Abstract

The decline in the use of fossil fuels in the future is due to the gradual depletion of their reserves and related environmental issues. Biofuels including ethanol are presented as a renewable alternative to fossil fuels. However, ethanol production, generally from sugarcane demands the use of agricultural land and other natural resources, with emphasis on water and other nutrients. Sorghum is tolerant to drought. The purpose of this study was to evaluate the potentiality of eight sweet sorghum cultivars in order to expand the ethanol production to areas with limited supply of water, not suitable for sugarcane which requires irrigation. The cultivars developed by breeding programs in the state of Pernambuco, Brazil, were analyzed for fermentation by industrial strain of Saccharomyces cerevisiae, at 33 °C, under static conditions for a period of 6 h. All assessed parameters showed some statistically significant differences among cultivars (p < 0.01), especially ethanol concentration (P) and the volumetric productivities (Qp) in the following order: Willey (P = 64.77 ± 4.4 g L−1 and Qp = 10.79 ± 0.74 g L−1 h−1), Wray (P = 59.10 ± 1.7 g L−1 and Qp = 9.85 ± 0.28 g L−1 h−1), BR 506 (P = 59.07 ± 1.3 g L−1 and Qp = 9.84 ± 0.21 g L−1 h−1) and SF 15 (54.40 ± 0.4 g L−1 and Qp = 9.07 ± 0.06 g L−1 h−1). The highest potentials for ethanol yield per hectare were observed for the cultivars SF 15 (3142.51 ± 428.47 L ha−1) and BR 506 (2193.95 ± 383.58 L ha−1). Therefore, the cultivars SF 15 and BR 506 seem to be very promising as an energy crop to be produced in areas with environmental conditions similar to Pernambuco.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Many factors, like the emission of greenhouse gases and availability and easiness to access the current reserves of fossil fuels, point out to a decline in the current consumption of fossil fuels. In this context, there have been increased opportunities in the use of renewable energy sources, and among them, the sources based in bioenergy (energy in form of biomass), including the use of energy crops in order to produce biofuels like biodiesel and ethanol (Sánchez and Cardona 2008).

The production of ethanol in the world is increasing every year. Ethanol can be produced from different biomass sources, such as starch (corn and cereal grains), sucrose (sugarcane, sugar beet and sweet sorghum) and cellulosic crops (crop residues and wood) (Walker 2011). In Brazil, ethanol production derives mainly from the fermentation of the sucrose from sugarcane juice and/or molasses. Brazil produced nearly 24 billion liters of ethanol during the 2009–2010 crop season, a figure that is projected to reach 37 billion liters by 2012–2013 (Amorim et al. 2009). Nevertheless, ethanol production from sugarcane has limitations, mainly in areas with low rainfall precipitation where sugarcane cultivation is not feasible. In the northeastern region of Brazil, only a narrow region along the coast of the Atlantic Ocean receives enough rainfall precipitation for the cultivation of sugarcane without irrigation. In the remaining areas, the adoption of new energy crops with better water use efficiency, like sweet sorghum, maybe a more sustainable solution to the expansion of ethanol production.

Sorghum’s potential for ethanol production has been widely reported, and its C4-type photosynthetic metabolism makes sweet sorghum appropriate for biomass production in conditions of high solar incidence and low water availability (Almodares and Hadi 2009; Vasilakoglou et al. 2011). Originally from Africa, is now the fifth most cultivated cereal in the world for its grain use as staple food for millions of people in Africa and Asia, and the use of its stalks and leaves as forage, and most recently for energy generation (Reddy et al. 2005), and also as a complement in animal feeding. It also produces fibers (Murray et al. 2008). Among other characteristics, efficient water usage (1/3 of water required for sugarcane and 1/2 of water required for corn) and the versatility of growing in different types of soil and climate. In general, sweet sorghum produces 2 t ha−1 of grains and 50 t ha−1 of stems, with a stem juice rich in sucrose, glucose and fructose (Wu et al. 2010). Ethanol production from fermentation of sorghum stem juice is about 3451 L ha−1 (Prasad et al. 2007).

In the context of pursuing new feedstock for biofuel production, the purpose of this study was to evaluate ethanol production by fermentation of stem juice derived from different sweet sorghum cultivars in the municipality of Goiana, state of Pernambuco, Northeast region, Brazil.

Materials and Methods

Sweet Sorghum Biomass and Juices

The stems from eight sorghum cultivars were obtained from the Agricultural Research Institute of Pernambuco (IPA) after a field experiment to evaluate biomass production in the municipality of Goiana, state of Pernambuco, Northeast, Brazil. The region has a yearly precipitation mean around 1,600 mm and average temperature of 25 °C. The evaluated cultivars were: IPA 467-4-2, Rio, Tale, Willey, Wray, BR 501, BR 506 and SF 15.

The field experiment was carried out in a randomized complete block design. Plants were harvested during the grain maturation phase. Leaves and panicles were removed from the stems in order to have the juice extracted from fully clean stems in a simple sugarcane crusher system. First, the sorghum juices were evaluated for: (1) total suspended solids as °BRIX values using a handheld refractometer (RT-30ATC, Instrutherm); and (2) the concentration of total reducing sugars (TRS) by the 3,5-dinitrosalicylic acid method (Miller 1959). After digestion with sulfuric acid and hydrogen peroxide, the following nutrient contents were determined (Thomas et al. 1967): total nitrogen (TN) by the Kjeldahl method; total phosphorus (TP) by the colorimetric method; and potassium (K) by flame photometry (EMBRAPA 1999). pH was determined using a Digimed potentiometer. Extracted juices were stored at −20 °C in a freezer for subsequent fermentation assays.

Fermentation Experiment

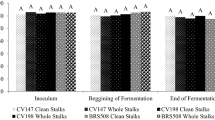

Fermentations were carried out in a single batch system in 500 mL Erlenmeyer flasks at 33 °C and static conditions for 6 h. All assays were conducted in triplicate, in a completely randomized design. A 100 mL volume of non-sterilized sorghum juice was added to the Erlenmeyer flasks and inoculated at 10 % w/v (108 cells mL−1) with pure industrial yeast Saccharomyces cerevisiae P1 strain (Silva-Filho et al. 2005) obtained directly from industrial process from Japungú distillery, Santa Rita, State of Paraíba, Brazil. The fermented juices were then centrifuged at 4,200×g for 10 min and the supernatant was collected and submitted to analytical analysis.

TRS were measured in the fermented juices using the DNS method (Miller 1959) and expressed in glucose equivalents. The amount of ethanol produced was quantified using gas chromatography coupled with a flame ionization detector under the following operational temperatures: 95 °C for the column, 130 °C for the injector and 160 °C for the detector. Nitrogen (N2) was used as carrier gas. Cellular viability was determined in a Neubauer chamber using methylene blue staining.

Physiological Parameters

The following parameters were calculated during fermentation: volumetric ethanol productivity (Qp); ethanol yield (YP/S), expressed as g of ethanol g−1 of consumed sugar; and sugar-to-ethanol conversion efficiency (SCE), using Eqs. (1) and (2):

and

where P is the ethanol concentration (g L−1), T is the fermentation time (h) and 0.51 is the maximum theoretical ethanol yield per gram of glucose consumed.

The theoretical ethanol yield per hectare for each sweet sorghum cultivar using the results from TRS and SCE in accordance to the Eq. (3) proposed by Zhao et al. (2009) with modification on SCE that in the original equation is 85 %.

where TRS is the percentage of total reducing sugars, fresh biomass is the fresh biomass production for sweet sorghum in Mg ha−1, 6.5 is the sugar-to-ethanol conversion, SCE is the sugar-to-ethanol conversion efficiency and 0.79 is the ethanol density in g mL−1.

Statistical Analysis

The study used a completely randomized experimental design and all analytical assays were performed in triplicate. The results from °BRIX, TN, P and K content, starting TRS concentration, starting pH, volumetric ethanol productivity, ethanol yield, SCE and theoretical ethanol yield per hectare were subjected to variance analysis (ANOVA) and the means were compared by the Tukey test (α = 0.05) using the Software ASSISTAT (Silva and Azevedo 2002).

Results and Discussion

Chemical Composition of the Juices

The initial content of TRS and BRIX in the juices showed different concentrations for each cultivar. Juices from Willey, Wray and BR 506 strains had the highest °BRIX and TRS values (Table 1). The ethanol production from sweet sorghum juices in submerged fermentation is directly related to TRS concentrations; that is, up a certain level, juices with higher TRS and °BRIX concentrations result in higher ethanol concentrations by the yeast. TRS concentration above 270 g L−1 is supposed to be inhibitory and might induce oxidative stress under very high gravity fermentation (Thomas et al. 1996).

°BRIX is a common analysis in sugar and ethanol producing companies, and allows direct field readings of the juices’ sugar content. This variable indicates the concentration of soluble solids in the juice (in g 100 mL−1) that are possibly correlated to the content of TRS. Under the experimental conditions of this study, an increase in the °BRIX of the juices from different sweet sorghum cultivars resulted in a linear increase (R2 = 0.895) in the TRS content (Fig. 1). Other studies on the fermentation of sweet sorghum juices also showed linear relations between TRS content and °BRIX (Guigou et al. 2011—R2 = 0.960 and Tsuchihashi and Goto 2004—R2 = 0.807).

Besides, the measurements of sugar content, nutrient availability and medium pH is essential to monitor the feedstock quality in the fermentation process. The mineral composition is very important for the alcoholic fermentation process, especially in the nutrition and fermentative metabolism of the yeast cells (Walker 2004). Among the analyzed minerals, potassium had the highest content in the level of 3742.9 mg L −1, the TN and phosphorus had an average of 681.2 and 47.4 mg L−1, respectively (Table 1). These contents are mostly influenced by soil type, crop management and by the ability of each cultivar to absorb nutrients from the soil.

Potassium is the most abundant cation in yeast, constituting 1–2 % of cell dry weight and acting as a major cofactor for enzymes involved in oxidative phosphorylation, protein biosynthesis and carbohydrate catabolism (Jones and Greenfield 1994). Nitrogen is important for yeast multiplication and also responsible for activation of conveyor systems sugars, increasing the entry of sugar into the cell (Lagunas et al. 1982). Phosphorus is essential for the energy metabolism and the synthesis of the nucleic acids. This element is considered essential for the absorption of carbohydrates, conversion of sugar into alcohol and ATP production in glycolysis so as respiratory chain (Amorim 1985; Vasconcelos 1987). Despite the importance of these elements in the fermentation there are no available studies that report the mineral composition of the feedstock used in the fuel ethanol production and even less about the synergistic effect of the minerals in the fermentative metabolism of the yeast. For this reason, more detailed studies are necessary to evaluate these effects.

The pH is a very valuable parameter in the fermentation process, as it controls nutrient dissolution and assimilation, extracellular degrading enzymatic activity. It also prevents the proliferation of contaminating microorganisms of the alcoholic fermentation (Lima et al. 2002). The juices of the eight evaluated cultivars showed an average initial pH of 5.04 (ranging from 4.60 to 5.41), which is adequate for fermentation with yeast (pH 5.0–6.5). Similar pH values were observed for Dale cultivar (pH 5.4) (Dimple et al. 2010) and for sweet and foraging cultivars (pH 4.56) (Davila-Gomes et al. 2011). There was a reduction in the pH of all fermentations to pH around 3.94 (data not shown) that may be related to the production of organic acids in the sugar metabolism by yeast (Bai et al. 2008).

Alcoholic Fermentation of the Juices and Ethanol Yield Per Hectare

Higher ethanol concentrations obtained from the fermentation of Willey, Wray and BR 506 (Table 2) cultivars juices can be explained by the high starting content of TRS, as there was a linear correlation (R² = 0.893) between the concentrations of starting TRS and ethanol (Fig. 2). The average ethanol concentration from the fermentation of the juices was 50.06 g L−1 (from 30.6 to 64.7 g L−1), which is lower than the 89.5 g L−1 obtained by Laopaiboon et al. (2007) by fermenting the juice of the Keller sweet sorghum variety. This difference can be explained by the higher concentration of soluble solids, the nutrient supplementation and the higher fermentation time (average of 48 h) of the said study.

The highest Qp values were observed for Willey, Wray and BR 506 cultivars (Table 2). Qp is directly related to ethanol concentration and fermentation time, representing a very important kinetic parameter for the viability of commercial alcoholic fermentation. In this sense, the mean volumetric productivity of 8.34 g L−1 h−1 is above near values reported for sweet sorghum juice fermentation in other studies (Khongsay et al. 2010—1.92 g L−1 h−1 and Ratnavathi et al. 2010—1.16 g L−1 h−1). This difference can be explained by the longer fermentation times seen in the referenced studies (36 and 60 h, respectively).

Another important kinetic parameter of the fermentation process is the ability of yeasts to produce ethanol from the available sugar and can be expressed as the sugar conversion efficiency (SCE). The results for SCE showed differences between cultivars (Table 3) and the better results obtained for IPA 467 and BR 501 cultivars may be related to lower ethanol content seen in the fermentation of their juices, as ethanol may inhibit the fermentation process (Walker 2004). Mean values obtained for SCE in the experimental data set (90.2 %) are within the range of the main results found in scientific literature (68.6–94.1 %) (Wu et al. 2010; Guigou et al. 2011), evidencing the potential for fermentation of the evaluated cultivars. The total and viable cell concentrations were almost constant during all fermentations.

In general terms, the values obtained for theoretical ethanol yield per hectare were low (mean = 1741.92), indicating that the cultivation practices under the assessed environmental conditions need to be improved, as well as the SCE. In a study conducted by Zhao et al. (2009) under another environmental condition and using distinct cultivars, estimated mean value for 2 years of cultivation was 4.729 L ha−1. However, the highest theoretical ethanol yields for hectare (Table 3) were obtained for SF 15 (3142.51 ± 428.47 L ha−1) and BR 506 (2193.95 ± 383.58 L ha−1), both influenced by the high production of biomass by these cultivars.

Conclusion

The sweet sorghum stem juice showed potential for ethanol production in northeastern, Brazil. The cultivars SF 15 and BR 506 presented great potential for ethanol production per hectare and are promising for large-scale cultivation.

References

Almodares, A., and M.R. Hadi. 2009. Production of bioethanol from sweet sorghum: a review. African Journal of Agricultural Research 4: 772–780.

Amorim, H.V., L.V. Basso, and M.L. Lopes. 2009. Sugar cane juice and molasses, beet molasses and sweet sorghum: composition and usage. In The alcohol textbook, vol. 5, ed. W.M. Ingledew, G.D. Austin, C. Kluhspies, and D.R. Kelsall, 39–46. Nottingham: Nottingham University Press.

Amorim, H.V. 1985. Nutrição mineral da levedura, aspectos teóricos e práticos. In: Semana de fermentação alcoólica “Jaime Rocha de Almeida”, Anais. Piracicaba: ESALQ, 144–148.

Bai, F.W., W.A. Anderson, and M. Moo-Yong. 2008. Ethanol fermentation technologies from sugar and starch feedstocks. Biotechnol Advances 26: 89–105.

Davila-Gomes, F.J., C. Chuck-Hernandez, E. Perez-Carrillo, W.L. Rooney, and S.O. Serna-Saldivar. 2011. Evaluation of bioethanol production from five different varieties of sweet and forage sorghums (Sorghum bicolor (L) Moench). Industrial Crops and Products 33: 611–616.

Dimple, K.K., D.D. Bellmer, R.L. Hunke, M.R. Wilkins, and P.L. Claypool. 2010. Influence of temperature, pH and yeast on in-field production of ethanol from unsterilized sweet sorghum juice. Biomass and Bioenergy 34: 1481–1486.

EMBRAPA—Empresa Brasileira de Pesquisa Agropecuária. Informática Agropecuária. 1999. Manual de análises químicas de solos, plantas e fertilizantes. EMBRAPA, Brasília.

Guigou, M., L.V. Pérez, C. Lareo, M.E. Lluberas, D. Vázquez, and M.D. Ferrari. 2011. Bioethanol production from three sweet sorghum varieties: evaluation of post-harvest treatment on sugar extraction and fermentation. Biomass and Bioenergy 35: 3058–3062.

Jones, R.P., and P.F. Greenfield. 1994. A review of yeast ionic nutrition, I.: growth and fermentative requirements. Process Biochemistry 4: 48–59.

Khongsay, N., L. Laopaiboon, and P. Laopaiboon. 2010. Growth and batch ethanol fermentation of Saccharomyces cerevisiae on sweet sorghum stem juice under normal and very high gravity conditions. Biotechnology 9: 9–16.

Lagunas, R., C. Dominguez, A. Busturia, and M.J. Sáez. 1982. Mechanisms of appearance of the pasteur effect in Saccharomyces cerevisiae: inactivation of sugar transport systems. Journal of Bacteriology 152: 19–25.

Laopaiboon, L., P. Thanonkeo, P. Jaisil, and P. Laopaiboon. 2007. Ethanol production from sweet sorghum juice in batch and fed-batch fermentations by Saccharomyces cerevisiae. World Journal of Microbiology & Biotechnology 23: 1497–1501.

Lima, U.A., E. Aquarone, W. Borzani, and W. Schmidell. 2002. Biotecnologia industrial: processos fermentativos e enzimáticos. São Paulo: Edgard Blucher.

Miller, G.L. 1959. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry 31: 426–428.

Murray, S.C., W.L. Rooney, S.E. Mitchell, A. Sharma, P.E. Klein, J.E. Mullet, and S. Kresovich. 2008. Genetic improvement of Sorghum as a biofuel feedstock: II. QTL for stem and leaf structural carbohydrates. Crop Science 48: 2180–2193.

Prasad, S., A. Singh, N. Jain, and H.C. Joshi. 2007. Ethanol production from sweet sorghum syrup for utilization as automotive fuel in India. Energy & Fuels 21: 2415–2420.

Ratnavathi, C.V., K. Suresh, V. Kumar, M. Pallavi, V.V. Komala, and N. Seetharama. 2010. Study on genotypic variation for ethanol production from sweet sorghum juice. Biomass and Bioenergy 34: 947–952.

Reddy, B.V.S., S. Ramesh, P.S. Reddy, B. Ramaiah, P.M. Salimath, and P. Kachapur. 2005. Sweet sorghum–a potential alternate raw material for bio-ethanol and bio-energy. International Sorghum and Millets Newsletter 46: 79–86.

Sánchez, O.J., and C.A. Cardona. 2008. Trends in biotechnological production of fuel ethanol from different feedstocks. Bioresource Technology 99: 5270–5295.

Silva, F.A.S., and C.A.V. Azevedo. 2002. Versão do programa computacional Assistat para o sistema operacional Windows. Revista Brasileira de Produtos Agroindustriais 4: 71–78.

Silva-Filho, E.A., S.K.B. dos Santos, A.M. Resende, J.O.F. Morais, M.A. Morais Júnior, and D.A. Simões. 2005. Yeast population dynamics of industrial fuel-ethanol fermentation process assessed by PCR-Fingerprinting. Antonie van Leeuwenhock 88: 13–23.

Thomas, K.C., S.H. Hynes, and W.M. Ingledew. 1996. Practical and theoretical considerations in the production of high concentration of alcohol by fermentation. Process Biochemistry 31: 321–331.

Thomas, R.L., R.W. Shearrd, and J.R. Moyer. 1967. Comparison of conventional and automated procedures for N, P and K analysis of plant material using a single digestion. Agronomy Journal 59: 240–243.

Tsuchihashi, N., and Y. Goto. 2004. Cultivation of sweet sorghum (Sorghum bicolor (L.) Moench) and determination of its harvest timer to make use as the raw material for fermentation, practiced during rainy season in dry land of Indonesia. Plant Production Science 7: 442–448.

Vasconcelos, J.N. 1987. Influência da complementação de nutrientes nitrogenados e fosfatados sobre o processo de fermentação alcoólica industrial. Brasil Açúcareiro 105: 41–48.

Vasilakoglou, I., K. Dhima, N. Karagianiannidis, and T. Gatsis. 2011. Sweet sorghum productivity for biofuels under increased soil salinity and reduced irrigation. Field Crops Research 120: 38–46.

Walker, G.M. 2004. Metals in yeast fermentation process. Advances in Applied Microbiology 54: 197–229.

Walker, G.M. 2011. Fuel alcohol: current production and future challenges. Journal of the Institute of Brewing 117: 3–22.

Wu, X., S. Staggenborg, J.L. Prophter, and W.L. Rooney. 2010. Features of sweet sorghum juice and their performance in ethanol fermentation. Industrial Crops and Production 31: 164–170.

Zhao, Y.L., A. Dolat, Y. Steinberger, X. Wang, A. Osman, and G.H. Xie. 2009. Biomass yield and changes in chemical composition of sweet sorghum cultivars grown for biofuel. Field Crops Research 111: 55–64.

Acknowledgments

The authors acknowledge the financial support from CNPq (edital 46/2009, processo 551284/2010-2) and Facepe (edital 09/2010, processo APQ 07185-01/10). The Genetech company for the equipment used in the fermentation assays and the Japungú distillery (PB) for making industrial yeast biomass and the gas chromatograph available.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dutra, E.D., Neto, A.G.B., de Souza, R.B. et al. Ethanol Production from the Stem Juice of Different Sweet Sorghum Cultivars in the State of Pernambuco, Northeast of Brazil. Sugar Tech 15, 316–321 (2013). https://doi.org/10.1007/s12355-013-0240-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-013-0240-y