Abstract

Nano-sized polyaniline (50–150 nm) has been prepared by polymerization of aniline on the surface of the commercial polyester fiber. A method for determination of adulteration in lemon juice samples was developed. Solid-phase microextraction (SPME) by polyester-polyaniline fiber to extract volatile organic compounds (VOCs) and analysis of gas chromatography (GC) profile were used. The effects of industrial lemon juice (ILJ) percent, organic lemon juice (OLJ) percent, and storage time of lemon juice as tree variable factors on the gas chromatography profile were studied. D-optimal combined design (DOCD) was applied to design the experiments that study the gas chromatography profile. For this purpose, the recorded chromatograms of VOCs were divided into four-time sections (0–5, 5–10, 10–15, and 15–20 min) and the peak number, total peak height, and total peak area in the four divided time sections were analyzed. The results were analyzed, and statistical test of correlation and linear regression was used. Results showed that there is good relation between industrial lemon juice percent, organic lemon juice percent, and storage time and peak characters (peak numbers, total peak height, and total peak area) in the divided time sections of each chromatogram. So, the presented method is a good method to find adulteration in organic lemon juice by gas chromatography profile analysis.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

For many years, polymers containing conjugated p-electron systems such as polypyrrole, polythiophene, and polyaniline have been well known. Polyaniline (PANI) attracted considerable attention because of its good environmental stability and high application potentials (Fabrizio et al. 1992; Cooper and Hall 1993; Ting et al. 1994). It can be obtained by chemical or electrochemical polymerization of aniline in the form of powder or a film. In situ chemical polymerization of aniline and pyrrole on the surface of textiles (nylon6 or 66, poly(ethylene terephthalate) (PET), and quartz) in aqueous solution was reported. Such conducting composites showed high flexibility and strength and many potential applications, such as absorbent, filtering system, the dissipation of electrostatic charge, heating elements, and conducting materials (Ansari 2006; Bhadra and Khastgir 2008; Yang et al. 2007). Solid-phase microextraction (SPME) is a solid-phase extraction sampling technique that involves the use of a fiber coated with an extracting phase, which can be a solid (sorbent)-like polyaniline, which extracts different kinds of analytes (volatile or non-volatile or including both of them) from different kinds of media, which can be in liquid or gas phase (Jordan et al. 2001; Jia et al. 1988; Shaw and Wilson 1982; Steffen and Pawliszyn 1996; Kovats 1958; Yang and Peppard 1994). The quantity of analyte extracted by the fiber is proportional to its concentration in the sample as long as equilibrium is reached or, in the case of short time pre-equilibrium, with the help of convection or agitation. The analysis of volatile organic compounds (VOCs) using SPME coupled with headspace has received attention from many researchers. In headspace SPME (HS-SPME) analyses, a fiber is placed in the headspace above an equilibrated sample. After extraction, the SPME fiber is transferred to the injection port of separating instruments, such as a gas chromatography, where desorption of the analyte takes place and analysis is carried out (Jordan et al. 2001; Jia et al. 1988; Shaw and Wilson 1982; Steffen and Pawliszyn 1996; Kovats 1958; Yang and Peppard 1994). One of the significant problems in the food industry is an adulteration of food and beverages that involve many different edible products (Zhengfang and Joseph 2015; Jamin et al. 2005; Malik et al. 1974). The high cost of the fruit, and the possibility of poor harvests conflicting with high consumer demand, makes the fruit juice industry, as well as many other relatively high commodity products susceptible. Detection and prevention of fruit juice adulteration are very complex tasks due to the natural variation in the cultivars, as well as differences that occur with different growing regions, storage conditions, and processing techniques (Malik et al. 1974; Widmer et al. 1992; Navarro-Pascual-Ahuir et al. 2015). Analytical methods that have been used to identify adulteration have been comprehensively reviewed. The most common forms of adulteration that occur within the fruit juice industry usually take the form of juice dilution, the addition of high fructose corn syrup (HFCS), or the addition of other fruit juices (Ehling and Cole 2011; Nam-Sun and Dong-Sun 2004; Heber 2009). The adulteration of food may have potential health risks if the consumer is allergic to an ingredient that is not declared on the label, if the product is contaminated with harmful microorganisms, or if the substances added contain harmful components.

Adulteration of juice composition undoubtedly has adverse effects on the quality of juice. Moreover, with increased globalization, the impact of a single food adulteration event will affect a larger and wider population than ever. As the adulteration of lemon juice is an ongoing problem, suitable analytical methods are needed to detect adulteration. Lemon juice has two regulatory specifications: titratable acidity (4.5% w/w as citric acid) and soluble solids content taken as the refractometric sucrose value (6% by weight at 20 °C) (Malik et al. 1974; Widmer et al. 1992; Navarro-Pascual-Ahuir et al. 2015; Ehling and Cole 2011; Nam-Sun and Dong-Sun 2004; Heber 2009). The titratable acidity and Brix (°Bx) values may be used as indicators to detect whether the juice has been diluted with too much water, which is the simplest adulteration practice. However, since these values are easy to measure, fraud performers commonly dilute fruit juices with water containing sugar and citric acid. Comprehensive analytical approaches for detecting chemical composition changes associated with adulteration of fruit juices are therefore needed (Heber 2009; Castaldo 2008; Yamamoto 2008; Domenico et al. 2008). Gas chromatography (GC) coupled with flame ionization detector (FID) is a powerful research tool routinely employed for characterizing food products. GC-FID has been used for targeted detection of lemon juice adulteration, for example, by measuring the VOCs (Domenico et al. 2008; Davis 1947; Moshonas et al. 1972). Using this technique, the types and concentrations of VOCs present in lemon juices obtained from lemons of different varieties and grown in different geographical regions can be accumulated to establish an in-house database; then, suspect juice samples can be quickly compared by their VOCs with those in this database (Malik et al. 1974; Widmer et al. 1992; Navarro-Pascual-Ahuir et al. 2015; Ehling and Cole 2011; Nam-Sun and Dong-Sun 2004; Heber 2009; Domenico et al. 2008; Davis 1947; Moshonas et al. 1972; Heber 2009; Castaldo 2008; Yamamoto 2008; Domenico et al. 2008).

In this work, the chemical polymerization of PANI on the polyester fibers was done in the solution of K2Cr2O7 (KDC) in acid medium. PANI-coated polyester substrate was used as SPME sorbent fiber to extract VOCs of lemon juice samples by HS-SPME sampling method and analysis by GC-FID. The GC chromatograms obtained by SPME-GC-FID method were statistically analyzed by linear regression analysis and was used to determination of lemon juice adulteration.

Experimental

Reagents and Chemicals

Aniline (Fluka, Switzerland) was distilled and stored in a refrigerator in dark prior to use. Potassium dichromate (K2Cr2O7) was used as oxidant from Aldrich. All organic compounds were purchased from Merck.

Apparatus

Polyester fiber coated with PANI was prepared by a chemical polymerization. An SPME fiber holder for manual sampling was designed and fabricated by Dr. Sajad Pirsa and Dr. Mohammad Alizadeh research group in Urmia University (Iran) (Pirsa et al. 2016). The GC apparatus used in this study was from Agilent7890 A, Wilmington, DE, USA. The composition and morphology of polyaniline coated polyester fiber surface wad evaluated by scanning electron microscopy (SEM) using a SEM instrument (Philips XL30, the Netherlands).

Preparation of Polyester-Polyaniline Fiber

The PANI polymer was synthesized by chemical polymerization on the polyester at room temperature. Ten milliliters of solution containing 0.1 mol l−1 aniline was provided, and 50 cm of polyester fiber was submerged to the solution and was shaken for 20 min. Ten milliliters of solution of 0.2 mol l−1 K2Cr2O7 as oxidant and 1 mol l−1 HCl were provided and added to the previous solution gradually. The mixed solution was maintained for 3 h at room temperature. PANI layer was prepared on the polyester substrate by using the dip coating method. After the polymerization and coating, the substrate was taken from the reaction solution and abundantly washed with deionized water for 10 min and, finally, dried for 1 h at 60 °C in oven.

Chromatographic Conditions

A gas chromatography instrument (Agilent7890 A, Wilmington, DE, USA) with GC-FID at the following condition was used to the separation, detection, and analysis of analytes: capillary column, silica, 30 m length, 0.25 μm phase thickness, and 320 μm i.d; N2 used as carrier gas with a flow rate of 2 ml⁄min; the column pressure was set at 8.8913 psi. Splitless mode injection was 50 ml/min splitting ratio in 0.75 min. The initial column temperature was 50 °C, and then the temperature was increased to 80 °C at the 2 °C/min and kept in 80 °C for 5 min. The detector temperature was 250 °C. Heater temperature 200 °C, H2 flow 27 ml/min, and air flow 20 ml/min.

Headspace Extraction Procedure

The lemon juice (2 ml) was extracted with PANI fiber using HS-SPME. PANI fiber connected to the needle of designed syringe was used (Pirsa et al. 2016). To the condition of provided PANI fiber, it was injected into GC injection port for 1 h at 100 °C prior to use. A glass (10 ml) with a polytetrafluoroethylene silicon septum containing a magnetic stir bar and 2 ml of lemon juice sample was provided. An aluminum cap was used to seal the vial to prevent sample loss due to evaporation. A hot plate was used to heat vials contained some lemon juice samples during the extraction process. When the stirring liquid sample in the sealed vial is heated on the hotplate, the PANI fiber by designed syringe was exposed to the headspace of it. After completing of extraction of the analyte to the polyaniline fiber, the fiber was withdrawn into the designed syringe needle and removed from the vial and then immediately inserted into the injection port of the GC. Some parameters that affect extraction efficiency, like extraction time (10 min) and temperature (90 °C), were optimized experimentally. The chromatographic separation is shown in Fig. 1.

Results and Discussion

Morphology

The morphology of PANI synthesized on the surface of polyester fiber analyzed by scanning electron microscopy. Figure 2 shows the morphology of PANI coated on the surface of the polyester fiber. It is clear that PANI particles are in the plate shape and sized between 50 and 150 nm. The PANI particles coated on the polyester fiber are relatively porous and have the high area to absorb VOCs of lemon juice samples in headspace.

Experimental Design

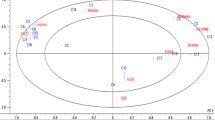

The GC profile of lemon juice VOCs was affected by some parameters of lemon juice. Tree variables, namely industrial lemon juice percent (F 1), organic lemon juice percent (F 2), and storage time of lemon juice (F 3), were investigated at five levels with four repeats at the central point. Polynomial equations, response surface, and contour plots for a particular response were created using SAS software version 9.2. The response of the model was defined by the following Scheffe Eq. (1):

where Y is the response (peak number, total peak area, and total peak height); F symbols are the variable parameters, and β values are the coefficient values obtained through least square method. For each of the tree studied variables, high (coded value +2) and low (coded −2) set points were chosen to construct an orthogonal design as tabulated in Table 1. Also, Tables 2 and 3 list the coded values of designed experiments based on D-optimal combined design (DOCD) and responses based on chromatogram characters including peak number, total peak area, and total peak height. DOCD was applied to design the experiments that study the gas chromatography profile. For this purpose, the recorded chromatograms of VOCs were divided into four-time sections (A = 0–5, B = 5–10, C = 10–15, and D = 15–20 min) and the peak number, total peak height, and total peak area in the four divided time sections were analyzed.

An SAS software version 9.2 was used to perform statistical analysis. Initially, the full-term quadratic × quadratic response surface models were fitted to each of the response variables, according to the Eq. (1). Where possible, stepwise deletion of terms was applied to remove the statistically non-significant terms, so simplifying the model. However, when the exclusion of such terms from the model decreases R 2 (adjusted) and increases the estimator of the variance S, the term was included in the model. The statistically non-significant linear terms also remained in the model when the respective quadratic and interactive effects were statistically significant. The quadratic polynomial models for three response functions accompanied by F values and corresponding R 2 was used; the estimated regression coefficients are summarized in Table 4.

Response Surface and Contour Plot of GC Profile to Discriminate Adulteration of Lemon Juice

The three-dimensional (3D) plots and contour plots based on the model function were used to predict responses to survey influence of each variable. Linear regression method was used to estimate the relation between organic lemon juice percent and storage time and responses (peak number, total peak area, and total peak height) in each time section.

Contour Plot of GC Profile in the 0–5 min Section

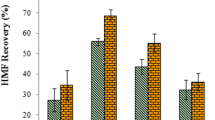

Figure 3 shows response contour plots (3D plots) of lemon juice samples (peak number, total peak area, and total peak height in the 0–5 min section of chromatogram) versus pairs of variables. Results show that there is a linear relation between the response and the variables, increasing of organic lemon juice percent in the mixed lemon juice cause to increase chromatogram characters.

Response Surface Plot of GC Profile in the 5–10 min Section

Figure 4 shows response surface plots (3D plots) and linear regression curve of lemon juice samples (total peak height in the 5–10 min section of chromatogram) versus pairs of variables. Results showed that total peak height was increased by increasing organic lemon juice component in the studied formulations.

Contour Plot of GC Profile in the 10–15 min Section

Figure 5 shows response contour plots of lemon juice samples (peak number, total peak area, and total peak height in the 10–15 min section of chromatogram) versus pairs of variables. Results show that there is a non-linear relation between the peak number and total peak height and the variables, but there is the linear relation between total peak area and the organic lemon juice percent.

Linear Regression of GC Profile in the 15–20 min Section

Figure 6 shows linear regression of lemon juice samples (peak number, total peak area, and total peak height in the 15–20 min section of chromatogram) versus pairs of variables. Results show that there is a linear relation between the response and the variables. According to the results, increasing the percent of organic lemon juice in the mixed lemon juice causes to increase peak number, total peak area, and total peak height. It is clear that it is possible to determine adulteration of industrial lemon juice in organic lemon juice by calculation and analysis of peak character in the time sections of a gas chromatogram.

Conclusions

Polyaniline particles were synthesized on the polyester fiber. PANI particles were analyzed by SEM technique, and particles size 50–150 nm was reported. PANI fiber was used as extraction agent to extract VOCs of lemon juice sample by headspace (HS) method to introduce to the GC system. Gas chromatograms obtained from HS-SPME process were divided into four-time sections (0–5, 5–10, 10–15, and 15–20 min), and the peak number, total peak height, and total peak area in the four divided time sections were analyzed. It was obtained that there is a linear relation between organic lemon juice percent and chromatogram characters including peak number, total peak height, and total peak area in the time sections. D-optimal combined design (DOCD) was applied to design the experiments that study the gas chromatography profile to find adulteration of industrial lemon juice in organic lemon juice. Results from analysis of response surface method, contour plot, and multi-linear regression showed that presented GC statistical analysis is a good method to find industrial lemon juice adulteration in organic lemon juice by gas GC profile analysis.

References

Ansari R (2006) Application of polyaniline and its composites for adsorption/recovery of chromium(VI) from aqueous solutions. Acta Chim Slov 53:88–94

Bhadra S, Khastgir D (2008) Extrinsic and intrinsic structural change during heat treatment of polyaniline. Polym Degrad Stab 93:1094–1099

Castaldo D (2008) Estimating bergamot juice adulteration of lemon juice by high-performance liquid chromatography (HPLC) analysis of flavanone glycosides. J Agric Food Chem 56:5407–5414

Cooper JC, Hall EAH (1993) Catalytic reduction of benzoquinone at polyaniline and polyaniline/enzyme films. Electroanalysis 5:385–397

Davis WB (1947) Determination of flavanones in citrus fruits. Anal Chem 19(7):476–477

Domenico C, Bruna L, Francesca S, Antonio T, Luigi S, Domenico C (2008) Estimating bergamot juice adulteration of lemon juice by high-performance liquid chromatography (HPLC) analysis of flavanone glycosides. J Agric Food Chem 56:5407–5414

Ehling S, Cole S (2011) Analysis of organic acids in fruit juices by liquid chromatography–mass spectrometry: an enhanced tool for authenticity testing. J Agric Food Chem 59:2229–2234

Fabrizio M, Furlanetto F, Mengoli G, Musiani MM, Paolicci F (1992) Polyaniline-based membranes for gas electrodes. J Electroanal Chem 323:197–212

Heber D (2009) International multidimensional authenticity specification (IMAS) algorithm for detection of commercial pomegranate juice adulteration. J Agric Food Chem 6:2550–2557

Jamin E, Martin F, Santamaria-Fernandez R, Lees M (2005) Detection of exogenous citric acid in fruit juices by stable isotope ratio analysis. J Agric Food Chem 53:5130–5133

Jia MY, Zhang QH, Min DB (1988) Optimization of solid-phase microextraction analysis for headspace flavor compounds of orange juice. J Agric Food Chem 36:2744–2747

Jordan M, Tillman TN, Mucci B, Laencina J (2001) Using HS-SPME to determine the effects of reducing insoluble solids on aromatic composition of orange juice. Lebens Wiss Technol 34:244–250

Kovats E (1958) Gas chromatography characterization of organic compounds. HelV Chim Acta 41:1915–1932

Malik MN, Scora RW, Soost RK (1974) Studies on the origin of the lemon. Hilgardia 42:361–382

Moshonas MG, Shaw PE, Veldhuis MK (1972) Analysis of volatile constituents from Meyer lemon oil. J Agric Food Chem 20:751–752

Nam-Sun K, Dong-Sun L (2004) Headspace solid-phase microextraction for characterization of fragrances of lemon verbena (Aloysia triphylla) by gas chromatography-mass spectrometry. J Sep Sci 27:96–100

Navarro-Pascual-Ahuir M, Lerma-García MJ, Simó-Alfonso EF, Herrero-Martínez JM (2015) Rapid differentiation of commercial juices and blends by using sugar profiles obtained by capillary zone electrophoresis with indirect UV detection. J Agric Food Chem 63:2639–2646

Pirsa S, Alizadeh M, Ghahremannejad N (2016) Application of nano-sized poly N-phenyl pyrrole coated polyester fiber to headspace microextraction of some volatile organic compounds and analysis by gas chromatography. Curr Anal Chem 12:2016

Shaw PE, Wilson CW (1982) Volatile sulfides in headspace gases of fresh and processed citrus juices. J Agric Food Chem 30:685–688

Steffen A, Pawliszyn J (1996) Analysis of flavor volatiles using headspace solid-phase microextraction. J Agric Food Chem 44:2187–2193

Ting YP, Neoh KG, Kang ET, Tan KL (1994) Recovery of gold by electroless precipitation from acid solutions using polyaniline. J Chem Tech Biotech 59:31–37

Widmer WW, Cancalon PF, Nagy S (1992) Methods for determining the adulteration of citrus juices. Trends Food Sci Tech 3:278–286

Yamamoto A (2008) Determination of adulteration in apple juice by HPLC. J Agric Food Chem 16:7302–7304

Yang X, Peppard T (1994) Solid-phase microextraction for flavor analysis. J Agric Food Chem 42:1925–1930

Yang CH, Huang LR, Chih YK, Lin WC, Liu FJ, Wang TL (2007) Molecular assembled self-doped polyaniline copolymer ultra-thin films. Polymer 48:3237–3247

Zhengfang W, Joseph E (2015) Targeted and non-targeted detection of lemon juice adulteration by LC-MS and chemometrics. Food Addit Contam Part A 1–14

Acknowledgements

This work has been supported by grants from the Urmia University Research Council, and the Iran National Science Foundation (INSF) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

This study was funded by Urmia University, Urmia, Iran.

Conflict of Interest

Sajad Pirsa declares that he has no conflict of interest. Mohammad Alizadeh declares that he has no conflict of interest. Nasrin Faraji declares that she has no conflict of interest.

Ethical Approval

All procedures performed in studies involving human participants were in accordance with the ethical standards of the institutional and/or national research committee and with the 1964 Helsinki Declaration and its later amendments or comparable ethical standards.

This article does not contain any studies with animals performed by any of the authors.

Informed Consent

Not applicable.

Rights and permissions

About this article

Cite this article

Alizadeh, M., Pirsa, S. & Faraji, N. Determination of Lemon Juice Adulteration by Analysis of Gas Chromatography Profile of Volatile Organic Compounds Extracted with Nano-Sized Polyester-Polyaniline Fiber. Food Anal. Methods 10, 2092–2101 (2017). https://doi.org/10.1007/s12161-016-0747-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-016-0747-4