Abstract

Labor and equipment costs are the main expenses in potato micropropagation. To determine if we could reduce costs associated with media sterilization, a disinfectant, sodium hypochlorite (NaOCl), in combination with microwave heating, were assayed as media sterilants. Incorporating a common 5 % NaOCl household beach at a concentration of 9 ppm (active chlorine) in media sterilized with an autoclave or microwave oven controlled microorganism growth and maintained plantlet growth performance. Non-sterile 473 ml (16 oz.) clear deli containers were selected as an inexpensive replacement for traditional culture vessels and were effectively sterilized with a 50 ppm (active chlorine) NaOCl solution. Reuse of the non-sterile clear deli containers and alternate media water sources were also tested but this decreased plantlet growth performance. Comparison of a controlled growth chamber and ambient laboratory conditions was also investigated. Microorganism growth was significantly less in a controlled growth chamber (5 %) as compared to uncontrolled conditions (26–36 %).

Resumen

Los costos de mano de obra y de equipo son los principales gastos en la micropropagación de papa. Con el fin de determinar si podríamos reducir los costos asociados con la esterilización del medio, se probó un desinfestante, hipoclorito de sodio (NaOCl), en combinación con calentamiento en el horno de microondas, como esterilizantes del medio. La incorporación de blanqueador doméstico de NaOCl común al 5 % a una concentración de 9 ppm (cloro activo), en medio esterilizado en una autoclave o en horno de microondas, controló el crecimiento de microorganismos y mantuvo el comportamiento del crecimiento de la plántula. Se seleccionaron recipientes transparentes no estériles de alimentos de 473 ml (16 oz.), como un reemplazo económico a los recipientes de cultivo tradicionales y se esterilizaron efectivamente con 50 ppm (cloro activo) de una solución de NaOCl. También se probó el re-uso de los recipientes transparentes no estériles y de fuentes alternativas de agua para el medio, pero esto disminuyó el buen comportamiento del crecimiento de la plántula. También se investigó la comparación de una cámara de crecimiento controlada con las condiciones ambientales de laboratorio. El crecimiento de los microorganismos fue significativamente menor en la cámara de crecimiento controlado (5 %) al compararlo con las condiciones no controladas (26–36 %).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Potato, Solanum tuberosum L., is an important vegetable crop throughout the world. In some countries, micropropagation (tissue culture) is used to maintain and increase potato supplies. The advantages of micropropagation include swift production of high quality, disease free plants. Additionally, micropropagation allows potato plant production year-round, regardless of the climate (Ahloowalia and Prakash 2002). Over the past decades, this technology has helped to reduce or eliminate potato diseases and allowed for rapid introduction of improved cultivars in the regions where it is used (Frost et al. 2013).

Although micropropagation has proven benefits, developing the infrastructure to maintain and produce plants via micropropagation is expensive compared to field production of potato and it is only cost effective if large volumes are produced (Guenthner et al. 2014). To produce plants, commonly known as plantlets, in micropropagation, sterile techniques, including the use of sterile growth media and propagation vessels, is required to eliminate microbial contamination. Microbial growth in plantlet growth medium may kill or stunt the plantlets, reducing propagation efficiency and pathogenic microbes in plantlets can initiate greenhouse or field epidemics if these plantlets are used for further production.

The common problems we have encountered when training people interested in potato micropropagation is the lack of media sterilization equipment in their production laboratories, the expense of the sterile culture vessels used to grow the plants and lack of ability to control microbial contamination within laboratories. Autoclaving is generally the recommended method of sterilization for culture vessels and media in micropropagation. Media may be sterilized by filtration through a 0.2-μm sterile filter, although this is not suitable or economical for large volumes (Tisserat et al. 1992). Microwave ovens may also be used to sterilize media (Tisserat et al. 1992; Youssef and Amin 2001), although not all have had success with this method (Teixeira et al. 2005). This may be due to differences in microwave ovens, culture vessels used, volume of media, or heating time. UV radiation, which is commonly utilized in hydroponic systems, has also been considered as a media sterilizing method for micropropagation, but it appears to have limited efficacy (Peters 2005).

Various types of culture vessels can be used for potato micropropagation, but if autoclaves or pressure cookers are used to sanitize the vessels, they must be made of heat-resistant material. If a suitable sterilant is identified, heat-sensitive vessel types could be used. These vessels would still need to have complete containment, be constructed of light transmitting material and allow for gas exchange. Gas exchange is needed to decrease the accumulation of ethylene and CO2 in the headspace of culture vessels and to decrease relative humidity, both of which are correlated with severe hyperhydricity (Park et al. 2004; Lai et al. 2005).

Controlling contamination by bacteria, fungi or yeast is a challenge throughout the many steps associated with potato micropropagation. To combat this issue, several studies have examined the use of antibiotic and fungicidal treatments but worry microorganisms will become less sensitive or build resistance to these treatments with continual exposure (Rihan et al. 2012). Plant preservative mixture (PPM), which is a combination of two-broad-spectrum industrial isothiazolone biocides called methylisothiazolone (MIT) and chloromethylisothiazolone (CMIT) may reduce the formation of resistant or less sensitive microorganisms (Rihan et al. 2012; Luna et al. 2013). However, knowledge is limited if using PPM continually in potato micropropagation will lead to increased phytotoxicity or affect plant growth performance (Compton and Koch 2001; Rihan et al. 2012; Luna et al. 2013). Several studies have presented PPM sensitivity across different plant species (George and Tripepi 2001; Paul et al. 2001; Rowntree 2006; Luna et al. 2008). Additionally, PPM can be difficult to obtain in developing countries due to limited availability and expense associated with obtaining it.

Sodium hypochlorite (NaOCl) is frequently used as a disinfectant and can be used to sterilize culture vessels and media used for micropropagation (Sawant and Tawar 2011). Sodium hypochlorite has been used as a media sterilant for sugarcane (Sawant and Tawar 2011), ornamental plants (Yanagawa et al. 2007), orchids (Yanagawa et al. 1995), banana (Matsumoto et al. 2009), and asparagus (Kohmura et al. 1999). It has also been used to sterilize banana propagation vessels (Matsumoto et al. 2009). The International Potato Center (Lizarraga et al. 1986) has also successfully used a 0.5 % NaOCl solution to disinfect potato stem segments for 15 min before extraction of axillary buds. However, no research has been published utilizing NaOCl as part of the regular production system in potato micropropagation. If this could be achieved an additional layer of protection again the introduction of microbial contamination could be implemented in less than ideal laboratory environments.

Our goal was to develop low cost potato micropropagation methods that allow for less specialized and expensive equipment, but still maintain quality plantlet growth performance, genetic uniformity and low levels of microbial growth. We compared culture vessels and the effectiveness of NaOCl incorporated into plantlet growth media at varying rates. After selection of a suitable chlorine sterilizer rate, a comparison of media sterilizing methods was investigated as this would allow for an even greater reduction in micropropagation costs. We compared ambient laboratory conditions with a controlled growth chamber to see if growth chambers provide plant growth benefits. Finally, we compared tap and deionized water in the plantlet growth media to determine if the water source affected plantlet growth or microbial contamination.

Methods

Examination of NaOCl Rates and Culture Vessels Types

Unless indicated, an amended Murashige and Skoog (1962) propagation medium (Haberlach et al. 1985) was used for all experiments. NaOCl was incorporated into media in the range of 2 to 90 ppm (active chlorine concentration), which corresponds to the following rates: 0.04, 0.12, 0.20, 0.28, 0.36, 0.50, 0.75, 1, 1.50 and 2.00 ml/L of common 5 % NaOCl household bleach. These rates were selected to establish an effective rate for future experiments. The pH of the media was adjusted to 5.85 with 1 N KOH or HCl before sterilization. Media were sterilized using an autoclave set to 121 °C for 30 min and allowed to cool to 50 °C. NaOCl was incorporated into the sterilize media in a sterile laminar air flow hood. Media were dispensed into two types of culture vessels. Non-sterile 473 ml (16 oz.) polypropylene clear deli container (Placon, RD 16C/RDTFL) and sterile 114 × 86 × 102 mm polyethylene terephthalate (PETG) culture vessels (Sigma, Phytatray II P5929) were selected for this experiment based on a preliminary study where six culture vessels were examined. Culture vessels were selected based on plantlet shoot height (cm), percent rooted and visual assessment of optimal growth characteristics. Non-sterile clear deli containers were sterilized by immersing lids and bottoms in a 50 ppm NaOCl solution for 15 min then drying in a sterile laminar air flow hood. Solution was made by adding 1 ml of 5 % common NaOCl household bleach to 1 L dionized water. In a sterile laminar air flow hood, seventy-five ml of media was dispensed into the PETG vessels and dried sterile clear deli containers.

Potato cultivars ‘Atlantic’, ‘Silverton’ and ‘Pike’ obtained from the Wisconsin Seed Potato Certification Tissue Culture Laboratory (WSPCTCL) were selected for this experiment. Nine single node cuttings were evenly spaced in a culture vessel. A 0 μl/L NaOCl treatment was included across culture vessels and cultivars as a control. Observations were taken 7, 14 and 21 days after transfer (DAT). Plant growth abnormalities (stunting, discoloration, curling and cupping), shoot height (cm), percent rooted and microorganism growth were recorded. Culture vessels were kept in a controlled growth chamber for the duration of the experiment with a 16-h photoperiod under cool white fluorescent lamps providing an average photosynthetically active radiation (PAR) of 280–300 μmol m−2 s−1. A constant temperature of 19 °C and a relative humidity of 25 % were maintained.

An analysis of variance (ANOVA) was performed using PROC MIXED in SAS (version 9.3; SAS Institute Inc., Cary, NC) on cultivar mean shoot height and percent rooted values. Models were fit for data across all ratings and separately for each rating. In the combined rating model NaOCl rate, cultivar, culture vessel and rating were considered fixed effects, while replication and NaOCl rate-cultivar-culture vessel nested in culture vessel were considered random effects. Models fit to individual ratings contained NaOCl rate, cultivar and culture vessel as fixed effects and replication and culture vessel as random effects.

Alterations to MS Propagation Media and Reusing Clear Deli Containers

To further reduce costs in medium preparation, we compared tap and dionized water and attempted to re-use the non-sterilize clear deli containers for a second round of propagation. A 2.5 cm2 section was cut into all clear deli container lids before sterilization by immersing lids and bottoms in the 50 ppm NaOCl solution for 15 min as completed previously to allow for gas exchange since hyperhydricity was observed in initial experiments. A piece of 3 M Micropore tape (19027761, Thermo Fisher Scientific) was applied to the cut section of the lids to exclude microbes (Bhalla and Sweeney 1998; Kancherla and Bhalla 2001). The tap water used had a 3 ppm active chlorine concentration. Media were sterilized in 1 L batches by boiling for five min in a 1200 W GE Profile Series Microwave (model JES2251SJ02, General Electric Company) set to 100 % power. The inside dimensions of the microwave were 43 × 29 × 48 cm. The media were then cooled to 50 °C, 9 ppm NaOCl (0.20 ml/L of common 5 % NaOCl household bleach) was added as previously determined, and the media were dispensed into clear deli container. Potato cultivars ‘Colorado Norkotah 8’, ‘Silverton’, ‘Mega Chip’, ‘Atlantic’, ‘Pike’ and ‘Red LaSoda 10’ obtained from the WSPCTCL were used. Nine single node cuttings were evenly placed into each clear deli container. Medium prepared with double distilled water was included as a control across clear deli containers and cultivars.

The clear deli containers were placed in a research lab bench near a window and the plantlets were assessed at 7, 14, 21, 28 and 35 DAT. Plant growth abnormities (stunting, discoloration, curling and cupping), shoot height (cm), percent rooted and microorganism growth were recorded. Upon completion of this experiment, clear deli containers were emptied, washed with soapy water, rinsed and stored at room temperature. The clear deli containers were re-sterilized by immersing lids and bottoms in a 50 ppm NaOCl solution (1 ml/L common 5 % household bleach) for 15 min and all steps were repeated as described above. Two replicates of this experiment were performed.

An analysis of variance (ANOVA) was performed using PROC MIXED in SAS (version 9.3; SAS Institute Inc., Cary, NC) on cultivar mean shoot height and percent rooted values. Models were fit for data across all ratings and separately for each rating. In the combined rating model, culture vessel, cultivar, water and rating were considered fixed effects. Models fit to individual ratings contained culture vessel, cultivar and water as fixed effects. Replication was included as a random effect across all models. Culture vessel-cultivar-water nested within culture vessel effect was included for the combined rating model.

For all experiments, Tukey multiple comparison correction was used to compare cultivar mean shoot height and percent rooted values across all models. Equal variance and normality assumptions were checked and found to be met for all PROC MIXED analyses. For all statistical tests, significance was inferred at P = 0.05. Estimated F-values obtained from the PROC MIXED and GLM outputs were found to be consistent to the third decimal point. All graphs were made in Microsoft Excel (2007).

Results

NaOCl can be Used to Effectively Sanitize Clear Deli Containers for Potato Micropropagation

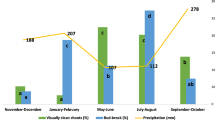

There was no significant difference in mean plantlet height between non-sterilize clear deli containers and sterile PETG vessels in combined and individual rating analyses (Figs. 1 and 2; Table SI). At 7 DAT, significantly more plantlets were rooted in the clear deli containers (12.7 %) than in the PETG vessels (7.7 %) (p = 0.014) (Fig. 1). No significant differences were found for the mean percent of rooted plantlets in the combined analysis and at 14 and 21 DAT.

Comparison of cultivar ‘Pike’ plantlets at 14 DAT (days after transfer) in a clear deli container (a) and a sterile PETG vessel (b) grown in a controlled growth chamber; and plantlets grown 14 DAT in a natural light environment (c). MS propagation media is amended with 9 ppm NaOCl. An example of NaOCl toxicity (d) with plantlets grown in MS propagation media amended with 90 ppm NaOCl is provided. Symptoms include reduced plantlet height, bleaching of lower leaves, and nodal cuttings

Microbial growth was observed in 2 % of the clear deli containers and 3 % of the PETG vessels. The incidence of microbial growth was low, even in containers where the growth medium contained no NaOCl. Therefore, the clear deli containers, which were sanitized with 50 ppm NaOCl for 15 min., had microbial contamination levels similar to sterile PETG vessels.

A 9 ppm NaOCl Level in Growth Media was the Highest Rate That did not Cause Plant Abnormalities

Rating events were examined separately due to highly significant rating, rating-cultivar interaction and NaOCl rate-rating interaction effects in the combined model. NaOCl rate and cultivar effects were significant across all ratings for mean shoot height and percent rooted plantlet values, except at 21 DAT where a NaOCl effect was not deemed significant for mean percent rooted plantlet values (p = 0.059). Cultivar ‘Silverton’ was more susceptible to bleach toxicity than the other varieties, which explained the significant effect of cultivar (Table SI). Based on these findings, we selected 9 ppm (active chlorine) NaOCl for further experiments. Higher NaOCl rates resulted in a higher incidence of plantlet abnormities (stunting, discoloration, curling and cupping), indicating NaOCl toxicity (Fig. 2).

Plantlet Growth Performance was Better in new Than in Reused Clear Deli Containers and in Media With Double Deionized Water Compared to Tap Water

Significant differences among mean shoot height and percent rooting values were revealed in the combined model, resulting in the five rating events being examined separately (Table 1). The mean shoot height and percent rooted values in new clear deli containers were similar or greater than for reused containers across most cultivars (Fig. 3). A larger range of values for percent rooted plantlets in reused containers was observed compared to new containers across cultivars. For example, at 21 DAT, 31 to 79 % of plantlets in reused containers were rooted, while 57 to 90 % were rooted in new containers. The mean shoot heights for medium made with double deionized water were greater than in medium made with tap water (Fig. 4). Mean shoot heights were also more consistent across cultivars when grown in medium made with double deionized water.

Plantlet Growth Performance was Better in a Controlled Growth Chamber Than Under Ambient Laboratory Conditions

The WSPCPTC maintains a laboratory with a filtered air system and high quality controlled growth chambers to produce plantlets. To determine if the lower cost micropropagation system with clear deli containers and bleach sterilization could be combined with using ambient laboratory conditions to growth plantlets, we grew plantlets on a research laboratory bench near a window. Visual assessment of plantlets in both environments was similar, but growth differences were observed (Fig. 2). Plantlets in the laboratory were slightly etiolated, lighter green, and had smaller leaves. Microbial contamination was also significantly higher in the laboratory than in the controlled environment (Table 2).

Discussion

The majority of cost associated with potato micropropagation and subsequent minituber production is in labor (Guenthner et al. 2014). However, some expensive pieces of equipment that require routine maintenance are needed for large scale propagation, such as autoclaves or pressure cookers for media preparation. We determined whether inexpensive vessels and low-cost sanitation with readily available equipment or chemicals could be reliably used for low-cost potato micropropagation.

Non-sterile clear deli containers were selected as a low cost alternative to traditional culture vessels. An individual container cost approximately $0.10 to 0.18, whereas a PETG vessel is approximately $1.19. The clear deli containers were sanitized with 50 ppm (1 ml/L) NaOCl solution for 15 min prior to use and only 2 % of the resulting vessels exhibited microbial growth, which was comparable to the 3 % contamination rate with PETG vessels, which are purchased sterile. Therefore, this initial experiment demonstrates that inexpensive clear deli containers can be effectively used for potato micropropagation with autoclave-sterilized media.

Our long term goal is to determine if we could eliminate the requirement for an autoclave entirely. Therefore, in our initial experiment, we tested varying levels of NaOCl to determine if this sterilant could be added directly to growth media and to determine the NaOCl level potato plantlets can tolerate. There are differences in NaOCl tolerance among cultivars, with cultivar ‘Silverton’, a Russet being the most sensitive of those tested. Based on the results, we chose 9 ppm NaOCl for our subsequent experiments; as it was the highest level that was not phytotoxic. This level is consistent with previous findings in other micropropagation systems. Kohmura et al. (1999) found that 5–10 ppm of NaOCl was optimal in asparagus micropropagation and levels of 50 ppm or greater suppressed plant growth. Some plants can tolerate higher levels. For example, Yanagawa et al. (2007) found that 50 ppm of chlorine disinfectant (NaOCl or Ca(ClO)2) was optimal for micropropagation of chrysanthemum and carnation, and that 100 ppm or higher was phytotoxic.

In our second experiment, we sanitized clear deli containers with bleach and used media boiled in a microwave; later treated with 9 ppm NaOCl and dispensed into the clear deli containers. As before, the plants grew well and none of the 16 containers placed in a controlled environment showed contamination. Previous research shows conflicting results on whether microwave ovens effectively sterilize media (Tisserat et al. 1992; Youssef and Amin 2001; Teixeira et al. 2005). This variation could be due to contamination levels in the media components, in the water used to prepare the media, or in the environment used to propagate the plants. In our case, this protocol is reliable enough that we have routinely implemented microwave sterilization, 9 ppm NaOCl rate, culture vessel sterilization with 50 ppm NaOCl when clear deli containers are used for plant propagation.

Upon examination of the plantlets grown in ambient laboratory conditions, we had a high rate of contamination overall, with 26 % of the culture vessels showing microbial contamination. Despite this, we observed a slightly improved plant growth in the new containers compared to the reused, perhaps either because the reused containers had become less transparent as they were exposed to light or because of microbial contamination that was not visible macroscopically. Because of the high contamination rates, we focused our attention on the micropore tape used to cover the ventilation holes in the vessel lids and learned that the pores in this tape are large enough to allow fungal and bacterial cells to cross. Therefore, it is likely that this high level of contamination in vessels grown in ambient lab conditions is due to the high level of activity in this research laboratory, which includes analysis of soil and field-grown plant samples.

Ventilation is required for optimal plant health and without it; hyperhydricity occurs (Jackson 2003; Park et al. 2004; Lai et al. 2005; Zobayed 2006). We have routinely used 3 M Micropore tape to cover ventilation holes in culture vessels in the WSPCPTC for at least the past 15 years. A recent article indicated that three-six holes measuring up to 10 μm in size can be found in a 100 μm square surface of 3 M Micropore tape and may allow for the introduction of microorganisms (Sale 2012). Sale recommended layering the 3 M Micropore tape to reduce introduction of microorganisms into a culture vessel and our current experiments are focused, in part, on reducing contamination by trialing different ventilation hole covers.

Upon completion of this paper, one area of interest to focus on in future experiments would be to incorporate NaOCl into media before sterilization. NaOCl was added after media sterilization to avoid break-down due to high heat exposure but manipulation of the NaOCl rate may lead to similar results when adding prior to sterilization. In addition, it would be beneficial to expand our research efforts on improving potato plantlets growth performance in an ambient laboratory environment. It is hypothesized that improving ventilation covers, such as adding multiple pieces of micropore tape, will reduce the need for specialized growth rooms. Furthermore, incorporating supplemental lighting may improve plant growth performance in the ambient laboratory environment.

We have had the opportunity to incorporate this research not only into our own laboratory setting but also in a potato micropropagation laboratory in Kenya, Africa. This particular laboratory was dealing with less than ideal growing conditions, high microbial contamination levels, limited availability of sterilizing equipment and limited culture vessels supplies. Implementation of the information provided in this paper allowed for more efficient production and reduced microbial contamination rates. Overall, our results support that inexpensive clear deli containers and a microwave-NaOCl sterilization method can be used for potato micropropagation, as long as a controlled low-traffic growth environment is available for plant propagation.

References

Ahloowalia, B.S., and J. Prakash. 2002. Physical components of tissue culture technology, low cost options for tissue culture technology in developing countries. In: Proceedings of a technical meeting organized by the joint FAO/IAEA division of nuclear techniques in food and agriculture. Vienna, Austria 26–30 August. Printed by IAEA in Austria.

Bhalla, P.L., and K. Sweeney. 1998. Micropropagation of Scaevola- australian native of ornamental horticulture. Australian Journal of Experimental Agriculture 38: 399–401.

Compton, M.E., and J.M. Koch. 2001. Influence of Plant Preservative Mixture (PPM)™ on adventitious organogenesis in melon, petunia, and tobacco. In Vitro Cell Development Biology 37: 259–261.

Frost, K.E., R.L. Groves, and A.O. Charkowski. 2013. Integrated control of potato pathogens through seed potato certification and provision of clean seed potatoes. Plant Disease 97: 1268–1280.

George, M.W., and R.R. Tripepi. 2001. Plant Preservative Mixture™ can affect shoot regeneration from leaf explants of Chrysanthemum, European birch, and Rhododendron. Hort Science 36: 768–769.

Guenthner, J.F., A.O. Charkowski, R. Genger, and G. Greenway. 2014. Varietal differences in minituber production costs. American Journal of Potato Research 91: 376–379.

Haberlach, G.T., B.A. Cohen, N.A. Reichert, M.A. Baer, and L.E. Towill. 1985. Isolation, culture and regeneration of protoplasts from potato and several related Solanum species. Plant Science 39: 67–74.

Jackson, M.B. 2003. Aeration stress in plant tissue cultures. Bulgarian Journal of Plant Physiology Special Issue: 96–109.

Kancherla, S.L., and P.L. Bhalla. 2001. In vitro propagation of pandoreas. Hort Science 36: 348–350.

Kohmura, H., T. Yanagawa, and M. Tanaka. 1999. An efficient micropropagation system using disinfectant incorporated medium and film culture vessel for in vitro plant regeneration of asparagus. Acta Horticulturae 479: 373–380.

Lai, C., H. Lin, S.M. Nalawade, W. Fang, and H. Tsay. 2005. Hyperhydricity in shoot cultures of Scrophularia yoshimurae can be effectively reduced by ventilation of culture vessels. Journal of Plant Physiology 162: 355–361.

Lizarraga, R., P. Tovar, U. Jayasinghe, and J. Dodds. 1986. Tissue culture for elimination of pathogens. Specialized Technology Document 3. International Potato Center, Lima, Peru. 21 pages.

Luna, C., M. Collavino, L. Mroginski, and P. Sansberro. 2008. Indentification and control of bacterial contaminants from Ilex dumosa nodal segments culture in a temporal immersion bioreactor system using 16S rDNA analysis. Plant Cell Tissue Organ 95:13–19.

Luna, C., R. Acevedo, M. Collavino, A. González, L. Mroginski, and P. Sansberro. 2013. Endophytic bacteria from Ilex paraguariensis shoot cultures: localization, characterization, and response to isothiazolone biocides. In Vitro Cell Development Biology 49: 326–332.

Matsumoto, K., M.C.F. Coelho, D.C. Monte, and J.B. Teixeira. 2009. Sterilization of non-autoclavable vessels and culture media by sodium hypochlorite for in vitro culture. Acta Horticulturae 839: 329–335.

Murashige, T., and F. Skoog. 1962. A revised medium for rapid growth and bioassays with tobacco tissue cultures. Physiology Plant 15: 473–497.

Park, S.W., J.H. Jeon, H.S. Kim, Y.M. Park, C. Aswath, and H. Joung. 2004. Effect of sealed and vented gaseous microenvironments on the hyperhydricity of potato shoots in vitro. Short Communication. Scientia Horticulturae 99: 199–205.

Paul, A.L., C. Semer, T. Kucharek, and R. Ferl. 2001. The fungicidal and phytotoxic properties of benomyl and PPM in supplemented agar media supporting transgenic Arabidopsis plants for a space shuttle flight experiment. Applied Microbiology Biotechnology 55: 480–485.

Peters, J.A. 2005. Potencial e demanda para a producão de plantas de alta qualidade genética e sanitária. Horticultura Brasileira 23(Suppl): 668.

Rihan, H.Z., M. Al-Issawi, F. Al-swedi, and M.P. Fuller. 2012. The effect of using PPM (plant preservative mixture) on the development of cauliflower microshoots and the quality of artificial see produced. Scientia Horticulturae 141: 47–52.

Rowntree, J.K. 2006. Development of novel methods for the initiation of in vitro bryophyte cultures for conservation. Plant Cell Tissue Organ Culture 87: 191–201.

Sale, A. 2012. 3M™ Micropore™ Tape. Home Tissue Culture Group Copyright, No. 6 June. http://hometissueculture.org/uploads/3/2/3/1/3231599/newsletter6.pdf Accessed 24 May 2013.

Sawant, R.A., and P.N. Tawar. 2011. Use of sodium hypochlorite as media sterilant in sugarcane micropropagation at commercial scale. Sugar Tech 14: 364–369.

Teixeira, S.L., R.T.S. de Souza, and T.M. Teixeira. 2005. Microwave oven sterilization of plant culture medium. Ceres 52: 449–507.

Tisserat, B., D. Jones, and P. Gallatta. 1992. Microwave sterilization of plant tissue culture media. Hort Science 27: 358–361.

Yanagawa, T., M. Nagai, T. Ogino, and R. Maeguchi. 1995. Application of disinfectants to orchids seeds, plantlets and media as a means to prevent in vitro contamination. Lindleyana 10: 33–36.

Yanagawa, T., R. Tanaka, and R. Funai. 2007. Simple micropropagation of ornamentals by direct application of chlorine disinfectants without equipment. Acta Horticulturae 764: 289–298.

Youssef, E.M.A., and G.A. Amin. 2001. Microwave sterilization of tissue culture media. Acta Horticulturae 506: 513–516.

Zobayed, S.M.A. 2006. Aeration in plant tissue culture. In Plant tissue culture engineering, ed. Gupta S. Dutta and Y. Ibaraki, 313–327. The Netherlands: Springer.

Acknowledgments

Non-sterile clear deli containers were generously donated by M. Olson (Placon, Madison WI). The active chlorine level in tap water was kindly provided by City of Madison Water Utilities (Madison, WI). We thank N. Keuler (University of Wisconsin-Madison) for statistical advice and the following University of Wisconsin undergraduate student hourlies: E. Hutchins, E. Schmid, J. Wochos, L. Jenison, M. Moritz and R. Shefchek (University of Wisconsin) for their dedication to this project.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 67 kb)

Rights and permissions

About this article

Cite this article

Weber, B.N., Witherell, R.A. & Charkowski, A.O. Low-Cost Potato Tissue Culture with Microwave and Bleach Media Preparation and Sterilization. Am. J. Potato Res. 92, 128–137 (2015). https://doi.org/10.1007/s12230-014-9423-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12230-014-9423-7