Abstract

In this work, a procedure is proposed for the direct analysis of powdered refreshments by fast sequential flame atomic absorption spectrometry (FS-F AAS), after a simple treatment of the sample. A full 23 factorial design was applied, and the variables chosen were as follows: acid concentration, acid type, and sonication time. Optimization provided the best conditions considering a mass of powdered refreshment of about 0.18 g diluted to a final volume of 15 mL with 0.5 mol L−1 HCl. The matrix effect was investigated, and external calibration was feasible for the determination of Cd, Co, Cu, Fe, Mg, Mn, Ni, Pb, and Zn. The limit of quantification (LoQ) obtained was between 0.6 (Cd) and 25 mg kg−1 (Pb). The analyte addition and recovery test were applied to evaluate the accuracy, and recovery percentage values ranging from 83.9 to 109.7% were obtained, which is considered adequate for quantitative analysis. Precision was expressed as relative standard deviation (% RSD); it was less than or equal to 5.0% (n = 7) for all analytes. The procedure was applied to 21 samples of powdered refreshment commercialized in Salvador (Brazil) and Buenos Aires (Argentina). The concentration range and average of the analytes in the samples (in mg kg−1) commercialized in Brazil (BZ) and Argentina (AG) were as follows: Co (BZ < 6.4–9.94, average 8.85; AG < 6.4–10.3, average 9.92), Fe (BZ < 6.9–376, average 270; AG < 6.9–32.81, average 29.11), Mg (BZ < 8.9–363, average 140; AG 770–3139, average 1464), Mn (BZ < 3.2–4.88, average 4.24; AG < 6.9), and Zn (BZ < 1.4–1.68, average 1.68; AG < 1.4). The concentrations of Cd, Cu, Ni, and Pb were lower than the LoQ of the proposed analytical method. For refreshment samples commercialized in Buenos Aires (Argentina), high concentrations of Mg were found in their chemical composition, but Mg had been used as anti-caking agent along with the other components.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Juices and refreshments are widely consumed foods around the world. They have a pleasant taste and are a good source of hydration and of minerals that are important for the human diet (Pinheiro et al. 2006). Currently, there are several types of processed juices available in the market that differs by the percentage of natural juice present in their content. Due to their low economic cost, these refreshments are consumed by a large portion of the population. The powdered refreshments have dyes, inorganic constituents, sweeteners, pH regulators, flavourings, stabilizers, fruit pulp extracts, and other chemical additives present in their composition (De Oliveira et al. 2006). Therefore, it is considered to be complex matrices.

The industrialized products, in order to be marketed, must comply with a series of norms, regulations, and laws that are created and supervised by governmental organs of the country (de Sousa 2006). All products must have labels that identify their origin, composition, and nutritional characteristics, facilitating their inspection. In Brazil, the National Agency for Health Surveillance (Agência Nacional de Vigilância Sanitária, ANVISA) and the Ministry of Agriculture, Livestock, and Food Supply (Ministério da Agricultura, Pecuária e Abastecimento, MAPA), linked to Ministry of Health, are responsible for supervising the production and marketing of food, guaranteeing quality control of the final product that reaches consumers (Ferrarezi et al. 2010).

Investigating the mineral composition in foods has been important to ensure food safety and food quality control. These are sources of minerals, but their production and storage processes can also be a potential source of contaminants which can cause serious harm to consumers’ health (King et al. 2017).

Food analyses in general can be performed using spectroanalytical techniques which are widely used mainly because of their ability for multi-elementary determination (de Campos et al. 2010; De Assis et al. 2008; Szymczycha-Madeja and Welna 2013). These techniques, for the most part, have a sample introduction system where the sample must be in the form of a solution that is aspirated or pumped. For this, the matrix under study needs to be mineralised or adequately prepared to allow for sample introduction and for analysis by the chosen analytical technique (Krug and Rocha 2016; Oliveira 2003). However, one can also carry out direct introduction of a sample in most of these techniques.

Direct sample analysis can be used for solids, slurries, and liquids after minimal treatment. In most liquid samples, simple dilution or emulsification are performed, followed by direct introduction into the instrument chosen for analysis. However, some liquid samples present complex matrices with a high fat content. These require more aggressive treatment to make the analytes available (Krug and Rocha 2016). The direct introduction of these samples with high solids content and viscosity can cause spectral and non-spectral interference during measurements (Szymczycha-Madeja et al. 2014).

The solid samples, by means of some techniques, can be analysed directly without the necessity of conversion into a solution. Among these techniques are graphite furnace atomic absorption spectrometry (GF AAS), arc spark optical emission spectrometry, and laser ablation inductively coupled plasma optical emission spectrometry (LA-ICP OES). These are based on combustion reactions. Another way to do direct analysis is by forming a slurry. This form of introduction for analysis is distinguished by the simplification of the pre-treatment stage of the sample which reduces the time of analysis and preparation, reduces contamination and loss of volatile elements, and reduces reagent consumption among other advantages (Galuch et al. 2018; Krug and Rocha 2016; Nascentes et al. 2004; Tormen et al. 2011). However, adequate homogeneity is required because the high solid concentration and particle size may interfere with the accuracy of the determinations (Silva and Nóbrega 2002).

The development of analytical methods for direct analysis has been proposed, but it must be optimized to make the methods efficient, accurate, and precise. In this way, simultaneous experimental design, when applied to the optimization of an analytical method, stands out by reducing the number of experiments and, consequently, reducing the preparation time of samples for analysis and the quantities of reagents used (Da Costa et al. 2013; Santos et al. 2011). The use of multiple responses is an alternative for the analysis of the results obtained when several data are generated at a one time, considering a simultaneous evaluation of the observed chemical system (Ferreira 2015).

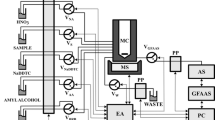

Multi-elementary determination employing fast sequential flame atomic absorption spectrometry (FS-F AAS) has been shown to be a simple alternative for chemical analysis. The advantage of using this technique is that sequential determination can be made through the rapid selection of a lamp by using an automatic selection mirror. It carries four lamps mounted in fixed positions, and the control of the experimental conditions is carried out by a computer program which sweeps the chosen wavelengths for the chemical elements during the aspiration of the sample, increasing the productivity of the analytical technique. The construction of the double beam spectrometer guarantees a stable baseline (De Assis et al. 2008; Projahn et al. 2004).

In this context, an analytical method was developed for the determination of Cd, Co, Cu, Fe, Mg, Mn, Ni, Pb, and Zn in powdered refreshments using FS-F AAS after simple treatment of a sample.

Materials and Methods

Reagents and Solutions

The reagents used in the experimental procedure were all of analytical grade. The solutions used were prepared with HNO3 65% m m−1 (Merck, Darmstadt, Germany), HCl 37% m m−1 (Merck, Darmstadt, Germany), H2O2 30% m m−1 (Merck, Darmstadt, Germany), and deionized water. The multi-elementary solutions were prepared from stock elemental solutions containing 1000 mg L−1 (Qhemis high purity, Hexis Científica, Jundiaí, Brazil) of the elements Cd, Co, Cu, Cr, Fe, Mg, Mn, Ni, Pb, and Zn. The analytical curves were obtained from 0.025 to 0.25 mg L−1 for Cd, Co, Cu, Mn, Ni, and Zn; 1.5 to 15.0 mg L−1 for Fe; 0.2 to 2.0 mg L−1 for Mg; and 0.1 to 1.0 mg L−1 for Pb. Laboratory glassware was conditioned for 24 h in 10% v v−1 nitric acid solution for cleaning. The glass material was rinsed with deionized water before use and dried in a dust-free environment.

Instrumentation

The difference equipments were used to determine the inorganic constituents in powdered refreshment: (1) a Marq Labor microprocessed digital forced air circulation oven (Model ES/CF230, São Paulo), (2) an ultrasonic bath with a frequency of 37 kHz (model Elmasonic E15H, Elma Ultrasonic Cleaner, Germany), (3) a Mettler digital analytical balance (model Toledo AB 204–5), and (4) a flame atomic absorption spectrometer equipped with fast sequential mode (model AA240FS, Agilent Technologies, Mulgrave, Australia), using a stoichiometry of the flame of air and acetylene with a flow rate of 13.5 L min−1 and 2.0 L min−1, respectively. A deuterium lamp was used to correct the background radiation. The analytes concentrations were measured at the following wavelengths and lamp currents of the hollow cathode lamps, respectively: Cd (228.8 nm and 5.0 mA), Cd (240.7 nm and 10.0 mA), Cu (324.8 nm and 10.0 mA), Cr (357.9 nm and 10.0 mA),, Fe (372.0 nm and 10.0 mA), Mg (285.2 nm and 10.0 mA), Mn (279.5 nm and 10.0 mA), Ni (232.0 nm and 10.0 mA), Pb (217.0 nm and 5.0 mA), and Zn (213.9 nm and 5.0 mA).

Collection and Pre-treatment of the Samples

Twenty-one samples of flavoured refreshment and diversified brands were purchased. Fifteen samples were from supermarkets in the city of Salvador (Bahia, Brazil), and six samples were acquired in the city Buenos Aires (Buenos Aires, Argentina).

Initially, the samples (sachets of approximately 26 g) were ground with a grade and pistil for better homogenisation of the grain size, because samples of the different brands had different particle sizes. After this, the particle sizes were closer to each other in order to achieve better homogeneity. The samples were then placed in polyethylene flasks, oven dried at 40 °C for at least 12 h, and then stored in a desiccator to preserve the low humidity throughout the experimental development.

Preparation of the Refreshment Samples

The sample preparation procedure consisted of simply diluting the powdered refreshment sample in acidic media with agitation for dissolution of the sample. A mass of approximately 0.18 g of powdered refreshment was measured into a 15.0-mL centrifuge tube. A volume of 5.0 mL of deionized water and volume of 0.62 mL of HCl (37% m m−1) were added. The final volume was completed to 15.0 mL with deionized water. The solution was agitated for homogenisation. The final concentration of the HCl solution obtained from this dilution was 0.5 mol L−1.

Optimization of Sample Preparation Procedure

A two-level factorial design was applied to optimize the sample preparation for direct introduction into a nebulization system by FS-F AAS. The following factors were evaluated in the experimental domain: acid type (HNO3 and HCl), acid concentration (0.1–0.5 mol L−1), and sonication time (0–10 min). There was a total of 16 experiments with the central point ran in triplicate. The experimental data were analysed using Statistica® software version 6.0 (Statsoft, Tulsa, OK, USA), obtaining the graphs and geometric figures, as well as the trends that indicate the optimized condition with the optimal condition with domains of the studied factors.

Results and Discussion

Study of the Amount of Mass for Sequential Determination Using 2k Factorial Design

A study was carried out on the amount of mass that would be used to prepare the solutions during the development of the analytical method. For this, a sample (A) of grapefruit flavoured powder was purchased from a supermarket in the city of Salvador.

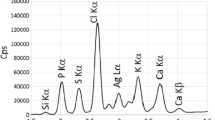

The study consisted of measuring the sample in triplicate, varying the mass from 0.20 g to 1.00 g with intervals of 0.20 g to 0.20 g, and diluting it with a solution of 2.0 HNO3 mol L−1 for final volume of 25 mL. The objective of this test was to know the maximum amount of mass that could be used during the analysis without any deposits in the burner. Thus, the absorbances for the Ca, Co, Cr, Cu, Fe, K, Mg, Mn, Na, Ni, and Zn were measured using FS-F AAS. Based on the absorbance measurements found for chemical elements, the mass was defined and which analytes would be used to compose the multiple responses of the experimental design to be applied to optimize the preparation of the sample.

The Ca, Na, and K elements showed high absorbance and need to be part of a separate study which was not performed in this part of the work. On other hand, it was decided to evaluate only the microelements. For determination of Cu, Co, Cr, and Ni, the absorbances were not measurable (about zero), so they were not taken into account in composing the multiple responses. Finally, the elements Fe, Mn, Zn, and Mg presented a linear relationship between the sample mass and absorbance so they were taken into account and used to establish the mass used in the proposed procedure. According to the study, it was noted that the relationship between the mass and the absorbance signal was proportionally linear with a correlation coefficient of 0.94, presenting a strong correlation (Miller and Miller 2010).

To determine the mass, the absorbance to mass ratio for Mn, Mg, Fe, and Zn present in the commercial powdered soft drink used in the experiment was taken into account and the mass chosen was suitable. Thus, based on the foregoing, it was identified that a mass of 0.40 g could be used for the final volume of 25 mL, and this amount would not cause interference during the analyses. However, considering the reduction of the generated residues, it was defined that a mass of 0.18 g was used for a final volume of 15 mL, maintaining the mass-volume proportionality equivalent to that of the study for the subsequent analyses.

Full 23 Factorial Design to Study the Sample Preparation Conditions for Direct Introduction into the Nebulization System of FS-F AAS

In order to study the preparation conditions of the samples for direct introduction in the FS-F AAS nebulization system, a full 23 factorial design was performed with triplicate of the central point. The central point is used to determine the experimental error of the design without having to repeat the whole experiment and to better evaluate the effect of factors within the experimental domain (Ferreira 2015). Because the composition of the design includes a qualitative variable, HCl and HNO3, we chose to perform replicates of each type of acid.

Table 1 presents the matrix of the full 23 factorial design with the individual values of the absorbance signal for each analyte and the values found for multiple response. In the optimization, one wants to find the best condition that simultaneously provides the highest absorbance for all the elements chosen. In this case, it is necessary to convert all of the individual responses into a general response that represents all of the signals of the elements under study. This was possible through the application of the concept of multiple responses (MR) which consists of the sum of the individual responses after their normalization. That is, it divides the intensities obtained in wavelength by the highest intensity value within that set of values (Ferreira et al. 2007). In this way, the values found will be in a range between 0 and 1, and then all normalized individual values are added, thus obtaining MR from the following equation

where the values of 0.3417, 0.0252, and 0.0104 were the maximum absorbances obtained for Fe, Mg, and Zn, respectively, used in the proposed design.

After the simultaneous analysis of the data, the Pareto graph was generated (Fig. 1) which shows the significance of the factors and interactions between the factors studied in the proposed design.

By analysing the Pareto graph (Fig. 1), the acid type variable is observed to be the most significant factor. This negative effect indicates that there is a tendency to obtain better multiple responses when hydrochloric acid is used to dilute the samples. In a study by Morgano et al. when evaluating the efficiency of two sample preparation for fruit juice, they concluded that extraction with HCl was the most efficient for all the analytes investigated in the study (Morgano et al. 1999).

The second most significant factor was the interaction between the type of acid and the acid concentration. This showed a negative effect which indicated that the best MR value was reached when using HCl at a concentration of 0.50 mol L−1 as is observed in Table 1 (second matrix of the design in experiments 2 and 4). Another important factor was the acid concentration whose effect is positive. That indicates a better MR is obtained when a concentration of 0.50 mol L−1 is used in preparing solutions of the samples for direct introduction.

In this proposed design, the curvature had a significant effect at a 95% confidence level. That is, the curvature allows us to evaluate more deeply the effect of a factor within the studied experimental domain, the behaviour of the factors in the region of the central point, and the determination of the experimental error (Ferreira 2015).

The sonication time, the interactions between sonication time × acid type, acid concentration × sonication time, and acid concentration × sonication time × acid type were not significant in this design at the 95% confidence level. The analysis of variance (ANOVA) was also carried out and is shown Table 2. The terms in italics type were those that showed significance (p ≤ 0.05). In this design, the lack of fit was not significant with the p value higher than 0.05. This shows that there is an adequate correlation between the predicted values and experimental values. The analysis of the correlation between predicted values versus observed values is observed in Figure S1 (see the supplementary material).

Thus, based on the p value and the correlation coefficient between the predicted values versus the observed values, it was considered that the generated mathematical model is well adjusted and able to say that the design was validated. After analysis of the data and observation of the experimental factors, respective domains evaluated, and the optimal conditions found through the application of the full 23 factorial design, the condition in experiment 4 was used for the simple procedure. Therefore, in the analysis of powdered refreshment, a sample mass of 0.18 g diluted to final volume of 15 mL with solution of 0.5 mol L−1 HCl was employed, with only simple agitation for homogenisation, without the need for time of sonication.

Validation of the Analytical Method

Linearity and Matrix Effect

Linearity and matrix effect were evaluated by comparing the sensitivities (slope) of the external calibration curve and the addition of the calibration curve of the analyte, both in solution of 0.5 mol L−1 HCl. The calibration curves were constructed with concentration ranges from 0.025 to 0.25 mg L−1 for Cd, Co, Cu, Mn, Ni, and Zn; 1.50 to 15.0 mg L−1 for Fe; 0.20 to 2.0 mg L−1 for Mg; and 0.10 to 1.0 mg L−1 for Pb. The ratio between the slope of the external calibration curve and the addition of the calibration curve of the analyte was calculated, and there was no matrix effect when the values obtained from this ratio were between 0.90 and 1.10 (Brandao et al. 2010; Pinho et al. 2009).

In Table S1 (see supplementary material), the ratios between the sensitivities of the two curves can be observed. For determination of Fe (248.3 nm) and Pb (283.3 nm), the analyte addition curves did not present linearity, implying values of 0.65 and 0.87, respectively. These interferences were overcome using other absorption lines for these analytes, a less sensitive line for Fe (372.0 nm) and a more sensitive line for Pb (217.0 nm). The absorption lines chosen did not show matrix effect for the wavelength, since the ratios ranged from 0.94 to 1.07. Thus, no interference of the matrix in obtaining an analytical signal was verified by FS-F AAS, demonstrating that the external calibration technique is efficient for procedure proposed (Froes et al. 2009; Ribani et al. 2004).

Limit of Detection and Limit of Quantification

The values of the limits of detection (LoD) and limit of quantification (LoQ) were obtained through the standard deviation (SD) from ten measures of the absorbances of analytical blank solutions multiplied by three and ten times, respectively, and divided by the slope (S) of the equation of the line of the external calibration curve for each inorganic constituent (ANVISA 2017). The LoD values obtained ranged from 0.2 mg kg−1 for Cd to 7.4 mg kg−1 for Pb. On the other hand, LoQ values ranged from 0.6 mg kg−1 for Cd to 25 mg kg−1 for Pb.

Precision and Accuracy

The precision of the method was evaluated in terms of repeatability expressed as the relative standard deviation from the results of seven replicates of the refreshment sample employing the analytical method proposed in which the sample was added at two concentration levels. The RSD values obtained ranged from 2.5 to 4.8% (n = 7). This is considered to be good precision for quantitative chemical analysis. Table 3 presents the LoD, LoQ, and RSD values obtained by the analytical method for analysis of refreshment samples by FS-F AAS.

Accuracy was confirmed, though an addition and recovery test was performed at two levels. After the test, the values found varied between 83.9 ± 17.3% (Mg) and 109.7 ± 4.3% (Mn) as shown Table 4. The values of the recovery percentages found showed that the analytical method confirms good accuracy and, even with the high organic matter content of the sample, indicated that there is no difference in viscosity between the external calibration curve and the directly introduced sample solution. This indicates that the matrix effect does not interfere with the determination of Cd, Co, Cu, Fe, Mg, Mn, Ni, Pb, and Zn in refreshment samples by FS-F AAS.

A comparison with a different method was carried out after simple treatment of the sample through the procedure of direct introduction and analysis by ICP OES. For this, five different samples were used as shown in Table 5. During the determination of Zn by FS-F AAS, a non-ideal behaviour was observed in the absorption process causing a deviation from linearity which implied a reduction of the working range. Thus, the concentration measurements for Zn were offering the same concentration absorbance measurements for the different samples used because they were outside of the linear range.

In order to overcome this limitation, the determination of Zn was performed in a mono-elementary determination. The strategy was to adjust the burner position. This reduced the optical path size and consequently the absorption line sensitivity in order to meet the increased ratio of the working range, which was extended to 4.0 mg L−1 with this strategy. The range was previously limited to 0.50 mg L−1.

For all samples analysed, the concentration values of Cd, Co, Cu, Mn, Ni, and Pb were below the LoQ for the analytical method proposed. For the other analytes, the F test was applied first to analyse the analysis of variances between the concentrations found in the two analytical methods. The results showed that there was no significant difference at the 95% confidence level. Then, the paired t test was applied for concentrations of Mg and Zn. The resulting values of tcalculated did not exceed tcritical, which indicates that there was no significant difference between the means when comparing the two methods.

For Fe concentration, it was possible to determine the concentration in only one sample, because the others were below the LoQ (< 6.9 mg kg−1). In this case, the replicates of the quantified sample were used for comparison. The F test was applied to the results and then the t test assuming equivalent variances. This verified that there was no significant difference between the results at the 95% confidence level. Thus, it can be concluded that the procedure proposed for the direct analysis of refreshment samples by FS-F AAS does not present a significant difference in the determination of Fe, Mg, and Zn in relation to the method of direct analysis by ICP OES.

Analytical Application

The proposed analytical method was applied for analyses of 21 samples of powdered refreshments for the determination of Cd, Co, Cu, Fe, Mg, Mn, Ni, Pb, and Zn by FS-F AAS. The powdered refreshment samples were purchased at commercial establishments in the cities of Salvador (Brazil, n = 15) and Buenos Aires (Argentina, n = 6). The results obtained are shown in Table 6.

For fifteen refreshment samples commercialized in Salvador, Brazil, it can be observed that the concentrations obtained using the proposed methodology varied between < 6.4 and 9.94 ± 0.33 mg kg−1 for Co (average 8.85 mg kg−1), < 6.9 and 376 ± 10 mg kg−1 for Fe (average 270 mg kg−1), < 8.9 and 363 ± 8 mg kg−1for Mg (average 140 mg kg−1), < 3.2 and 4.88 ± 0.10 mg kg−1 for Mn (average 4.24 mg kg−1), and < 1.4 and 1.68 ± 0.36 mg kg−1 for Zn (average 1.68 mg kg−1). For these samples, the concentrations of the elements Cd, Pb, Ni, and Cu were below the LoQ of the proposed method.

On the other hand, the six refreshment samples commercialized in Buenos Aires, Argentina, had concentrations ranging from < 6.9 to 32.81 ± 1.14 mg kg−1 for Fe (average 29.11 mg kg−1), < 6.4 to 10.3 ± 0.4 mg kg−1 for Co (average 9.92 mg kg−1), and 770 ± 16 and 3139 ± 6 mg kg−1for Mg (average 1464 mg kg−1). For all samples from Argentina, the concentrations of the elements Cd, Co, Cu, Mn, Ni, Pb, and Zn were below the LoQ of the proposed method.

Samples commercialized in Buenos Aires (Argentina) were found to have high concentrations of Mg in their chemical composition. This may be related to the fact that magnesium oxide (MgO), rather than calcium phosphate (Ca3PO4), had been used as anti-caking agent in the components of the refreshment collected in Buenos Aires (Argentina). These additives are used to decrease the hygroscopic characteristics of food and prevent the particles from bonding together (Damodaram et al. 2010).

The ANVISA, according to Collegiate Board Resolution (Resolução da Diretoria Colegiada—RDC) No. 269, discriminates the specified amounts of the amounts of minerals that should be consumed daily to meet the nutritional needs of the majority of individuals in a healthy population (ANVISA 2004). The values for the recommended daily intake (RDI) of minerals for an adult are as follows: Ca (1000 mg), Cu (900 μg), Cr (35 μg), Fe (14 mg), F (4 mg), P (700 mg), I (130 μg), Mg (260 mg), Mo (45 μg), Se (34 μg), and Zn (7 mg). Taking into consideration the values indicated for the recommended daily intake of minerals for an adult, the following can be concluded: (1) the concentration of Cu in the samples evaluated does not contribute to the daily intake requirement recommended; (2) in order to supply the concentration of Fe according to the RDI, it would be necessary to consume about 6.70 g of the GUA 5 refreshment, which has a relatively high amount of Fe; (3) the concentration of Mn present in the MAG 5 brand refreshment, the highest concentration found among the samples, would only supply the RDI if approximately 84.84 g was ingested and this is equivalent to approximately 3 packets per day; and (4) the RDI of the Mg concentration would be supplied if one ingested about 13.61 g of the MAZ 8 refreshment. In spite of supplying the need for Mg, the consumption of this quantity of this powdered refreshment could lead to other problems that are mainly related to the large amount of sugars in this product.

Conclusions

The proposed method for sequential determination of Co, Fe, Mn, Mg, and Zn in powdered refreshment samples by FS-F AAS was suitable. The simple treatment of a sample with 0.5 mol L−1 HCl and subsequent analysis has the advantage of reducing the possibility of contamination and loss of analyte, because little manipulation of the sample occurs when compared to conventional digestion procedures.

The use of the full 2k factorial design in the optimization of the method allowed us to find a better experimental condition with a small amount of experiments. The proposed analytical method presented good accuracy. The precision also presented satisfactory results with RSD values lower than 5.0% (n = 7). Thus, the methodology provided good analytical frequency, accuracy, repeatability, and low generation of residues.

For all of the refreshment samples, the concentrations of Cd, Cu, Ni, and Pb were below the LoQ of the proposed analytical method. The concentrations of Mg in refreshments samples from Buenos Aires (Argentina) present higher values than those found in Brazil. According to the RDI for an adult, the concentration of Fe found would supply the RDI, by consuming about 6.70 g of GUA 5 brand powdered refreshment, because of its high amount in the sample composition.

Finally, it was concluded that the figures of merit of the analytical method proposed were adequate for a quantitative analysis of refreshment samples, ensuring reliability of the analytical results. In addition, the analytical method was considered to be fast and simple with the application of a treatment for refreshment sample preparation and determination of the inorganic constituents by FS-F AAS.

References

ANVISA (2004) Consulta Pública no. 80, de 13 de dezembro de 2004. D. O. U de 17/12/2004. Retrieved from http://www.anvisa.gov.br/divulga/consulta/index.htm%0A. Accessed 02 may 2018

ANVISA (2017) RDC N. 166, de 25 de Julho de 2017, Dispõe sobre a validação de métodos analíticos e dá outras providências. Ministerio Da Saúde, 2017, 1–21. Retrieved from http://portal.anvisa.gov.br/documents/10181/2721567/RDC_166_2017_COMP.pdf/d5fb92b3-6c6b-4130-8670-4e3263763401. Accessed 02 may 2018

Brandao GC, de Jesus RM, da Silva EGP, Ferreira SLC (2010) Use of slurry sampling for the direct determination of zinc in yogurt by high resolution-continuum source flame atomic absorption spectrometry. Talanta 81(4–5):1357–1359. https://doi.org/10.1016/j.talanta.2010.02.033

Da Costa SSL, Lima Pereira AC, Andrade Passos E, Hora Alves JDP, Borges Garcia CA, Oliveira Araujo RG (2013) Multivariate optimization of an analytical method for the analysis of dog and cat foods by ICP OES. Talanta 108:157–164. https://doi.org/10.1016/j.talanta.2013.03.002

Damodaram S, Parkin KL, Fennema OR (2010) Química dos alimentos de Fennema, 4th edn. Artmed, Porto Alegre

De Assis RA, Küchler IL, Miekeley N, Da Silveira CLP (2008) Elementos-traço e sódio em suco de uva: Aspectos nutricionais e toxicológicos. Quim Nova 31(8):1948–1952. https://doi.org/10.1590/S0100-40422008000800006

de Campos EMF, Rogoni TT, Massocatto CL, Diniz KM, Caetano J, Dragunski DC (2010) Quantificação de minerais em sucos industrializados. Arquivos de Ciências Da Saúde Da UNIPAR 14(1):11–16

Oliveira, C. H. De, Binotti, R. S., Quagliara, P. C., & Rebechi, M. (2006). Substâncias químicas presentes em sucos de frutas em pó comercializados no Brasil Chemical components present in powdered fruit juices commercially available in Brazil

de Sousa CP (2006) Segurança alimentar e doenças veiculadas por alimentos: utilização do grupo coliforme como um dos indicadores de qualidade de alimentos. Revista APS 9(1):83–88 Retrieved from http://www.ufjf.br/nates/files/2009/12/Seguranca.pdf

Ferrarezi AC, Dos Santos KO, Monteiro M (2010) Avaliação crítica da legislação brasileira de sucos de fruta, com ênfase no suco de fruta pronto para beber. Revista de Nutricao 23(4):667–677. https://doi.org/10.1590/S1415-52732010000400016

Ferreira SLC (2015) Introdução às técnicas de planejamento de experimentos. Vento Leste, Salvador

Ferreira SLC, Bruns RE, Ferreira HS, Matos GD, David JM, Brandão GC, da Silva EGP, Portugal LA, dos Reis PS, Souza AS, dos Santos WNL (2007) Box-Behnken design: an alternative for the optimization of analytical methods. Anal Chim Acta 597(2):179–186. https://doi.org/10.1016/j.aca.2007.07.011

Froes RES, Borges Neto W, Naveira RLP, Silva NC, Nascentes CC, da Silva JBB (2009) Exploratory analysis and inductively coupled plasma optical emission spectrometry (ICP OES) applied in the determination of metals in soft drinks. Microchem J 92(1):68–72. https://doi.org/10.1016/j.microc.2008.12.008

Galuch MB, Piccioli AFB, Neto ES, Fier N, Saldan NC, Garcia EE (2018) Microemulsion as sample preparation for direct flame atomic absorption spectrometry (FAAS) determination of total iron in crude and refined vegetable oils. J Braz Chem Soc 29(4):748–756. https://doi.org/10.21577/0103-5053.20170197

King T, Cole M, Farber JM, Eisenbrand G, Zabaras D, Fox EM, Hill JP (2017) Food safety for food security: relationship between global megatrends and developments in food safety. Trends Food Sci Technol 68:160–175. https://doi.org/10.1016/j.tifs.2017.08.014

Krug FJ, Rocha FRP (2016) Métodos de Preparo de Amostras: Fundamentos sobre métodos de preparo de amostras orgânicas e inorgânicas para análise elementar, 2nd edn. Edição do autor, Piracicaba

Miller JNM, Miller JC (2010) Statistics and chemometrics for analytical chemistry. In: Technometrics, 6th edn. Pearson, London. https://doi.org/10.1198/tech.2004.s248

Morgano MA, Queiroz SC d N, Ferreira MMC (1999) Determinação dos teores de minerais em sucos de frutas por espectrometria de emissão óptica em plasma indutivamente acoplado (ICP-OES). Cienc Tecnol Aliment 19(3). https://doi.org/10.1590/S0101-20611999000300009

Nascentes CC, Arruda MAZ, Nogueira ARA, Nóbrega JA (2004) Direct determination of Cu and Zn in fruit juices and bovine milk by thermospray flame furnace atomic absorption spectrometry. Talanta 64(4):912–917. https://doi.org/10.1016/j.talanta.2004.04.004

Oliveira E (2003) Sample preparation for atomic spectroscopy: evolution and future trends. J Braz Chem Soc 14(2):174–182. https://doi.org/10.1590/S0103-50532003000200004

Pinheiro AM, Fernandes AG, Fai AEC, Prado G, Do M, De Sousa PHM, Maia GA (2006) Avaliação química, físico-química e microbiológica de sucos de frutas integrais: abacaxi, caju e maracujá. Cienc Tecnol Aliment 26(1):98–103. https://doi.org/10.1590/S0101-20612006000100017

Pinho GP, Neves AA, Queiroz MELR, Silvério FO (2009) Efeito de matriz na quantificaçao de agrotóxico por cromatografia gasosa. Química Nova 32(4):987–995. https://doi.org/10.1590/S0100-40422009000400030

Projahn HD, Steeg U, Sanders J, Vanclay E (2004) Application of the reference-element technique for fast sequential flame atomic-absorption spectrometry. Anal Bioanal Chem 378(4):1083–1087. https://doi.org/10.1007/s00216-003-2200-y

Ribani M, Bottoli CBG, Collins CH, Jardim ICSF, Melo LFC (2004) Validação de métodos cromatográficos e eletroforéticos. Quim Nova 27(5):771–780. https://doi.org/10.1590/S0100-40422004000500017

Santos JS, Teixeira LSG, Araújo RGO, Fernandes AP, Korn MGA, Ferreira SLC (2011) Optimization of the operating conditions using factorial designs for determination of uranium by inductively coupled plasma optical emission spectrometry. Microchem J 97(2):113–117. https://doi.org/10.1016/j.microc.2010.08.002

Silva CS, Nóbrega JA (2002) Análise De Suspensões De Argilas Por Espectrometria De Emissão Óptica Com Plasma Induzido Com Configuração Axial. Quim Nova 25(6):1194–1196

Szymczycha-Madeja A, Welna M (2013) Evaluation of a simple and fast method for the multi-elemental analysis in commercial fruit juice samples using atomic emission spectrometry. Food Chem 141(4):3466–3472. https://doi.org/10.1016/j.foodchem.2013.06.067

Szymczycha-Madeja A, Welna M, Jedryczko D, Pohl P (2014) Developments and strategies in the spectrochemical elemental analysis of fruit juices. TrAC - Trends Anal Chem 55:68–80. https://doi.org/10.1016/j.trac.2013.12.005

Tormen L, Torres DP, Dittert IM, Araújo RGO, Frescura VLA, Curtius AJ (2011) Rapid assessment of metal contamination in commercial fruit juices by inductively coupled mass spectrometry after a simple dilution. J Food Compos Anal 24(1):95–102. https://doi.org/10.1016/j.jfca.2010.06.004

Funding

This work was supported by Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq, Brazil), Fundação de Amparo à Pesquisa do Estado da Bahia (FAPESB, Brazil), and Programa de Apoio a Jovens Professores Doutores (PROPESQ/UFBA, Brazil—Edital PROPCI/PROPG No. 004/2016), providing scholarship, financial support, and infrastructure.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Joelem de Carvalho Melo declares that he has no conflict of interest. Wellington Correia Carvalho declares that she has no conflict of interest. Elane S. Boa Morte declares that she has no conflict of interest. Rennan Geovanny Oliveira Araujo declares that he has no conflict of interest. Daniele Cristina M. B. Santos declares that he has no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals.

Informed Consent

Not applicable for this study.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

ESM 1

(DOCX 29 kb)

Rights and permissions

About this article

Cite this article

Melo, J.C., Carvalho, W.C., Boa Morte, E.S. et al. Sequential Determination of Cd, Co, Cu, Fe, Mg, Mn, Ni, Pb, and Zn in Powdered Refreshments by FS-F AAS After a Simple Sample Treatment. Food Anal. Methods 13, 212–221 (2020). https://doi.org/10.1007/s12161-019-01589-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-019-01589-2