Abstract

In this assay, headspace single-drop microextraction (HS-SDME) coupled with gas chromatography–mass spectrometry (GC–MS) as a simple, low-cost and rapid method has been developed and validated for determining volatile oxidation compounds including hexanal and heptanal in mayonnaise. The main microextraction variables affecting the HS-SDME procedure such as extraction temperature and time, stirring rate, and amount of NaCl were optimized by response surface methodology employing a central composite design. Obtained results demonstrated that higher yield of extracted analytes could be achieved under the following optimal conditions: extraction temperature of 45 °C, extraction time of 16 min, stirring rate at 700 rpm, and addition of 2 g NaCl. The optimized HS-SDME/GC–MS method was validated for oxidized mayonnaise samples (50 °C/48 h) by calculating analytical parameters (linearity, precision, accuracy, and sensitivity). Good linearity (R 2 > 0.99) was observed by plotting calibration curves of extracted hexanal and heptanal over the concentration range of 0.025–10 μg g−1, and the repeatability of the method, expressed as relative standard deviation, were found to be 4.04 % for hexanal and 3.68 % for heptanal (n = 7). After the microextraction process of spiked mayonnaise sample, high levels of relative recovery were obtained for hexanal (107.33 %) and heptanal (91.43 %). The detection limits were 0.008 ng g−1 and 0.021 ng g−1 for hexanal and heptanal, respectively, while quantification limits of hexanal and heptanal were calculated to be 0.027 ng g−1 and 0.071 ng g−1, respectively. The possibility of the HS-SDME followed GC–MS to determine and quantify volatile oxidation compounds such as hexanal and heptanal was confirmed by analyzing commercial fresh mayonnaise stored at 4 and 25 °C during 3 months.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Mayonnaise is an oil-in-water emulsion which contains high amounts of oil and therefore is highly sensitive to autoxidation and rancidity. Traditional mayonnaise comprises about 70–80 % edible oil while unsaturated fatty acids consist the major fraction of lipid phase which can participate in oxidation reaction so easily (Depree and Savage 2001). Lipid oxidation has been recognized as the main cause of quality deterioration in food emulsions (Coupland and McClements 1996). Development and production of undesirable off-flavors (rancidity) and toxic compounds occur during oxidation of oils and fats (Halliwell et al. 1995). Foods with high amount of oil such as mayonnaise are sensitive to rancidity, and this is due to the resulting oxidation of their lipid portion. Hydroperoxides are primary oxidation products derived from oxidation process of unsaturated fatty acids; these compounds are highly reactive and unstable that decompose quickly and produce a complex mixture of non-volatile and volatile products such as hydrocarbons (ethane, pentane), acids, alcohols, aldehydes (propanal, pentanal, hexanal, heptanal, and 2-octenal), and ketones, which significantly affect the sensory and quality properties of foodstuffs (Frankel 1983, 1993; Sanches-Silva et al. 2004). Volatile oxidation compounds (VOCs), also mentioned as secondary oxidation products, can deteriorate the taste and odor in foods. Actually, for a very long time lipid oxidation has been identified as the main reason of quality deterioration in fatty foods, and it is mostly the definitive agent in recognizing the shelf-life of food products and production of undesirable odors, destroying the texture and decline of nutritional value and can eventually shorten the storage time of oils and lipid-containing foods (Lozano et al. 2007).

The food industry is intensively interested in the prevention of lipid oxidation and also in the primary discovery of oxidation changes in order to gain economical benefits that result from the growth of sales and consumers’ acceptance. So, determination and quantification of an indicator that could investigate the status of lipid oxidation have gained enormous attention (Mallia et al. 2008).

Aldehydes are specifically significant due to flavor alteration and from a toxicological viewpoint (Frankel 1993). Among studied aldehydes, hexanal has been referred to as a prominent oxidation marker that is being recognized as the major product of oil oxidation, and its concentration increases during storage time. It is mainly produced from oxidation of linoleic acid through 13-hydroperoxide, and its odor is defined as “grassy” which results in off-flavors owing to its low odor threshold in water (4.5 μg kg−1) (García-Llatas et al. 2007).

In the last decade, some aldehydes including pentanal, hexanal, and heptanal have been evaluated and quantified in different food samples by employing various sample preparation techniques and analyzing methods (García-Llatas et al. 2007; Gromadzka and Wardencki 2010; Panseri et al. 2011; Sanches-Silva et al. 2004).

Sample preparation step for isolation and pre-concentration of organic compounds from food matrix is the most challenging and time-consuming task in analytical methods (Buldini et al. 2002). Headspace techniques have been extensively applied for extraction, determination, and quantification of volatile components (Pillonel et al. 2002; Zhao et al. 2004). The most common method for extraction of secondary oxidation products is headspace sampling due to their high volatility. Recently, the most outstanding headspace sampling methods employed for analyzing the volatile fraction of foods are static headspace sampling (SHS) and dynamic headspace sampling (DHS) (van Ruth et al. 2002).

SHS is a simple, rapid, and solvent-free sample preparation method for analyzing volatile compounds. The main disadvantage of this technique is lacking enough sensitivity; hence, it is not able to determine very low amounts of analytes in samples (Frankel 1993; Frankel et al. 1989; Mohammadi and Alizadeh 2006). Determination of pentane, hexanal, and propanal as oxidation markers of polyunsaturated fatty acids (PUFAs) in some biological samples have been done extensively by SHS method (Frankel 1993; Frankel et al. 1989).

The drawbacks of static headspace can be overcome by the employment of dynamic headspace sampling, recognized as “purge and trap”. The DHS provides greater sensitivity than the SHS, but breakthrough of volatile compounds can happen during the sampling process (Irwin et al. 2004). The analysis of aroma components in fish oils or fish-oil-enriched emulsions has been widely performed by using DHS (Hartvigsen et al. 2000).

Solid-phase microextraction (SPME) is described as a rapid, sensitive, and solvent-free sampling method which has been developed to eliminate many mentioned drawbacks of discussed methods above (Arthur and Pawliszyn 1990). In recent years, HS-SPME has been noticeably applied for extraction of volatile to semi-volatile components from headspace of various samples (del Mar Caja et al. 2011; Vandendriessche et al. 2012; Verzera et al. 2010; Ye et al. 2012). There are also many published data about application of HS-SPME for analyzing volatile compounds in some kinds of foods including oils (Beltran et al. 2011; Steenson et al. 2006), infant formula (García-Llatas et al. 2007), oil-in-water emulsions (Beltran et al. 2005), and mayonnaise (Iglesias et al. 2007).

Nowadays, much attention has been devoted to microextraction into a solvent drop as an alternative to the conventional liquid–liquid extraction (Asensio-Ramos et al. 2011; Pena-Pereira et al. 2010; Xu et al. 2007b). Among the proposed headspace techniques, liquid-phase microextraction (LPME) has opened valuable perspectives for analyzing volatile compounds. In LPME technique, extraction usually happens between several microliters of a water-immiscible solvent (known as acceptor phase) and an aqueous phase (also known as donor phase) which includes the analytes. LPME is a miniaturized sample preparation method, which is rapid and low-cost, with minimum usage of organic solvents (Theis et al. 2001; Asensio-Ramos et al. 2011). Two reports have been recently published about the application of headspace LPME (HS-LPME) method for determining furanic compounds in coffee (Chaichi et al. 2012) and baby food samples (Habibi et al. 2012).

Single-drop microextraction (SDME) is one of the modes of LPME, using commonly about 1–3 μL of an organic solvent. In headspace SDME (HS-SDME), diffusion of analytes from sample solution (aqueous phase), into headspace and finally to suspended microdrop of solvent at the tip of a microsyringe, constitutes foundation of this method. HS-SDME is one of the most useful methods of microextraction with solvent which can be used to determine volatile analytes without any interference of sample matrix because there is no connection between the sample and drop of extraction solvent (Asensio-Ramos et al. 2011;Sarafraz-Yazdi and Amiri 2010). The HS-SDME method has gained many attentions in the field of investigating volatile or semi-volatile compounds by suspending a microdrop of organic extraction solvent in the headspace of sample solution (Theis et al. 2001). The importance of this technique is due to its simple and low-cost procedure, rapid analysis, and minimal usage of solvent. Highlighted superiority of HS-LPME, HS-SPME, and HS-SDME toward conventional extraction techniques is the integration of sample preparation and extraction and pre-concentration of analytes into a single step. One of the supposed disadvantages for LPME and SDME methods is transience of solvent microdrop at higher microextraction temperatures. Therefore, choosing the best range of temperature can solve this problem (Xu et al. 2007a).

In the last few years, some researchers have published their findings about application of SDME for analyzing certain compounds in several environmental, biological, and food samples (Batlle and Nerı́n 2004; Deng et al. 2007; Tankeviciute et al. 2001; Xiao et al. 2008). But there is not any available data until now about using the HS-SDME method for extraction and determination of VOCs in complex food emulsions such as mayonnaise.

Many factors (variables) exist which influence the efficiency of HS-SDME technique. Response surface methodology (RSM) is a famous and beneficial statistical method for optimizing variables and can also be performed by fewer experiments, in comparison to one variable at a time, as a time-consuming and deficient design due to dissembling of the interaction of variables. RSM has been considered as an applicable and suitable method used for investigating the individual and interactive effects of numerous variables to obtain a favorable response (Bezerra et al. 2008).

The first purpose of this study was the optimization, development, and validation of the HS-SDME technique followed by GC–MS as a rapid, sensitive, and simple method for extraction and quantification of VOCs including hexanal and heptanal as secondary oxidation components in thermally oxidized mayonnaise. RSM via central composite design (CCD) mode was applied for optimizing the microextraction conditions (temperature and time of extraction, stirring rate, and amount of NaCl). Capability of the proposed method for evaluating oil oxidation changes during storage of a commercial fresh mayonnaise was proposed as the second purpose.

Materials and Methods

Chemical and Reagents

Hexanal, heptanal, methanol, n-dodecane, and sodium chloride were purchased from Merck (Darmstadt, Germany). 2,5-Dimethylfuran was provided by Sigma-Aldrich Chemie GmBH (Steinheim, Germany). Individual stock solutions of hexanal and heptanal were prepared in methanol to achieve the concentration of 1 mg mL−1. These stock standard solutions were diluted with methanol weekly to make a mixed working solution with a concentration of 2 μg mL−1 for each compound. In order to investigate the extraction efficiency under various conditions for optimization purposes, the model solutions containing the desired amount of each analyte in the concentration range of 0.025–10 μg g−1 were prepared daily by diluting the mixed working solution with distilled water. A methanolic solution of 2,5-dimethylfuran, with a concentration of 1 mg mL−1, was prepared and utilized as the internal standard (IS). N-Dodecane containing a constant amount of 2,5-dimethylfuran (1 mg L−1) as IS was used as the extraction solvent. The stock and working solutions and the extraction solvent were stored at 4 °C in darkness. All chemicals and solvents were of analytical reagent grade or HPLC grade with purity more than 99 %.

Sample Oxidation Treatment

Fresh commercial mayonnaise samples were collected from one manufacturer immediately after production. Mayonnaise samples in a sealed glass flask were placed into an oven with the temperature set at 50 ± 2 °C for about 48 h in order to accelerate the oxidation process. Oxidized mayonnaise samples were stored at room temperature for further analysis.

Apparatus

A hot-plate magnetic stirrer was purchased from Heidolph Company (Heidolph, Germany) and equipped with a temperature-controlling probe for heating and stirring the sample solution simultaneously. In microextraction procedure, a 10-μL GC microsyringe with a bevel needle tip (Hamilton, Switzerland) was employed.

Gas chromatography analysis was performed using a 7890A GC system purchased from Agilent Technologies (Palo Alto, CA, USA) equipped with a split/splitless injector and a 5975 inert MSD network mass selective detector with quadrupole analyzer. A HP-5 MS capillary column (30 m × 250 μm ID, 0.25 μm film thickness) was used to separate some of the volatile oxidation compounds (hexanal and heptanal) under the split mode (1:50 ratio). The oven program temperature was as follows: initial temperature was set at 40 °C (2 min hold), then the temperature increased to 80 °C at 5 °C/min (1 min hold) in ramp 1, and finally increased to 280 °C at 30 °C/min (5 min hold) in ramp 2; the temperatures of interface and injector were set at 280 °C. Helium with a constant flow rate of 0.8 mL min−1 was employed as a carrier gas. Selected ion monitoring (SIM) mode was applied to quantify extracted compounds. The following ions were used for quantification: the selected m/z were 56 and 57 for hexanal and 55 and 70 for heptanal, respectively. Data acquisition and integration were carried out with the ChemStation chromatography software.

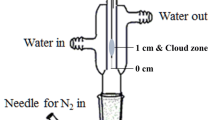

HS-SDME Procedure

First, different amounts of NaCl (0–3 g) and 0.2 g of the oxidized mayonnaise sample (50 °C/48 h) were weighted into a 17-mL glass vial containing a 0.5-cm magnetic stirring bar and 10 mL of distilled water; then the vial quickly was capped with a silicon/PTFE septum and crimped firmly with an aluminum seal to avoid the evaporation of analytes from the vial during the microextraction procedure. The sample vial was introduced into a temperature-controlled water bath (30–50 °C) placed on a magnetic hot-plate stirrer. The sample solution was equilibrated for 10 min at a stirring speed of 100–700 rpm.

After the equilibrium time, 3 μL of extraction solvent (n-dodecane) containing a constant concentration (10 mg L−1) of 2,5-dimethylfuran as IS was pulled into the GC microsyringe. During the extraction process, the microsyringe was fixed above the sample vial with a clamp. The needle of microsyringe pierced the septum and passed through it, while the end of needle was located about 1 cm above the surface of the sample solution. Then the plunger was pressed down and a microdrop was formed on the needle tip and exposed to the headspace of the sample vial. After the microextraction time (5–20 min), the drop of extraction solvent was retracted back into the needle of the microsyringe and injected directly into the GC–MS injection port for further analysis.

Results and Discussion

Selecting the Organic Solvent

It is a necessary step to discover a suitable organic solvent for HS-SDME method. Some fundamental specifications such as high boiling point, low vapor pressure, excellent purity, high chromatographic behavior, and effective partitioning coefficient of the analyte in the solvent need to be considered and are highly recommended when selecting an appropriate extraction solvent for the microextraction process. Based on previous literature, three different organic solvents including 1-octanol, n-decane, and n-dodecane were examined to be applied as extraction solvents for HS-LPME headspace microextraction technique (Chaichi et al. 2012; Habibi et al. 2012). Their results indicated that n-dodecane had the most compatibility with microextraction conditions and showed a desirable gas chromatographic manner. Consequently, n-dodecane was selected as the extraction solvent for our study. 2,5-Dimethylfuran was employed as an internal standard (IS) to modify differences in injection volumes of solvent.

Selecting the Volume of Organic Solvent

As demonstrated in the theory of single-drop microextraction, the amount of extracted analyte increases with the increasing volume of the organic solvent drop. Unfortunately, the maximum drop volume for a normal 10-μL microsyringe is about 2–3 μL. When the size of the drop is more than 3 μL, it becomes unstable and detaches from the needle. It must be kept in mind that even organic solvents with high boiling temperatures have partial volatility and some water-immiscible solvents really show limited solubility in water. As a result, a part of the solvent microdrop may be evaporated and/or dissolved in the sample solution, specifically when high extraction temperatures, lengthy extraction times, and speedy stirring rates of the microextraction procedure are applied (Asensio-Ramos et al. 2011; Jeannot et al. 2010; Sarafraz-Yazdi and Amiri 2010). Based on previous studies (Chaichi et al. 2012; Habibi et al. 2012), we selected 3 μL as an appropriate volume of extraction solvent for the HS-SDME procedure.

Headspace Single-Drop Microextraction

In the HS-SDME method, distribution of the analytes happens among three phases: (1) aqueous phase or sample solution, (2) headspace, and (3) single drop of organic solvent. During the extraction process, mass transfer of analyte from the aqueous phase to the drop of solvent has been proposed as the rate-determining step which affects the extraction performance (Theis et al. 2001). Accordingly, microextraction conditions including stirring speed, addition of salt, temperature, and time of extraction are crucial parameters that determine analyte mass transfer among mentioned phases in the HS-SDME method.

Experimental Design and Statistical Analysis

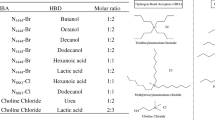

From a statistical view, the central composite design (CCD) has been proposed as one of the most employed response surface designs, which is composed of several factors (Ribeiro et al. 2010). Usually, CCD comprised 2k factorial runs with 2k axial runs and C 0 center points. The total number of experimental points needed (N) is determined: N = 2 k + 2k + C 0, where k is the number of variables to be optimized and C 0 is the number of center points (Stalikas et al. 2009). So, we selected the CCD with four independent variables in five levels (−2, −1, 0, +1, and +2) as a design for performing the RSM. The CCD was applied to optimize the most significant parameters (extraction temperature, extraction time, stirring rate, and amount of NaCl) on HS-SDME performance. This design includes 30 treatments overall: 16 in the factorial points, eight in the axial points, and six central points. Independent variables (microextraction parameters) and their limited areas are shown in Table 1, which were selected based on previous studies and preliminary experiments.

Design Expert software 7.0.0 was used to investigate the effects of microextraction parameters and their interaction on extracted hexanal and heptanal by analysis of variance (ANOVA) in order to determine the significant parameters and efficiency of models. Multiple linear regression was applied for fitting the experimental results on a quadratic polynomial equation mentioned as follows:

where Y is the predicted response variable, C k0 the constant coefficient, C ki the coefficient of linear effect, C kii the coefficient of squared effect, and C kij the coefficient of interaction effect; x i and x j are the coded independent variables.

For optimizing microextraction parameters which affect the efficiency of the extraction method, the sum of relative peak areas of extracted hexanal and heptanal to IS was expressed as GC response. In the optimization step of the extraction procedure, all of the experiments were done with oxidized mayonnaise sample.

Optimization of HS-SDME Method

Optimizing the most important parameters on the performance of HS-SDME procedure was done by using CCD. Analysis of variance (ANOVA) was carried out to investigate the suitability of recommended models and to check the significance of every parameter and their interactions (Table 2). A quadratic polynomial model was fitted on generated data of microextraction process; this model has the ability to predict response at every point, even those that have not been placed in the design. The model equation of applied RSM is illustrated in coded forms of independent variables in Eq. (2):

where R (the GC response) is the sum of relative peak areas for extracted analytes (hexanal and heptanal) as a function of X 1 (extraction temperature), X 2 (extraction time), X 3 (stirring rate), and X 4 (amount of NaCl).

Employing CCD in response surface methodology gave us this opportunity to evaluate the linear, quadratic, and interaction effects of four independent variables (extraction temperature and time, stirring rate, and amount of salt) on the response.

The ANOVA confirmed acceptability and qualification of the quadratic regression model which had excellent ability in predicting responses by considering very low probability (p value <0.0001) of the F value 19.94. The “lack of fit (LOF) p value” of 0.1247 indicates that the LOF is not significant relative to the pure error.

According to ANOVA results, it can be concluded that linear effects of extraction temperature (X 1) and amount of salt (X 4) were significant on obtained responses. Additionally, the interactive effect of extraction temperature and extraction time (X 1 X 2) on response was also significant.

In the plot of predicted responses versus actual responses, it is evident to see that most points of predicted and actual values intercept in 45 °C line which demonstrates qualification of the quadratic model for response prediction (Fig. 1).

The objective of many experiments and empirical models is to discover an optimum condition for obtaining the maximum response. In this way, response surface plots have been applied to understand the optimum range of parameters in regards to improving the response. The response surface is graphed by two independent variables while the others have been stabilized at their center points (zero levels in the CCD matrix).

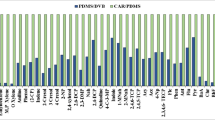

Figure 2a is the response surface plot showing the effects of extraction temperature and time on the response at the fixed center values for stirring rate (400 rpm) and amount of salt (1.5 g). Among the interaction terms of extraction parameters, the largest coefficient was dedicated to interaction effect of extraction temperature and extraction time (X 1 X 2) in the model equation. As can be seen, the extraction efficiency (GC response) increased with the simultaneous increase in temperature and time up to around 45 °C and 16 min, respectively. Thus, the extraction temperature had a positive effect on the performance of the extraction, and by increasing the temperature from 30 to 45 °C, the response increased due to enhancing vapor pressure of analytes. Furthermore, temperature induces a decline in the viscosity of the sample solution (aqueous phase) and an increase in mass transfer from the aqueous phase to headspace; therefore, it resulted in enhancement of analytes absorption into the solvent drop and induced an increase in extraction efficiency. A slight decline occurred at a higher temperature (above 45 °C) that could be a result of reduction in partition coefficient of analyte between the headspace and the extraction solvent. On the other hand, we observed that when increasing the extraction time to more than 16 min, a reduction in the volume of solvent drop occurred or the drop was no longer touching the needle, and consequently the response decreased. These obtained results are in agreement with previous studies (Chaichi et al. 2012; Habibi et al. 2012; Tankeviciute et al. 2001); they have proved that higher values of temperature and time resulted in a decrement of extraction performance because the volume of the extraction solvent decreased or the drop became detached from the needle and fell down.

Obtained response surfaces of microextraction variables relying on a central composite design: a extraction temperature vs. extraction time (stirring rate = 400 rpm, salt = 1.5 g); b extraction temperature vs. stirring rate (extraction time = 12.5 min, salt = 1.5 g); c extraction time vs. salt amount (extraction temperature = 40 °C, stirring rate = 400 rpm)

The combined effect of extraction temperature and stirring rate on the response has been displayed in Fig. 2b, while the extraction time and salt amount maintained a steady position in their center points (12.5 min and 1.5 g, respectively). As can be seen, with the concurrent increase in extraction temperature and stirring rate, the performance of the microextraction process was enhanced. The maximum response was obtained at 45 °C temperature and 700 rpm stirring rate. In headspace analysis, the synergistic effect of temperature and stirring rate on increasing mass transfer of analytes into headspace for obtaining higher response has been confirmed (Mohammadi and Alizadeh 2006).

We observed that by increasing the stirring rate from 100 to 700 rpm, the response enhanced continuously. Based on documented findings, it is demonstrated that using stirring rate above 800 rpm for HS-LPME technique may result in instability of solvent drop (Zhao et al. 2004). In our preliminary experiments, it was observed that higher stirring rate produced turbulence in the sample solution and detaching of the drop occurred.

The stirring of sample solution may speed up the analyte mass transferring from the aqueous phase and creating convection in the headspace. An equilibration between the aqueous and vapor phases can be reached more quickly by stirring the aqueous sample. In headspace sampling, it is necessary to achieve a linear correlation between the amounts of analytes in the sample solution and in the vapor phase.

The response surface plot of extraction time against amount of salt is given in Fig. 2c. This plot indicates that 16 min of extraction time and addition of 2 g salt can provide the best microextraction conditions to achieve a favorable response. As can be seen, the efficiency of the extraction process increases with the increase in the amount of salt up to 2 g. The addition of salt to the sample solution can reduce the solubility of analytes in the sample matrix as a result of the salting-out effect, so more analytes can transfer into the headspace, and the extraction efficiency can be enhanced greatly (Xu et al. 2007a; Zhao et al. 2004).

From the mentioned plot, it is also obvious that higher values of NaCl (more than 2 g) bring about a decline in extraction performance. According to Eq. 2, it can be understood that the coefficient of squared term for NaCl (X 4 2) is negative with a high level, indicating an inverse effect of high amounts of salt on response. This event can be described in this way that higher amounts of salt cause an increase in viscosity of sample solution. Moreover, dissolved ions of NaCl may make complexation with analyte molecules and induce hurdles for releasing analytes from sample phase to headspace; eventually, a reduction in vapor pressure of analytes in the headspace would occur. This finding is in accordance with some published results (Habibi et al. 2012; Xu et al. 2007a).

Based on obtained results of the optimization experiments, the optimum conditions for extraction of hexanal and heptanal from mayonnaise samples were selected as follows: extraction temperature of 45 °C, extraction time 16 min, stirring rate at 700 rpm, and 2 g of NaCl.

Validation of the HS-SDME Method

After optimization procedure for microextraction conditions, the analytical parameters of the method (linearity, precision, accuracy, and sensitivity) were calculated in order to validate the usefulness of the HS-SDME/GC–MS method for the determination of hexanal and heptanal in oxidized mayonnaise samples. The results are displayed in Table 3.

Nine-point calibration curves were figured by relative peak areas of hexanal and heptanal versus their concentrations over the range of 0.025–10 μg g−1. Good linearity was found for extracted analytes with the acceptable square of correlation coefficient (R 2 > 0.99) (Table 3).

Repeatability was calculated from seven replicate extractions of the thermally oxidized mayonnaise sample and is shown as relative standard deviation percentage (RSD%). As Table 3 represents, the values of RSD were 4.04 % and 3.68 % for hexanal and heptanal, respectively.

Relative recoveries of hexanal and heptanal were obtained by spiking four mayonnaise samples with the mixed working solution to achieve a final concentration of 5 μg L−1 for each aldehyde. The relative recovery of each analyte was determined for the HS-SDME procedure by comparing the amount of analyte added to a mayonnaise sample with the concentration found after the procedure. As shown in Table 3, the values of relative recovery using the proposed method were 107.33 % and 91.43 % for hexanal and heptanal, respectively. A similar value has been reported for hexanal (106.6 %) in infant formulas with HS-SPME method (García-Llatas et al. 2007), but lower value (97.37 %) for extracted hexanal from butter samples (Panseri et al. 2011).

According to the American Chemical Society guidelines (1980), the limit of detection (LOD) and limit of quantification (LOQ) were defined as signal three and 10 times the height of the noise level, respectively (MacDougall and Crummett 1980). In this study, the calculated LOD and LOQ (0.008 and 0.027 ng g−1, respectively) for hexanal were lower than reported values in infant formulas, butters, and potato crisps employing the HS-SPME technique (García-Llatas et al. 2007; Panseri et al. 2011; Sanches-Silva et al. 2004). The estimated LOD and LOQ for heptanal (0.021 and 0.071 ng g−1, respectively) were also lower than the limits obtained by Gromadzka and Wardencki (2010) for edible oils using the SPME method (Gromadzka and Wardencki 2010).

Comparing the results of isolation and determination of hexanal and heptanal by applying the optimized HS-SDME as a novel technique in this study with previous data using the other methods (Chitsamphandhvej et al. 2008; García-Llatas et al. 2007; Gromadzka and Wardencki 2010; Iglesias et al. 2007; Panseri et al. 2011) indicated that the recommended technique is similar or superior for analysis of volatile oxidation compounds in foodstuffs (Table 4).

Application to Real Sample

With the purpose of checking the suitability of the proposed method for measuring hexanal and heptanal as the major volatile oxidation compounds, commercial fresh mayonnaise samples were stored at two different temperatures (4 and 25 °C) during a 3-month storage time. Extraction was done by HS-SDME under optimized conditions as described above. Concentrations of hexanal and heptanal were determined with the regression equations which were acquired from the calibration curves. Analysis of each mayonnaise sample was done in triplicate and results expressed as average values. The analytical results, verified by standard addition method, are represented in Table 5.

According to the obtained results, the concentration of hexanal was higher than heptanal in mayonnaise samples. The mayonnaise samples that were stored at 25 °C showed higher amounts of hexanal and heptanal during storage time. In this study, the levels of hexanal in mayonnaise stored at 25 °C ranged between 915 and 3,990 ng g−1, while Panseri et al. reported lower levels of hexanal in butter samples stored at 4 °C during 6 months of storage (15.12–86.25 ng g−1) (Panseri et al. 2011). Amounts of heptanal in mayonnaise stored at 4 °C were in the range of 360–1,054 ng g−1; similar amounts of heptanal (190–720 ng g−1) were reported for fried pork skin (Capmoo) during 14 weeks of storage in their study (Chitsamphandhvej et al. 2008).

These results confirmed that HS-SDME/GC–MS is a reliable and sensitive method for monitoring hexanal and heptanal at very low concentrations in a commercial mayonnaise. The obtained chromatogram by HS-SDME/GC–MS method under SIM mode for a mayonnaise sample is shown in Fig. 3, which demonstrates good separation without presence of sample-matrix interference. Peak splitting was clearly observed in hexanal and heptanal peaks. This is probably due to the formation and partial separation of hexanal and heptanal isomers in oxidized mayonnaise samples.

Conclusion

In the present study, a rapid, simple, sensitive, and reliable headspace microextraction technique was developed and validated for the determination of hexanal and heptanal as lipid oxidation products in commercial mayonnaise. Optimization of microextraction variables was done by RSM using central composite design to achieve maximum efficiency of the extraction method. The ANOVA determined the interactive and quadratic effects of variables when choosing the most efficient microextraction conditions with the least experiments and amount of time. Minimal consumption of organic solvent (about 3 μL per sample), integration of sample preparation and extraction into a single step, simple analysis procedure, no interference of sample matrix, and high sensitivity (lower values of LOD and LOQ) with good precision and accuracy are the main highlighted properties of the HS-SDME/GC–MS method as a good alternative for other headspace analytical techniques. The results obtained in this study confirmed the capability of HS-SDME coupled with GC-MS for extracting and quantifying hexanal and heptanal in mayonnaise.

References

Arthur CL, Pawliszyn J (1990) Solid phase microextraction with thermal desorption using fused silica optical fibers. Anal Chem 62(19):2145–2148

Asensio-Ramos M, Ravelo-Pérez LM, González-Curbelo MÁ, Hernández-Borges J (2011) Liquid phase microextraction applications in food analysis. J Chromatogr A 1218(42):7415–7437

Batlle R, Nerı́n C (2004) Application of single-drop microextraction to the determination of dialkyl phthalate esters in food simulants. J Chromatogr A 1045(1):29–35

Beltran G, Aguilera MP, Gordon MH (2005) Solid phase microextraction of volatile oxidation compounds in oil-in-water emulsions. Food Chem 92(3):401–406

Beltran A, Ramos M, Grane N, Martin M, Garrigós M (2011) Monitoring the oxidation of almond oils by HS-SPME–GC–MS and ATR–FTIR: application of volatile compounds determination to cultivar authenticity. Food Chem 126(2):603–609

Bezerra MA, Santelli RE, Oliveira EP, Villar LS, Escaleira LA (2008) Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 76(5):965–977

Buldini PL, Ricci L, Sharma JL (2002) Recent applications of sample preparation techniques in food analysis. J Chromatogr A 975(1):47–70

Chaichi M, Mohammadi A, Hashemi M (2012) Optimization and application of headspace liquid-phase microextraction coupled with gas chromatography–mass spectrometry to determination of furanic compounds in coffee using response surface methodology. Microchem J 108:46–52

Chitsamphandhvej W, Phakdee W, Thanasan W (2008) A headspace solid phase microextraction method for using to monitor hexanal and heptanal content in food samples. Kasetsart J Nat Sci 42:206–212

Coupland JN, McClements DJ (1996) Lipid oxidation in food emulsions. Trends Food Sci Technol 7(3):83–91

del Mar CM, del Castillo MLR, Blanch GP (2011) Solid-phase microextraction to the study of the stability of selected volatile constituents in irradiated Manchego cheese. Food Anal Methods 4(4):608–613

Deng C, Mao Y, Hu F, Zhang X (2007) Development of gas chromatography–mass spectrometry following microwave distillation and simultaneous headspace single-drop microextraction for fast determination of volatile fraction in Chinese herb. J Chromatogr A 1152(1):193–198

Depree J, Savage G (2001) Physical and flavour stability of mayonnaise. Trends Food Sci Technol 12(5–6):157–163

Frankel E (1983) Volatile lipid oxidation products. Prog Lipid Res 22(1):1

Frankel E (1993) Formation of headspace volatiles by thermal decomposition of oxidized fish oils vs. oxidized vegetable oils. J Am Oil Chem Soc 70(8):767–772

Frankel E, Hu ML, Tappel A (1989) Rapid headspace gas chromatography of hexanal as a measure of lipid peroxidation in biological samples. Lipids 24(11):976–981

García-Llatas G, Lagarda MJ, Romero F, Abellán P, Farré R (2007) A headspace solid-phase microextraction method of use in monitoring hexanal and pentane during storage: application to liquid infant foods and powdered infant formulas. Food Chem 101(3):1078–1086

Gromadzka J, Wardencki W (2010) Static headspace sampling and solid-phase microextraction for assessment of edible oils stability. Chromatographia 71(1–2):81–86

Habibi H, Mohammadi A, Hoseini H, Mohammadi M, Azadniya E (2012) Headspace liquid-phase microextraction followed by gas chromatography–mass spectrometry for determination of furanic compounds in baby foods and method optimization using response surface methodology. Food Anal Methods. doi:10.1007/s12161-012-9510-7

Halliwell B, Murcia MA, Chirico S, Aruoma OI (1995) Free radicals and antioxidants in food and in vivo: what they do and how they work. Crit Rev Food Sci Nutr 35(1–2):7–20

Hartvigsen K, Lund P, Hansen LF, Holmer G (2000) Dynamic headspace gas chromatography/mass spectrometry characterization of volatiles produced in fish oil enriched mayonnaise during storage. J Agric Food Chem 48(10):4858–4867

Iglesias J, Lois S, Medina I (2007) Development of a solid-phase microextraction method for determination of volatile oxidation compounds in fish oil emulsions. J Chromatogr A 1163(1):277–287

Irwin J, Hedges N (2004) Measuring lipid oxidation. In: Steele R (ed) Understanding and measuring shelf life of food. CRC, Boca Raton, pp. 289–316

Jeannot MA, Przyjazny A, Kokosa JM (2010) Single drop microextraction—development, applications and future trends. J Chromatogr A 1217(16):2326–2336

Lozano PR, Miracle ER, Krause AJ, Drake M, Cadwallader KR (2007) Effect of cold storage and packaging material on the major aroma components of sweet cream butter. J Agric Food Chem 55(19):7840–7846

MacDougall D, Crummett WB (1980) Guidelines for data acquisition and data quality evaluation in environmental chemistry. Anal Chem 52(14):2242–2249

Mallia S, Escher F, Schlichtherle-Cerny H (2008) Aroma-active compounds of butter: a review. Eur Food Res Technol 226(3):315–325

Mohammadi A, Alizadeh N (2006) Automated dynamic headspace organic solvent film microextraction for BTEX renewable liquid film as a sampler by a programmable motor. J Chromatogr A 1107(1–2):19–28

Panseri S, Soncin S, Chiesa LM, Biondi PA (2011) A headspace solid-phase microextraction gas-chromatographic mass-spectrometric method (HS-SPME–GC/MS) to quantify hexanal in butter during storage as marker of lipid oxidation. Food Chem 127(2):886–889

Pena-Pereira F, Lavilla I, Bendicho C (2010) Liquid-phase microextraction techniques within the framework of green chemistry. Trends Anal Chem 29(7):617–628

Pillonel L, Bosset J, Tabacchi R (2002) Rapid preconcentration and enrichment techniques for the analysis of food volatile. A review. LWT-Food Sci Technol 35(1):1–14

Ribeiro J, Teófilo R, Augusto F, Ferreira M (2010) Simultaneous optimization of the microextraction of coffee volatiles using response surface methodology and principal component analysis. Chemom Intell Lab Syst 102(1):45–52

Sanches-Silva A, Rodriguez-Bernaldo de Quiros A, Lopez-Hernandez J, Paseiro-Losada P (2004) Determination of hexanal as indicator of the lipidic oxidation state in potato crisps using gas chromatography and high-performance liquid chromatography. J Chromatogr A 1046(1–2):75–81

Sarafraz-Yazdi A, Amiri A (2010) Liquid-phase microextraction. Trends Anal Chem 29(1):1–14

Stalikas C, Fiamegos Y, Sakkas V, Albanis T (2009) Developments on chemometric approaches to optimize and evaluate microextraction. J Chromatogr A 1216(2):175–189

Steenson D, Lee J, Min D (2006) Solid phase microextraction of volatile soybean oil and corn oil compounds. J Food Sci 67(1):71–76

Tankeviciute A, Kazlauskas R, Vickackaite V (2001) Headspace extraction of alcohols into a single drop. Analyst 126(10):1674–1677

Theis AL, Waldack AJ, Hansen SM, Jeannot MA (2001) Headspace solvent microextraction. Anal Chem 73(23):5651–5654

van Ruth SM, Vries G, Geary M, Giannouli P (2002) Influence of composition and structure of oil-in-water emulsions on retention of aroma compounds. J Sci Food Agric 82(9):1028–1035

Vandendriessche T, Nicolai B, Hertog ML (2012) Optimization of HS SPME Fast GC–MS for high-throughput analysis of strawberry aroma. Food Anal Methods 6(2):512–520

Verzera A, Condurso C, Romeo V, Tripodi G, Ziino M (2010) Solid-phase microextraction coupled to fast gas chromatography for the determination of migrants from polystyrene-packaging materials into yoghurt. Food Anal Methods 3(2):80–84

Xiao Q, Hu B, He M (2008) Speciation of butyltin compounds in environmental and biological samples using headspace single drop microextraction coupled with gas chromatography–inductively coupled plasma mass spectrometry. J Chromatogr A 1211(1):135–141

Xu H, Liao Y, Yao J (2007a) Development of a novel ultrasound-assisted headspace liquid-phase microextraction and its application to the analysis of chlorophenols in real aqueous samples. J Chromatogr A 1167(1):1–8

Xu L, Basheer C, Lee HK (2007b) Developments in single-drop microextraction. J Chromatogr A 1152(1–2):184–192

Ye N, Zhang L, Gu X (2012) Discrimination of green teas from different geographical origins by using HS-SPME/GC–MS and pattern recognition methods. Food Anal Methods 5(4):856–860

Zhao R, Lao W, Xu X (2004) Headspace liquid-phase microextraction of trihalomethanes in drinking water and their gas chromatographic determination. Talanta 62(4):751–756

Acknowledgments

The authors would like to thank the Institute of National Nutrition & Food Technology Research/Iran for financial assistance for this research. The authors also wish to thank Mahram Food Manufacturing Company for supplying samples in this study.

Conflict of Interest

Maryam Enteshari declares that she has no conflict of interest. Abdorreza Mohammadi has received research grants from National Nutrition and Food Technology Research Institute. Kooshan Nayebzadeh declares that he has no conflict of interest. Ebrahim Azadniya declares that he has no conflict of interest. This article does not contain any studies with human or animal subjects.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Enteshari, M., Mohammadi, A., Nayebzadeh, K. et al. Optimization of Headspace Single-Drop Microextraction Coupled with Gas Chromatography–Mass Spectrometry for Determining Volatile Oxidation Compounds in Mayonnaise by Response Surface Methodology. Food Anal. Methods 7, 438–448 (2014). https://doi.org/10.1007/s12161-013-9643-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-013-9643-3