Abstract

Abstract

In this study, pre-tanning stage goat hide was treated with atmospheric pressure air dielectric barrier discharge with the aim to provide an eco-friendly antimicrobial finishing. The untreated and the air plasma-treated hide pieces were incubated in sterilized agar media. Upon incubation, untreated sample showed noteworthy growth of fungus, while the plasma-treated piece remains unaffected which clearly reveals the sterilization capacity of the plasma treatment. The fungus grown on untreated sample was cultured and identified with fungal specific ITS rRNA gene sequence and Basic Local Alignment Search Tool and found to be strains of Curvularia sp. with 100% similarity to Curvularia caricae-papayae and 99% similarity to Curvularia pseudobrachyspora. The untreated and plasma-treated goat hide samples were subsequently dipped into the extract obtained from bark of two Cassia species: Cassia renigera and Cassia fistula to provide antifungal/antibacterial finishing. Effectiveness of this anti-fungal finishing was demonstrated by inoculating the samples with culture of the fungus and incubation. The obtained results indicate that samples treated with the plasma and the extracts finishing deliver substantial antifungal activity in comparison to that of untreated extract finished goat hide. Additionally, the plasma treated followed by plant extract finished samples provide evidence of antibacterial finish which has been confirmed by zone of inhibition against a Gram-positive bacteria Staphylococcus aureus. Activation of hide surface and generation of various functional groups due to the plasma treatment were accountable for better uptake of the extracts and thus imparting antimicrobial finish.

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Leather manufacturing involves conversion flayed animal hides into commodities by pre-tanning, tanning, and post-tanning operations. Microbial degradation of raw hides is obvious; also, microbial degradation occurs usually during leather manufacturing processes as well as during storage/use of finished leather and leather products (Lindner and Neuber 1990; Orlita 2004). In case of raw hides, microbial degradation by bacteria results mainly due to decomposition of untanned collagen of raw hides at pre-tanning stages; conversely fungi has ability to thrive even after tanning process at various stages of leather processing and also on finished products (Lindner and Neuber 1990; Orlita 2004; Fontoura and Gutterres 2015; Fontoura et al. 2016). In fact, fungal growth is inexorable during leather processing due to nature of chemicals used and favorable environment during leather processing, so fungicides are always used by tanners during leather processing (Orlita 2004; Meneses et al. 2005; Bryant et al. 2010Sahu et al. 2017b). Moreover, for finished leather products, particularly for footwear antimicrobial properties are desired. In case of footwear, leather’s collagen-fibrous network provides an excellent environment for microbial proliferation due to absorption of sweat containing metabolite and sebum; the warm and moist conditions along with oxygen availability results in to bio-film formation and subsequent problems such as unpleasant odor, discoloration, decreased mechanical strength and even risk for skin infection (Fernandes et al. 2013; Liu et al. 2017). Thus, at industrial level and for consumers, antimicrobial treatment of hide/leather is indispensable requirement (Liu et al. 2017).

At present, synthetic organic chemicals are mainly used to provide antimicrobial finishing to textiles (Windler et al. 2013) and likewise widely used during processing of leather as well as during final finishing particularly to provide protection against fungi (Orlita 2004; Carvalho et al. 2018). There are two general class of fungicides used for leather manufacturing: Phenolics and Heterocyclics (Lindner and Neuber 1990; Orlita 2004; Font et al. 2011). Pentachlorophenol (PCP) was commonly used fungicide in leather manufacturing which is replaced by other fungicides after 1980s due to toxicity and poor biodegradability; use of PCP as leather preservatives has been banned in many countries and mandatory residual substances limits (RSLs) of PCP in finished product set to 30 ppm (Muralidharan and Rao 1994; Orlita 2004; Font et al. 2011; Dixit et al. 2015). Currently, chemicals particularly 2-(thiocyanomethylthio) benzothiazole (TCMTB), N-OITZ (N-Octylisothiazolinone), OPP (Ortho phenyl phenol), PCMC (p-Chlorom-cresol), Carbendazim, Merkaptobenzothiazole, TCP (tri-chloro phenol), p-nitro phenol, BMC, DIMTS are commonly used as fungicide by leather industries. These are generally found harmful to human health and nature (Bryant et al. 2010; Lkhagvajav et al. 2015; Sahu et al. 2017a). It is reported in the literature that, 2-thiocyanomethylthiobenzothiazole (TCMTB), Ortho phenyl phenol (OPP) and Pentachlorophenol (PCP), specifically used fungicides for leather processing are now banned in many countries due to toxicity, carcinogenic effect and poor degradability (Sahu et al. 2017a, Sahu et al. b; Carvalho et al. 2018). Furthermore, these chemical finds way to environment through tannery wastewater; recent study indicates high cytotoxicity due to residual fungicides in tannery wastewater (Hansen et al. 2020).

Growing concern for environment protection, and implementation of stringent health and environmental regulations and restrictions, laid a serious challenge for utilization of synthetic organic chemicals as antimicrobials and thus uncertainty for future usage (Orlita 2004; Windler et al. 2013). Thus, research on antimicrobials/natural products derived from plant is the focus of scientific community which can likewise provide antimicrobial properties to textiles and leather (Alihosseini 2016), can be an alternative to chrome tanning (Sahu et al. 2017b; Maier et al. 2017). Use of Azadirachta indica oil (Venkatachalam et al. 1977), Clerodendrum viscosum leaf paste (Hashem et al. 2017), Moringa oleifera leaf paste (Hashem et al. 2018), Citrus limon (Lemon) leave paste (Tamil Selvi et al. 2020), Rumex abyssinicus (mekmeko) roots (Mohammed et al. 2016) for preservation of goat skin, Calophyllum inophyllum oil and Citrullus colocynthis oil as antifungal fat-liquor for leather industry (Sahu et al. 2017a, Sahu et al. b), microencapsulated Melaleuca alternifolia (Tea Tree) oil as biocide (Sánchez-Navarro et al. 2011), commercial essential oils of Eucalyptus slobulus and Lavandulae officinalis (Sirvaitytė et al. 2011), essential oils of Thymus vulgaris (Sirvaitytė et al. 2011) as alternative preservatives for tanned leather, essential oil of Origanum minutiflorum (Bayramo et al. 2006), sweet orange seed oil as antifungal preservative in leather processing (Akpomie 2010), Cedar and Coriander oils for antifungal finish (Niculescu et al. 2017, 2018, p. 2), and many more (Zhiyuan et al. 2013) are been reported in scientific literature.

For any material, surface property and surface charge play important role in treatment carried over it and thus desired surface property is anticipated. Similarly, for leather and leather products, role of desired surface property and surface charge on hide/leather is well recognized and considered requisite for organic tanning (Thanikaivelan et al. 2005) as well as to provide antimicrobial finishing (Koizhaiganova et al. 2015). Surface modification of hide/leather by non-thermal plasma can assuredly be a worthy treatment to acquire effective antimicrobial finish. Use of non-thermal plasma as eco-friendly technology for hide/leather surface modification is of current interest of researchers and have been studied for surface functionalization, improving wettability, water proof property and wet-rubbing property, printability, leather dressing, leather dyeing and finishing, improvement in adhesion (Osin et al. 1998; Choi et al. 2003; Acikel et al. 2013; You et al. 2016; Kaygusuz et al. 2017, 2018; Štěpánová et al. 2017). In other studies, application of atmospheric pressure dielectric barrier discharge (DBD) for surface functionalization of goat hide and to improve dye uptake with various natural dyes also been reported (Dave et al. 2016, 2017).

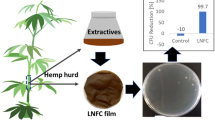

In the present study, atmospheric pressure air DBD plasma employed for grain surface treatment of goat hide; the plasma treatment can sterilize the hide and thus with this study application of the atmospheric pressure non-thermal plasma for short-term preservation of goat hide demonstrated first time. Surface functionalization and activation of goat hide by the air DBD treatment subsequently results in better uptake of plant-based extracts and thus antimicrobial finishing can be imparted. Furthermore, to explore antimicrobial finishing to goat hide, we had used the extract obtained from bark of two Cassia species: Cassia renigera and Cassia fistula, since plants of genus Cassia are known for antimicrobial and other biological activities (Dave and Ledwani 2012). Leave paste of Cassia fistula has been explored and proved very efficient for phyto-based preservation of freshly flayed goat hide due to excellent antibacterial and antifungal properties (Vinodhkumar et al. 2016). The effectiveness of finishing by the atmospheric pressure plasma and subsequent treatment with the plant extract-treated samples demonstrated with fungus culture isolated from the hide sample itself, while antibacterial effect confirmed by zone of inhibition against a Gram-positive bacteria Staphylococcus aureus.

2 Experimental

2.1 Materials

Goat hide (pickled, full grain) having average thickness of 1 mm were procured from local market at Agra, Uttar Pradesh, India. Bark of Cassia renigera and Cassia fistula were collected from trees growing at local areas of Jaipur, Rajasthan, India. Bark was rinsed with distilled water (DI) to remove impurities present then dried in shadow to prevent bio-degradation and loss of active compounds. All the chemicals and solvents used in this experiment were of analytical grade. 99.9% Ethanol (CSS Pvt. Ltd.) was used to obtain extract from bark of Cassia renigera and Cassia fistula. Agar–Agar and nutrient agar medium and potato dextrose agar supplied by HiMedia Laboratories Pvt. Ltd. were used for isolation of fungus from hide sample and for testing of antifungal, antibacterial finishing.

2.2 Surface modification of goat hide by atmospheric pressure air DBD

To activate the goat hide surface and incorporate functional groups, grain surface of goat hide was exposed to atmospheric pressure air DBD for duration of 15 min by keeping the hide sample on bottom electrode of an experimental plasma system. The schematic of experimental system is shown in Fig. 1. The experimental plasma system consists of low-frequency (50 Hz) power source connected with SS wire mesh electrodes (flat, rectangular, separated 3 mm apart) covered by polyethylene–terephthalate (PET) film as dielectric medium. The air DBD generated in this experimental system by applying high voltage of 7 kV rms across the electrodes. Further details about air DBD plasma experimental system and characterization of air DBD-treated goat hide sample by employing ATR-FTIR spectroscopy, X-ray photoelectron spectrometric (XPS) analysis and Scanning Electron Microscopy (SEM) are reported in previous study (Dave et al. 2016).

2.3 Preparation of extract from Cassia renigera and Cassia fistula bark

Bark of Cassia renigera and Cassia fistula were thoroughly washed, separately with deionized water and dried in shade for 4–5 days to remove any moisture. It was then crushed to powder form and stored for further use. The active plant constituents from the bark powder were extracted by soxhlet method using ethanol (99.9%) as a solvent. After 10–12 h of the process, crude extracts were obtained.

2.4 ATR-FTIR analysis of Cassia renigera and Cassia fistula bark extract

Chemical constituents of the extracts were analyzed by ATR-FTIR (Attenuated total reflectance Fourier transform infrared spectroscopy) spectrophotometer Alpha, Bruker, Germany. The spectra were recorded in the range of 4000–600 cm−1 with 64 scans, resolution of 4 cm−1).

2.5 XRD analysis of untreated goat hide

X-ray diffraction patterns for grain surface of the untreated goat hide were collected by X-ray Diffractometer (GNR APD 2000 PRO) using an X-ray tube with Cu anode (CuKα radiation with a wavelength of 1.541874 Å). For measurement, the hide sample was cut around 20 mm × 20 mm and fixed in sample holder. The 2θ angle was scanned between 10° and 50°, with 0.020 step size and 1.5 s time per step.

2.6 Isolation and identification of fungus strain from the goat hide sample

As described above, the hide sample was bought from local market, where it was already exposed to air and dust. Henceforth, the presence of bacterial/fugal spore in the hide sample was assumed. When piece of untreated hide sample and hide piece treated with the air DBD for 15 min were placed in sterilized agar media poured in Petri-dishes and incubated at 27 ± 1 °C in aseptic condition, fungus growth was observed on untreated hide sample. No fungal growth found on the air DBD-treated hide sample which due to sterilization by the air DBD treatment as described in Sect. 3.4. The fungus grown on untreated hide pieces was isolated and cultured as per the previously reported method (Rathore 2015) and identification of fungus strain carried out using fungal specific ITS rRNA gene sequencing (White et al. 1990; Krizsán et al. 2015). For that, chromosomal nucleic acid extraction from the cultured fungus was performed using commercial DNA isolation kit. The Basic Local Alignment Search Tool (BLAST) which finds regions of similarity between sequences and NCBI/Gen Bank Database were used to generate identification report (Altschul et al. 1990; Krizsán et al. 2015). The BLAST compares nucleotide or protein sequences to sequence databases and calculates the statistical significance of matches; the BLAST algorithms also used to infer functional and evolutionary relationships between sequences as well as help to identify members of gene families. For the fungal strain identification, first step is initial search to find closely related sequences using the BLAST program, afterwards pairwise alignment done to calculate the sequence similarity values between the query sequence and the sequences identified in first step (Karlin and Altschul 1990; States et al. 1991). Therefore, each isolate is reported with the first five-ten hits observed in the said database.

2.7 Antimicrobial finishing with extracts obtained from bark of Cassia renigera and Cassia fistula

The plasma-treated and untreated leather samples were dipped in plant extracts at material to liquor ratio of 1:10 for 50 min. After the process, leather samples were removed from extract and allowed to dry. Effectiveness of this finishing against fungus was demonstrated by inoculating the samples with culture of the fungus strain isolated and identified as describe above. For that, inoculated pieces of the plant extract-treated hide and plasma followed by the plant extract-treated hide were incubated in sterilized potato dextrose agar media poured in Petri-dishes and incubated for 48 h at 27 ± 1 °C in aseptic condition. Also, antibacterial property of this finish confirmed by zone of inhibition against a Gram-positive bacteria Staphylococcus aureus (MTCC9542) by agar diffusion test. Sterile Petri plates with 20 ml of nutrient agar medium were prepared, subsequently solidified media swabbed uniformly with test culture of Staphylococcus aureus and allowed to dry. Specimens of plasma plus plant extract-treated hide along with untreated and the plasma-treated hide were placed on the swabbed agar plates. The plates were incubated at 37 ± 1 °C for 24 h, and zone of inhibition recorded in millimeter after completion of incubation.

3 Result and discussion

3.1 Air DBD—suitable configuration for hide/leather treatment

Among atmospheric pressure non-thermal plasma sources, atmospheric pressure air DBD is found useful for hide/leather treatment because of various advantages such as no need for vacuum, continuous processing, use of flat electrodes providing large area for plasma generation and one can change configuration as per the requirement. The configuration of atmospheric pressure air DBD plasma generator is a very suitable for industrial usage (Nema et al. 2008; Chandwani et al. 2014; Rani et al. 2018; Dave et al. 2014). As reported in various scientific studies, current–voltage characteristics and emission spectra of the air DBD obtained by optical emission spectroscopy indicate filamentary behavior of the discharge, i.e. the air DBD consists of numbers micro discharge formed across the electrodes during each half cycle of the applied voltage (Dave et al. 2012; Chandwani et al. 2014). These micro-discharges being in the range of few nanometers in diameter, the discharge appears to be uniform, as seen from naked eye. Determination of electron, vibrational and rotational temperatures of the air DBD indicate characteristics of non-thermal, non-equilibrium discharge. The obtained value for electron kinetic temperature (Te) of 2.2 eV, vibrational temperature (Tv) of 3000–4000 K along with the low gas temperature (Tg) of around 400 K indicate classic in-equality i.e. Te > Tv > Tr ~ Tg and such discharge is very much suitable for energy-efficient and low-temperature material processing applications (Chandwani et al. 2014). When hide/leather surface exposed to the air DBD, chemical composition and physical properties of grain surface changes due to reactions of active chemical species present in air DBD as well as etching due to energetic species. As reported in previous study, air DBD treatment of grain surface of the hide results in incorporation of functional groups particularly oxygen containing functional groups, make surface more uniform by removal of asperities while bulk properties of the hide remain unaffected (Dave et al. 2016).

3.2 X-ray diffraction

Hide is matrix of three-dimensional collagen bundle weaves while leather is of tanned collagen fiber bundle weaves. Triple helix structure of collagen with different degrees of arrangement to form micro-fibril, fibril and fiber bundle and its different degree of weaving impart unique nature to hide/leather having variation within matrix imposing constraint in uptake and diffusion of chemicals during processing and finishing (Dave et al. 2016). Therefore, XRD patterns obtained for grain surface of the goat hide used in this study to understand structural properties of composing material. Figure 2 represents XRD patterns for grain surface of the hide, which reveals the amorphous nature of hide composing materials. Pure crystalline collagen exhibits main diffraction peaks distinctly at 2θ values of 14.1, 16.9 and 25.5°; such peaks generally observed for collagen-based materials, even in vegetable tanned leather (Cucos et al. 2011) but these peaks are not observed in XRD pattern obtained for grain surface of goat hide used in this study. Furthermore, it is reported in the literature that semi-crystalline collagen exhibits characteristic peaks around 2θ values of 7.5° due to intermolecular packing distance between collagen molecular chain; 21.8° due to diffuse scattering by amorphous collagen, unorder component of fibers; and 31° attributed to the unit height that was representative of the typical triple-helix structure (Xu et al. 2017; Tian et al. 2020). Of these peaks, peak due to diffuse scattering at 21.76° is mainly observed in XRD pattern of the goat hide used in this study. During various processing stages, the hide gone through, crystalline structure of collagen gets affected and therefore, peaks related to triple helix structure are not observed for the pre-tanning stage pickled goat hide used in this study (Yao et al. 2018).

The observed peak around 20.67° can be ascribed to diffuse peaks caused by the reflection of the weave of collagen fibers, intensity of which represents the regularity of the dimensional structure of collagen and cross-linking (Yao et al. 2018). Considerable intensity of the peak indicates compact and constrict weaving of collagen fibrils at grain surface and no cross-linking observed, as cross linking due to tanning results in disappearing of the peak. Also, negligible diffraction peaks at 31.76° further indicate collagen bundles are less dispersed and tightly weaved (Yao et al. 2018).

3.3 ATR-FTIR spectrum of plant extracts

Figure 3 represents ATR-FTIR spectrum of ethanolic extract obtained from bark of both the species which has ample similarities to the commercially available antimicrobial extracts of different flavonoids and phenols rich plant species such as Croton lechleri, Punica granatum, Salvia officinalis as well as Propolis (Oliveira et al. 2016). As seen from the figure, two major peaks observed at 1637 cm−1 and 3345 cm−1; these peaks are common peaks in all the commercially available antimicrobial extract mentioned above. The peak at 1637 cm−1 assigned to stretching vibration of C=C and C=O vibration, aromatic ring deformation, due to flavonoids and polyphenols (Trifunschi et al. 2015; Oliveira et al. 2016).

The broad peak at 3345 cm−1 assigned to –OH stretching vibration of alcohols, hydroxyl groups, –OH wagging of phenolic (Trifunschi et al. 2015; Oliveira et al. 2016). A broad peak observed at 2105 cm−1 in spectrum of both the extracts as well as all the commercially available extracts but not identified (Oliveira et al. 2016). Few minor peaks observed in case of bark extract of C. fistula, such as 1283 cm−1 due to C–O stretching vibration due to alcohol, carboxylic acid and ester, 1387 cm−1 assigned to phenolic –OH group (Trifunschi et al. 2015), 1474 cm−1 assigned to CH and CH2, CH3 vibration/aromatic vibration of flavonoids, should at 1519 cm−1 may be assigned to aromatic ring deformation and to flavonoids (Oliveira et al. 2016). Symmetric, asymmetric stretching of aliphatic methyl group observed at 2926 and 2882 cm−1, may be due to ethanol (Oliveira et al. 2016).

3.4 Sterilization capacity of the air DBD treatment

Non-thermal plasmas being a highly reactive in nature, are well studied for its antimicrobial actions and sterilization capacity; in fact, non-thermal plasma emerging as very effectual alternative sterilization technique (Moisan et al. 2001; Moreau et al. 2008; De and Morent 2012; Scholtz et al. 2015). Despite well documented for sterilization capacity in food industries (Pignata et al. 2017; Hertwig et al. 2018), medical and biomedical applications (Laroussi 2005), textile sterilization (Senthilkumar et al. 2015), etc. application of non-thermal plasma for sterilization of leather/hide is not reported in scientific literature. In this study, sterilization capacity of the DBD treatment demonstrated by incubating in sterilized agar medium a piece of untreated goat hide and a piece of the hide treated with the atmospheric pressure air DBD for 15 min.

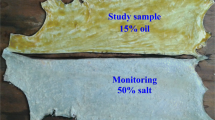

As seen from Fig. 4, upon incubation in sterilized agar media fungal growth observed on piece of untreated hide within a day while the piece of hide treated with air DBD for 15 min remain unaffected even after 2 days. The fungus grown identified as Curvularia caricae-papayaeas described in subsequent section. The hide sample was purchased from local market and already exposed to dust and air. The fungus growth on untreated hide piece can be attributed to fact that in ambient air fugal spore are more in number than viable bacterial cell/spore. Fungus have ability to release reproductive and propagative structures called “spores” directly to the air from aerial branches, also fungal spores have protective coat that shields them from harsh environmental conditions (for example, drying out, high temperatures) in ambient air (Misra et al. 2019). The surface modification treatment of goat hide by exposure of grain surface of goat hide to the air DBD resulted in complete sterilization of the hide sample, even killing of spores (Puligundla and Mok 2018; Liao et al. 2018). Thus, the plasma-treated hide sample remain unaffected upon incubation in agar media. The sterilization by non-thermal plasma linked to various factors such as heat, ultraviolet radiation, reactive chemical species such as reactive oxygen species (ROS) (O*, O3, OH*) and reactive nitrogen species (RNS) (NO, NO2), charged particles, electrons, etc. directly affecting microbes and high electrical field pulse indirectly being microbicidal (De and Morent 2012; Guo et al. 2015; Bourke et al. 2017; Liao et al. 2017). For inactivation of spore, spore coat damage by etching and resultant spore leakage, diffusion of reactive species in spore and functional damage to macromolecules, oxidation by ROS, effect of UV radiation, damage to DNA, damage to metabolic proteins such as germination receptor are the chief causes for sporicidal effect of non-thermal plasma (Puligundla and Mok, 2018; Liao et al. 2018). It is reported that due to difference in composition of cell wall and spore coat, fungi are generally more resistant to non-thermal plasma sterilization, however, the reactive species of non-thermal plasma play key role for killing of fungi as well as fungal spore by morphological alteration of fungal spore (Misra et al. 2019).

The reactive species of plasma discharge can be studied by optical emission spectroscopy (OES). The OES study of air DBD used in surface modification of the goat hide samples indicate the presence of reactive nitrogen species and oxygen species. The generation of ozone takes place by a well-studied three-body reaction (Chandwani et al. 2014; Dave et al. 2016). In the air DBD, atomic oxygen produces by dissociation of oxygen molecule by high-energy electrons, which further collide with O2 and a third particle, either O2 or N2 which do not react chemically but takes part in energy absorption process. This ozone generation process in the air DBD results in quenching of atomic oxygen species. Quenching is two orders of magnitude faster than radiative process for emission of atomic oxygen (5So–5P at 777 nm and 3So–3P at 844 nm) and thus with OES study, ozone generation in the air DBD was confirmed (Chandwani et al. 2014; Dave et al. 2016). Hide/leather being porous, three dimensional weaves of collagen fibers, role of ozone for sterilization cannot be ignored (Mastanaiah et al. 2013). In fact, application of ozone has been reported as antifungal and sporicidal for fungal spores (Hudson and Sharma 2009; Freitas-Silva and Venancio 2010; Kang et al. 2015). Though non-thermal plasma not reported so far for sterilization/preservation of hide, application of ozone already been reported for preservation of raw hides in leather making (Sivakumar et al. 2010; Vaduganathan 2017), sanitization of shoe, finished leather products to prevent fungal infection of feet (Gupta and Versteeg 2019). In this context, result obtained in this study point out towards suitability of the air dielectric barrier discharge at atmospheric pressure for sterilization/preservation of hides offering advantages such as possibility to sterilize large area, continuous processing, effective sterilization by action of reactive species as well as by ozone, and importantly surface functionalization which can be beneficial for subsequent treatment/finishing.

3.5 Identification of fungus species

To identify strain of the fungus grown on the untreated hide upon incubation in agar media, the fungus-specific ITS rRNA gene amplified and sequenced from culture of the fungus. Species level identification done by use of Basic Local Alignment Search Tool (BLAST) to find similarity between sequences in the NCBI GenBank (Jeon et al. 2015; Krizsán et al. 2015). The BLAST analysis of ITS r RNA sequences primer [ITS1_ITS4 (561 bp)] indicated that the fungus strain grown on the untreated hide sample highly resembled with Curvularia caricae-papayae (Accession No. NR_147458.1) the most, displaying 100% (556/556 base pair) similarity (Madrid et al. 2014); and to Curvularia pseudobrachyspora (Accession No. MF490819.1) with 99% similarity (588/562 base pair) (Marin et al. 2017). Hence, the fungal species was confirmed to be a strain of Curvularia sp. (Closer to caricae-papayae). Curvularia is a species-rich genus, which includes numerous grass pathogens and saprobes occurring on plant material, dung and soil, and hence contamination of the goat hide sample by Curvularia sp. presumed due to contact with ambient air and dust (Madrid et al. 2014).

3.6 Antimicrobial finishing of hide with aid of the plasma treatment

Treatment of grain surface of the goat hide with air DBD for 15 min results in functionalization of surface by generation of oxygen containing functional groups. As reported in our previous study, the plasma treatment induced oxidation resulted in increase in O/C atomic ratio of hide grain surface from 0.53 to 0.68, N/C atomic ratio from 0.27 to 0.31 when compared to the untreated hide; and significant increase in relative concentration of amine, alcohol and acid functional groups as reveled by XPS study and also ATR-FTIR spectroscopy. The plasma treatment also resulted swelling, loosening of surface and overgrowing of pores; consequential more uniform surface (Dave et al. 2016). These chemical and morphological changes resulted in better uptake of the extracts from bark of Cassia species and provided perceptible antifungal finish.

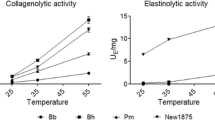

Figure 5 represents the effectiveness of antifungal finish imparted to hide samples by surface modification with the air DBD and subsequent treatment with ethanolic extract obtained from Cassia renigera bark and Cassia fistula bark. Hide pieces treated with air DBD plus the bark extracts and inoculated with culture of the fungus strain of Curvularia species, shown clear antifungal effect. At the other side, untreated hide pieces treated with the extracts did not provide effective resistance against the fungus strain of Curvularia species. Upon incubation in agar media after inoculation, on untreated hide pieces treated with the bark extracts, deferred but evident growth of the fungus observed after incubation for a day, while the hide pieces treated with air DBD and the bark extracts remain unaffected by the fungus even after four days of incubation. The results indicate that surface functionalization on by air DBD resulted in better uptake of the phyto-constituents from the plant extracts and thus effective antifungal finishing. The hide pieces treated with the air DBD and the plants extracts further tested for antibacterial effects against Gram-positive bacteria Staphylococcus aureus. As seen from Fig. 6, untreated hide pieces and the air DBD-treated piece of hide, treated with bark extract of C. renigera were placed on nutrient agar media swabbed uniformly with the test organism and incubated for at 37° for 24 h. The untreated hide piece which treated with bark extract of C. renigera did not provide zone of inhibition against Staphylococcus aureus, whereas clear zone of inhibition obtained in case of the hide piece treated with air DBD and subsequently treated with bark extract of C. renigera. The obtained bacteriostatic activity inferred to better uptake of active compounds from the bark extract due to surface functionalization by the air DBD treatment. E. coli strains were also used to investigate antibacterial activity, however, no zone of inhibition was observed against the same.

Further as seen from Fig. 7, zone of inhibition obtained against Staphylococcus aureus when hide piece treated with air DBD and the bark extracts put along with air DBD treated (treated and incubated immediately) and untreated hide piece. Zone of inhibition did not obtain for untreated hide piece, while hide specimen treated with air DBD plus bark extract of Cassia renigera showed 4.4 cm zone of inhibition and hide specimen treated with air DBD plus bark extract of Cassia fistula show 4.2 cm zone of inhibition. Interestingly, slight zone of inhibition obtained for air DBD-treated hide piece which was placed immediately after the plasma treatment. The obtained zone may be due to ozone produced in air DBD which diffused and trapped inside the matrix of hide sample. The obtained result indicates the applicability of the air DBD treatment for short-term preservation of hide against bacterial deterioration (Sivakumar et al. 2010; Vaduganathan 2017).

4 Conclusion

In this study, pre-tanning stage goat hide sample was treated with atmospheric pressure air dielectric barrier discharge (DBD) to modify its surface. The treatment proved to be beneficial for subsequent processing and reducing environmental impacts. Treatment of hide with the air DBD for 15 min results in complete sterilization of hide by killing all microorganisms including fungal spore present in the hide. Thus, the air DBD treatment can be used for preservation of hide/prevention of bio-degradation and thus it can reduce the use of chemical microbicidal agent. The antimicrobial property of samples was investigated after dipping the untreated and the air DBD-treated goat hide samples into the bark extract of Cassia renigera and Cassia fistula, respectively. Effectiveness of this antimicrobial finishing was demonstrated against culture of fungi Curvularia caricae-papayae and Gram-positive bacteria Staphylococcus aureus. The experiments showed that air DBD treatment for 15 min has substantially modified the chemical and physical properties of leather hide, which leads to an effective bonding between substrate and active constituents of extract of Cassia renigera and Cassia fistula.

References

Acikel S, Aslan A, Oksuz L, Aktan T (2013) Effects of atmospheric pressure plasma treatments on various properties of leathers. J Am Leather Chem Assoc 108:266–276

Akpomie OO (2010) The preservative potentials of sweet orange seed oil on leather products in Nigeria. Afr J Biotech. https://doi.org/10.4314/ajb.v9i5

Alihosseini F (2016) 10—Plant-based compounds for antimicrobial textiles. In: Sun G (ed) antimicrobial textiles. Woodhead Publishing, Cambridge, pp 155–195

Altschul SF, Gish W, Miller W et al (1990) Basic local alignment search tool. J MolBiol 215:403–410. https://doi.org/10.1016/S0022-2836(05)80360-2

Bayramo EE, Gülümser G, Karaboz (2006) Ecological and innovative fungicide for the leather industry: essential oil of Origanum minutiflorum. J Am Leather Chem Assoc 101:96–104

Bourke P, Ziuzina D, Han L et al (2017) Microbiological interactions with cold plasma. J Appl Microbiol 123:308–324. https://doi.org/10.1111/jam.13429

Bryant SD, Hurlow EL, Whittemore MS (2010) A new antifungal agent for the leather industry: S-hexyl-S’-chloromethyl-cyanodithiocarbimate (CHED). SLTC J 95:7–10

Carvalho I, Ferdov S, Mansilla C et al (2018) Development of antimicrobial leather modified with Ag–TiO2 nanoparticles for footwear industry. Sci Technol Mater 30:60–68. https://doi.org/10.1016/j.stmat.2018.09.002

Chandwani N, Chowdhuri MB, Nema S, Mukherjee S (2014) Determination of rotational, vibrational and electron temperatures in dielectric barrier discharge in air at atmospheric pressure. Available at http://nopr.niscair.res.in/bitstream/123456789/14810/1/IJNPR%203(3)%20291-319.pdf

Choi JH, Lee ES, Baik HK et al (2003) Surface modification of natural leather using low-pressure parallel plate plasma. Surf Coat Technol 171:257–263. https://doi.org/10.1016/S0257-8972(03)00282-2

Cucos A, Budrugeac P, Miu L et al (2011) Dynamic mechanical analysis (DMA) of new and historical parchments and leathers: correlations with DSC and XRD. Thermochim Acta 516:19–28. https://doi.org/10.1016/j.tca.2011.01.006

Dave H, Ledwani L (2012) A review on anthraquinones isolated from Cassia species and their applications. Indian J Nat Prod Resour 3:291–319. http://nopr.niscair.res.in/bitstream/123456789/14810/1/IJNPR%203(3)%20291-319.pdf

Dave H, Ledwani L, Chandwani N et al (2012) Use of dielectric barrier discharge in air for surface modification of polyester substrate to confer durable wettability and enhance dye uptake with natural dye eco-alizarin. Compos Interfaces 19:219–229. https://doi.org/10.1080/15685543.2012.702594

Dave H, Ledwani L, Chandwani N et al (2014) The removal of impurities from gray cotton fabric by atmospheric pressure plasma treatment and its characterization using ATR-FTIR spectroscopy. J Text Inst 105:586–596. https://doi.org/10.1080/00405000.2013.827900

Dave H, Ledwani L, Nema SK (2016) Surface Modification by atmospheric pressure air plasma treatment to improve dyeing with natural dyes: an environment friendly approach for leather processing. Plasma Chem Plasma Process 36:599–613. https://doi.org/10.1007/s11090-015-9687-9

Dave H, Ledwani L, Nema SK (2017) Improvement in natural dyeing with the aid of atmospheric pressure plasma treatment: a green solution for leather processing. Curr Environ Eng 4:140–149. https://doi.org/10.2174/2212717804666161208125652

De NG, Morent R (2012) Nonthermal plasma sterilization of living and nonliving surfaces. Annu Rev Biomed Eng 14:255–274. https://doi.org/10.1146/annurev-bioeng-071811-150110

Dixit S, Yadav A, Dwivedi PD, Das M (2015) Toxic hazards of leather industry and technologies to combat threat: a review. J Clean Prod 87:39–49. https://doi.org/10.1016/j.jclepro.2014.10.017

Fernandes IP, Amaral JS, Pinto V et al (2013) Development of chitosan-based antimicrobial leather coatings. Carbohyd Polym 98:1229–1235. https://doi.org/10.1016/j.carbpol.2013.07.030

Font J, Reyes M, Cuadros S et al (2011) Determination of TCMTB and other fungicides in leather. J Am Leather Chem Assoc 106:341–348

Fontoura J, Gutterres M (2015) Damage of pickled hides, wet-blue leather and vegetable tanned leather due to biodeteriation. J Am Leather Chem Assoc 110:138–144

Fontoura J, Ody D, Gutterres M (2016) Performance of microbicides for the preservation of vegetable tanned leather. J Am Leather Chem Assoc 111:259–266

Freitas-Silva O, Venancio A (2010) Ozone applications to prevent and degrade mycotoxins: a review. Drug Metab Rev 42:612–620. https://doi.org/10.3109/03602532.2010.484461

Guo J, Huang K, Wang J (2015) Bactericidal effect of various non-thermal plasma agents and the influence of experimental conditions in microbial inactivation: a review. Food Control 50:482–490. https://doi.org/10.1016/j.foodcont.2014.09.037

Gupta AK, Versteeg SG (2019) The Role of shoe and sock sanitization in the management of superficial fungal infections of the feet. J Am Podiatr Med Assoc 109:141–149. https://doi.org/10.7547/17-043

Hansen É, Monteiro de Aquim P, Hansen AW et al (2020) Impact of post-tanning chemicals on the pollution load of tannery wastewater. J Environ Manag 269:110787. https://doi.org/10.1016/j.jenvman.2020.110787

Hashem A, Arman N, Sheikh HR, Islam M (2017) Sodium chloride substitute for lower salt goat skin preservation: a novel approach. J Am Leather Chem Assoc 112:8

Hashem MdA, Momen MdA, Hasan M (2018) Leaf paste aided goat skin preservation: significant chloride reduction in tannery. J Environ Chem Eng 6:4423–4428. https://doi.org/10.1016/j.jece.2018.06.050

Hertwig C, Meneses N, Mathys A (2018) Cold atmospheric pressure plasma and low energy electron beam as alternative nonthermal decontamination technologies for dry food surfaces: a review. Trends Food Sci Technol 77:131–142. https://doi.org/10.1016/j.tifs.2018.05.011

Hudson JB, Sharma M (2009) The Practical application of ozone gas as an anti-fungal (anti-mold) agent. Ozone Sci Eng 31:326–332. https://doi.org/10.1080/01919510903043996

Jeon SJ, Nguyen TTT, Lee HB (2015) Phylogenetic status of an unrecorded species of Curvularia, C. spicifera, based on current classification system of Curvularia and Bipolaris group using multi loci. Mycobiology 43:210–217. https://doi.org/10.5941/MYCO.2015.43.3.210

Kang MH, Pengkit A, Choi K et al (2015) Differential inactivation of fungal spores in water and on seeds by ozone and arc discharge plasma. PLoS ONE 10:1–16. https://doi.org/10.1371/journal.pone.0139263

Karlin S, Altschul SF (1990) Methods for assessing the statistical significance of molecular sequence features by using general scoring schemes. Proc Natl Acad Sci USA 87:2264–2268. https://doi.org/10.1073/pnas.87.6.2264

Kaygusuz M, Meyer M, Junghans F, Aslan A (2017) Surface activation and coating on leather by dielectric barrier discharge (DBD) plasma at atmospheric pressure. J Soc Leather Technol Chem 101:86–93

Kaygusuz M, Meyer M, Junghans F, Aslan A (2018) Modification of leather surface with atmospheric pressure plasma and nanofinishing. Polym Plast Technol Eng 57:260–268. https://doi.org/10.1080/03602559.2017.1320725

Koizhaiganova M, Yaşa I, Gülümser G (2015) Assessment of antibacterial activity of lining leather treated with silver doped hydroxyapatite. Int Biodeterior Biodegrad 105:262–267. https://doi.org/10.1016/j.ibiod.2015.09.017

Krizsán K, Tóth E, Nagy LG et al (2015) Molecular identification and antifungal susceptibility of Curvularia australiensis, C. hawaiiensis and C. spicifera isolated from human eye infections. Mycoses 58:603–609. https://doi.org/10.1111/myc.12367

Laroussi M (2005) Low Temperature plasma-based sterilization: overview and state-of-the-art. Plasma Process Polym 2:391–400. https://doi.org/10.1002/ppap.200400078

Liao X, Liu D, Xiang Q et al (2017) Inactivation mechanisms of non-thermal plasma on microbes: a review. Food Control 75:83–91. https://doi.org/10.1016/j.foodcont.2016.12.021

Liao X, Muhammad AI, Chen S et al (2018) Bacterial spore inactivation induced by cold plasma. Crit Rev Food Sci Nutr. https://doi.org/10.1080/10408398.2018.1460797

Lindner W, Neuber H-U (1990) Preservation in the tannery. Int Biodeterior 26:195–203. https://doi.org/10.1016/0265-3036(90)90059-G

Liu G, Li K, Luo Q et al (2017) PEGylated chitosan protected silver nanoparticles as water-borne coating for leather with antibacterial property. J Colloid Interface Sci 490:642–651. https://doi.org/10.1016/j.jcis.2016.11.103

Lkhagvajav N, Koizhaiganova M, Yasa I et al (2015) Characterization and antimicrobial performance of nano silver coatings on leather materials. Braz J Microbiol 46:41–48. https://doi.org/10.1590/S1517-838220130446

Madrid H, da Cunha KC, Gené J et al (2014) Novel Curvularia species from clinical specimens. Persoonia 33:48–60. https://doi.org/10.3767/003158514X683538

Maier M, Oelbermann A-L, Renner M, Weidner E (2017) Screening of European medicinal herbs on their tannin content—new potential tanning agents for the leather industry. Ind Crops Prod 99:19–26. https://doi.org/10.1016/j.indcrop.2017.01.033

Marin Y, Cheewangkoon R, Crous P (2017) New species and records of Bipolaris and Curvularia from Thailand. Mycosphere 8:1555–1573. https://doi.org/10.5943/mycosphere/8/9/11

Mastanaiah N, Banerjee P, Johnson JA, Roy S (2013) Examining the role of ozone in surface plasma sterilization using dielectric barrier discharge (DBD) plasma. Plasma Process Polym 10:1120–1133. https://doi.org/10.1002/ppap.201300108

Meneses ES, Arguelho MLPM, Alves JPH (2005) Electroreduction of the antifouling agent TCMTB and its electroanalytical determination in tannery wastewaters. Talanta 67:682–685. https://doi.org/10.1016/j.talanta.2005.01.058

Misra NN, Yadav B, Roopesh MS, Jo C (2019) Cold plasma for effective fungal and mycotoxin control in foods: mechanisms, inactivation effects, and applications. Comp Rev Food Sci Food Saf 18:106–120. https://doi.org/10.1111/1541-4337.12398

Mohammed SA, Madhan B, Demissie BA et al (2016) Rumex abyssinicus (mekmeko) Ethiopian plant material for preservation of goat skins: approach for cleaner leather manufacture. J Clean Prod 133:1043–1052. https://doi.org/10.1016/j.jclepro.2016.06.043

Moisan M, Barbeau J, Moreau S et al (2001) Low-temperature sterilization using gas plasmas: a review of the experiments and an analysis of the inactivation mechanisms. Int J Pharm 226:1–21. https://doi.org/10.1016/S0378-5173(01)00752-9

Moreau M, Orange N, Feuilloley MGJ (2008) Non-thermal plasma technologies: new tools for bio-decontamination. Biotechnol Adv 26:610–617. https://doi.org/10.1016/j.biotechadv.2008.08.001

Muralidharan D, Rao VSS (1994) Identification of leather preservatives by gas chromatography-mass spectrometry. J Chromatogr A 675:257–260. https://doi.org/10.1016/0021-9673(94)85282-0

Nema SK, Tanwani N, Rane R, et al (2008) Indian patent: an apparatus for plasma surface modification and sterilization of materials, application No. 928/MUM/2008, Publication Date: 06/11/2009

Niculescu O, Deselnicu DC, Georgescu M, Niţuică M (2017) Finishing product for improving antifungal properties of leather. LFJ 17:31–38. https://doi.org/10.24264/lfj.17.1.4

Niculescu O, Coară G, Chelaru C, Gurău D (2018) New products based on essential oils for inishing natural leathers with antifungal performances—Part 2. Proceedings of the International Conference on Advanced Materials and Systems (ICAMS 2018). 1: 281–286. https://doi.org/10.24264/icams-2018.V.4

Oliveira RN, Mancini MC, de Oliveira FCS et al (2016) FTIR analysis and quantification of phenols and flavonoids of five commercially available plants extracts used in wound healing. Matéria (Rio de Janeiro) 21:767–779

Orlita A (2004) Microbial biodeterioration of leather and its control: a review. Int Biodeterior Biodegrad 53:157–163. https://doi.org/10.1016/S0964-8305(03)00089-1

OsinYuN MLY, Abutalipova LN, Abdullin IS (1998) SEM and X-ray analysis of surface microstructure of a natural leather processed in a low temperature plasma. Vacuum 51:221–225. https://doi.org/10.1016/S0042-207X(98)00163-8

Pignata C, D’Angelo D, Fea E, Gilli G (2017) A review on microbiological decontamination of fresh produce with nonthermal plasma. J Appl Microbiol 122:1438–1455. https://doi.org/10.1111/jam.13412

Puligundla P, Mok C (2018) Inactivation of spores by nonthermal plasmas. World J Microbiol Biotechnol 34:143. https://doi.org/10.1007/s11274-018-2527-3

Rani KV, Chandwani N, Kikani P et al (2018) Optimization and surface modification of silk fabric using DBD air plasma for improving wicking properties. J Text Inst 109:368–375. https://doi.org/10.1080/00405000.2017.1347230

Rathore DS (2015) Study of fungal diversity on different types of finished leather and leather articles. Res J Recent Sci 4:7

Sahu B, Aravindhan R, Mohammed AJ (2017a) Application of Calophyllum inophyllum oil as antifungal fat-liquor for leather industry. Ind Crops Prod 105:104–112. https://doi.org/10.1016/j.indcrop.2017.04.064

Sahu B, Rathinam A, Javid MA, Gupta S (2017b) Preparation of fatliquor having antifungal activity using the oil of Citrullus colocynthis for application in leather processing. Ind Crops Prod 108:553–557. https://doi.org/10.1016/j.indcrop.2017.06.029

Sánchez-Navarro MM, Cuesta-Garrote N, Arán-Aís F, Orgilés-Barceló C (2011) Microencapsulation of Melaleucaalternifolia (Tea Tree) oil as biocide for footwear applications. J Dispers Sci Technol 32:1722–1727. https://doi.org/10.1080/01932691.2011.616126

Scholtz V, Pazlarova J, Souskova H et al (2015) Nonthermal plasma—a tool for decontamination and disinfection. Biotechnol Adv 33:1108–1119. https://doi.org/10.1016/j.biotechadv.2015.01.002

Senthilkumar P, Arun N, Vigneswaran C (2015) Plasma sterilization: new epoch in medical textiles. J Inst Eng India Ser E 96:75–84. https://doi.org/10.1007/s40034-014-0056-7

Sirvaitytė J, Šiugždaitė J, Valeika V (2011) Application of commercial essential oils of eucalyptus and lavender as natural preservative for leather tanning industry. REV. CHIM. (Bucharest). 62: 884-893. https://doi.org/10.37358/Rev.Chim.1949

Sivakumar V, Balakrishnan PA, Muralidharan C, Swaminathan G (2010) Use of ozone as a disinfectant for raw animal skins—application as short-term preservation in leather making. Ozone Sci Eng 32:449–455. https://doi.org/10.1080/01919512.2010.515524

States DJ, Gish W, Altschul SF (1991) Improved sensitivity of nucleic acid database searches using application-specific scoring matrices. Methods 3:66–70. https://doi.org/10.1016/S1046-2023(05)80165-3

Štěpánová V, Kelar J, Slavíček P et al (2017) Surface modification of natural leather using diffuse ambient air plasma. Int J Adhes Adhes 77:198–203. https://doi.org/10.1016/j.ijadhadh.2017.05.004

Tamil Selvi A, Brindha V, Vedaraman N et al (2020) Eco-friendly curing of hides/ skins using phyto based Citrus limon leaves paste. J Clean Prod 247:119117. https://doi.org/10.1016/j.jclepro.2019.119117

Thanikaivelan P, Rao JR, Nair BU, Ramasami T (2005) Recent trends in leather making: processes, problems, and pathways. Crit Rev Environ Sci Technol 35:37–79. https://doi.org/10.1080/10643380590521436

Tian Z, Wang Y, Wang H, Zhang K (2020) Regeneration of native collagen from hazardous waste: chrome-tanned leather shavings by acid method. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-020-09183-4

Trifunschi S, Munteanu M, Agotici V et al (2015) Determination of flavonoid and polyphenol compounds in viscum album and allium sativum extracts. Int Curr Pharm J 4:382–385. https://doi.org/10.3329/icpj.v4i5.22861

Vaduganathan L (2017) The Ozone treatment for Elimination of toxic waste—an alternate for preservation of goat skins and enhancement of bleaching property of starch. J Adv Chem 1(13):6005–6010. https://doi.org/10.24297/jac.v13i11.5883

Venkatachalam PS, Sadulla S, Duraisamy B, Krishnamurthi VS (1977) Short-term preservation of hide with neem oil. J Soc Leather Technol Chem 61:24

Vinodhkumar M, Brindha V, Kanagaraj J et al (2016) Phyto-Based Preservation of Raw Skins for Salinity Reduction in Tannery Wastewater. LFJ 16:113–132. https://doi.org/10.24264/lfj.16.2.3

White TJ, Bruns T, Lee S, Taylor J (1990) Amplification and direct sequencing of fungal ribosomal RNA Genes for phylogenetics. PCR protocols: a guide to methods and applications. Academic Press, New York, pp 315–322

Windler L, Height M, Nowack B (2013) Comparative evaluation of antimicrobials for textile applications. Environ Int 53:62–73. https://doi.org/10.1016/j.envint.2012.12.010

Xu Z, Guan X, Liu J et al (2017) Improving collagen extraction through an alternative strategy based on succinic anhydride pretreatment to retain collagen’s triple-helix structure. J Appl Polym Sci 134:45424. https://doi.org/10.1002/app.45424

Yao Q, Chen H, Huang H, Liu B (2018) Mechanism and effect of hydroxyl-terminated dendrimer as excellent chrome exhausted agent for tanning of pickled pelt. J Clean Prod 202:543–552. https://doi.org/10.1016/j.jclepro.2018.08.164

You X, Gou L, Tong X (2016) Improvement in surface hydrophilicity and resistance to deformation of natural leather through O2/H2O low-temperature plasma treatment. Appl Surf Sci 360:398–402. https://doi.org/10.1016/j.apsusc.2015.11.030

Zhiyuan W, Gu H, Wuyong C (2013) Antimicrobial leather: preparation, characterization and application. J Soc Leather Technol Chem 97:154–165

Acknowledgements

Authors are thankful to Central Analytical Facility Lab, Manipal University Jaipur and CSIR-National Chemical Laboratory, Pune for carrying out characterization technique like, FTIR, fungal species identification by BLAST. Authors acknowledge financial support of DST-FIST for X-ray Diffractometer (GNR APD 2000 PRO) at Institute of Research and Development, Gujarat Forensic Sciences University, Gandhinagar, Gujarat.

Funding

This experimental work did not receive any grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vajpayee, M., Singh, M., Dave, H. et al. Antimicrobial finishing of hide/leather by atmospheric pressure plasma and extracts of Cassia renigera and Cassia fistula bark. Rend. Fis. Acc. Lincei 31, 1105–1116 (2020). https://doi.org/10.1007/s12210-020-00954-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12210-020-00954-2