Abstract

To facilitate the international food trade as well as to protect consumers from exposure to unacceptable pesticide residue levels, Codex Alimentarius Commission, European Union, and National Authorities set maximum residue limits for different food commodities. The control of pesticide residues at national and international level requires reliable and comparable analytical data that can be obtained by applying validated methods and implementing an effective internal quality control and quality assurance system in the testing laboratories. For the correct interpretation of the analytical results, measurement uncertainty should be estimated. Pesticide residue analysis includes two main steps: sampling performed outside of the laboratory and laboratory operations comprising of sample preparation, sample size reduction, sample processing, extraction, cleanup, and chromatographic determination. By taking into consideration the contribution of the individual steps to the overall uncertainty of the results, the analytical procedures can be optimized to fit for the purpose of the analysis with minimum cost. The scope of this paper is to review major steps of pesticide residue analysis in the light of current developments, to highlight the importance of identification and estimation of the uncertainties associated with the results, to describe suitable methods for their estimation, and to summarize the contribution of each step to the combined uncertainty.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Infestation caused by pests can significantly reduce the yield of agricultural and horticultural crops. In order to protect crops, plant protection products are used. The use of pesticides dates back to 1,000 bc when Chinese used sulfur as a pesticide to control powdery mildew on fruit (Winter 2001). The value of worldwide agricultural production increased from $1,115,933 to $1,543,783 between the years 1993 and 2007 (http://www.fao.org). The use of pesticides in the agricultural production increases the yield of crops; on the other hand, uncontrolled and abusive application of pesticides can cause health problems and contaminates the environment. The adverse effects depend on the toxicities, application rates of pesticides, and consumption of treated food. The use of these chemicals is regulated in order to protect consumers from exposure to unacceptable levels of pesticide residues in food and feed (http://ec.europa.eu).

To facilitate the international food trade and to protect consumers’ health, the Codex Alimentarius Commission (CAC), European Union, and National Authorities set maximum residue limits (MRLs) based on good agricultural practice (CAC 2009a; EC 2005). Pesticide residue analysis of food commodities is generally required for registration of pesticides, checking compliance with MRLs in foods, and to provide data for protection of the environment and risk assessment, as well as verification of organic food labeling. For these purposes, each year many thousands of food and environmental samples are analyzed worldwide. In the European Union, more than 70,000 samples of nearly 200 different types of food were analyzed for pesticide residues in 2008 (EFSA 2010). In order to assist laboratories producing reliable and reproducible analytical results, guidelines have been developed on good laboratory practice in residue analysis (CAC 2003) and method validation and analytical quality control requirements (SANCO 2011). Reliable and comparable analytical data can be obtained by applying validated methods and implementing an effective internal quality control and quality assurance system in the testing laboratories. For the correct interpretation of the results, the uncertainty of the whole measurement process should be taken into account as required by the International Organization for Standardization/International Electrotechnical Commission (ISO/IEC) Standard 17025 (ISO/IEC 2005).

The scope of this paper is to review the major steps of pesticide residue analysis in the light of current developments, to highlight the importance of identification and estimation of the uncertainties associated with the results, to describe suitable methods for their estimation, and to summarize the contribution of each step to the combined uncertainty.

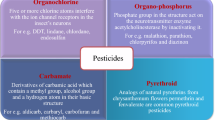

Pesticide Residue Analysis

Steps in Pesticide Residue Analysis

Determination of pesticide residues was generally performed in seven steps: sampling, sample preparation, sample size reduction, sample processing, extraction and cleanup, and instrumental determination (Fig. 1).

Sampling

Sample is defined as one or more units selected from a population of units, or a portion of material selected from a larger quantity of material (IUPAC 1990; CAC 1999; EC 2002). If a representative sample reflecting the properties of the sampled object in adequate manner can be provided, reliable results can be reported to an end user (Thompson and Ramsey 1995).

CAC set sampling methods for the determination of pesticide residues for compliance with MRLs. A Codex MRL for meat and poultry is applied to a bulk sample derived from a single primary sample, while MRLs for plant products, eggs, and dairy products are applied to a composite bulk sample derived from one to ten primary samples. The primary samples must be taken randomly and should consist of sufficient material to provide laboratory sample(s) required from a single lot. If the bulk sample is larger than the required laboratory sample, it should be divided to obtain a representative portion. If mixing is inappropriate to form the bulk, the units should be allocated randomly to replicate laboratory samples at the time of taking primary samples. In this case, the replicate laboratory samples should be considered independent and their residue content interpreted accordingly. The minimum sizes of laboratory sample are defined, and these change according to food commodity. Samples of large-sized fresh fruits and vegetables (e.g., cabbages and cucumbers) with a unit generally larger than 250 g should contain a minimum of five crop units (2 kg), whereas samples of medium-sized commodities (e.g., apples and oranges) with unit weight between 25 and 250 g should contain ten fruits (1 kg). The European Community together with many countries applies the Codex sampling method (CAC 1999; EC 2002).

Sample Preparation

A sample received at laboratory not including package is known as laboratory sample. Conversion of laboratory sample into analytical sample may need sample preparation which includes removal of parts such as soil, stones, bones, withered leaves, etc. Sample preparation may be subject to systematic and random errors and it cannot be validated (Hill et al. 2000) Therefore, the analysts should exactly follow the Codex standard procedure (CAC 1999).

Sample Size Reduction

Pesticide residues are not homogenously distributed within the laboratory sample. Therefore, it is mandatory to process the whole laboratory sample to obtain a representative portion for extraction. The whole laboratory sample of large crops will be too big for the processing equipment, since, for instance, one cabbage, jackfruit, and papaya can weigh 2–3, 4–50, and 1–2 kg, respectively. Therefore, the size of the laboratory sample should be reduced by selecting one longitudinal segment from each fruit composing of the laboratory sample.

Sample Processing

The sample processing may include cutting, grinding, and mixing to make the analytical sample acceptably homogeneous with respect to the analyte distribution, prior to removal of the analytical portion. Sample processing must be designed to avoid inducing changes in the concentration of the analyte. Sample processing and preparation are often used equivalently, though they should be clearly distinguished.

The following categories of equipment are mostly used for sample processing of food commodities (FDA 1999): (a) Blenders and homogenizer, the most popular equipment used in routine laboratories, generally consist of blades that are capable of high-speed movement. Blenders and homogenizers are most effective with liquids or samples that liquefy easily when blended (Kovalczuk et al. 2008). (b) Choppers and food processors have large capacities to comminute solid raw agricultural commodities, such as fruits and vegetables (Paya et al. 2007). (c) Grinders are effective equipment for homogenization of raw meat and fish; (d) Mills are used for comminuting dry, hard commodities, such as grains (Mastovska et al. 2010).

Sample processing can be performed with the equipment explained as above either at ambient temperature or with the presence of dry ice. Homogenization time and speed of the equipment are adjusted to get pieces of peel ≤2–3 mm in size. This particle size was found as the minimum requirement for getting a well-homogenized analytical portion of ≥30 g (Maestroni et al. 2000a, b). If smaller portions (2–10 g) are extracted, the particles in the homogenized material must be much smaller.

Extraction

During extraction, pesticide residues and relevant metabolites are separated from the matrix and transferred into a liquid phase. The undissolved materials can be separated with filtration and centrifugation. Extraction efficiency of the analytical methods has been studied by some researcher so far (Senseman et al. 2003; Riley et al. 2005; Riedel et al. 2010). It was reported that the main parameters that affect the efficiency of extraction and consequently its uncertainty include sample matrix, particle size distribution, pH, extraction solvents, water content, temperature, and sample: solvent ratio, extraction method, time of extraction, types and amount of salt added, pressure, etc. (Lehotay and Mastovska 2007).

The extraction of a solid sample using a liquid (solvent) is typically applied in pesticide residue analysis (Krynitsky and Lehotay 2002). Some blenders and homogenizers can be used to disintegrate the matrix. The extraction solvents are chosen according to nature of the compounds to be determined and on the matrix under investigation. Ethyl acetate, acetonitrile, acetone, hexane, and methanol are the other commonly used solvents for sample extraction, depending on the commodity extracted (Pang et al. 1995; Klein and Alder 2003; Lehotay and Mastovska 2007; Schenk and Wong 2007). In recent years, more sophisticated equipment such as liquid-phase microextraction, microwave-assisted extraction, and supercritical fluid extraction have been developed as alternative methods to solvent-based extractions. Unfortunately, the equipment are costly and need specialized servicing (Lehotay and Eller 1995; Eskilsson and Björklund 2000; Lambropoulou and Albanis 2007).

Cleanup

Extraction cannot remove easily co-extractives such as oils, fats, waxes, and plant pigments, which can interfere significantly with the determination step. The removal of the extraneous co-extractives from the extract is known as sample clean up. Cleanup procedures depend on the differences in the physicochemical properties of the analytes from co-extracted matrix components (Krynitsky and Lehotay 2002).

There are various cleanup methods used in pesticide residue analysis. One of them is gel permeation chromatography (GPC) that allows the separation of compounds based on their molecular size (Tekel and Hatrik 1996). Solid-phase extraction (SPE) is a cleanup technique that uses high-performance liquid chromatography (HPLC) sorbents to separate analytes from the sample matrix. The sample is passed over a stationary phase. Florisil, alumina, aminopropil, and primary secondary amine (PSA) are common SPE sorbents. Polar organics such as sugars and fatty acids are strongly remained by PSA (Krynitsky and Lehotay 2002). The cleanup step of recently developed method, known as QuEChERS (quick, easy, cheap, effective, rugged, and safe), for pesticide residues in foods involves PSA (25 mg PSA for a 1-ml aliquot of 1 g sample equivalent) with anhydrous MgSO4, and the approach was defined as “dispersive-solid phase extraction.” The sorbents are simply mixed with acetonitrile extract on a vortex mixer to evenly distribute the SPE material (Anastassiades et al. 2003; Lehotay et al. 2005a, b, c; 2010).

Quantitative Determination

Gas chromatography (GC) with element-selective detectors [nitrogen phosphorus detector (NPD), FPD, and electron capture detector (ECD)] has been used for the determination of pesticides for many years. These systems are used for pesticides containing hetero-atoms such as halogens, phosphorus, sulfur, and nitrogen (Schenk and Wong 2007). Polar pesticides are not amenable to direct GC analysis. Therefore, they should be determined by HPLC. While element-selective detectors are still widely used (Aysal et al. 2004 and 2007; Georgakopoulos et al. 2009; Hernandez-Borges et al. 2009), they are being replaced or complemented by mass spectrometric (MS) detectors (Chen et al. 2009; SANCO 2011; Lehotay et al. 2010). Ultra-performance liquid chromatography with tandem quadruple mass spectrometry (UPLC-MS/MS) has been applied as a fast multi-residue method for determining polar pesticides (Kovalczuk et al. 2008; Pico et al. 2009). It was reported that the total time required for UPLC-MS/MS analysis of 64 pesticide residues and their toxic metabolites in fruit extracts was approximaely 8 min (Kovalczuk et al. 2008).

Measurement Uncertainty

Definition of Error and Uncertainty

Identification of the sources of errors is required to estimate their magnitude and to decrease them if possible in order to optimize the procedures. There are three types of errors: gross or spurious, random, and systematic. Gross error is generally unintentionally occurred by analyst mistake or an instrumental malfunction when analytical result is generated. Therefore, it invalidates a measurement. Since it cannot be evaluated statistically, it is not included in the combined uncertainty. A sample that has been contaminated by poor handling can be given as an example to gross errors. Random errors which exist in all measurements cause variations in repeated observations of the measurand. As a result of random errors, replicate results can fall on either side of the mean value. Its magnitude can be decreased by increasing the number of observation. Systematic errors are also common in measurements. It is reported that systematic error always affects a series of measurements in the same sense; it means that all the data in a sample have values either too high or too low. In contradiction to random error, it cannot be reduced by increasing number of analysis (Miller and Ambrus 2000, EURACHEM/CITAC 2000; JCGM 2008a). Codex Guideline defines the most common random and systematic error in pesticide residue analysis. Some systematic errors include selection of analytical sample analyzed, decomposition of analyte during sample processing, incomplete recovery of analyte, and biases in calibration. Non-homogeneity of the analyte in single units of analytical sample, variation in composition of sample materials taken from a commodity, and precision and linearity of balances are examples of random errors in pesticide residue analysis (CAC 2006).

Uncertainty is defined as a non-negative parameter characterizing the dispersion of the quantity values being attributed to a measurand, based on the information used (JCGM 2008b). The parameter may be expressed as a standard deviation or half width of an interval with a given probability. Uncertainty is a different concept from measurement error, which can be defined as the difference between an individual result and the true value. Error is a single value; on the other hand, uncertainty is a range or an interval. The standard deviation of a repeated analysis results is not a measure of random error. Instead, it is the measure of the uncertainty of the mean value occurred by random effects (JCGM 2008a).

Approaches to Estimation of Measurement Uncertainty

It is a requirement under ISO/IEC 17025 that laboratories shall determine and make available the uncertainty associated with analytical results (ISO/IEC 2005). Therefore, laboratories should estimate the uncertainty of measurement results with an appropriate approach. To estimate uncertainty, measurand is firstly specified, possible sources of uncertainty are identified, uncertainty components are quantified, and finally combined uncertainty is calculated (EURACHEM/CITAC 2000).

There are basically two main approaches for estimating the uncertainty of analytical measurements. These are defined as bottom-up and top-down methods. Bottom-up approach is introduced by ISO (1993) and elaborated in 1995 by A focus for Analytical Chemistry in Europe/Cooperation on International Traceability in Analytical Chemistry (EURACHEM/CITAC) for analytical chemistry. In the bottom-up method, analytical procedures are divided into individual components or steps. Their standard uncertainties are estimated and summed up together to form the combined uncertainty. The bottom-up approach is very laborious and needs specific knowledge of the whole procedure. On the other hand, it is a useful approach that provides an understanding of the major components of measurement uncertainty. By taking into consideration the contribution of the individual procedures or steps to the overall uncertainty of the results, the analytical procedures can be optimized to fit for the purpose of the analysis with minimum cost (Ambrus 2004).

The top-down method is dependent on the results of inter-laboratory proficiency tests, collaborative trials, internal quality control data, and inter- or intra-laboratory validation studies (precision and trueness). If estimation is based on inter-laboratory studies, it takes into account the between-laboratory variability of the results. The second edition of EURACHEM Guide uses the validation and related data for obtaining uncertainty estimates (EURACHEM/CITAC 2000). Alder et al. (2001) estimated between laboratories’ relative reproducibility standard deviation of 25 % for pesticide residue analysis from proficiency test results in the concentration range of 1 μg/kg–10 mg/kg. This estimate naturally does not include sampling and sample processing. Furthermore, there are some more standard and guidelines, based on top-down method (Barwick and Ellison 2000, ISO 2004; Magnusson et al. 2004). Eurolab released a technical report on measurement of uncertainty. The report provides a summary of the current main approaches for uncertainty evaluation as well as outlines in detail the use of method validation and proficiency test results data for estimating measurement uncertainty (EUROLAB 2007).

Based on these background guidelines and standards, Codex Committee on Pesticide Residue is in the step of proposing a revised guideline on the uncertainty estimation of pesticide residue analysis from simplified top-down approach (CAC 2009b). Furthermore, Codex Committees on Methods of Analysis and Sampling (CCMAS) are working on the development of guidelines for estimation and interpretation of uncertainty of measurement results (CAC 2010). These guidelines are mostly concentrated on the analysis part, and they are not covering the estimation of uncertainty in individual steps of analysis such as sampling and sample processing.

Identification of Standard Uncertainties in Pesticide Residue Analysis

The uncertainty of analytical results obtained from pesticide residue analysis (S R) can be calculated from the uncertainty of sampling, S S, uncertainty of sample processing (S Sp), and uncertainty of the analysis (extraction, cleanup, and instrumental determination) (S A) with the application of the general law of error propagation. If sample size reduction is applied to a laboratory sample prior to sample processing, its uncertainty (S Size reduction) should also be added.

where S L refers to uncertainty arisen from laboratory phase.

If the whole sample is analyzed, the mean residue remains the same and the equation can be written as:

where CVR refers to relative uncertainty of analytical results obtained from pesticide residue analysis.

The relative uncertainty of results of the analysis of a laboratory sample (CVL) is influenced by the random errors of sample size reduction (CVSizereduction), sample processing (CVSp), extraction (CVex), cleanup (CVcleanup), and chromatographic determination (CVch). If the relative uncertainties of the individual steps are identified, the combined relative uncertainty of laboratory phase can be expressed as:

Estimation Methods of Standard Uncertainties in Pesticide Residue Analysis and Contribution of Individual Steps to Combined Uncertainty

Sampling

Variations, which are caused by heterogeneity as well as contamination, loss of analyte, or use of an incorrect sampling plan, may be observed between the compositions of random samples taken from a lot (Thompson 1998). These variations can lead to uncertainty in sampling step and should be taken into account (Ramsey et al. 1992; Ramsey et al. 1995; Glaeser 2002). However, in the past measurement uncertainty was generally considered only for laboratory phase (Zorzi et al. 2002). This conception has been changing, and sampling uncertainty is becoming increasingly recognized after the first edition of ISO/IEC 17025 released in 1999.

Various methods, which are dedicated to estimate sampling uncertainty for many contaminants and residues, have been published (Ambrus 1996; Ramsey 1997; Ramsey and Argyraki 1997; Ramsey et al. 1999; Squire et al. 2000; Gustavsson et al. 2006; Whitaker et al. 2006). One of them introduced by Ambrus (1996) and applied successfully in other studies (Hill 2000; Ambrus and Soboleva 2004; Caldas et al. 2006; Ambrus 2009) is based on the analysis of pesticide residues in crop units taken from a single field and drawing random samples of various sizes with replacement from them with a computer. The uncertainty of sampling, expressed as the standard deviation of the calculated residues in composite samples, could be calculated without error of sample processing and analyses and any additional costs. The results can be used for optimizing sampling protocols.

The methods used by Ramsey and Argyraki (1997) provided the basis for the recent international guideline elaborated by EURACHEM/EUROLAB/CITAC/Nordtest for estimation of uncertainty arising from sampling (Ramsey and Ellison 2007). After that, the Nordtest (Gron et al. 2007) group provided further case studies to complement the guideline.

The current international guideline defines the application of bottom-up and top-down approach in the estimation of sampling uncertainty. One of the methods based on top-down approach is defined as a duplicate method. In this method, a single sampler, a person carrying out the sampling procedures at the sampling point, should take duplicate samples from at least eight sampling targets (lot) (i.e., 10 % of the total number of sampling target, but no less than eight targets). Target refers to a portion of material at a particular time that the sample is intended to represent. On the other hand, the ISO Standard 11648–1 (ISO 2003) for sampling bulk materials recommends that, for obtaining sufficient information about the variability of the analyte, ∼20 lots should be sampled with preferably several pairs of samples taken from each lot. If duplicates are collected from the same sampling target, then sampling uncertainty just characterizes that target. However, if they are taken from different targets, then more rugged estimates can be obtained. All duplicate samples are prepared physically to obtain a test sample for further analysis. Replication can also be done in the sample preparation or in the other analytical steps to get more information on uncertainty (called as balanced design). Analysis of variance (ANOVA) is used as a statistical tool for estimating the random component of the uncertainty and it enables to separate sampling and analysis variances. Range statistics is also offered for calculations (Ramsey and Ellison 2007). Lyn et al. (2007) reported that duplicate method is a simple and cost-effective procedure for estimating sampling uncertainty. CAC (2008) also recommended duplicate method as broadly applicable across the food sector.

The uncertainty of sampling in pesticide residue analysis may contribute to the 80–90 % of the combined uncertainty of the results (Ambrus and Lantos 2002). Variability of residues within a field causes sampling uncertainty in pesticide residue analysis. Active ingredient application conditions, the agro-climatic and environmental conditions at the time of application, or delivery, size, shape, and density of plants have been claimed as significant factors influencing the distribution of residues within a field. On the other hand, physicochemical properties of some active substances did not appear to influence the variability. Besides the effect of pre-harvest, interval was considered insignificant for influencing the variability where the crop unit size did not change significantly during the period under consideration (Ambrus 2000; Harris 2000; Harris et al. 2000; Hamilton et al. 2004).

Variability of pesticide residues in composite samples has been related to the sample size. The relationship between the standard deviation of the residues in primary samples and composite samples of size can be described by the central limit theorem. According to the theorem, sampling uncertainty can be decreased by increasing sample size. Ambrus and Soboleva (2004) estimated typical relative standard uncertainties of sampling medium-sized crops for pesticide residue analysis in the cases of sample sizes of 1, 5, 10, and 25 as 81, 37, 25, and 16 %, respectively. Ambrus (2009) conducted additional field trials to provide residue data for refining the estimated sampling uncertainty for small- and large-sized crops. It was concluded that the estimated typical relative uncertainties of taking composite samples according the Codex sampling procedure for determination of pesticide residues in small- and medium-sized and large-sized crops are 25 and 33 %, respectively.

Between-fields variation of residues in composite samples is usually two to three times larger than the variation within field due to the differences in mean values of residue. The typical coefficient of variation (CV) values of between-fields variation of residues in composite samples ranged between 80 and 120 % (Ambrus 2000). In a mixed consignment, a lot containing residues above the maximum residue limit can easily remain unobserved. Consequently, sampling of mixed lots should be avoided as far as practically possible (Hill 2000).

Sample Processing

It is generally assumed that sample processing procedure results in analytical portions that are representative of the analytical sample, even if 2–10-g portions are withdrawn from a large composite sample. Collaborative studies and proficiency tests are carried out with homogenized test materials. The recovery studies are usually performed with analytical portions spiked prior to extraction. Therefore, efficiency of sample processing cannot be estimated through such studies.

There are some reported methods on estimation of sample processing efficiency. Bettencourt da Silva et al. (2002, 2003) proposed a method for the estimation of sample processing and subsampling performance, based on comparisons of the experimental dispersion of results with the uncertainty estimated from developed models for the subsequent analytical steps. Lyn et al. (2003) applied a semi-balanced variant of staggered nested design. Data produced from the hierarchical design are treated with robust ANOVA to generate uncertainty estimates as standard uncertainties for sampling, physical sample preparation, and chemical analysis.

Another approach is to determine the sampling constant. Sampling constant concept was first applied by Ambrus et al. (1996) for estimating uncertainty of sample processing in pesticide residue analysis based on the work of Wallace and Kratochovil (1987). If a laboratory sample is statistically well mixed, the sampling constant, K s, is defined as:

where, W is the weight of a single increment and CVSp refers to uncertainty of sample processing. The K s is the weight of a single increment that must be withdrawn from a well-mixed material to hold the relative sampling uncertainty, CV%, to 1 % at the 68 % confidence level. This method was further used in case of various sample matrices in combination with 14C-labeled compound which enabled direct and precise (CV = 1–2 %) determination of analyte concentration in the extracts of test portions (Maestroni et al. 2000a, b; 2003; Suszter et al. 2006; Tiryaki and Baysoyu 2006). The processing uncertainty depends on the nature of the sample, the heterogeneity of the pesticide residues in the sample, the processing equipment, as well as the sample processing procedure. The efficiency of different commercially available processing equipment can be substantially different. On the other hand, it is independent from the analyte, and its concentration provided that it is not volatile or decomposes during sample processing. It was recommended to use easily and reproducibly extractable, stable compounds for determining the K s value. The use of 14C-labeled compound is preferable, but unlabelled pesticides can also be used. In the latter case, the estimation of sample processing uncertainty takes longer especially where cleanup of the extract is required.

These studies revealed that random error of sample processing can be around 56, 23, and 18 % respectively, when a kitchen blender is used in a usual manner for obtaining 5-, 30-, or 50-g analytical portions of apples. In several cases, even statistically well-mixed samples could not be prepared especially from tomato and soil. The extraction of a 5-g analytical portion has advantage in terms of solvent consumption and reduction of waste materials. The well-mixed status of homogenized analytical sample should always be verified before it is used; otherwise, reproducible analytical results may not be obtained. On the other hand, the analysis of 100- or 150-g analytical portions would only slightly improve the sample processing uncertainty compared to 30 g. Taking into account the typical uncertainty of analysis, the targeted sample processing uncertainty should be at or below 0.3 CVA as in such cases it does not contribute significantly to the combined uncertainty of the results (Ambrus 2004).

Once the efficiency of sample processing is determined during method validation and verified by internal quality control procedures, the results obtained are valid for all pesticide residues except highly volatile and labile compounds, which can evaporate or degrade during the process to a various extent, depending on the conditions of the laboratory environment. The results underline the importance of applying appropriate internal quality control measures to confirm the effectiveness of the sample processing procedure.

Hill et al. (2000) reported that sample processing at ambient temperature can cause degradation for some pesticides such as chlorothalonil and folpet. Some pesticides such as bitertanol, heptenophos, isofenphos, and tolyfluanid decomposed partially at ambient temperature, but loss of residues did not occur at cryogenic processing (Fussell et al. 2002). In cryogenic milling, analytical samples are frozen usually at −20 °C and then they are disintegrated into a fine, free-flowing powder in the presence of dry ice (solid CO2) or liquid nitrogen. Decreasing the temperature at sample processing, the potential reactions between any pesticide residues present in the samples and chemicals/enzymes released when plant cells are disrupted can be decreased. Studies revealed that cryogenic sample processing could improve sample processing uncertainty as well as decrease the pesticide decomposition (Fussell et al. 2007).

Extraction and Cleanup

It is reported that the major source of bias in extraction step is the efficiency of extraction. Ineffective cleanup can result in insufficient recovery of analyte, which is a source of systematic/random error, and matrix effects on GC (Ambrus 2000).

The compound’s distribution coefficient between two solvents in liquid–liquid partitioning, solvent strength required for elution, and adsorbent used in column chromatography will affect the effectiveness of cleanup. The efficiency of both steps can be determined by adding known amounts of the analyte(s) concerned to the matrix blank and determining their concentrations by complete analysis (Ambrus 2000). On the other hand, such an experiment only gives an impression of the overall recovery of the method. Therefore, Tiryaki and Baysoyu (2008) spiked cucumbers with radiolabelled 14C-Carbaryl prior to extraction and measure the radioactivity after each step to get separate recovery values for each step. Tiryaki and Baysoyu (2008) applied top-down and bottom-up approach to estimate uncertainties in both steps. It is reported that there was little difference between the two approaches, and relative uncertainties (CV) of EtAc extraction and GPC cleanup steps were 3 and 10.7 %, respectively.

Chromatographic Determination

Determination of analyte by chromatographic methods is the last step in pesticide residue analysis. The quantification of pesticide residues is based on calibration curves constructed at each batch of analysis from injecting known amounts of the respective standard compounds at different concentration levels covering the concentration range in the analyzed samples.

It is reported that the uncertainty of GC and HPLC measurements of residues can be caused by different sources including (a) re-isomerization, decomposition, and transformation of the target analytes before and during sample preparation and processing; (b) bad separation or non-selective detection of the target analytes (from each other or from the matrix); (c) varying matrix blank response, and matrix effect; low or largely differing detection sensitivity for some of the analytes; (d) integration error; varying conversion rate of derivatisation; (e) standard preparation, injection, and calibration. The sources from a to d can be identified during method validation and can be controlled by daily internal quality control studies (Soboleva et al. 2004). The other point is the contribution of multi-component residues arising from the application of technical mixtures including structural and optical isomers, metabolites, and other breakdown products to the uncertainty of chromatographic determination (CAC 2006). Soboleva et al. (2004) explained the methods that can be used for identification of uncertainty of multi-components.

The uncertainty of standard preparation can be calculated using the bottom-up approach (EURACHEM/CITAC 2000). The relative uncertainty of replicate injections should be higher than the uncertainty of standard preparation to satisfy the linear regression precondition. The uncertainty of predicted concentration can be estimated from calibration data obtained either from weighted linear regression (WLR) or ordinary linear regression (ORL). Moreover, an Excel template was created to facilitate the complex calculations (Miller and Ambrus 2000).

The predicted analyte concentration based on multi-point calibration was studied by Ambrus et al. (2002) using 68 gas chromatography–electron capture detector (GC–ECD), GC–NPD, and HPLC–ultraviolet calibration data sets. It was found that, regardless of the actual concentration range of the calibration, the relative random error at the lowest calibrated level range in the case of ordinary linear regression was between 3 and 110 % and for weighted linear regression, between 1 and 18 %. At or above 1/3 of the calibrated range, it ranged between 1 and 7 %, and there was no significant difference between the estimates obtained with WLR or ORL. Similarly, no difference was found in the uncertainty of the predicted concentration at the upper and of the calibrated range estimated with OLR or WLR when pesticide residues in apples were determined with GC–ECD.

Interpreting the Results of Measurements

Once combined standard uncertainty (S R) is obtained from the contribution of individual steps in pesticide residue analysis, results can be provided with expanded uncertainty.

The expanded uncertainty (U) can be calculated from the combined standard uncertainty (S R) by multiplying with a coverage factor of 2 which gives a level of confidence of approximately 95 %. Besides, if the combined uncertainty is based on statistical observation with relatively few degrees of freedom (less than 20), Student’s t value can be used to calculate coverage factor (EURACHEM/CITAC 2000).

Where, υ is the degrees of freedom and 95 % represents the level of confidence.

The emerging practice of EU is to use the default expanded uncertainty figure of 50 % (95 % confidence level with 2 as coverage factor). It is recommended that if uncertainty estimation based on in-house method validation data is higher than the default value, the higher uncertainty figure must be considered on a case-by-case basis. In European Union, it is reported that in case of official food control by regulatory authorities, compliance with the MRL must be checked by assuming the lower limit of the uncertainty interval (x − U) to be the highest confirmed analyte concentration in the sample. It is emphasized that the MRL is exceeded if x − U > MRL (SANCO 2011).

The interpretation of analysis result related with compliance with MRL at national level is different from the compliance of a commodity to be exported. Since MRL for pesticide residues in commodities of plant origin refers to the average residue in the bulk sample of specified minimum size and mass, sampling uncertainty will not take into account at national level. On the other hand, for commodity to be exported, the laboratory has to certify that any composite sample of specified size will comply with the MRL. Therefore, the uncertainty of sampling should be taken into account and the compliance has to be stated at specified probability level with a given confidence level (Ambrus 2009).

Conclusion

The estimated typical relative uncertainties of taking composite samples according to the Codex sampling procedure for determination of pesticide residues in small- and medium-sized and large-sized crops can be 25 and 33 %, respectively. Further studies would be valuable to estimate sampling uncertainty for dried products. Sampling uncertainty should be taken into account when commodities are exported. Sample processing uncertainty should be kept at or below 10 %. Sample processing would be the major contributor to combined uncertainty if statistically well-mixed analytical samples cannot be prepared. Therefore, internal quality control measures should be established to confirm the effectiveness of the sample processing procedure during actual conditions of routine laboratories. Uncertainty arisen from sample size reduction should be taken into account during the sample processing of large-sized crops. The limited studies revealed that the relative uncertainties of EtAc extraction and GPC cleanup of cucumber for radio-labeled chlorphyrifos are 3 and 10.7 %, respectively. Efficiency of extraction and cleanup step depends on the pesticide and matrix combination as well as salt and solvents. Therefore, further study can be performed for the other pesticides and extraction–cleanup techniques. Regardless of the actual concentration range of the calibration, the relative random error at the lowest calibrated level can range in the case of ordinary linear regression between 3 and 110 % and for weighted linear regression, between 1 and 18 %. At or above 1/3 of the calibrated range, uncertainty of calibration curve obtained from the two methods gives comparable results. Weighted linear regression can be selected to construct calibration curve in routine analysis.

The uncertainty of the results obtained from pesticide residue analysis is influenced by the performance of all individual steps. Once combined uncertainty is obtained from the contribution of individual steps in pesticide residue analysis, results can be provided with expanded uncertainty. Finally, decision on interpreting the results of measurements should be taken by related authorities.

References

Alder L, Korth W, Patey AL, Van Der Schee HA, Schoeneneweiss S (2001) Estimation of measurement uncertainty in pesticide residue analysis. J AOAC Int 84:1569–1578

Ambrus A (1996) Estimation of uncertainty of sampling for analysis of pesticides residues. J Envir Sci Health B 31(3):435–442

Ambrus A (2000) Within and between field variability of residue data and sampling implications. Food Addit and Contam B 17(7):519–537

Ambrus A (2004) Reliability of measurements of pesticide residues in foods. Accred Qual Assur 9(6):288–304

Ambrus A (2009) Estimation of sampling uncertainty for determination of pesticide residues in plant commodities. J Envir Sci Health B 44(7):627–639

Ambrus A, Lantos J (2002) Evaluation of the studies on decline of pesticide residues. J Agric Food Chem 50(17):4846–4851

Ambrus A, Soboleva E (2004) Contribution of sampling to the variability of pesticide residue data. J AOAC Int 87(6):1368–1379

Ambrus A, Solmosne AM, Korsos I (1996) Estimation of uncertainty of sample preparation for the analysis of pesticide residues. J Envir Sci Health B 31(3):443–450

Ambrus A, Jarju O, Soboleva E, Turcu MS (2002) Uncertainty of analyte concentration predicted by GLC and HPLC analysis. 10th IUPAC Congress on Pesticide Chemistry, Basel

Anastassiades M, Lehotay SJ, Stajnbaher D, Schenck FJ (2003) Fast and easy multiresidue method employing acetonitrile extraction partitioning and “dispersive solid phase extraction” for the determination of pesticide residues in produce. J AOAC Int 86(2):412–431

Aysal P, Ambrus A, Lehotay SJ, Yolci P, Kwong MC (2004) The use of ethylacetate in QuEChERS method. 5th European Pesticide Residues Workshop, Stockholm

Aysal P, Ambrus A, Lehotay SJ, Cannavan A (2007) Validation of an efficient method for the determination of pesticide residues in fruits and vegetables using ethyl acetate for extraction. J Envir Sci Health B 42(5):481–490

Barwick VJ, Ellison SLR (2000) VAM Project 3.2.1 Development and harmonization of uncertainty principles, Part (d): Protocol for uncertainty evaluation from validation data. LGC/Valid Analytical Measurement, Teddington

Bettencourt da Silva RJN, Lino MJ, Santos JR, Camoes MFGFC (2002) Evaluation of the sampling procedure adopted by the EU pesticide residue control programme to assess consumer exposure to high acute toxicity pesticides-methamidophos in sweet peppers. Accred Qual Assur 7(5):195–201

Bettencourt da Silva RJN, Lino MJ, Santos JR, Camoes MFGFC (2003) Estimation of precision and efficiency mass transfer steps for the determination of pesticides in vegetables aiming at the expression of results with reliable uncertainty. Analyst 125(8):1459–1464

Caldas E, Jardim A, Ambrus A, Souza LC (2006) Variability of organophosphorus insecticide residues in large size crops grown in commercial farms in Brazil. Food Addit Contam 23(2):148–158

Chen S, Yu X, He X, Xie D, Fan Y, Peng J (2009) Simplified pesticide multiresidues analysis in fish by low-temperature cleanup and solid phase extraction coupled with gas chromatography/mass spectrometry. Food Chem 113(4):1297–1300

Codex Alimentarius Commission (CAC) (2009a) Maximum residue limits (MRLs) for pesticides. CAC MRL/1. FAO, Rome. http://www.codexalimentarius.net/pestres/data/index.html?lang=en

Codex Alimentarius Commission (CAC) (2009b) Report of the forty-first session of the Codex Committee on Pesticide Residues. FAO, Rome, ALINORM 09/32/24, Appendix X. http://www.codexalimentarius.net/web/archives.jsp?year=09

Codex Alimentarius Commission (CAC) (1999) Recommended methods of sampling for the determination of pesticide residues for compliance with MRLs. CAC/GL 33. FAO, Rome. http://www.codexalimentarius.net/web/standard_list.do?lang=en

Codex Alimentarius Commission (CAC) (2003) Guidelines on good laboratory practice in residue analysis. FAO, Rome, CAC/GL 40–1993, Revision 1. http://www.codexalimentarius.net/web/standard_list.do?lang=en

Codex Alimentarius Commission (CAC) (2006) Guidelines on estimation of uncertainty of results. FAO, Rome, CAC/GL 59–2006. http://www.codexalimentarius.net/web/standard_list.do?lang=en

Codex Alimentarious Commision (CAC) (2008) Guidance on measurement uncertainty and uncertainty of sampling, 29th Session of Codex Committee on Methods of Analysis and Sampling (CCMAS). CX/MAS 29/9- Add 1. ftp://ftp.fao.org/codex/ccmas29/ma2909ae.pdf

Codex Alimentarious Commision (CAC) (2010) Report of Thirthy-First Session of Codex Committee on Methods of Analysis and Sampling (CCMAS). ALINORM 10/33/23. http://www.codexalimentarius.net/web/archives.jsp?year=10

Eskilsson CS, Björklund E (2000) Analytical-scale microwave-assisted extraction. J Chromatogr A 902(1):227–250

EURACHEM/CITAC (2000) Guide quantifying uncertainty in analytical measurements, 2nd edition. http://www.eurachem.org/guides/pdf/QUAM2000-1.pdf

EUROLAB (2007) Measurement uncertainty revisted: alternative approaches to uncertainty evaluation. Eurolab Technical Report No.1/2007

European Commission (EC) (2002) Commission Directive 2002/63/EC of 11 July 2002 establishing community methods of sampling for the official control of pesticide residues in and on products of plant and animal origin and repealing Directive 79/700/EEC. OJ L 187: 30–45

European Commission (EC) (2005) Regulation (EC) No 396/2005 of the European Parliament and of the Council of 23 February 2005 on maximum residue levels of pesticides in or on food and feed of plant and animal origin and amending Council Directive 91/414/EEC. OJ L 70: 1–16

European Food Safety Agency (EFSA) (2010) 2008 Annual report on pesticide residues according to Article 32 of Regulation (EC) No 396/2005. EFSA J 8(6):1646

Food and Drug Administration (FDA) (1999) In: Makovi CM, McMahon M (eds) Pesticide analytical manual, vol. I, 3rd edn. US Food and Drug Administration, Washington, DC. http://www.fda.gov/Food/ScienceResearch/LaboratoryMethods/PesticideAnalysisManualPAM/ucm111455.htm

Fussell RJ, Addie KJ, Reynolds SL, Wilson MF (2002) Assessment of the stability of pesticides during cryogenic sample processing. 1. Apples. J Agri Food Chem 50(3):441–448

Fussell RJ, Hetmanski MT, Macarthur R, Findlay D, Smith F, Ambrus A, Brodesser PJ (2007) Measurement uncertainty associated with sample processing of oranges and tomatoes for pesticide residue analysis. J Agric Food Chem 55(4):1062–1070

Georgakopoulos P, Mylona A, Athanasopoulos P, Drosinos EH, Skandamis PN (2009) Evaluation of cost-effective methods in the pesticide residue analysis of non-fatty baby foods. Food Chem 115(3):1164–1169

Glaeser H (2002) Compliance with legal requirements: definition of limits, sampling and measurement uncertainty. Accred Qual Assur 7(10):388–391

Gron C, Hansen JB, Magnusson B, Nordbotten JB, Krysell M, Andersen KJ, Lund U (2007) Uncertainty from sampling. A Nordtest handbook for sampling planners and sampling quality assurance and uncertainty estimation. NORDTEST Tec 604/TR604, Norvic Innovation Center

Gustavsson B, Luthbom K, Lagerkvist A (2006) Comparison of analytical error and sampling error for contaminated soil. J Hazardous Materials 138(2):252–260

Hamilton D, Ambrus A, Dieterle R, Felsot A, Harris C, Peterson B, Racke K, Wong SS, Gonzalez R, Tanaka K, Earl M, Roberts G, Bhula R (2004) Pesticide residues in food—acute dietary exposure. Pest Manag Sci 60(4):311–319

Harris CA (2000) How the variability issue was uncovered: the history of the UK residue variability findings. Food Addit Contam A 17(7):491–495

Harris CA, Mascall JR, Warren SFP, Crossley SJ (2000) Summary report of the International Conference on pesticide residues variability and acute dietary risk assessment. Food Addit Contam A 17(7):481–485

Hernandez-Borges J, Cabrera JC, Rodriguez-Delgado MA, Hernandez-Suarez EM, Sauco VG (2009) Analysis of pesticide residues in bananas harvested in the Canary Islands (Spain). Food Chem 113(1):313–319

Hill ARC (2000) Residue variability and sampling—practical problems and consequences for residues monitoring. Food Addit and Contam A 17(7):539–546

Hill ARC, Harris CA, Warburton AG (2000) Effects of sample processing on pesticide residues in fruit and vegetables. In: Fajgelj A, Ambrus A (eds) Principles and practices of method validation. Royal Society of Chemistry, Cambridge, pp 41–48

International Standard Organization (ISO) (1993) Guide to the expression of uncertainty in measurement. International Organization for Standardization (ISO), Geneva

International Standard Organization (ISO) (2003) ISO 11648–1 Statistical aspects of sampling from bulk materials-part 1: general principles

International Standard Organization (ISO) (2004) ISO/TS 21748:2004 Guidance for the use of repeatability, reproducibility and trueness estimates in measurement uncertainty estimation

International Standard Organization and International Electrochemical Community (ISO/IEC) (2005) ISO/IEC 170205:2005 General requirements for the competence of testing and calibration laboratories

IUPAC (1990) Nomenclature for sampling in analytical chemistry (recommendations for 1990). Int Union Pure Appl Chem 62(6):1193–1208

Joint Committee for Guides in Metrology (JCGM) (2008a) Evaluation of measurement data—guide to expression of uncertainty in measurement. JCGM 100:2008

Joint Committee for Guides in Metrology (2008b) International vocabulary of metrology—basic and general concepts and associated terms (VIM). JCGM 200: 2008

Klein J, Alder L (2003) Applicability of gradient liquid chromatography with tandem mass spectrometry to the simultaneous screening for about 100 pesticides in crops. J AOAC Int 86(5):1015–1037

Kovalczuk T, Lacina O, Jech M, Poustka J, Hajslova J (2008) Novel approach to fast determination of multiple pesticide residues using ultra-performance liquid chromatography-tandem mass spectrometry (UPLC-MS/MS). Food Addit Contam A 25(4):444–457

Krynitsky AJ, Lehotay S (2002) Overview of analytical technologies available to regulatory laboratories for the determination of pesticide residues. In: Lee PW (ed) Handbook of residue analytical methods for agrochemicals, vol. 2. Wiley, Chichester, pp 753–786

Lambropoulou DA, Albanis TA (2007) Liquid-phase micro-extraction techniques in pesticide residue analysis. J Biochem Biophys Methods 70(2):195–228

Lehotay SJ, Eller KI (1995) Development of a method of analysis for 46 pesticides in fruits and vegetables by supercritical fluid extraction and gas chromatography/ion trap mass chromatography. J AOAC Int 78(3):821–830

Lehotay SJ, Mastovska K (2007) Determination of pesticide residues. In: Otles S (ed) Method of analysis of food components and additives. CRC Press Taylor and Francis Group, Boca Raton

Lehotay SJ, de Kok A, Hiemstra M, Van Bodegraven P (2005a) Validation of a fast and easy method for the determination of 229 pesticides in fruits and vegetables using gas and liquid chromatography and mass spectrometric detection. J AOAC Int 88(2):595–614

Lehotay SJ, Mastovska K, Lightfield AR (2005b) Use of buffering and other means to improve results of problematic pesticides in a fast and easy method for residue analysis of fruits and vegetables. J AOAC Int 88(2):615–629

Lehotay SJ, Mastovska K, Yun S (2005c) Evaluation of two fast and easy methods for pesticide residue analysis in fatty food matrices. J AOAC Int 88(2):630–638

Lehotay SJ, Mastovska K, Lightfield AR, Gates RA (2010) Multi-analyst, multi-matrix performance of the QuEChERS approach for pesticide residues in foods and feeds using HPLC/MS/MS analysis with different calibration techniques. J AOAC Int 93(2):355–367

Lyn JA, Ramsey MH, Fussell RJ, Wood R (2003) Measurement uncertainty from physical sample preparation: estimation including systematic error. Analyst 128(11):1391–1398

Lyn JA, Ramsey MH, Coad DS, Damant AP, Wood R, Boon KA (2007) The duplicate method of uncertainty estimation: are eight targets enough. Analyst 132(11):1147–1152

Maestroni B, Ghods A, El-Bidaoui M, Rathor N, Ton T, Ambrus A (2000a) Testing the efficiency and uncertainty of sample processing using C14-labelled chlorphyrifos: part I. In: Fajgelj A, Ambrus A (eds) Principles and practices of method validation. Royal Society of Chemistry, Cambridge, pp 49–57

Maestroni B, Ghods A, El-Bidaoui M, Rathor N, Ton T, Ambrus A (2000b) Testing the efficiency and uncertainty of sample processing using C14-labelled chlorphyrifos: part II. In: Fajgelj A, Ambrus A (eds) Principles and practices of method validation. Royal Society of Chemistry, Cambridge, pp 59–74

Maestroni B, Ambrus A, Culin S (2003) Uncertainty of sample processing of tomato and olive samples. The BCPC International Congress: Crop Science and Technology 2003, Glasgow

Magnusson B, Naykki T, Hovind H, Krysell M (2004) Handbook for calculation of measurement uncertainty in environmental laboratories 2nd Edition. NORDTEST Report TR537, Nordic Innovation Center, Finland. http://www.nordtest.org/register/techn/tlibrary/tec537.pdf

Mastovska K, Dorweiler KJ, Lehotay SJ, Wegsheid JS, Szpylka KA (2010) Pesticide multiresidue analysis in cereal grains using modified QuEChERS method combined with automated direct sample introduction GC-TOFMS and UPLC-MS/MS techniques. J Agric Food Chem 58:5959–5972

Miller JN, Ambrus A (2000) Manual on basic statistics. Training Course Notes of FAO/IAEA Training and Reference Centre for Food and Pesticide Control on Quality Assurance Quality Control in Analysis of Pesticide Residues and Pesticide Products, Vienna

Pang GF, Chao YZ, Liu XS, Fan CL (1995) Multiresidue liquid chromatographic method for simultaneous determination of pyrethroid insecticides in fruits and vegetables. J AOAC Int 78(6):1474–1480

Paya P, Anastassiades M, Mack D, Sigalova M, Tasdelen B, Oliva J, Barba A (2007) Analysis of pesticide residues using Quick Easy Cheap Effective Rugged and Safe (QuEChERS) pesticide multiresidue method in combination with gas and liquid chromatography and tandem mass spectrometric detection. Anal Bioanal Chem 389:1697–1714

Pico Y, Blasco C, Farre M, Barcelo D (2009) Analytical utility of quadrupole time-of-flight mass spectrometry for the determination of pesticide residues in comparison with an optimized column high-performance liquid chromatography/tandem mass spectrometry method. J AOAC Int 92(3):734–744

Ramsey MH (1997) Measurement uncertainty arising from sampling implications for the objectives of geoanalysis. Analyst 122(11):1255–1260

Ramsey MH, Argyraki A (1997) Estimation of measurement uncertainty from field sampling: implications for the classification of contaminated land. Sci Total Environ 198(3):243–257

Ramsey MH, Ellison SLR (2007) Eurachem/EUROLAB/CITAC/Nordtest/AMC guide: measurement uncertainty arising from sampling: a guide to methods and approaches, 1st edn. Eurachem, Prague. http://www.eurachem.org/guides/pdf/UfS_2007.pdf

Ramsey MH, Thompson M, Hale M (1992) Objective evaluation of precision requirements for geochemical analysis using robust analysis of variance. J Geochem Explor 44(1–3):23–36

Ramsey MH, Argyraki A, Thompson M (1995) Estimation of sampling bias between different sampling protocols on contaminated land. Analyst 120(5):1353–1356

Ramsey MH, Squire S, Gardner MJ (1999) Synthetic reference sampling target for the estimation of measurement uncertainty. Analyst 124(11):1701–1706

Riedel M, Speer K, Stuke S, Schmeer K (2010) Simultaneous analysis of 70 pesticides using HPLC/MS/MS: a comparison of the multiresidue method of Klein and Alder and the QuEChERS method. J AOAC Int 93(6):1972–1986

Riley MB, Dumas JA, Gubur EE, Massey JH, Mattice JD, Mersie W, Muller TC, Potter T, Senseman SA, Watson E (2005) Pesticide extraction efficiency of two solid phase disk types after shipping. J Agric Food Chem 53:5079–5083

SANCO (Directorate General for Health and Consumer Affairs) (2011) Method validation and quality control procedures for pesticide residues analysis in food and feed. SANCO 12495/2011. http://ec.europa.eu/food/plant/protection/pesticides/docs/qualcontrol_en.pdf

Schenk FJ, Wong JW (2007) Determination of pesticides in food and vegetal origin. In: Tadeo JL (ed) Analysis of pesticides in food and environmental samples. CRC Press, New York

Senseman S, Mueller T, Reiley M, Wauchope R, Clegg C, Young R, Southwick L, Moye A, Dumas J, Mersie W (2003) Interlaboratory comparison of extraction efficiency of pesticides from surface and laboratory water using solid-phase extraction disks. J Agric Food Chem 51:3748–3752

Soboleva E, Jarju O, Ambrus A (2004) Estimation of uncertainty of analytical results based on multiple peaks. J Chromatogr A 41(5):161–166

Squire S, Ramsey MH, Gardner MJ (2000) Collaborative trial in sampling for the spatial delineation of contamination and the estimation of uncertainty. Analyst 125(1):139–145

Suszter G, Ambrus A, Schweikert MT, Kalus PM (2006) Estimation of efficiency of processing soil samples for pesticide residues analysis. J Envir Sci Health B 41(5):531–552

Tekel J, Hatrik S (1996) Pesticide residue analysis in plant material by chromatographic methods: clean-up procedures and selective detectors. J Chromatogr A 754(1–2):301–331

Thompson M (1998) Uncertainty of sampling in chemical analysis. Accred Qual Assur 3(3):117–121

Thompson M, Ramsey MH (1995) Quality concepts and practices applied to sampling—an exploratory study. Analyts 120(2):261–270

Tiryaki O, Baysoyu D (2006) Estimation of sample processing uncertainty for chlorphyriphos residue in cucumber. Accred Qual Assur 10(10):550–553

Tiryaki O, Baysoyu D (2008) Estimation of the efficiencies and uncertainties of the extraction and cleanup steps of pesticide residue determination in cucumber using 14C-carbaryl. Accred Qual Assur 13(2):91–94

Wallace D, Kratochvil B (1987) Visman equations in the design of sampling plans for chemical analysis of segregated bulk materials. ACS 56:226–232

Whitaker TB, Slate AB, Jacobs M, Hurley JM, Adams JG, Giesbrecht F (2006) Sampling almonds for aflatoxin, part I: estimating of uncertainty associated with sampling, sample preparation and analysis. J AOAC Int 89(4):1027–1034

Winter CK (2001) Pesticide residues in food supply. In: William H, Carl KW (eds) Food toxicology. CRC Press LLC, Florida, pp 163–185

Zorzi P, Belli M, Barbizzi S, Menegon S, Deluisa A (2002) A practical approach to assessment of sampling uncertainty. Accred Qual Assur 7(5):182–188

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Omeroglu, P.Y., Boyacioglu, D., Ambrus, Á. et al. An Overview on Steps of Pesticide Residue Analysis and Contribution of the Individual Steps to the Measurement Uncertainty. Food Anal. Methods 5, 1469–1480 (2012). https://doi.org/10.1007/s12161-012-9396-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-012-9396-4