Abstract

Cu-based metal-organic frameworks modified by silver (Ag/Cu-MOFs) were in situ fabricated through a one-step direct synthesis. The as-prepared mixed-node MOFs were modified on glassy carbon (GC) electrode, which was utilized as a voltammetric sensor for probing malachite green. Compared with the bare GC electrode, the introduced Ag/Cu-MOF film on the electrode surface dramatically improved the sensitivity of the sensor response according to the accumulation and catalytic activity of Ag/Cu-MOFs for malachite green. The developed electrochemical sensor exhibited a low detection limit of 2.2 nM with a wide linear range of 10–140 nM and high anti-interference ability. The feasibility of the assay was verified by test of malachite green in fish sample. The proposed strategy presents valuable information for the evaluation of the food safety in aquaculture industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Malachite green as an industrial triphenylmethane dye is also widely used in the aquaculture industry owing to its effectiveness against fungal and parasite infection in fish (Culp and Beland 1996). Malachite green has a long life in fish and can lead to some side effects, such as high toxins, high residual, carcinogenic, teratogenic, and mutation. Consequently, eating contaminated fish may result in serious problems for human health (Srivastava et al. 2004; Zusková et al. 2007). Although malachite green is prohibited in many countries, its use in aquaculture remains common because of its highly effective parasiticide and fungicide (Fallah and Barani 2014). Thus, the search for sensitive and reliable methods for determination of malachite green in fish has attracted increasing interest.

Variety of strategies have been proposed for the detection of malachite green, which can be classified into chromatography-based methods (Chen and Miao 2010; Maxwell and Tong 2016; Nebot et al. 2013; Xie et al. 2013; Wang et al. 2015), spectroscopy-based methods (Jia et al. 2018; Ouyang et al. 2017; Stead et al. 2010; Tan et al. 2012; Wu et al. 2017; Zhang et al. 2015), enzyme-linked immunosorbent assay (ELISA) (Dong et al. 2014; Li et al. 2016; Shen et al. 2011; Wang et al. 2016), and electrochemical methods (Guo et al. 2011; Huang et al. 2015; Martín-Yerga et al. 2018; Shao et al. 2015). Chromatographic techniques with high sensitivity and accuracy have been used as standard methods in laboratory, but these methods are not suitable for in-field fast analysis of malachite green due to the expensive instruments and tedious, time-consuming pre-treatment procedure. Spectroscopy-based methods including fluorescence spectroscopy, surface plasmon resonance scattering, and the surface-enhanced Raman scattering display simplicity and high sensitivity. However, the limitations in weak anti-interference ability still exist in complex bio-matrix. ELISA with high reliability is widely used in fast inspection area, but the labor-intensive problem and the requirement of expensive enzyme-linked antibodies should not be ignored.

Electrochemical method is an attractive alternative for sensing owing to its advantages of sensitivity, simplicity, low cost, and easy miniaturization. Various materials for modification on the electrode surfaces have been widely utilized to enhance high sensitivity and chemical specificity of electrochemical sensors (Sacara et al. 2017a, b; Wang et al. 2014; Yi et al. 2008; Zhang et al. 2012). Metal-organic framewoks (MOFs) as new porous crystalline materials have been widely applied in gas storage, catalysis, separations, and sensors because of their ordered structure, large surface areas, tunable pore sizes, and tailorable chemical property (Bétard and Fischer 2012; Morozan and Jaouen 2012). Recently, MOF-based materials play a crucial role in the electrochemical sensors (Liu et al. 2018). The high porous and surface areas of MOFs could load the guest molecules and/or catalyze the targets with high electrocatalytic activity, which could generate inherent sensitivity for the electroanalysis. Despite the porosity of MOFs increase the active area of the electrode, the signal transduction is one major challenge due to the large proportion of building ligands. Additionally, the macroscale of crystalline products for most MOFs results in the low reproducibility of the electrocatalytical response. The improvement in the conductivity and the design of MOFs is still required to enhance the performances to satisfy the realistic applications of MOF-based electrochemical sensors. The two aspects may be solved by size-controlled synthesis of nanoscaled MOFs with high uniformity and utilization of mixed-node MOF for improvement of the catalytic activity (Stassen et al. 2017). It has been reported that Cu-MOFs have a high electrocatalytic activity for the targets and the introduction of catalytically active metal including gold, silver, platinum, and palladium could improve catalytic efficiency (Zhu and Xu 2014). Importantly, Cu-MOFs could adsorb malachite green in waste water (Shi et al. 2017). Therefore, the fabrication of electrochemical sensors based on the use of Cu-MOF materials should be a meaningful strategy for the detection of malachite green.

Based on above considerations, a new electrochemical sensing platform for detection of malachite green was developed based on Ag/Cu-MOF modified electrode, which was prepared by one-step direct synthesis. Morphological and structural characterization of the prepared Ag/Cu-MOFs was investigated. The analytical characteristics including sensitivity, concentration range, and stability of this fabricated Ag/Cu-MOF-modified electrode were studied. The further determination of malachite green for fish sample was also researched to test the effectivity of the method for food quality control. This strategy for analysis of malachite green is advantageous in terms of its simplicity, sensitivity, high stability, and anti-interference ability.

Experimental

Chemical Reagents

Cu(NO3)2·3H2O with the purity of > 99.999%, AgNO3 with the purity of 99.99%, 1,3,5-benzenetricarboxylic acid (BTC) with purity of >98%, and malachite green assay standard were purchased from Aladdin Chemistry Co., Ltd. (Shanghai, China). ELISA assay kit for malachite green was purchased from mlbio Co., Ltd. (Shanghai, China). All other chemicals and reagents with analytical reagent grade were used as received without any prior purification. Doubly distilled water used in all experiments was obtained from a Millipore Milli-Q gradient system (> 18 MΩ cm). 0.1 M phosphate buffer (PB) was prepared by varying the volume ratios of the solution containing Na2HPO4 and NaH2PO4. An acidic solution containing 0.04 M each of H3PO4, HOAc, and H3BO3 was used to prepare 0.04 M Britton-Robinson (BR) buffer solution by adjusting to pH 7.5 using 0.2 M NaOH. 0.1 M Tris-HCl (pH 7.5) was also prepared by varying the volume ratios of the solution containing Tris(hydroxymethyl) aminomethane and HCl.

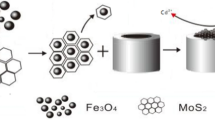

Preparation of Ag/Cu-MOFs

Ag/Cu-MOFs were prepared following the procedure described for the solvothermal synthesis, but one-step synthesis replaced the postsynthetic exchange. Typically, an aqueous solution (12 mL) of 0.365 g (1.5 mmol) Cu(NO3)2·3H2O was added to an absolute ethanol solution (12 mL) of 0.42 g (2.0 mmol) of BTC. 0.255 g AgNO3 was dissolved in the above mixture under magnetic stirring condition. The mixture was transferred into a Teflon-lined autoclave and then left in an oven at 120 °C. Next, the mixture was allowed to react for 14 h, and blue precipitates were produced. After cooling the synthesis mixture to room temperature, the precipitates were extensively washed with water and methanol via centrifugation and dried at vacuum overnight. The morphological and structural characterization was carried out on the scanning electron microscope (SEM, Quanta FEG 250), X-ray powder diffractometer (XRD, D8 Advance), energy-dispersive X-ray spectroscopy (EDS, OXFORD X-Max 50), and X-ray photoelectron spectroscopy (XPS, Thermo Fisher K-Alpha).

Fabrication of Ag/Cu-MOF-Modified Electrode

Before modification, the bare glassy carbon (GC, Φ = 3 mm) electrode was polished with aqueous slurries of fine alumina powders (i.e., 1, 0.3, and 0.05 μm, respectively) on a polishing cloth to create a mirror finish. After that, the electrode was sonicated in acetone and deionized water for 10 min in succession, and then it was dried under ambient temperature. Meanwhile, 0.5 mg mL−1 dispersions were prepared by dispersing 0.5 mg Ag/Cu-MOFs into 1 mL pure water. Then, a 10-μL as-prepared modification material was dropped on the electrode surface, and the surface loading was 5 μg. Finally, 1.0 μL 0.5% Nafion was cast onto the Ag/Cu-MOF-modified electrode surface and dried at room temperature.

All electrochemical measurements were carried out on CHI 660D electrochemical workstation (Shanghai Chenhua Instrument, China). A conventional three-electrode system (Shanghai Chenhua Instrument, China) was composed of a modified GC electrode (10 × 10 × 3 mm) as working electrode, a platinum wire as auxiliary electrode, and a Ag/AgCl electrode as reference electrode. Prior to electrochemical test, the PB was passed through the N2 gas for 15 min to remove the oxygen.

Preparation of Fish Sample

The malachite green was determined in fish sample purchased from the local market. The fish sample was immersed into the standard solution of malachite green at different concentrations for 12 h. The fish sample was filled, skinned, deboned, and further cut into small pieces. A weighed 20-g amount of carp muscle was extracted according to an acetonitrile method with a minor modification reported by Yi et al. (2008). The final residue was dissolved in 500 μL of 0.1 M PB (pH 7.5) and transferred into a vial for analysis.

Results and Discussion

Morphological and Structural Characterization

The utilization of different metal ions in the synthetic system is an effective strategy to prepare mixed-node MOFs. Sun et al. (2015) prepared a mix-node Ag/Cu-MOF by postsynthetic exchange method, and this MOF catalyst exhibited a good catalytic performance for toluene oxidation. Herein, a simple one-step synthesis was utilized for the preparation of Ag/Cu-MOFs. Both the size of MOFs and the ratio of Ag/Cu could be controlled by the regulation of the condition of synthetic process. The size and morphology of the as-synthesized Ag/Cu-MOF were characterized by SEM. As shown in Fig. 1a, the SEM images supported the crystalline nature of the Ag/Cu-MOF with size distribution from tens of nanometers to several hundred nanometers. In Fig. 1b, a new spectrum of Ag for Ag/Cu-MOFs was observed compared with that of Cu-MOFs. The EDS analysis revealed that actual Ag/Cu proportion of Ag/Cu-MOFs prepared by one-step direct synthesis was about 7.38%. The elemental mapping in Fig. 1c–e demonstrated the even distribution of Ag element, which signified the location of Ag species in the crystal lattices of Ag/Cu-MOFs (Sun et al. 2015).

The XRD patterns were also utilized to identify the prepared Ag/Cu-MOFs as shown in Fig. 2a. The Cu-MOF sample showed one strong diffraction peak of the product (i.e., (222)), which was consistent with the results reported by Sun et al. (2015). The Ag/Cu-MOFs had similar patterns with Cu-MOFs owing to the fact that the crystal structure of Ag/Cu-MOFs remained unchanged because of the isomorphous replacement for the ion exchange process. Moreover, the absence of Ag diffraction peak (2θ from 35 to 70°) in the inset of Fig. 2a further identified that Ag is located in the crystal lattices of MOFs (Misran et al. 2018). In addition, XPS measurements were conducted as shown in Fig. 2b. Besides the Cu2p, O1s, and C1s photoelectron peaks of Cu-MOFs, the Ag spectrum included a doublet at binding energy of 374.9 and 369.1 eV, which assigned to Ag 3d3/2 and Ag 3d5/2 photoelectron peaks of Ag/Cu-MOFs, respectively. The Ag/Cu proportion was calculated to be 7.65%, which was consistent with EDS analysis. The values of binding energy are higher than that of common chemical states of Ag element due to the structure of four oxygen atoms of carboxylic ligands linked with Ag in Ag/Cu-MOFs. Thus, the oxygen atoms with large electronegativity lead the increase of inner electron binding energy because of the deviation of share electron pair deviate from Ag ion. The above results reveal that the mixed-node MOFs (Ag/Cu-MOFs) have prepared by the one-step synthesis.

Voltammetric Characterization

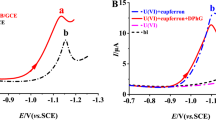

Figure 3a shows a comparison of cyclic voltammograms (CVs) for oxidation of malachite green at the bare, Cu-MOF-modified, and Ag/Cu-MOF-modified GC electrodes. Firstly, there was no oxidation peak in the blank solution without malachite green. After the addition of malachite green, well-defined oxidation peaks located at about 0.57 V (vs. Ag/AgCl) for the oxidation of malachite green and the absence of a cathodic peak on reverse sweep indicated irreversibility of the electrode process. Clearly, compared with bare GC electrode, the oxidation signal at the Cu-MOF-modified electrode increased to a certain extent due to the accumulation of malachite green on the Cu-MOF materials (Shi et al. 2017). The oxidation peak current of malachite green had a further increase at the Ag/Cu-MOF-modified electrode, which was attributed to the combined properties of accumulation and catalytic activity of Ag/Cu-MOFs. Figure 3b shows the CVs at different scan rates, and the oxidation peak current increased with increasing scan rate (Fig. 3c). There was a linear correlation between the peak current (Ip/μA) and the scan rate (υ/V s−1), and the linear equation was Ip = 23.63 υ + 3.21 (R = 0.998). Meanwhile, a linear correlation between the logarithms of peak current and the logarithm of scan rate (log Ip = 0.61 log υ + 1.34, R = 0.995) was also obtained. The results indicated the control mechanism of the adsorption process. Synchronously, an oxidation peak and a reduction peak were observed at about 0.44 V and 0.39 V, respectively, which should be a redox pair due to the accumulation effect of negatively charged Nafion and the positively charged malachite green molecules (Zhang et al. 2012).

a CVs of 0.1 M PB (pH 7.5) containing 0.5 μM malachite green on the bare (1), Cu-MOF-modified (2), and Ag/Cu-MOF-modified GC electrodes (3) at the scan rate of 25 mV s−1; curve 4 was the CV of 0.1 M PB (pH 7.5) at the Ag/Cu-MOF-modified electrode; b CVs of the Ag/Cu-MOF-modified electrode in 0.1 M PB (pH 7.5) containing 0.5 μM malachite green at the different scan rates of (1) 0.1, (2) 0.15, (3) 0.2, (4) 0.25, (5) 0.3, (6) 0.35, (7) 0.4, and (8) 0.45 V s−1; effect of the scan rate on c the oxidation peak current and d the peak potential of malachite green

Figure 3d illustrates the effect of scan rate on the oxidation peak potential. The peak potential shifted to a less positive value with the increase of scan rate, and there was a linear correlation between the peak potential and the natural logarithm of scan rate (Ep = 0.61 + 0.028 ln ʋ, R = 0.998). For the irreversible electrode process, the relationship between the oxidation peak potential and the scan rate obeys the following equation (Laviron 1974):

where E0′ is the formal standard potential, na is the number of the electron transferred in the rate determining step, α is the charge transfer coefficient, k0 is the electron transfer rate constant, F is the Faraday constant, R is the gas constant, and T is the temperature. From the slope of Fig. 3d, a value of 0.92 was obtained for αna. In general calculation, the value of α was usually assumed to be 0.5. Thus, na was estimated to be 2 for the oxidation of malachite green at the Ag/Cu-MOF-modified electrode. The electrochemical oxidation of malachite green occurs with the ejection of an integral unit of the central carbon linked to a phenyl group, which is followed by intramolecular coupling of two phenyl fragments. The process produces an electrochemically irreversible, two-electron transfer process owing to the formation of a diquinoid form (1,1′-biphenyl-4.4′-diamine, TMBOx) from N,N,N′,N′-tetramethylbenzidine (TMB) intermediate (Sacara et al. 2017a, b; Zhang et al. 2012). The two-electron transfer process for the oxidation of malachite green was postulated in Fig. 4.

For the surface-controlled process, a nearly constant charge (Q) value was acquired for the oxidation peaks with different scan rates in Fig. 3b. According to the Faraday’s law Q = nFAΓ*, the average surface coverage (Γ*) of absorbed malachite green could be estimated (Lvov and Mohwald 2000), where A is the electrode surface area. The value of Γ* was calculated as 5.9 × 10−7 mol cm−2, which was higher than the monolayer absorption owing to the high surface area of Ag/Cu-MOF material.

Optimization of the Experimental Variables

The experimental variables for determination malachite green at the Ag/Cu-MOF-modified electrode were optimized in regard to buffer system, pH value of the PB, surface loading of MOF materials, and accumulation time. The supporting electrolyte (pH 7.5) was first investigated by CVs (Fig. 5a). In all the supporting electrolyte solution, the oxidation peak around at 0.57 V was present. Compared with other supporting electrolyte solution, the oxidation peak current of malachite green was higher in the 0.1 M PB. In Fig. 5b, the effect of pH value from 6.0 to 9.0 for 0.1 M PB was carried out by differential pulse voltammetry (DPV) response rates. The peak current increased initially up to a pH of 7.5 and then gradually decreased. Therefore, 0.1 M PB (pH 7.5) was fixed as the supporting electrolyte for the following studies.

a Effect of buffer system, b pH value of the PB, c loading of MOF materials, and d accumulation time on oxidation peak current of 0.5 μM malachite green using the Ag/Cu-MOF-modified electrode. For the CV measurements (a), the scan rate was 0.2 V s−1. For the DPV measurements (b–d), the pulse amplitude was 0.005 V and a pulse width was 0.1 s

The surface loading of MOF materials was further controlled to find out the suitable thickness for effective response to malachite green, as shown in Fig. 5c. As the surface loading of MOF materials was less than 5 μg, the performance of the electrode enhanced with the increase of surface loading. The voltammetric response reached a maximum value when the surface loading was 5 μg and then decreased as the surface loading increased beyond this value. This characteristic response for the surface loading of MOFs up to 5 μg might be ascribed to two factors: the increase of active surface area of MOF materials with the increase of the surface loading and the increased barrier of electron transfer at a higher film thickness. Thus, 5 μg was selected as an optimal surface loading of MOF materials. In addition, the Nafion film also resulted in a physical barrier that hindered the electron transfer between malachite green and electrode surface. Nevertheless, without or a too thin layer of Nafion film could not keep good stability of the modified electrode (Sacara et al. 2017a). As a prerequisite, to ensure good stability, a low Nafion solution concentration of 0.5% was employed for the modification of Ag/Cu-MOFs on the electrode surface.

Finally, the accumulation time of malachite green under open-circuit potential conditions was studied from 15 to 150 s in Fig. 5d. The peak current gradually increased with increasing time from 15 s to 90 s, while it began to decrease as the accumulation time was over 90 s because the adsorption achieved balance status at 90 s. In brief, the maximum response for the 90-s accumulation was obtained and 90 s was chosen as the accumulation time for the following measurements.

Quantitative Detection of Malachite Green

Under the above optimized conditions, a typical DPV response was utilized to evaluate the sensitivity of the Ag/Cu-MOF-modified electrode in Fig. 6a. After the addition of successive aliquots of malachite green to 0.1 M PB (pH 7.5), the oxidation peak current of malachite green kept on increasing with the increasing concentration of malachite green under identical conditions. As shown in Fig. 6b, the calibration of the Ag/Cu-MOF-modified electrode to malachite green illustrated that the peak current was proportional to the concentration of malachite green. The peak current to the concentration of malachite green was linear in the range from 10 to 140 nM (R = 0.996). The detection limit could be calculated to be 2.2 nM according to the formula 3.3 sa/b at a signal-to-noise ratio of 3, where sa was the standard deviation of the background current and b was the slope of the calibration curve. The limit of quantity (10.0 nM) was also obtained based on 10 sa/b. The detection limit is lower than those obtained at the reported electrodes modified by other nanomaterials such as CeO2/Nafion (3.2 μM), new silica/Nafion (0.36 μM), multi-wall carbon nanotube (6.0 nM), and ethylenediamine/graphene oxide (5 nM) (Sacara et al. 2017a, b; Yi et al. 2008; Zhang et al. 2012). The low detection limit could be according to the accumulation and catalytic activity of Ag/Cu-MOFs for malachite green. The analytical properties, advantages, and limitations of existing methods for the detection of malachite green are summarized in Table 1. Compared with ELISA and spectroscopy-based methods, the proposed sensor is a simple and efficient method without the need for expensive instruments, labor-intensive process, and expensive enzyme-linked antibodies.

In order to explore the repeatability and reproducibility of this assay, six different Ag/Cu-MOF-modified electrodes were independently fabricated in the same way. The peak current of these electrodes to 0.5 μM malachite green was recorded, and the relative standard deviation (RSD) of the current response was 6.1% (n = 6). Furthermore, nine repetitive measurements using a modified electrode gave an RSD of 3.7%. These results verify that this modified electrode has good reproducibility and repeatability for the detection of malachite green. The long-term stability of this assay was tested by recording peak current every 3 days, and 96.4% of its initial activity can be retained after a month of storage. The long-term stability of the Ag/Cu-MOF-modified electrode could be explained by the immobilization of Nafion film.

The interference study was investigated by the detection of 0.5 μM malachite green in the presence of some species including Ca2+, Mg2+, Zn2+, Mn2+, Fe3+, Cu2+, uric acid, xanthine, and hypoxanthine in real sample. The interferences were selected because the above foreign species were possible to be found in pond water for aquaculture (Yi et al. 2008; Zhang et al. 2012). The influence of 100-fold high concentrations (100 μM) of the interfering species was inquired at the Ag/Cu-MOF-modified electrode for the detection of malachite green. No significant alteration of the current signal was detected in the presence of the above interference, which indicated that the designed assay had a good selectivity towards malachite green. Thus, the outstanding advantages of the assay with characteristics of high selectivity should be suitable for the analysis of malachite green in real systems.

Analysis of Malachite Green in Fish

It has been reported that malachite green is stored primarily in serum, liver, kidney, muscle, skin, and viscera of fish (Srivastava et al. 2004). Muscle is often used as a real sample for the detection of malachite green because of its facility of treatment (Xie et al. 2013). To verify the practicality of the developed method, the residue of malachite green was diluted using 0.1 M PB (pH 7.5) solution and was then analyzed for the evaluation of the malachite green level at this proposed electrode. No malachite green was found at detectable levels in the fish sample (S1). After the immersion of the fish sample into the standard solution of malachite green at different concentrations (20, 40, 60, 80, 100 nM, as S2, S3, S4, S5, and S6, respectively), the malachite green residue was illustrated in Table 2. The real sample was also determined by commercially available ELISA assay kit. The optical density value was monitored on a microplate reader, and the absorbance at 450 nm was utilized for the quantitative assay. The comparative results for the malachite green detection by the Ag/Cu-MOF-modified electrode and the quantitative assay kit were illustrated in Table 2, and the results displayed that there was no significant difference (P value = 0.97 > 0.05) between this method and ELISA kit. Thus, the simplicity, high sensitivity, anti-interference ability, and accuracy of the Ag/Cu-MOF-modified electrode may make it as a malachite green detector in the food analysis.

Conclusions

In summary, a simple and highly sensitive sensing platform based on Ag/Cu-MOFs was established for the detection of the malachite green by DPV. Compared with known sensors for malachite green, the proposed voltammetric sensor provided important advantages as follows. (1) Preparation of the Ag/Cu-MOF film by one-step direct synthesis was a simple and efficient technique. (2) The sensor was sensitive for the detection of the malachite green due to the adsorption and catalytic activity of Ag/Cu-MOFs. (3) The selective adsorption of malachite green on Ag/Cu-MOFs endowed the excellent anti-interference ability in real sample. Thus, the proposed electrochemical strategy provided valuable information for the analysis of malachite green levels in fish sample. The effective analysis should get us closer to find a way for the food safety of aquaculture industry.

References

Bétard A, Fischer RA (2012) Metal organic framework thin films: from fundamentals to applications. Chem Rev 112:1055–1083

Chen GY, Miao S (2010) HPLC determination and MS confirmation of malachite green, gentian violet, and their leuco metabolite residues in channel catfish muscle. J Agric Food Chem 58:7109–7114

Culp SJ, Beland FA (1996) Malachite green: a toxicological review. J Am Coll Toxicol 15:219–238

Dong JX, Xu C, Wang H, Xiao ZL, Gee SJ, Li ZF, Wang F, Wu WJ, Shen YD, Yang JY, Sun YM, Hammock BD (2014) Enhanced sensitive immunoassay: noncompetitive phage anti-immune complex assay for the determination of malachite green and leucomalachite green. J Agric Food Chem 62:8752–8758

Fallah AA, Barani A (2014) Determination of malachite green residues in farmed rainbow trout in Iran. Food Control 40:100–105

Guo ZY, Gai PP, Hao TT, Duan J, Wang S (2011) Determination of malachite green residues in fish using a highly sensitive electrochemiluminescence method combined with molecularly imprinted solid phase extraction. J Agric Food Chem 59:5257–5262

Huang BM, Zhou XB, Chen J, Wu GF, Lu XQ (2015) Determination of malachite green in fish based on magnetic molecularly imprinted polymer extraction followed by electrochemiluminescence. Talanta 142:228–234

Jia J, Yan S, Lai XX, Xu YZ, Liu T, Xiang YH (2018) Colorimetric aptasensor for detection of malachite green in fish sample based on RNA and gold nanoparticles. Food Anal Methods 11:1668–1676

Laviron E (1974) Study on the behavior of the mercury film electrode. J Electroanal Chem 52:355–393

Li L, Lin ZZ, Peng AH, Zhong HP, Chen XM, Huang ZY (2016) Biomimetic ELISA detection of malachite green based on magnetic molecularly imprinted polymers. J Chromatogr B 1035:25–30

Liu LT, Zhou YL, Liu S, Xu MT (2018) The applications of metal-organic frameworks in electrochemical sensors. ChemElectroChem 5:6–19

Lvov Y, Mohwald H (2000) In protein architecture: interfacing molecular assemblies and immobilization biotechnology. Marcel Dekker, New York, pp 125–166

Martín-Yerga D, Pérez-Junquera A, Hernández-Santos D, Fanjul-Bolado P (2018) In situ activation of thick-film disposable copper electrodes for sensitive detection of malachite green using electrochemical surface-enhanced Raman scattering (EC-SERS). Electroanalysis 30:1095–1099

Maxwell EJ, Tong WG (2016) Sensitive detection of malachite green and crystal violet by nonlinear laser wave mixing and capillary electrophoresis. J Chromatogr B 1020:29–35

Misran H, Salim MA, Ramesh S (2018) Effect of Ag nanoparticles seeding on the properties of silica spheres. Ceram Int 44:5901–5908

Morozan A, Jaouen F (2012) Metal organic frameworks for electrochemical applications. Energy Environ Sci 5:9269–9290

Nebot C, Iglesias A, Barreiro R, Miranda JM, Vázquez B, Franco CM, Cepeda A (2013) A simple and rapid method for the identification and quantification of malachite green and its metabolite in hake by HPLCeMS/MS. Food Control 31:102–107

Ouyang L, Yao L, Zhou TH, Zhu LH (2017) Accurate SERS detection of malachite green in aquatic products on basis of graphene wrapped flexible sensor. Anal Chim Acta 1027:83–91

Sacara AM, Cristea C, Muresan LM (2017a) Electrochemical detection of malachite green using glassy carbon electrodes modified with CeO2 nanoparticles and Nafion. J Electroanal Chem 792:23–30

Sacara AM, Nairi V, Salis A, Turdean GL, Muresan LM (2017b) Silica-modified electrodes for electrochemical detection of malachite green. Electroanalysis 29:2602–2609

Shao JT, Zhao YM, Liu FY, Li W, Gao YL (2015) Determination of malachite green and leucomalachite green based on electrochemiluminescence of Ru(bpy)3 2+ at graphene oxide modified glassy carbon electrodes. RSC Adv 5:14547–14552

Shen YD, Deng YF, Xu ZL, Wang Y, Lei HT, Wang H, Yang JY, Xiao ZL, Sun YM (2011) Simultaneous determination of malachite green, brilliant green and crystal violet in grass carp tissues by a broad-specificity indirect competitive enzyme-linked immunosorbent assay. Anal Chim Acta 707:148–154

Shi ZN, Li L, Xiao YX, Wang YX, Sun KK, Wang HX, Liu L (2017) Synthesis of mixed-ligand cu-MOFs and their adsorption of malachite green. RSC Adv 7:30904–30910

Srivastava S, Sinha R, Roy D (2004) Toxicological effects of malachite green. Aquat Toxicol 66:319–329

Stassen I, Burtch N, Talin A, Falcaro P, Allendorfc M, Ameloot R (2017) An updated roadmap for the integration of metal–organic frameworks with electronic devices and chemical sensors. Chem Soc Rev 46:3185–3241

Stead SL, Ashwin H, Johnston BH, Dallas A, Kazakov SA, Tarbin JA, Sharman M, Kay J, Keely BJ (2010) An RNA-aptamer-based assay for the detection and analysis of malachite green and leucomalachite green residues in fish tissue. Anal Chem 82:2652–2660

Sun ZG, Li G, Zhang Y, Liu HO, Gao XH (2015) Ag–Cu–BTC prepared by postsynthetic exchange as effective catalyst for selective oxidation of toluene to benzaldehyde. Catal Commun 59:92–96

Tan EZ, Yin PG, You TT, Wang H, Guo L (2012) Three dimensional design of large-scale TiO2 nanorods scaffold decorated by silver nanoparticles as SERS sensor for ultrasensitive malachite green detection. ACS Appl Mater Interfaces 4:3432–3437

Wang HZ, Wang Y, Liu S, Yu JH, Xu W, Guo YN, Huang JD (2014) An RNA aptamer-based electrochemical biosensor for sensitive detection of malachite green. RSC Adv 4:60987–60994

Wang YL, Liao KR, Huang XJ, Yuan DX (2015) Simultaneous determination of malachite green, crystal violet and their leuco-metabolites in aquaculture water samples using monolithic fiber-based solid-phase microextraction coupled with high performance liquid chromatograph. Anal Methods 7:8138–8145

Wang F, Wang H, Shen YD, Li YJ, Dong JX, Xu ZL, Yang JY, Sun YM, Xiao ZL (2016) Bispecific monoclonal antibody-based multi-analyte ELISA for furaltadone metabolite, malachite green and leucomalachite green in aquatic products. J Agric Food Chem 64:8054–8061

Wu L, Lin ZZ, Zhong HP, Chen XM, Huang ZY (2017) Rapid determination of malachite green in water and fish using a fluorescent probe based on CdTe quantum dots coated with molecularly imprinted polymer. Sensor Actuators B Chem 239:69–75

Xie J, Peng T, Chen DD, Zhang QJ, Wang GM, Wang X, Guo Q, Jiang F, Chen D, Deng J (2013) Determination of malachite green, crystal violet and their leuco-metabolites in fish by HPLC–VIS detection after immunoaffinity column clean-up. J Chromatogr B 913–914:123–128

Yi HC, Qu WY, Huang WS (2008) Electrochemical determination of malachite green using a multi-wall carbon nanotube modified glassy carbon electrode. Microchim Acta 160:291–296

Zhang K, Song G, Yang LX, Zhou J, Ye BX (2012) A novel self-assembly voltammetric sensor for malachite green based on ethylenediamine and graphene oxide. Anal Methods 4:4257–4263

Zhang YY, Yu WS, Pei L, Lai KQ, Rasco BA, Huang YQ (2015) Rapid analysis of malachite green and leucomalachite green in fish muscles with surface-enhanced resonance Raman scattering. Food Chem 169:80–84

Zhu QL, Xu Q (2014) Metal-organic framework composites. Chem Soc Rev 43:5468–5512

Zusková E, Máchová J, Svobodova Z, Vesely T (2007) Negative effects of malachite green and possibilities of its replacement in the treatment of fish eggs and fish: a review. Vet Med 52:527–539

Funding

This work was supported by grants from the National Natural Science Foundation of China (Grant Nos. 21675109), the Central Thousand Talents Plan (No. ZYQR201810151), the Natural Science Foundation of Henan Province (162300410209), and Henan Joint International Research Laboratory of Chemo/Biosensing and Early Diagnosis of Major Diseases.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Yanli Zhou declares that she has no conflict of interest. Xiaoqiao Li declares that she has no conflict of interest. Zhonghao Pan declares that he has no conflict of interest. Baoxian Ye declares that he has no conflict of interest. Maotian Xu declares that he has no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants performed by any of the authors.

Informed Consent

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, Y., Li, X., Pan, Z. et al. Determination of Malachite Green in Fish by a Modified MOF-Based Electrochemical Sensor. Food Anal. Methods 12, 1246–1254 (2019). https://doi.org/10.1007/s12161-019-01459-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-019-01459-x