Abstract

In this work, we investigated the influence of dextranase enzyme on the molecular weight parameters of remaining dextran and intrinsic viscosity after different enzymatic treatments at different steps during sugar manufacturing. A spectrophotometric method was used to determine the relative activity of dextranase and the result has been confirmed by measured reducing sugar using HPLC system. For comparison, the action patterns of concentrated and diluted enzymes were additionally included in the experiments. Addition of dextranase to juice were much more efficient and economical to reduce the Mw of remaining dextran than adding it to evaporator syrups. Addition of dextranase at juice pH 5.5 showed similar minimum Mw with the lowest intrinsic viscosity, observed at 55.0 °C, and activities decreased after 20°Brix. The highest dextran removal was observed at dextranase concentration at 100 ppm/juice which was resulted in 80.29 % removal dextran in the juice, Moreover, the higher the level of concentrated dextranase applied to the juice, the more the removal of dextran occurred. In addition, the longer the availability of the residence time in the factory, the lower dextran Mw has been observed. To reach a satisfactory level of dextran hydrolysis, it was necessary to correct the dose of dextranase enzyme according to the losses of activity caused by the high °Brix.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

During the process of sugar production, dextrans are undesirable compounds produced by Leuconostoc mesenteroides which are able to utilize high percentages of the sugar present in juices in a short time period. Under favorable temperature and humidity conditions, the dextransucrase hydrolyses the sucrose, forming dextrans. These dextrans are extracted in the mills along with the juices and contaminate the sugar mill flow, reaching levels in the juice exceeding 10,000 ppm (1 %) in very extreme cases (Cuddihy and Porro 1998). In burnt sugar cane a rapid increase in the level of dextrans of almost ten times was observed from 12 to 48 h, reaching 3,200 ppm (Cuddihy 1999).

Dextrans are high molecular weight polysaccharides, formed of at least 50 %, by α-(1–6) linked glucose units, with α-(1–3) branch linkages and may contain other branch linkages such as α-(1–2) or α-(1–4) (Khalikova et al. 2005). The presence of dextran in the sugar factories leads to a false high polarization, increased viscosity, slowing of filtration, lower evaporation rates, elongated crystals (needle grain), longer wash and separation cycles in centrifuges and increase of sugar loss to molasses (Kim and Day 2004). The presence of dextrans during evaporation provokes an increase of scale deposits in the heating surface and hence a greater energy loss. The most damaging effects of elevated dextran concentrations in a technical sucrose solution are foreseen in the crystallization process. Dextrans slow down the crystallization rate or even inhibit crystallization (Abdel-Rahman et al. 2008). Recently, Eggleston et al. (2011) suggested that high Mw dextran may have contributed to the hard-to-boil phenomenon which occurs in some massecuite samples.

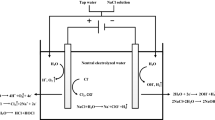

Dextranase (1,6-α-d-glucan-6-glucanohydrolase, EC3.2.1.11), is an enzyme, which catalyzes endohydrolysis of α-(1–6)-d-glycoside linkages in random sites of dextran (Khalikova et al. 2005). Dextranases are produced by various microorganisms, including bacteria (Kim et al. 2009), yeast (Millson and Evans 2007) and filamentous fungi (Khalikova et al. 2005). Fungal dextranase has attracted much attention due to higher enzyme activity and due to the synthesis of isomaltooligosaccharides (Thitaram et al. 2005). Furthermore, hydrolysis of dextran by microbial dextranase is of significant interest in drug formulation, vaccines, cosmetics, and other food industries (Khalikova et al. 2005). The application of dextranases in the sugar industry was pioneered in Australia in the 1970s (Inkerman 1980). In South Africa where diffusers are used, dextranase application in diffuser cane juices was deemed unsuitable mostly because of the high temperatures (Morel du Boil and Wienese 2002). DeStefano (1988) advocated the addition of dextranase in syrup storage tanks as the volumes of material to be treated were smaller and some clean-up had already been achieved via clarification. However, it was acknowledged that the pH and °Brix of the syrup are not optimized and relatively higher levels of dextranase would have to be added compared to juice concentrations.

In view of fact, the application of dextranase in sugar manufacture is still not optimized (Eggleston et al. 2009). This is partly because dextranases have a small market and low volume sales compared to other industrial enzymes such as α-amylase in food industries. Thus, they have not been subjected to much research and development by large enzyme companies and their properties have not been tailored to sugar industry conditions (Eggleston et al. 2009). Also because of the confusion prevailing about which dextranase to use, and how and where to add the dextranase. As a sequence, the research focus of our present work, is to optimize the addition and investigate the conditions of dextranase in cane sugar manufacturing by studying the effect of dextranase on the Mw-parameters of remaining dextran after different enzymatic treatments at different steps, in vogue in the sugar industry. The influence of the enzymatic treatments conditions on the dextranase activities and intrinsic viscosity of the pure dextran solution and juices during the process were also investigated.

Materials and Methods

Dextranase produce by Chaetomium erraticum, dextran from L. mesenteroides (Mw ~ 2,000 kDa (T2000)), and α-amylase were obtained from Sigma-Aldrich (Shanghai, China). Analytical grade sucrose was obtained from Sinopharm Chemical Reagent Co., (Shanghai, China). Sugarcane and fresh sugarcane juice, expressed from a hand mill, were obtained from the local market and stored in a −30 °C freezer, to be used in our experiment. All other chemicals and solvents used were of analytical grade.

Dextranase Activity

Two different methods were used for enzyme activity measurements. A spectrophotometric method measured reducing sugar from dextranase action on dextran (T2000) which reacts with 3,5 dinitrosalicyclic acid to give a yellow–brown color, which was measured at 540 nm. One dextranase unit (DU/ml) was the amount of enzyme that degrades dextran to produce reducing sugar equivalent to 1 mg isomaltose per hour at 40 °C and pH 5.4 (Anon 2002). To confirm this result, dextranase activities of the different enzyme treatments were determined by measured reducing sugar using the high-performance liquid chromatography (HPLC) system (Brown and Inkerman 1992), after dextran T2000 was hydrolysed by the dextranase for 30 min at 40 °C in a shaking (120 rpm) water-bath (DKZ, Shanghai Yi Heng Technology Co., Ltd., Shanghai, China). One dextranase unit (DU/ml) was the amount of enzyme that degrades dextran T2000 to produce reducing sugar equivalent to 1 mg isomaltose per hour at 40 °C and pH 5.4.

Determination of Mw-Parameters and Intrinsic Viscosity

To investigate the effects of the different enzymatic treatments on the Mw-parameters of dextran, the weight average molecular weight (Mw), the number average molecular weight (Mn), the z-average molecular weight (Mz), the molecular weight distribution (also known as polydispersity index (PDI)) and intrinsic viscosity (η), were investigated using the high-performance size exclusion chromatography (HP-SEC) system after dextran has been hydrolyzed by dextranase at different processing conditions. For remaining dextran in juice samples, the molecular weight parameters were measured after starch has been hydrolyzed using α-amylase at 55 °C for 15 min followed by proteins precipitation using trichloroacetic acid (TCA) solution (10 %). The mixture was then filtered through a 0.45 μm filters for three times and then subjected to analyse by HP-SEC systems.

HP-SEC–MALLS–RI–UV Measurements

The molecular weight parameters for all samples were determined by the analytical HP-SEC system consisting of a Waters 1525 binary pump (Waters, USA) equipped with columns consisted of an OHPAK SB-G guard column as protection and two OHPAK SB 804 and 806 HQ columns (8.0 mm × 300 mm; Shodex Showa Denko K.K., Tokyo, Japan) in series. The mobile phase was sodium phosphate buffer saline (8 mM dibasic sodium phosphate, 22 mM monobasic sodium phosphate, 150 mM sodium chloride in MilliQ-grade water). The mobile phase and the samples were filtered through a 0.45 μm filters and degassed before use. The injection volume was 100 μl. The flow rate was 1.0 ml/min. Chromatographic detectors included in series a UV detector (Water), a Dawn HELSOS MALLS detector, a ViscoStar differential viscometer, and an Optilab T-rEX interferometric refractive index detector (all from Wyatt Technology, California, USA). The refractive index increment (dn/dc) value was 0.141 in 0.2 M NaCl aqueous solution at λ = 633 nm (Nordmeier 1993). Astra software (version 5.3) was utilized for the data acquisition and analysis.

HPLC Measurements

The HPLC analysis of samples after dextran (T2000) was hydrolyzed by dextranase enzyme was carried out according to the method of Bashari et al. (2013). The chromatographic system consisted of a Waters 1525 binary pump and differential refractive index detector (RI-150, Japan). Thermo Aps-2 Hypersil column (250 mm × 4.6 mm ID; Waters, USA) was used for separation. The column thermostat was set at 35 °C. The mobile phase was acetonitrile: water (70:30). Sample injection volume was 20 μl and the flow rate was 1 ml/min. Standard calibration curve was constructed by plotting peak areas against concentrations of pure isomaltose standard. Throughout the experimental work, data was collected and integrated using LCsolution software (Shimadzu, Japan). The calibration curve was calculated by the least square method. Linearity was assessed by determining the coefficient of correlation (R2) of the points of the curve, which was higher than 0.998.

Determination of Dextran

Dextran concentration for all samples was determined according to ICUMSA GS1–15 (1994) and rapid haze (Clarke et al. 1987) methods with some modifications to improve the accuracy. Juice (5 ml) was pi-petted into a conical flask and 0.03 ml α-amylase was added at 55 °C for 15 min to degrade starch. TCA (10 %) solution (2 ml) was then added and left for 2 min. The mixture was filtered through 0.45 μm filter for three times and then 3 ml filtrate was added to 3 ml absolute ethanol, mixed and left for 2 min. The absorbance at 720 nm was immediately read in a 1-cm cell on a UV–1800 spectrophotometer (Shanghai Mapada Instruments Co., Ltd, China). Dextran (T2000) was used to prepare the standard and dextran was precipitated with 100 % absolute ethanol.

Effects of the Processing Condition on Dextranase Activity and Dextran Removal

Effect of pH-Values on Dextranase Activity

The activity of dextranase enzymes was measured at different pH values. Dextran as a substrate was prepared with different pH values using 50 mM sodium acetate (pH 3.5–5.8); 50 mM sodium phosphate pH 5.8–8. 3 ml concentrated and diluted enzymes prepare in the same pH value, were separately added to the dextran (6 ml) in a test-tube, covered with an aluminum foil, and thoroughly mixed. For the control, de-ionized water (3 ml) was added instead of dilute dextranase. The test-tubes were placed in a shaking water-bath (120 rpm) at 55 °C for 30 min. After incubation, the test-tubes were immediately placed in a boiling water-bath for 2.5 min, and cooled on ice. After cooling, the samples were analyzed, in duplicate, for haze dextran and diluted aliquots were also analyzed by HPLC and HP-SEC systems after filtrated through a 0.45 μm filters.

Effect of the Processing Temperature on Dextranase Activity and Mw-Parameters

Enzymatic Treatment of Pure Dextran Solution

2000 ppm dextran T2000 solution was prepared in pH 5.4 phosphate buffer. Concentrated and diluted enzyme (3 ml) were separately added to the dextran solution (6 ml) in a test-tube, covered with aluminum foil, and thoroughly mixed. For the control, de-ionized water (3 ml) was added instead of dilute dextranase. The test-tubes were placed in a shaking water-bath (120 rpm) at different temperatures ranging from 25 to 70 °C for 30 min. After incubation, the test-tubes were immediately placed in a boiling water-bath for 2.5 min to denature the enzyme, and cooled on ice. After cooling, the samples were analyzed, in duplicate, for haze dextran and diluted duplicate aliquots were also analyzed on HPLC and HP-SEC systems.

Enzymatic Treatment of Cane Juice

Mixed juice (12°Brix; pH 5.6) was prepared in our laboratory. A required level of Haze dextran (10,000 ppm Haze dextran/juice) was achieved by adding dextran (T2000) and sodium azide 0.002 % was also added to prevent further dextran formation reactions. The mixture was then stored in a −30 °C freezer until used. Concentrated and diluted enzymes (3 ml) were separately added to the cane juice (6 ml) in a test-tube, covered with aluminum foil, and thoroughly mixed. For control, de-ionized water (3 ml) was added instead of the enzyme. The test-tubes were placed in a shaking water-bath (90 rpm) at different temperatures ranging from 25 to 70 °C for 35 min. After incubation the test-tubes were immediately placed in a boiling water-bath for 2.5 min, and cooled on ice. After cooling, the samples were analyzed, in triplicate, for haze dextran and triplicate samples were diluted, then analyzed on HPLC and HP-SEC systems after filtration through a 0.45 μm filters.

Effect of the Residence Time and Enzyme Concentration on Dextranase Activity

25 ml concentrated and diluted dextranase (0, 25, 50, 75, and 100 ppm/juice) were added separately to 50 ml dextran solution (T2000, 10,000 ppm) and 50 ml cane juice (12.0°Brix; pH 5.6; 10,000 ppm Haze dextran/juice) and then mixed thoroughly and immediately placed in a shaking water-bath at 55 °C and 120 rpm. Aliquots (10 ml) were removed after timing intervals 0, 5, 10, 15, 20, 30, 35 and 40 min, and boiled immediately for 2.5 min and cooled on ice. After cooling the samples were analyzed, in duplicate, for haze dextran. Diluted aliquots were also analyzed by HPLC and HP-SEC systems after filtration through a 0.45 μm filters.

Effect of Brix on Reactivity of Dextranase

Sucrose solutions with concentrations of 0–75 % °Brix and dextran T2000 (10,000 ppm) were prepared in pH 5.4 acetate buffers according to method of Bashari et al. (2012). Concentrated and diluted enzymes (3 ml) was added to the dextran/sucrose solution (6 ml) in a test-tube, covered with aluminum foil, and thoroughly mixed. For the control, de-ionized water (3 ml) was added instead of enzyme. The test-tubes were placed in a shaking water-bath (120 rpm) at 55 °C for 35 min. After incubation the test-tubes were immediately placed in a boiling water bath for 2.5 min, and cooled on ice. Diluted aliquots were also analyzed by HPLC and HP-SEC systems after filtration through a 0.45 μm filters.

Statistical Analysis

All the experiments described above, were performed in triplicate for each sample. The data was subjected to an analysis of variance (ANOVA) and the significance of the difference between means was determined by Duncan’s multiple range test (P < 0.05) using SPSS 17 for Windows program (SPSS Inc., Chicago, USA).

Results and Discussion

Preparation of Dextranase Enzyme

From the economic point of view, it was considered that the dextranase enzyme is relatively expensive, therefore in this work, diluted enzyme was used after a five-fold dilution of concentrated enzyme to make it economically equivalent to the nearest non-concentrated dextranase and to decrease the cost of the enzymatic treatment. For comparison, the action patterns of concentrated and diluted enzyme were additionally included in the experiments.

Effects of pH Values on Dextranase Activity, Removal of Dextran and Mw Parameters

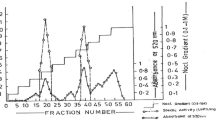

Figure 1A represented the HPLC chromatogram used to accurately the determination of the relative dextranase activities obtained after dextran (T2000) has been hydrolysed by the dextranase after different enzymatic treatments. Figure 2A shows the dextranase activities at different pH values. The maximum dextranase activity, for concentrated and diluted dextranase, was observed at initial pH of 5.5. The pH values of juices before clarification are often between pH 5.0 and 6.0. However, addition of lime in the clarification process increases the pH well above pH 6.0, indicating that dextranase should never be added to limed juice. Syrup pHs are often between pH 6.0 and 6.5, which are less optimal than natural juice pHs (Eggleston and Monge 2005). Therefore, according to our results, dextranase could be successfully applied in juice tank. The results also indicate that dextranase was also active between pH 5.0 and 5.5. Therefore, the pH activity profiles for the enzyme are almost consistent within this range of the optimum value. As also shown in Fig. 2A, dextranase activity was declined rapidly at pH rising above 6.0, indicate that dextranase should not be added to syrups. This result was further confirmed by study the pH effects on dextran removal as can be shown in Fig. 2B. Dextran removal for all samples was measured using the haze dextran method because of its ease of use and because it gives a reliable estimate of high Mw dextrans which are responsible for the major processing difficulties associated with this polysaccharide (Inkerman 1980). The result indicates that 90.7 % of dextran has been hydrolyzed by using the concentrated dextranase at pH 5.5, compared to 55.2 % using diluted enzyme. As the result the activity of diluted enzyme was still high across the temperature range studied which highlights the differential between relative economic price and activity.

(A) Representative HPLC chromatogram used to accurately determine of the relative dextranase activities obtained after dextran T2000 has been hydrolysed by the dextranase for 30 min at 55.0 °C. The first peak elutes at 4.620 min and corresponds to glucose, whereas the second peak elutes at 8.221 min and corresponds to isomaltose. (B) HP-SEC chromatogram obtained after dextran T2000 has been hydrolysed by dextranase enzyme at the same conditions; the second peak elutes at 30.0 min and corresponds to remaining dextrans

Studies on the effects of dextranase on the Mw-parameters of remaining dextran after different enzymatic treatments were undertaken using the HP-SEC–MALLS–RI–UV system as can be seen in Fig. 1B. The results of the kinetic study of the effect of pH values on the molecular weight parameters of remaining dextran and intrinsic viscosity of juice are summarized in Table 1. These results shown that, for concentrated and diluted dextranase, the minimum Mw of remaining dextran was obtained at pH 5.5. The results also indicate that the Mw of remaining dextran at pH values between 4.5 and 5.5 were lower than that observed at pH rising above 6.0, however the maximum Mw of remaining dextran was obtained at pH above 7.0 because of partial denaturation of the dextranase enzyme. In the context of the above discussion, dextranase could be successfully applied in juice tank before clarification to reach a satisfactory level of dextran hydrolysis and should not be added to syrups.

Effect of Processing Temperature

Effect of Processing Temperature on Dextranase Activity and Dextran Removal

The effects of processing temperature on dextranase enzymatic activity for pure dextran and dextran formed in juice are shown in Fig. 3. As a result, the maximum activity was observed at 55 °C. The lowest activity occurred at 65–70 °C, Dextranase activities were also low at 40–50 °C, but were still better than that were observed at 65 °C. This was in agreement with the result observed by Eggleston and Monge (2005). However, the enzyme is reported to become unstable above approximately 70 °C because of partial denaturation of the dextranase enzyme. Therefore, the activity of dextranase was tested between pH 25 and 70 °C.

Our results, therefore, indicate that dextranase should not be add to evaporators bodies, where have syrup temperatures above 65.5 °C, cause the activity has dropped off dramatically at this temperature as can be seen in (Fig. 3). This was in agreement with the results observed by DeStefano (1988) and Eggleston and Mong (2005). This result was also confirmed by study the temperature effects on dextran removal as can be shown in Fig. 3. The result indicates that 83 % of dextran has been removed from juice by using the concentrated dextranase at 55.0 °C, compared to 61.9 % using diluted enzyme. However, more than 94.7 % of dextran has been removed from the pure dextran solution by using the concentrated dextranase, compared to 70.3 % using diluted enzyme at the same processing temperature. This difference in the observations of the remove of dextran may due to the effect of Brix as will be discussed in greater detail later in this study. Inkerman and James (1976) reported that, from the economic point of view it was considered sufficient to hydrolyze two-thirds of the dextrans present in the process and it was argued that this was able to provide a formidable economic improvement in sugar production.

Effect of Processing Temperature on the Mw Parameters of Remaining Dextran

The results of the study on the effect of processing temperatures on the molecular weight parameters of remaining dextran are shown in Table 2. The minimum Mw of remaining dextran, 0.591 ± 0.04 × 106 and 0.951 ± 0.02 × 106 (g/mol), for concentrated and diluted dextranase respectively, were observed at 55 °C. The higher Mw were observed at 65.5 °C, however, both the concentrated and diluted dextranase were also active at 40–54 °C indicating by low Mw observed, which were still lower than at 65 °C. This result has, therefore, confirmed that the applications of dextranase to juice were much more efficient and economical than adding them to evaporator syrups. Furthermore, Inkerman (1980) reported that Leuconostoc and Lactobacillus growth does not occur readily at or above a temperature of 50 °C, therefore, the possible problem of simultaneous dextran formation and breakdown is expected to be limited. Our results also indicate that, application of concentrated dextranase was more efficient than application of the diluted one. This was in agreement with the results observed by DeStefano (1988) and Eggleston and Monge (2005).

The effects patterns of dextranase enzyme on the intrinsic viscosity at different processing temperatures are summarized in Table 2. As can be seen in Table 2 the lowest intrinsic viscosity has been observed at 55 °C. It could also observe that, the intrinsic viscosities at 40–50 °C were lower than at 65 °C. In our previous work using laboratory trials performed by adding standard dextrans to pure sucrose solutions (Bashari et al. 2012), we have demonstrated that, both the apparent viscosity and dynamic modulus increased with an increase in dextran concentrations and they demonstrated strong dependence on its Mw. Conversely, it can be expected that the use of dextranase will reduce the contribution from dextran concentrations and Mw, resulting in decreased viscosity and, presumably, better boiling house recoveries. However, several byproducts are associated with the formation of dextran. These include acetic acid, lactic acid, ethanol, mannitol and carbon dioxide as well as several oligosaccharides (Morel du Boil and Wienese 2002). Many of these products are melassegenic and will also contribute to decreased exhaustion. Their influences will be unaffected by the dextranase treatment.

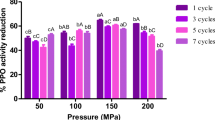

Dextranase Concentration and Residence Time Effects on Juice Enzymatic Treatments

The effects of various concentrations of dextranase on the syrup containing dextran (1,000 ppm/juice) at 55 °C are shown in Fig. 4. The result shown that at 25 ppm/juice concentrated of dextranase had a little effect on dextran degradation, with only 9.11 % being removed after 15 min. Some improvements occurred at 50 ppm/juice (Fig. 4A) with 25.7 % dextran removal after 20 min. However 75 and 100 ppm/juice has significant effects on dextran degradation which were resulted in 54.3 and 80.29 % dextran removal, respectively. Compared to the concentrated dextranase, the diluted dextranase (Fig. 4B) performed markedly a much lower effect patterns at the same condition. At 25 ppm/juice, diluted dextranase was able to remove only 4.7 % of dextran after 15 min. No significant increase has been observed at all other studied concentration, except at 100 ppm/juices rising above 30 min, shown that, only 26.3 % dextran has removed.

The results of the kinetic study on dextran Mw showed that the minimum Mw of remaining dextran (0.324 ± 0.02 × 106 g/mol) was obtained within 40 min of the reaction (Table 3). The Mw of the dextran decreased with longer reaction time, which is similar to the trend observed by Kim et al. (1996). The Mw decreased more rapidly from 5 to 25 min than from 25 to 40 min because dextranase showed a higher hydrolytic affinity toward higher molecular weight dextrans were enriched. However, the effect patterns of applying concentrated dextranase to reduce the dextrans Mw in the juice under the same conditions was much better than for the diluted dextranase, therefore, controlling the remaining dextran is possible and dextrans of lower Mw values can be obtained by adjusting the reaction time.

Based on the results presented in Table 4, the increases in dextranase concentration decreased Mw of remaining dextran, indicating that the Mw of dextran decreased more rapidly at high dextranase concentrations. The concentration of dextranase had a significant effect on the molecular weight of remaining dextrans. Low concentrations of dextranase could also hydrolysed dextrans to low Mw dextrans when the reaction time is increased. Results, therefore showed that, the higher the level of concentrated dextranase applied the more dextran removal occurred. This indicates that the juices viscosity of the juices can by controlled by the MW of remaining dextrans which could be controlled by the dextranase concentration according to resident times that could be available during the process.

The effects of the concentrated (and diluted) dextranase on the intrinsic viscosity reduction of the juice at different residence times are illustrated in Table 4. At 0 ppm dextranase, the viscosity increased slightly across min residence time, most likely because of evaporation. No significant effect on viscosity was found at 25 ppm/juice. It was only at 75 and 100 ppm/juice addition of the diluted dextranase, that viscosity reductions were found. In compare, the significant effect of diluted dextranase on the intrinsic viscosity of the juice has been found just at 100 ppm/juice. Similar small viscosity reductions of syrup in the presence of dextranase were found by Eggleston and Monge (2005).

°Brix Effects on Dextranase Activity and Remaining Dextran

Figure 5 shows the effect of °Brix on dextranase activities and removal dextran. The activity of the dextranase was stable up to 20°Brix, and then decreased dramatically with an increase of the sugar contents. Furthermore, as can be also shown in Fig. 5 the percentages of remaining dextran after the enzymatic treatments was also stable up to 20°Brix, but afterwards increased dramatically conformed that an increase in °Brix reduced the hydrolysis rate of the dextran. Similar faster reaction with dextranase from Chaetomium sp. has been reported previously (Brown and Inkerman 1992; Morel Du Boil and Wienese 2002). As per our expectations, it could be inferred that two factors were responsible for the above-observed behavior: firstly, as the °Brix increases, the water activity decreases, which is the second substrate in the hydrolysis of dextran by dextranase. Secondly, due to an increase on impurities concentration which inhibits dextranase and reduced the hydrolysis rate. As can be seen in Fig. 5 100 ppm of concentrated dextranase has hydrolyzed 84.3 % of the 10,000 ppm of dextrans in the presence of 0–20 % sucrose, in contrast 33 % has been hydrolysed in the presence of 70 % sucrose at the same condition. However, application of diluted enzymes lad to hydrolysed 52 and 6 % of dextran in the presence of 0–20 and 70 % sucrose respectively at the same conditions.

As a result, the applications of dextranase to juice were much more economical than adding them to evaporator syrups, and massecuites where the °Brix is often 80 %. Furthermore, when the dextranase is applied later in the process, the previous stages have already had perturbations generated by the elevated viscosity and the earlier the viscosity is reduced in the process, the larger the amount of sugar that will be recovered and thus less economic losses will be generated. To reach a satisfactory level of dextran hydrolysis, it was necessary to correct the dose of dextranase enzyme according to the losses of activity caused by the high °Brix (Fig. 5). Results, therefore, confirmed the notes reported by Anon (1996) that, the higher dosages used at the higher Brix and higher temperatures were based on the supplier’s recommendations. In addition, these results also provided that, the application of concentrated dextranase was more efficient than diluted dextranase, therefore in very extreme cases, when the dextranase enzyme must apply to syrups, evaporator bodies or massecuites, it must be at higher concentration which highlights the relative economic prices.

Conclusions

In our current research work, the influence of dextranase enzyme on the molecular weight parameters of remaining dextran and intrinsic viscosity measured by HP-SEC–MALLS–UV–RI system after different enzymatic treatments at different steps during sugar manufacturing has been investigated. A spectrophotometric method was used to determine the relative activity of dextranase and the result has been confirmed by measured reducing sugar using HPLC system. For comparison, the action patterns of concentrated and non concentrated enzymes were additionally included in the experiments. Applications of dextranase to juice were much more efficient and economical to reduce the Mw of remaining dextran than adding them to evaporator syrups. Applied of dextranase at juice pH 5.5 showed similar minimum Mw with the lowest intrinsic viscosity has been observed at 55.0 °C, however, the results also indicate that dextranase was also relatively active between pH 5.0 and 5.5 and at 40–50 °C, furthermore, activities decreased after 20°Brix. The higher the level of concentrated dextranase applied to the juice, the more dextran removal occurred. It was also observed that, the longer the availability of the residence time in the factory, the more dextran hydrolysis occurred. To reach a satisfactory level of dextran hydrolysis, it was necessary to correct the dose of dextranase enzyme according to the losses of activity caused by the higher °Brix.

References

Abdel-Rahman, E.A., Q. Smejkal, R. Schick, S. El-Syiad, and T. Kurz. 2008. Influence of dextran concentrations and molecular fractions on the rate of sucrose crystallization in pure sucrose solution. Journal of Food Engineering 84: 501–508.

Anon. 1996. Data sheet for Dextranex L-4000, Genencor.

Anon. 2002. Determination of dextranase using spectrophotometry. Novo-zymes EB-SM-0120-02/01.

Bashari, M., M. Nikoo, Z. Jin, Y. Bai, X. Xu, and N. Yang. 2012. Thermal and rheological properties of the supersaturated sucrose solution in the presence of different molecular weight fractions and concentrations of dextran. European Food Research and Technology 234(4): 639–648.

Bashari, M., A. Eibaid, J. Wang, Y. Tian, X. Xu, and Z. Jin. 2013. Influence of low ultrasound intensity on the degradation of dextran catalyzed by dextranase. Ultrasonics Sonochemistry 20: 155–161.

Brown, C.F., and P.A. Inkerman. 1992. Specific method for quantitative measurement of the total dextran content of raw sugar. Journal of Agriculture and Food Chemistry 40: 227–233.

Clarke, M.A., J. Bergeron, and F. Cole. 1987. A rapid dextran screening test. Sugar y Azucar 82(3): 23–24.

Cuddihy J.A., and D.F. Day. 1999. The process and financial impact of dextran on sugar factory. http://www.midlandresearchlabsinc.com. Accessed 13 May 2011.

Cuddihy J.A., J.S. Rauh, and M.E. Porro. 1998. Improving sugar recovery with sugar process chemicals. http://www.midlandresearchlabsinc.com. Accessed 13 May 2011.

DeStefano, R.P. 1988. Potential uses and associated benefits of dextranase enzyme in the raw sugar mill. Journal American Society of Sugar Cane Technologists 8: 99–104.

Eggleston, G., G. Côté, and C. Santee. 2011. New insights on the hard-to-boil massecuite phenomenon in raw sugar manufacture. Food Chemistry 126: 21–30.

Eggleston, G., and A. Monge. 2005. Optimization of sugarcane factory application of commercial dextranases. Process Biochemistry 40: 1881–1894.

Eggleston, G., A. Monge, B. Montes, and D. Stewart. 2009. Application of dextranases in sugarcane factory: Overcoming practical problems. Sugar Tech 11(2): 135–141.

Inkerman, P.A. 1980. An appraisal of the use of dextranase. Proceedings International Society of Sugar Cane Technologists 17: 2411–2427.

Inkerman P.A., and G.P. James. 1976. Dextranase II, practical application of the enzyme to sugar mills. Proceedings Queensland Society Sugar Cane Technologists, 43rd Conf, Watson Ferguson and Co, Brisbane, Queensland, Australia p 307–15.

Khalikova, E., P. Susi, and T. Korpela. 2005. Microbial dextran-hydrolyzing enzymes: Fundamentals and applications. Microbiology and Molecular Biology Reviews 69(2): 306–324.

Kim, D., and D.F. Day. 2004. Determination of dextran in raw sugar process streams. Food Science and Biotechnology 13: 248–252.

Kim, D., H.C. Seo, and D.F. Day. 1996. Dextran production by Leuconostoc mesenteroides in the presence of a dextranase producing yeast, Lipomyces starkeyi. Biotechnology Techniques 10: 227–232.

Kim, Y., E. Ko, H. Kang, and D. Kim. 2009. Construction, expression and characterization of fusion enzyme from Arthrobacter oxydans dextranase and Klebsiella pneumoniae amylase. Biotechnology Letters 31: 1019–1024.

Millson, S.H., and I.H. Evans. 2007. Multiple dextranases from the yeast Lipomyces starkeyi. Antonie van Leeuwenhoek 92: 399–404.

Morel du Boil, P.G., and S. Wienese. 2002. Enzymic reduction of dextran in process-laboratory evaluation of dextranases. Proceedings of South African Sugar Technologist Association 76: 435–443.

Nordmeier, E. 1993. Static and dynamic light-scattering solution behavior of pullulan and dextran in comparison. Journal of Physical Chemistry 97: 5110–5185.

Thitaram, S.N., C.H. Chung, D.F. Day, A. Hinton, J.S. Bailey, and G.R. Siragusa. 2005. Isomaltooligosaccharide increases cecal Bifidobacterium population in young broiler chickens 1. Poultry Science 84(7): 998–1003.

Acknowledgments

This study was financially supported by the Fundamental Research Funds for the Central Universities (No. JUSRP11225), Project of the State Key Laboratory of Food Science and Technology, Jiangnan University (No. SKLF-ZZB-201206), and the National Key Technology R&D Program for the 12th Five-Year Plan (Nos. 2012BAD37B01, 2012BAD37B02 and 2012BAD37B06).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bashari, M., Tounkara, F., Abdelhai, M.H. et al. Impact of Dextranase on Sugar Manufacturing and its Kinetic on the Molecular Weights of Remaining Dextran. Sugar Tech 15, 84–93 (2013). https://doi.org/10.1007/s12355-012-0195-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-012-0195-4