement and other field operations; therefore, open burning is a common practice in ratoon sugarcane. In situ retention of sugarcane trash can play an important role in replenishing soil quality and reducing environmental pollution, but there is a lack of suitable machine for placement of fertilisers. To address this and other issues for low yields of ratoon sugarcane, a prototype of multi-purpose machine was developed for operations like stubble shaving, off-barring, root pruning and drilling of basal fertilisers, and evaluated with ten on-farm trials on black soils varying in texture (clay 27–44 % and fertility (Org-C 4.4–9.3 g kg−1). The improvement in cane yields averaged 16 and 11 % over the trash burning (farmer’s practice) and chopping followed by recommended practices of fertiliser application (0.45, 0.45 and 0.10 N as basal, at earthing-up and onset of monsoon rains, respectively) while the nitrogen uptake efficiency (NUE) improved by 9.9 %. Band placement of double the dose of N as basal rather than the recommended two splits as basal and at earthing-up further boosted the initial growth and improved the cane yields and NUE by 22 and 11 % over farmer’s practice. Therefore, the fine-tuning of this prototype should offer a practical and economic solution of trash burning problem in sugarcane cultivation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sugarcane is one of the important cash crops in India that occupies around 5.0 million hectare area. Its average productivity is about 70 t ha−1, and its ratoon crop that is cultivated on half the sugarcane area yields 20–25 % less than the main crop (Gomathi et al. 2013). Poor sprouting of stubbles and higher mortality of tillers (Singh et al. 2013), soil compaction (Verma 2002), decreased soil fertility (Hunsigi 2001) and inefficient use of applied fertilisers (Sundara and Tripathi 1989; Singh et al. 2013) have been put forward to be the main causes of lower yields in ratoon crop. About 10–20 t ha−1 trash is left after sugarcane harvest which is usually burnt because of constraints for fertiliser placement and other intercultural operations. Trash burning results in loss of organic carbon, plant nutrients such as N and S (Hemwong et al. 2009), soil biota besides the environmental and health hazards due to release of soot particles, smoke and greenhouse gases (Arbex et al. 2007). Long-term benefits of surface retention of paddy straw in wheat under conservation agriculture systems have been widely documented from Indo-Gangetic plains (Gupta and Seth 2007; Hobbs et al. 2008). Even in sugarcane, the benefits of such a practice include increased soil organic matter (Vallis et al. 1996; Graham and Haynes 2005; Robertson and Thorburn 2007; Yadav et al. 2009; Fortes et al. 2012), improved physico-chemical properties and ultimately crop yields (Wood 1991; Yadav et al. 2009; Fortes et al. 2012). Basanta et al. (2003) indicated that unburned trash remaining as surface mulch resulted in annual recycling of 105 kg N ha−1 year−1 and therefore complemented to the fertiliser needs. Moreover, surface-retained trash is expected to improve soil water and thermal regimes in ratoon sugarcane during the following summer season (Denmead et al. 1997; Olivier and Singels 2007; Ng Cheong and Teeluck 2015). Nevertheless, the practice of surface retention of trash is not becoming popular due to non-availability of appropriate machinery. Only the chopping of trash has been attempted with some of the recently developed machines. These are becoming popular (Sri Escorts: Sreenath Sugarcane Trash Cutting Machine, Tamil Nadu; Guru Agro Industries, Haryana and Maharashtra), but those like ‘Happy Seeder’ are not available where drilling of fertilisers is possible with surface-retained straw. Therefore, with surface trash retention, broadcasting N on to crop residue continues to be an inefficient method of application because of its hold back by trash and immobilisation in association with the microbial break down of trash and because of greater ammonia volatilisation from surface-applied fertilisers (Yadvinder-Singh et al. 2015). The possible solution to the immobilisation and volatilisation problem is placement of fertiliser-N below the surface.

Moreover, in ratoon sugarcane, the mortality of facultative tillers usually occurs, especially in case those sprout from the above-ground uneven portions of canes left after harvest. Therefore, stubble shaving and off-barring are recommended within a week of harvest of sugarcane (Bakker 1999; Ahmed and Giridharan 2000). In addition to above, the suberised old roots in ratoon become less effective for nutrient and water uptake. To overcome this, it was hypothesised that the new slush of fine roots should be more effective if the older roots are pruned. To address all the above issues, a new prototype of multi-purpose machine was designed to perform multiple operations of stubble shaving, off-barring, root pruning and placement of basal dose of fertilisers in one go while retaining the trash at the soil surface. Thereafter, the machine was tested for its performance in terms of growth and productivity of ratoon sugarcane under farmers’ field’s conditions where comparisons were made with the usual practice of burning trash or its simple chopping and retention over the soil surface.

Materials and Methods

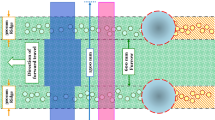

Experiments were conducted with sugarcane ratoon crop during January 2014 to May 2015 at ten farmer’s fields in Malegaon village and adjoining areas of Baramati tehsil, Pune district (18.15°N latitude, 74.49°E longitude and 552 m above mean sea level). The area has semi-arid monsoonal type of climate with a long-term average annual rainfall of 588 mm. Before initiation of the experiment, soil samples were drawn for analysing physico-chemical characteristics and the fields selected to have a wider range of soil texture as well as initial fertility. The selected sites had mostly the black soils with clay content ranging between 27 and 44 %, organic carbon 0.43–0.93 %, pH 7.63–8.07, EC (1:2) 0.32–1.13 dS m−1 and available N 158.2–224.6 kg ha−1 (Table 1). The total rainfall and reference evapo-transpiration (ET0) during the crop growing period (January 2014 to May 2015) were 882 and 3017 mm, respectively. The distribution of rainfall and other weather parameters are depicted in Fig. 1. The basic prototype of stubble shaver, off-bar cum fertiliser applicator was developed at ICAR-IISR, Lucknow, which was further upgraded into a multi-purpose drill machine with the inclusion of large-capacity fertiliser box and root pruning cum fertiliser placement mechanisms at ICAR-NIASM, Baramati, which is shown in Fig. 2. This is a tractor (50–65 hp) PTO-driven three-point hitch linkage operated drill machine of 1.5 m working width. In addition to drilling of fertilisers (0.15–0.25 m soil depth depending on height of raised beds), the machine is suitable to perform various other operations viz, stubble shaving, covering of trash with loose soil, off-barring and root pruning in a single go for sugarcane ratoon crop. In brief, equipment broadly consist of power transmission unit, central horizontal rotating disc attachment with fixed peripheral blades for stubble shaving and two vertical discs for off-barring along with root pruning cum fertiliser placement mechanisms. Gearbox mounted on the main frame (1.6 m × 1.4 m) with vertical downward driving shaft revolved bottom horizontal disc (0.62 m dia.) and peripheral high carbon steel blades (17 No.) of trapezoidal shape (4-cm cutting edge) at 120–180 rpm. The 0.4-m ground clearance from main frame was maintained during operation. The rotating fixed blades cut the sugarcane stubbles (of size 5–18 cm left after manual harvesting above the ground) by shearing action below the ground up to 3 cm uniformly. The spacing (0.7–1.2 m) between two high carbon steel root pruners (0.95 m × 0.07 m × 0.02 m) mounted at 45° to the main frame is adjustable depending on the row spacing used for planting sugarcane. Adjustable vertical off-bar discs cut the raised bed (0.10–0.20 m soil depth) from outer sides and spread the lifted soil over the chopped trash. Root pruners fitted and aligned just behind the vertical off-bar discs further cut the soil down to 0.10–0.20 m depth and fertiliser was placed simultaneously through fertiliser box using fluted role-star wheel (0.6 m dia.) metering drill mechanism depending upon adjusted fertiliser rate below the surface. Off-barring and root pruning also helps to prune the old roots of sugarcane ratoon crop. It is simple, energy saving, cost-effective and environment friendly equipment that has a number of applications like stubble shaving, covering of trash with loose soil, root pruning and fertiliser application in a sugarcane ratoon crop. The machine is hereafter referred as SORF machine. The damage of ratoons/stubbles with the usage of machine was negligible in most of the fields except for at field no. 8 (1.4–4.5 % of clumps). While testing this machine at farmers’ fields, the following four treatments were imposed in randomised complete block design at each site:

- T1::

-

Burning of left over trash and broadcasting of basal fertiliser doses (farmer’s practice).

- T2::

-

Chopping and surface retention of trash and thereafter broadcasting of basal fertiliser doses.

- T3::

-

Chopping and surface retention of trash and use of multi-purpose machine for stubble shaving, off-barring, root pruning and drilling of basal doses of fertilisers.

- T4::

-

Same as T3 but increasing the basal N to double the recommended.

The recommended doses of N, P and K for ratoon sugarcane in the area are 275, 60 and 116 kg ha−1. Half the P and K and 45 % N are recommended as basal during the beginning of ratoon while remaining half of P and K and another 45 % of N is recommend just before the earthing-up operation, i.e. 18–21 weeks after the ratoon crop initiation (WARI). The left over 10 % N is top dressed 23–26 WARI. Thus, in treatment T4, 90 % of the N was applied as basal instead of 45 % as basal and 45 % at earthing-up. The plot size varied between 75 and 225 m2. The most common variety of the area ‘Co-86032’ was grown in all the fields. Recommended package of other agronomic practices was followed for raising the crop. Ten randomly selected clumps were tagged in each plot for observation on plant height and tillers under each treatment. The yield attributing parameters were monitored before harvest following the standard procedures. The net plot area harvested at each site was 45 m2. Samples for dry leaves, green tops and canes were drawn and dried in oven to a constant weight and later used for computation of the total biomass. These samples were also analysed for N content by Kjeldahl method using Kjeltec™ 8400 Auto-analyser (FOSS, Denmark). The nitrogen uptake efficiency (NUE, %) was computed from the total N uptake in above-ground parts and N supply. The latter included applied fertiliser-N as well as available N in surface 0.15-m soil. The data collected on different parameters were subjected to appropriate statistical analysis following the procedures described by Gomez and Gomez (1984).

Results

The growth monitored in terms of plant height followed a sigmoid pattern (Fig. 3). Initially, the height gain was 1.0 cm day−1 until 90 days after ratoon initiation (DARI), and it increased to 1.51–1.68 until 240 DARI. Thereafter, it declined and height became stagnant at 300 DARI. The plants were the tallest under T4, i.e. when 90 % N was applied as basal with SORF machine followed by T3, i.e. 45 % N as basal using SORF machine. The maximum effects of these treatments on plant height were monitored at 240–270 DARI. When averaged for all the sites, the plant height at maturity was 1.49-, 1.16- and 1.05-fold under T4, T3 and T2 than the farmer’s practice (T1), respectively. Similarly, the emergence of tillers was very fast during the initial 60 DARI when these increased to 1.5–2.0 times those at 30 DARI (Fig. 3). The maximum tillers were recorded at 120 DARI, and thereafter, mortality in tillers was noticed that persisted until maturity. The maximum tillers at maturity were observed in T3 followed by T4. These were 1.29, 1.17 and 1.09 times more in T3, T4 and T2 than T1, respectively. The different trash and N management practices also showed significant impact on yield attributes of sugarcane ratoon, viz. millable cane, internodes per cane, internode length, cane diameter, cane length, cane weight and cane juice yield of ratoon crop (Table 2). The highest values of these yield attributes were recorded with T4 that were at par with T3. The millable cane was improved by 27, 20 and 7 % with T4, T3 and T2 over T1, respectively. Similarly, internodes per cane, internode length, cane diameter, cane length, cane weight and cane juice yields improved under T4 by 17.6, 14.3, 8.9, 18.8, 25.0 and 22.2 % than the T1 while the counter figures were 14.8, 12.4, 6.2, 15.7, 19.2 and 15.5 % with T3. These parameters were at par under T2 and T1.

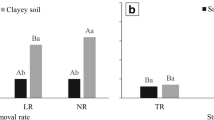

Data pertaining to cane yield obtained at each farmers’ field are presented in Fig. 4 while their means are given in Table 2. The crop at most of the sites responded to both trash and N management treatments; though large site-to-site variations existed in cane yield, e.g. under farmer’s practice, the cane yield varied between 91 to 140 t ha−1. Cane yields recorded were >160, 130–160 and <130 t ha−1 at 3, 5 and 2 farmer’s fields, respectively. The lack of supplemental irrigation with canal closure that coincided with active tillering stage lead to higher mortality of tillers and thus the lower millable canes vis-à-vis cane yields at tail-end sites. However, when averaged for all the sites, the cane yields were improved by 20.6, 16.3 and 5.1 % under T4, T3 and T2, respectively, when compared with T1.

Of the total uptake of N by the crop, averaging 197.4 kg ha−1, a major (52 %) portion was retained in cane and this was followed by dry leaves (26 %) while the green leaves contained about 22 % (Table 3). Amongst the treatments, the maximum N uptake was recorded under T4 (221 kg ha−1) that was at par with T3 (216 kg ha−1) followed by T2 (183 kg ha−1 and minimum was under T1 (170 kg ha−1). This also resulted in improving NUE by about 11 % and least soil apparent N balance in T4 and T3 as compared with T1.

Discussion

The high load and tough nature of loose trash generated after sugarcane harvest hampers the fertiliser placement and other field operations; therefore, open burning is a common practice in ratoon sugarcane. This not only results in loss of organic carbon and nutrients like N and S, but also the broadcasted fertiliser-N as basal dose has restricted the mobility and availability of nutrients to ratoon plants (Shukla et al. 2008; Yadav et al. 2009). Greater losses of N as ammonia volatilisation further reduce the quantity of N for plants. In situ retention of sugarcane trash can play an important role in replenishing soil quality and reducing environmental pollution. Srivastava et al. (2012) reported that trash mulching just after ratoon initiation checks the weed growth and contributed to 21–28 % increase in cane yield. However, the inefficient use of N is a major problem since the broadcasted fertilisers onto gets immobilised in association with microbial breakdown of trash and subject to volatilisation losses (Yadvinder-Singh et al. 2015). One of the solutions for this can be to apply minimum dose of fertilisers as basal and delay top dressing until earthing-up. But such practice discourages the initial growth and development of crop. The crop growth though picks up with top dressing, but the growth never matches the initially well-fertilised crop. The other option is to band the fertiliser-N few centimetres below the surface to minimise its loss by volatilisation (Weier 1994). Prasertsak et al. (2002) reported that drilling the urea into the soil instead of applying it to the trash surface reduced ammonia loss from 37.3 to 5.5 % of the applied N. The NUE improved by 7.6 % under retaining of chopped trash in the field over burning of trash. De Resende et al. (2006) observed that over a long period, trash conservation (abandonment of burning) in Brazil has increased cane yields by 25 % from a mean of 46–58 t ha−1 and resulted in positive total N balance for the soil/plant system. Thus, sustainable sugarcane cropping systems must include crop residue return rather than burning in order to maintain active C and N pools in the system to drive nutrient cycles and to build up or maintain soil organic matter. However, there is a lack of suitable machine for placement of fertilisers. Even the off-barring of old roots by interculture close to the sugarcane rows has been shown to induce vigorous initial growth and proper ratoon crop stand (Srivastava et al. 2012). To address fertiliser placement and other issues for low yields of ratoon sugarcane, a prototype of multi-purpose machine for operations like stubble shaving, off-barring, root pruning and drilling of basal fertilisers was developed and evaluated through on-farm trials. As given above, such practice not only improved the cane yields by 16 and 11 % over the trash burning (farmer’s practice) and chopping followed by recommended practices of fertiliser application (0.45, 0.45 and 0.10 N as basal, at earthing-up and onset of monsoon rains, respectively), it significantly increased the N uptake vis-à-vis NUE that was improved by about 10 %. Further, it is observed that even the second split applied at earthing-up also comes in contact with decomposing trash and still immobilises a major portion of the added N. To overcome this, it was hypothesised that if basal and first split N doses are combined and banded initially, this would be transported to deeper soil with irrigation water and thus would not prone to immobilisation and would rather boost the initial growth of ratoon crop. The latter was in fact observed in terms of taller plants and more tillers (Fig. 3). The better growth was maintained until harvest and ultimately band placement of double the dose of N as basal rather than the recommended practice of two splits as basal and at earthing-up produced highest cane yields and NUE. The improvement in cane yield and NUE were 22 and 11 % over the farmer’s practice, respectively. Thus, this study has shown that a better applied management strategy than the presently recommended would be drilling of 90 % N into soil as basal.

Conclusions

It is concluded that stubble shaving, off-barring, pruning of older roots and fertiliser placement, especially, double the basal N with the multi-purpose ‘SORF’ machine substantially improved the N-use efficiency and productivity of sugarcane ratoon crop under surface-retained trash conditions. This certainly can help in boosting income of the sugarcane growers in addition to improving soil health, conserving water and environmental protection. Long-term monitoring would be required to quantify the latter benefits.

References

Ahmed, S.N., and S. Giridharan. 2000. Study on the influence of management practices on sugarcane ratoon crop. Indian Sugar 49(10): 835–837.

Arbex, M.A., L.C. Martins, R.C. de Oliveira, L.A.A. Pereira, F.F. Arbex, J.E.D. Cancado, P.H.N. Saldiva, and A.L.F. Braga. 2007. Air pollution from biomass burning and asthma hospital admissions in a sugar cane plantation area in Brazil. Journal of Epidemiology and Community Health 61: 395–400.

Bakker, H. 1999. Sugarcane cultivation and management, 207. New York: Springer.

Basanta, M.V., D. Dourado-Neto, K. Reidchardt, O.O.S. Bacchi, J.C.M. Oliveira, P.C.O. Trivelin, L.C. Timm, T.T. Tominaga, V. Correchel, F.A.M. Cassaro, L.F. Pires, and J.R. de Macedo. 2003. Management effects on nitrogen recovery in a sugarcane crop grown in Brazil. Geoderma 116: 235–248.

De Resende, A.S., R.P. Xavier, O.C. de Oliveira, S. Urquiaga, B.J.R. Alves, and R.M. Boddey. 2006. Long-term effects of pre-harvest burning and nitrogen and vinasse applications on yield of sugar cane and soil carbon and nitrogen stock on a plantation in Pernambuco, NE Brazil. Plant and Soil 281: 339–351.

Denmead, O.T., C.L. Mayocchi, and F.X. Dunin. 1997. Does green cane harvesting conserve soil water? Proceedings of the Australian Society of Sugar Cane Technologists 18: 139–146.

Fortes, C., P.C.O. Trivelin, and A.C. Vitti. 2012. Long-term decomposition of sugarcane harvest residues in Sao Paulo state, Brazil. Biomass and Bioenergy 42: 189–198.

Gomathi, R., P.N.G. Rao, P. Rakkiyappan, B.P. Sundara, and S. Shiyamala. 2013. Physiological studies on ratoonabilty of sugarcane varieties under tropical Indian condition. American Journal of Plant Sciences 4: 247–281.

Gomez, K.A., and A.A. Gomez. 1984. Statistical procedures for agricultural research, 2nd ed, 680. New York: Wiley.

Graham, M.H., and R.J. Haynes. 2005. Organic matter accumulation and fertilizer-induced acidification interact to affect soil microbial and enzyme activity on a long-term sugarcane management experiment. Biology and Fertility of Soils 41(4): 249–256.

Gupta, R., and Ashok Seth. 2007. A review of resource conserving technologies for sustainable management of the rice–wheat cropping systems of the Indo-Gangetic plains (IGP). Crop Protection 26: 436–447.

Hemwong, S., B. Toomsan, G. Cadisch, V. Limpinuntana, P. Vityakon, and A. Patanothai. 2009. Sugarcane residue management and grain legume crop effects on N dynamics, N losses and growth of sugarcane. Nutrient Cycling in Agroecosystems 83: 135–151.

Hobbs, P.R., K. Sayre, and R. Gupta. 2008. The role of conservation agriculture in sustainable agriculture. Philosophical Transactions of the Royal Society B 363: 543–555.

Hunsigi, G. 2001. Ratoon management. In Sugarcane in agriculture and industry, ed. Hunsigi, G., 217. Bangalore: Prism Books.

Ng Cheong, L.R., and M. Teeluck. 2015. The practice of green cane trash blanketing in the irrigated zone of Mauritius: effects on soil moisture and water use efficiency of sugarcane. Sugar Tech. doi:10.1007/s12355-015-0374-1.

Olivier, F.C., and A. Singels. 2007. Effect of a trash blanket on irrigation water use efficiency of sugarcane. Proceedings of the International Society of Sugar Cane Technologists 26: 404–408.

Prasertsak, P., J.R. Freney, O.T. Denmead, P.G. Saffigna, B.G. Prove, and J.R. Reghenzani. 2002. Effect of fertilizer placement on nitrogen loss from sugarcane in tropical Queensland. Nutrient Cycling in Agroecosystems 62: 229–239.

Robertson, F.A., and P.J. Thorburn. 2007. Management of sugarcane harvest residues: consequences for soil carbon and nitrogen. Australian Journal of Soil Research 45: 13–23.

Srivastava, T.K., M. Lal, and S.K. Shukla. 2012. Agronomic research in sugar crops: an overview. Indian Journal of Agronomy 57(3rd IAC Special Issue): 83–91.

Shukla, S.K., R.L. Yadav, A. Suman, and P.N. Singh. 2008. Improving rhizospheric environment and sugarcane ratoon yield through bioagents amended farm yard manures in udic Ustochrept soil. Soil and Tillage Research 99: 158–168.

Singh, P., R.K. Rai, A. Suman, T.K. Srivastava, K.P. Singh, and R.L. Yadav. 2013. Ratooning induced rhizospheric changes impede nutrient acquisition and growth in sugarcane ratoon crop during grand growth stage in sub-tropics. Sugar Tech 15(1): 52–64.

Sundara, B., and B.K. Tripathi. 1989. Available N changes and N balance under multi ratooning of sugarcane varieties in tropical vertisol. Proceedings of the International Society of Sugar Cane Technologists 23: 80–88.

Vallis, I., W.J. Parton, B.A. Keating, and A.W. Wood. 1996. Simulation of the effects of trash and N fertilizer management on soil organic matter levels and yields of sugarcane. Soil and Tillage Research 38: 115–132.

Verma, R.S. 2002. Sugarcane ratoon management, 202. Lucknow: International Book Distributing Co. Pvt. Ltd.

Weier, K.L. 1994. Nitrogen use and losses in agriculture in subtropical Australia. Fertilizer Research 39: 245–257.

Wood, A.W. 1991. Management of crop residues following green harvesting of sugarcane in north Queensland. Soil and Tillage Research 20: 69–85.

Yadav, R.L., S.K. Shukla, A. Suman, and P.N. Singh. 2009. Trichoderma inoculation and trash management effects on soil microbial biomass, soil respiration, nutrient uptake and yield of ratoon sugarcane under subtropical conditions. Biology and Fertility of Soils 45: 461–468.

Yadvinder-Singh, Manpreet-Singh, H.S. Sidhu, E. Humphrerys, H.S. Thind, M.L. Jat, J. Blackwell, and V. Singh. 2015. Nitrogen management for zero till wheat with surface retention of rice residues in north-west India. Field Crops Research. doi:10.1016/j.fcr.2015.03.025.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Choudhary, R.L., Wakchaure, G.C., Minhas, P.S. et al. Response of Ratoon Sugarcane to Stubble Shaving, Off-barring, Root Pruning and Band Placement of Basal Fertilisers with a Multi-purpose Drill Machine. Sugar Tech 19, 33–40 (2017). https://doi.org/10.1007/s12355-016-0438-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-016-0438-x