Abstract

Acrylamide (AA) has been classified as a probable human carcinogen and forms in certain foods, particularly plant-based foods that are rich in carbohydrates and low in proteins, during processing or cooking at high temperatures. In this study, polyclonal antibodies were raised against a hapten derived from acrylamide and 3-mercaptobenzoic acid (3-MBA). An indirect competitive enzyme-linked immunosorbent assay was developed to rapidly quantify AA in complex food matrices and water. The assay was very specific to the AA-3-MBA derivative and showed no cross-reactivity to asparagine, the main precursor of AA formation in foods, aspartic acid, AA, or 3-MBA. The assay was very sensitive with a limit of detection of 5.0 ng/g in model for food matrices to 0.1 μg/L in water. Good recoveries for AA were observed in all matrices tested, and the results using this method were comparable to those obtained from mass spectrometry methods including Food Analysis Performance Assessment Scheme control samples and results for different food products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Acrylamide (AA) is an important industrial chemical used in the production of polyacrylamide and a variety of other organic chemicals (Zhou et al. 2008). Polyacrylamide was widely used in the paper and textile industries as flocculants in the treatment of wastewater, as soil conditioners in ore processing, and in cosmetics (Friedman 2003). Acrylamide also forms as a result of a reaction among naturally occurring components of certain foods, particularly plant-based foods that are rich in carbohydrates and low in protein, during processing or cooking at high temperatures. Acrylamide gained notoriety for its unexpected formation in foods, containing asparagines and reducing sugars as the major precursors (Becalski et al. 2003; Mottram et al. 2002; Stadler et al. 2002).

AA has been classified as a probable human carcinogen by the International Agency for Research on Cancer (IARC 1994), and it was concluded by Joint FAO/WHO Expert Committee on Food Additives that for a compound that is both genotoxic and carcinogenic, dietary exposures could indicate a human health concern (JECFA 2011). Therefore, since its discovery in 2002, there has been more concern regarding the acrylamide content in certain food products, especially in potato chips, French fries, breads, breakfast cereals, biscuit, and crackers.

Acrylamide is a colorless and odorless crystalline solid which is highly soluble in water and can readily penetrate and contaminate ground and drinking water. In 2003, the World Health Organisation has set a guideline; the maximum concentration of AA in drinking water is 0.5 μg/L (WHO 2003). However, the European legal limit for acrylamide in drinking water is 0.1 μg/L (EC 1998). To date, there has been no legal limit set for acrylamide levels in food products, but European Union recommended the monitoring of acrylamide in certain foodstuffs (EC 2007).

Whereas a number of analytical procedures for AA in food have been developed and published, most of these techniques are based on gas chromatography-mass spectrometry or liquid chromatography coupled with tandem mass spectrometry (LC-MS/MS) (Taeymans et al. 2004; Wenzl et al. 2003). These techniques rely on expensive instruments operated by well-trained analysts, and the preparation of samples is time consuming.

Alternatively, enzyme-linked immunosorbent assay (ELISA) is a rapid, specific, and sensitive method that has been used for surveillance purposes to enable high throughput sample screening. ELISA is based on structural recognition and the affinity between antibodies and antigens. It is a simple and cost-effective method compared with conventional LC-MS/MS methods. To date, three papers have been published for the conception and the development of immunoassays for the detection of acrylamide (Preston et al. 2008; Quan et al. 2011; Zhou et al. 2008).

In the present study, a method for the production of polyclonal antibodies against derivatives of acrylamide (AA-3-mercaptobenzoic acid (3-MBA)) was adapted from the method of Preston et al. (2008), and a sensitive competitive indirect ELISA was optimized. Moreover, we demonstrated that the performance of this ELISA in the detection of AA in bagels, potato chips, and French fried samples was comparable to the results obtained from conventional LC-MS/MS.

Materials and Methods

Materials and Chemicals

All reagents were of analytical grade unless specified otherwise. AA, 3-MBA, 1-ethyl-3-(3-dimethylaminopropyl)-carbodiimide (EDC), N-hydroxysuccinimide (NHS), sodium carbonate, sodium bicarbonate, OVA albumin from chicken egg whites, Grade V min 98 % agarose gel electrophoresis, phosphate-buffered saline (pH 7.4), Tween 20, bovine serum albumin (BSA), keyhole limpet hemocyanin (KLH), bovine thyroglobulin (BTG), horseradish peroxidase (HRP), goat anti-rabbit immunoglobulin (IgG) HRP conjugate, jeffamine, sodium tetraborate decahydrate, and hydroxylamine hydrochloride were all purchased from Sigma-Aldrich (Oakville, Ontario, Canada). Skim milk powder (Nestle Canada Inc.) was purchased from a local store (Ottawa). 3,3′,5,5′-Tetramethylbenzidine (TMB) peroxidase substrate (A) and peroxidase substrate solution (B) were purchased from KPL Gaitherburg, ML, USA. HCl (ACS grade) was purchased from BDH (Toronto, Ontario, Canada). Food Analysis Performance Assessment Scheme (FAPAS®) test material nos. T3025 (biscuit) and T3026 (crisp bread) control materials for acrylamide were purchased from Food and Environment Research Agency (York, UK). Sodium chloride was purchased from EMD (Darmstadt, Germany). Corning Costar 2592 microplates, EIA/RIA, flat bottom, certified high binding plates were purchased from VWR. Amber glass GC vials were purchased from Canadian Life Science. Bread, potato chips, and French fries were purchased in Ottawa.

Buffers and Solutions

Buffers and solutions used in this study are as follows:

-

1.

Phosphate-buffered saline (PBS): one packet Sigma PBS, 1,000 mL deionized water, pH 7.4

-

2.

Coating buffer: 1.4 g NaCO3, 2.93 g NaHCO3, 1 L deionized water, pH 9.6

-

3.

Diluent buffer: 0.15 g skim milk powder, 100 mL PBS

-

4.

Sodium borate buffer (0.1 M): 3.81 g Na2B4O7·10H2O, diluted up to 100 mL with deionized (DI) water

-

5.

NaOH (5.1 N): 4 g NaOH, diluted up to 100 mL with deionized water

-

6.

Washing buffer: 9 g NaCl, 500 μL Tween 20, 1,000 mL deionized water

-

7.

3-MBA stock solution: 0.0411 g 3-MBA in 1 mL 1 N NaOH

Instrumentation

The microplate reader was from Multiskan Ascent® Thermo Labsystems (Helsinki, Finland) with Ascent Software, version 2.6; Multiskan Verification plate from Thermo Fisher Scientific (Asheville, NC); and tissue homogenizer from Polytron® Brinkmann Homogenizer, model PT 10/35, Brinkmann Instruments Co. by Kinematika, AG (made in Switzerland). The calibration curves were analyzed with a four-parameter logistic equation using the software GraphPad Prism (GraphPad Software Inc., San Diego, CA). Thermomixer-Eppendorf® Thermo mixer® R was procured from Eppendorf AG (Hamburg Germany); centrifugal filters from Amicon® Ultra, Ultacel 3K (cat no. UFC900324); Millipore (Carrigtwohill, Ireland); incubator was a Quincy Incubator model 12-140, Quincy Lab, Inc. (Chicago, IL, USA); horizontal shaker was an Eberbach model 6010 from Eberbach Corp. (Ann Arbor, MI, USA).

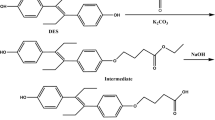

Conjugation of AA-3-MBA with KLH (AA-3-MBA-KLH)

AA-3-MBA was prepared according to published procedure (Preston et al. 2008). AA-3-MBA (10 mg) was dissolved in DMSO (1 mL), and then, three drops of 0.1 M sodium borate buffer were added, followed by addition to EDC (15 mg) and NHS (10 mg). The reaction mixture was stirred at room temperature for 4 h. The resulting activated ester was slowly added to the KLH solution (20 mg), dissolved in 4 mL of sodium borate buffer. After complete addition, the solution was stirred overnight at room temperature. The final solution was dialyzed (12–14 kDa tubing) against several changes of PBS at 4 °C for 3 days and then lyophilized for storage.

Conjugation of AA-3-MBA with BSA (AA-3-MBA-BSA)

AA-3-MBA (11.5 mg) was dissolved in 2 mL of DMF/1,4-dioxane (1:1) and adding triethylamine (10 μl). The reaction mixture was stirred on ice for 10 min, ethyl chloroformate (10 μl) was added, and the reaction mixture was brought to room temperature and stirred for 1 h. The mixture was added to an ice-cold BSA solution (50 mg BSA, dissolved in 3 mL of 0.1 M sodium borate). The resulting mixture was brought to room temperature and stirred overnight. The final solution was dialyzed and then lyophilized as described for KLH.

Polyclonal Antibody Production and Titer Determination

IgG antibodies were raised by immunizing ten New Zealand white rabbits: five with AA-3-MBA-BSA and five with AA-3-MBA-KLH. The emulsified antigens were injected subcutaneously at four sites on the animals. The usual immunization's schedule was followed: the initial dose (0.2 mg) has been administered using Freund's complete adjuvant from Difco Laboratories (Michigan, USA). After a period of 14 days, booster doses were given with incomplete adjuvant for all subsequent boosters at day 14, day 28, and then every 28 days. Blood was collected from the marginal ear vein 10 days after immunizations (from the third immunization onwards). The blood was centrifuged and the collected serum was stored at −20 °C until used. Trial bleeds were monitored by indirect ELISA for their titer and the inhibition concentration corresponding to 50 % response (IC50).

Assay Development

Preparation of Standard Curve of AA and Derivatization

Acrylamide stock solutions were prepared in distilled water to have a final concentration of 100, 50, 25, 12.5, 6.3, and 3.1 ng/mL in a 1-mL volume. Derivatization of the AA standard solutions with 3-MBA was done by transferring 975 μL of each standard solution and 25 μL of stock 3-MBA (0.041 g/mL in 1 N NaOH) into amber glass GC vials (blanks were also run, each containing only 975 μL water). The solutions were then capped, mixed, and incubated for 2 h at 60 °C in a thermomixer set at 300 rpm. The derivatized standards (AA-3-MBA) were cooled to room temperature and were then adjusted to ~pH 7 by adding 1 N HCl (5–10 μL). Derivatized standards were diluted by a factor of 10 on the plate to produce a calibration curve from 0.31 to 10 ng/mL. Standard curves AA were also prepared in potato and bread matrix extracts to determine any nonspecific binding or interferences compared with the aqueous calibration curve.

Sample Preparation

The samples were first homogenized in a food processor, and then, 2.0 g of the sample was weighed into a 50-mL centrifuge tubes and 20 mL of deionized water was added. The samples were homogenized for 30 s using a Polytron® homogenizer and further mixed on a horizontal shaker set at high for 15 min at room temperature. The samples were then centrifuged at 7,500 rpm at 8 °C for 40 min. Further cleanup was performed on a smaller volume of supernatant (8 mL) by centrifuging through an Amicon® filter centrifuge tube for 40 min at 8 °C. The sample supernatants were transferred to clean tubes and stored in the fridge until needed. Sample extracts were derivatized in the same manner as the standards (vide supra).

Immunoassay Procedure

Plates were prepared by coating with 200 μL of 1 μg/mL of AA-3-MBA-BSA in coating buffer and blocking with 20 μg/mL OVA in coating buffer. The plates were incubated at 4 °C for at least 16 h. The plates were then washed three times with washing buffer followed by three rinses with deionized water. The plates were put in a 37 °C incubator to dry (60 min) and were then stored at −20 °C until needed.

Derivatized standard or sample (100 μL) was added to diluted (1/10,000) anti-AA-3-MBA-KLH (100 μL) in microtiter tubes for a pre-incubation step. The tubes were vortexed for ~15 s and then incubated at room temperature for 1 h. After this time, diluent buffer (800 μL) was added to each tube and mixed. Pre-incubated solutions (200 μL) were added to previously coated wells and incubated at room temperature for an additional 30 min. The plate was then washed five times with washing buffer. After washing, 200 μL of goat anti-rabbit peroxidase conjugate (1/15,000) diluted in diluent buffer) was added to each well and incubated at room temperature for 30 min. After incubation, all wells were emptied and washed five times with washing buffer. Then, 200 μL of TMB substrate (1 part A:1 part B mixed) was added to each well, and the plate was incubated in the dark at room temperature for 30 min. The enzyme reaction was halted by the addition of 50 μL of stop solution to each well. After 5 min of incubation at room temperature in the dark, the plate was read on the plate reader at 450 nm.

Specificity of Antibody

The assay cross-reactivity was tested against asparagine, aspartic acid, acrylamide (non-derivatized), and 3-MBA. Stock solutions of 0.02 g/mL of each compound were prepared and then serial diluted in diluent buffer (100–2.5 μg/mL). The diluted working solutions were then adjusted to pH = 7 with HCl. The compounds were analyzed using the ELISA procedure above alongside a standard solution dilution series. Their cross-reactivity was determined and calculated as follows:

Recovery Studies

The recovery of the analyte after sample treatment was assessed by spiking blank potato and bread samples in triplicate at two concentration levels (200 and 1,000 ng/g). The spiked samples were then extracted with 10 mL (DI water)/g (sample) and treated as described above, and the percent recovery was calculated against the fortified concentration. With a final dilution of 1/10 before plating, these spiked concentrations of AA would be measured as 10 and 2 ng/mL on the plate. Bread and biscuit control samples from the FAPAS (T3025 and T3026) were purchased and extracted to determine the recovery from these samples. In addition, we spiked these FAPAS quality control samples with acrylamide at (250 ng/g) to determine the additive recovery from these characterised samples. Percent recovery was calculated as:

The concentrations were expressed as mean ± standard deviation in Table 1.

Results and Discussion

Antibody Production and Serum Screening

Specific humoral immune response against a small molecule is difficult and usually requires coupling of the small molecule to a higher molecular weight carrier protein (Singh et al. 2004). Acrylamide is a small molecule (molecular weight 71.08) with little chance of stimulating host antibody production alone. In fact, even directly conjugated with human serum albumin and BTG carrier proteins, it still cannot stimulate the immune response (Preston et al. 2008). It is not clear why this occurs, but it could be speculated that the small molecule is simply buried on the surface of the protein and hidden from the immune system. Conjugation of acrylamide with 3-MBA (AA-3-MBA) was used to produce a larger hapten that would enhance the epitope characteristics and produce a better immune response once coupled with the carrier protein. This system was chosen because nucleophilic compounds, such as thiols, quickly react with the double bond of acrylamide under mild conditions (Friedman 2003). This aspect was important for derivatisation of sample extracts prior to analysis. The derivatised acrylamide (AA-3-MBA) was conjugated to KLH (AA-3-MBA-KLH) and BSA (AA-3-MBA-BSA) to produce potential immunogens. Ten New Zealand rabbits were subcutaneously inoculated: five rabbits with the AA-3-MBA-BSA and five rabbits with AA-3-MBA-KLH immunogen. Although two of the ten immunized rabbits did not provide any response, the remaining positive responses proved that the conjugation of acrylamide to produce a larger entity was a successful strategy. The antisera obtained from these rabbits was monitored via indirect ELISA format with AA-3-MBA-BSA coating antigen to test the antisera of AA-3-MBA-KLH whereas AA-3-MBA-KLH coating antigens for antisera of AA-3-MBA-BSA. The best titer was obtained from anti-AA-3-MBA-KLH with 1/10,000 dilution was used for assay development.

Assay Development, Sensitivity, and Specificity

The derivatization of AA with 3-MBA was an essential component of the overall assay and needed to be optimized. The aspects that were considered were the molar ratio of 3-MBA to acrylamide, the pH, the reaction time, and the temperature. In order to minimize the reaction time, we looked at maximizing the amount of 3-MBA that could be used for the derivatization. We varied the concentration of 3-MBA from 67 to 1,367 μg/mL, which represents a 3,100–63,000 mole ratio with respect to the largest AA control standard (10 ng/mL). Although the reaction times for this series were shortened, we observed interferences in the assay when the unreacted 3-MBA exceeded approximately 4,700 times the mole ratio of 10 ng/mL of acrylamide. To limit these interferences, all subsequent experiments used a maximum amount of 3-MBA (102 μg/mL) after dilutions, in the derivatization process of standards and samples. The reaction in the thermomixer was studied 1–24 h and from a temperature of 25 to 60 °C with a constant motion of 300 rpm. The optimal time and temperature were found to be 2 h at 60 °C. This reaction time and temperature combination were found to maximize the conversion while minimizing the possibility of side reactions that could interfere with the assay. The pH of the solution had a big impact on the reaction, and it was found that the optimal range for the derivatization was between pH 8 and 12. This pH was not suitable for the assay and needed to be adjusted to approximately pH = 7 before plating the standards and samples.

The assay is an indirect competitive format where the antigen AA-3-MBA-BSA is bound to the plate while standards and samples are pre-incubated with antibodies raised against AA-3-MBA-KLH before being introduced to the wells of the plate. The sensitivity of the assay was determined by the concentration of acrylamide necessary to inhibit 50 % antibody binding (IC50). Deionized water, boiled potato, and bread extracts were three model matrices prepared as negative samples and tested for matrix inferences in the assay. The blank samples were treated in the same manner as those that contained acrylamide. Given in Fig. 1 are the results obtained for three calibration curves prepared in deionized water. These calibration curves were prepared on different days and show how reproducible the assay is from the acrylamide derivatization step through to the analysis. The assay in water is very sensitive (IC50 = 1.5 ng/mL) with limit of detection (LOD) of 0.08 ng/mL (represented by the IC80) and reproducible (%CV = 25) at this low concentration. In addition to water, calibration curves (range 0.31–10 ng/mL) were prepared in boiled potato and bread extracts to determine any interference in the derivatization or the assay. Given in Fig. 2 are the calibration curves for these three model matrices showing that there are no interferences in the assays (IC50 = 2.7 ng/mL) using potato and bread extract compared with water (IC50 = 1.5 ng/mL). This suggests that standard curves generated in water can be used for these matrices. The LOD measured in the potato and bread extracts was 0.5 ng/mL (represented by the IC80); however, the LOD for food matrices would be 5.0 ng/g because of the dilution of 1/10 for the extraction of the sample. The LODs of immunological assays reported in the literature were 67.7 ng/g (Preston et al. 2008), 6 ng/mL (Quan et al. 2011), and 18.6 ng/mL (Zhou et al. 2008). By comparison, the assay developed in this study was more sensitive with an LOD of 0.1 ng/mL in water, well below the WHO guidelines for AA in drinking water of 0.5 ng/mL (WHO 2003).

The specificity of the antibodies in the assay was determined by testing the cross-reactivity of these polyclonal antibodies with analogues of similar structure to the AA-3-MBA and with the precursors to acrylamide. These included asparagine, aspartic acid, acrylamide, and 3-MBA .The antibodies were very specific to the derivatized acrylamide and showed little to no cross-reactivity towards acrylamide or 3-MBA itself.

Recovery Studies for Model Food Matrices and Control Samples

Recovery studies were performed in bread, potato, biscuit (cookie), and crisp bread (cracker). In the first set of experiments, acrylamide was spiked into blank potato and bread matrices at two levels within the calibration curve (2.0 and 10 ng/mL). The results showed good recoveries (61–90 %; Table 1). In another set of experiments, FAPAS test samples from a previous round of proficiency tests were purchased and used as quality control samples to test recoveries for the entire experimental process. These samples are processed to represent a more realistic material that would be found on the market and comprised biscuit and crisp bread samples. Both of these materials were first analyzed for the level of acrylamide determined from the previous round of proficiency testing (Table 1). The analysis of the biscuit material (T3025) produced a level of acrylamide (357 ng/g) that was very close to the assigned value (322 ng/g) and within the range (200–444 ng/g) determined from the proficiency testing scheme. It should be noted that the assigned value for this sample was determined by conventional LC-MS/MS protocols. The proficiency test sample (T3025) used in this study was also analysed by an in-house LC-MS/MS method, and the acrylamide concentration was determined from multiple extractions (295 ± 14 ng/g). A similar result was found for the crisp bread material which produced a level (168 ng/g) very close to the assigned value (157 ng/g) and within the range (91–233 ng/g) determined from the FAPAS study for this material. Both of these proficiency test samples were also spiked with a known amount of acrylamide (250 ng/g) to determine the additive recoveries. In both materials, the recoveries were very good and ranged from 95 to 100 % (Table 1).

Analysis of Commercial Samples

It is always beneficial to determine how a method performs on naturally incurred materials and therefore commercial samples representing matrices known to contain AA: bagels, potato chips, and French fries were analyzed. As a part of this study, we compared the ELISA-based method with LC-MS/MS which is a conventional method for determining AA (Becalski et al. 2004). In general, the amounts of AA determined by LC-MS/MS are lower in most of cases (Table 2), which is not totally understood. However, the FAPAS samples that were tested have a very wide documented range, which was determined by mass spectrometry techniques. For example, T3025 has an assigned value of 322 ng/g, with a range from 200 to 444 ng/g. Sample T3026 has an even wider range (91–223 ng/g, 157 ± 40 %). If we consider this range, the results obtained from the ELISA in Table 2 are not significantly different from those obtained from mass spectrometry for most of the samples analyzed. For the case of the FAPAS sample (T3025), the concentrations of AA determined by LC-MS/MS (295 ± 14 ng/g) and ELISA (357 ± 99 ng/g) were statistically similar (p = 0.15) by t test. The results show that the indirect ELISA method developed in this study is sensitive and able to detect AA in a variety of food matrices for screening and semiquantitative purposes.

Conclusion

The development of a rapid, specific, and sensitive immunological method for small molecules can be achieved by producing a more immune-sensitive derivative of the target. This derivatization added steps and time to the final analysis, but these were minimized by selecting a rapid chemistry and optimizing the conditions. The result was an immunological assay with a high affinity and specificity towards derivatized acrylamide. The assay was very sensitive compared to other immunological assays reported in the literature with a limit of detection of 5.0 ng/g for AA in model matrices and an even lower 0.08 ng/mL in water. The assay performed well in a variety of matrices and was able to produce some comparable results to those obtained using mass spectrometry methods. While the ELISA method did overestimate the concentration of acrylamide in some samples, it can be anticipated that a larger collaborative study might be expected to demonstrate a better correlation.

References

Becalski A, Lau BPY, Lewis D, Seaman SW (2003) Acrylamide in foods: occurrence, sources, and modeling. J Agric Food Chem 51(3):802–808

Becalski A, Lau BPY, Lewis D, Seaman SW, Hayward S, Sahagian M, Ramesh M, Leclerc Y (2004) Acrylamide in French fries: influence of free amino acids and sugars. J Agric Food Chem 52(12):3801–3806

EC (1998) European Council, European Council drinking water directive EU 98/83/EC, Brussels

EC (2007) European Commission Recommendation of 3 May 2007 on the monitoring of acrylamide levels in food 2007/331/EC. Off J Eur Union L123:33–40

Friedman M (2003) Chemistry, biochemistry, and safety of acrylamide. A review. J Agric Food Chem 51(16):4504–4526

IARC (1994) IARC monographs programme on the evaluation of carcinogenic risks to humans. IARC Monogr Eval Carcinog Risks Hum 60:13–33

JECFA (2011) Joint FAO/WHO Expert Committee on Food Additives (JECFA): JECFA review (monograph 8)

Mottram DS, Wedzicha BL, Dodson AT (2002) Food chemistry: acrylamide is formed in the Maillard reaction. Nature 419(6906):448–449

Preston A, Fodey T, Elliott C (2008) Development of a high-throughput enzyme-linked immunosorbent assay for the routine detection of the carcinogen acrylamide in food, via rapid derivatisation pre-analysis. Anal Chim Acta 608(2):178–185

Quan Y, Chen M, Zhan Y, Zhang G (2011) Development of an enhanced chemiluminescence ELISA for the rapid detection of acrylamide in food products. J Agric Food Chem 59(13):6895–6899

Singh KV, Kaur J, Varshney GC, Raje M, Suri CR (2004) Synthesis and characterization of hapten-protein conjugates for antibody production against small molecules. Bioconjug Chem 15(1):168–173

Stadler RH, Blank I, Varga N, Robert F, Hau J, Guy PA, Robert MC, Riediker S (2002) Food chemistry: acrylamide from Maillard reaction products. Nature 419(6906):449–450

Taeymans D, Wood J, Ashby P, Blank I, Studer A, Stadler RH, Gondé P, Van Eijck P, Lalljie S, Lingnert H et al (2004) A review of acrylamide: an industry perspective on research, analysis, formation, and control. Crit Rev Food Sci Nutr 44(5):323–347

Wenzl T, de la Calle MB, Anklam E (2003) Analytical methods for the determination of acrylamide in food products: a review. Food Addit Contam 20(10):885–902

WHO (2003) World Health Organization guidelines for drinking water quality, vol. 1: recommendations, 2nd edn., Geneva

Zhou S, Zhang C, Wang D, Zhao M (2008) Antigen synthetic strategy and immunoassay development for detection of acrylamide in foods. Analyst 133(7):903–909

Acknowledgments

The authors give sincere thanks to Dr. Xu-Liang Cao and Dr. Zhongwen Wang for their helpful comments during the editing of this manuscript.

Conflict of Interest

Gurmit Singh has no conflict of interest. Beth Brady has no conflict of interest. Terry Koerner has no conflict of interest. Adam Becalski has no conflict of interest. Tony Zhao has no conflict of interest. Sherry Feng has no conflict of interest. Samuel Benrejeb Godefroy has no conflict of interest. Anne-Catherine Huet has no conflict of interest. Philippe Delahaut has no conflict of interest. All institutional and national guidelines for the care and use of laboratory animals were followed.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, G., Brady, B., Koerner, T. et al. Development of a Highly Sensitive Competitive Indirect Enzyme-Linked Immunosorbent Assay for Detection of Acrylamide in Foods and Water. Food Anal. Methods 7, 1298–1304 (2014). https://doi.org/10.1007/s12161-013-9749-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-013-9749-7